- The Manufacturers

- Why Work in Manufacturing?

- Early Careers Recruitment

- Careers Fairs

- News & Blogs

- Learning Resources

Back to manufacturers Back to map

Did you know?

From their beginnings in 1965, over 17,000 Princess Yachts have been manufactured. Now, they build an amazing average of 270 yachts a year. This means that every few days another yacht is completed which is incredible!

Over 21 miles of cable go into a 40 M yacht. If you laid the cable along the road, it would take you all the way from Plymouth to Totnes.

In the furniture factory, the team processes 500 sheets of wood a day. The sheets of walnut or oak are produced in Holland and the trees they are taken from are hand-chosen for Princess.

Around 7 times each month, roads in Plymouth are closed between 2.30am – 4.30am so the yachts can be pulled around the roundabouts and down streets in the wrong direction!

The biggest boat has only 13 mm height clearance under the Marsh Mills flyover and in warm weather the tyres need to be deflated to make it under and through.

Princess Yachts own 4 police cars which are driven by police officers (on non-emergency duty) to escort the boats during the early morning moves.

Princess Yachts

Princess Yachts are famous for building some of the world’s finest and most luxurious yachts, which they manufacture at their 5 different sites in Plymouth and sell all over the world. The company is extremely proud of their Plymouth heritage – their logo includes the words “Crafted in Plymouth”. 80-85% of everything you see on a Princess Yacht has been made in-house by the company’s Plymouth teams.

“Where there’s warm weather and water, you will find Princess Yachts. There’s always a carefully crafted part of Plymouth floating around some of the most beautiful places in the world” Antony Sheriff, Executive Chairman, Princess Yachts

Princess Yachts is also honoured to be the first luxury yacht manufacturer to officially partner with the Marine Conservation Society. Since 2016 they have worked together to support marine environments, preserving reefs and sea life for present and future generations.

Typical job roles include: Marine Engineering, Fabrication/Welding, Carpentry, Computer Aided Design,Composites, HR, Learning and Development and Finance

Apprenticeships: Princess Yachts has a variety of four year apprenticeship courses available each year including; Marine Engineering, Carpentry/boat building, CAD Development, Fabricating and Welding, Business Administration, HR, Finance, IT and Composites. Find out more about the company’s Apprenticeship Scheme below in the Get to Know Princess Yachts section.

Princess look for potential apprentices with the right attitude, the right qualities and the desire to fulfil their potential – people who can stand out from the crowd and deliver the high standards of quality and service expected in the luxury yacht business. Applicants need to be dedicated, eager to learn, and keen to combine hands on work with study in their own time.

University Placements are available in the CAD department.

Graduate Programme : Princess Yachts also offers a graduate programme for those who are leaving university, with opportunities in Accountancy and Finance, Business Operational Management, Commercial, Sales, Human Resources, Naval Engineering, Naval Architecture, Marketing and Communications, Development

Princessyachts.com

3000 Employees Worldwide

5 Plymouth Manufacturing Sites at Stonehouse, Coypool, South Yard, Langage, Lee Mill.

Distributors in over 100 countries.

Get to Know Princess Yachts

Princess yachts apprenticeship scheme (section 1 of 2).

Princess works in partnership with the South Devon Marine Academy which has a dedicated Princess Yachts workshop, equipped with a V40 hull where apprentices can learn skills in all aspects of the business, offering a truly immersive experience.

The Scheme offers a mix of classroom-study with practical work and real experience and gives participants the chance to work with world-class boat-builders and other professionals who are passionate about passing on their knowledge.

The first year of the apprenticeship programme, is undertaken at South Devon College where apprentices complete additional marine qualifications such as RYA Powerboat Level 2, RYA Sea Survival, RYA VHF Radio Operators Licence and RYA First Aid as well as taking part in off water activities. SEE NEXT SECTION FOR MORE INFO…

PRINCESS YACHTS APPRENTICESHIP SCHEME (Section 2 of 2)

In the third week of an apprenticeship, the apprentices can undertake a week long residential programme at Heatree, Exeter with activities such as canoeing, rock climbing and abseiling to learn new skills including team working, self-motivation and leadership.

Apprentices’ are also taken to the Southampton Boat Show where they enjoy attending the Princess Yachts stand to really help them grasp the bigger picture and understand the exceptional global luxury brand that they are now part of.

After their first year is completed, each Apprentice is assigned to work at one of Princess Yachts’ five sites around Plymouth where they will be fully trained in their specialism.

Find out more about the Apprenticeship Scheme here

LUXURY MOTOR YACHTS AND SUPER YACHTS

Princess Yachts craft a range of highly developed luxury yachts, which are said to be the envy of the yacht manufacturing and retail community.

At 40 metres long, the Princess 40M is the company’s largest yacht to date and is classed as a super-yacht. It has the luxury price tag of £18 million! Across the yacht’s three decks, there are sunbathing hideaways, a spa bath, dining areas and even a walk-in beach club.

Click here to take a 360 tour of the Princess 40M and see the amazing craftsmanship of the Plymouth yacht building teams.

The M Class super-yachts are constructed in one of Plymouth’s most historically important areas at South Yard, which is a former naval yard dating back to the 17th century and where the city’s dockyard originally began.

CAREFULLY DESIGNED INTERIORS

As you can see here, the Y85 caters for relaxation as well as speed. The flybridge has a fantastic deck for enjoying the sights and sounds of the ocean and marinas while the saloon creates an elegant space for seating and dining.

There is a careful design process for every element of a Princess Yacht. Each newly designed yacht goes through a Mock-Up stage. This is a one-to-one scale replication of the final yacht to test exactly how the new layout works, to check head heights, door way functionality, and how the furniture and materials will feel in the space. You can watch a film about the Mock-Up Stage here.

NEW PERFORMANCE SPORTS YACHTS

The R Class is the brand new range of performance sports yachts by Princess. The R35 pictured here, is a revolutionary yacht which was designed in conjunction with Ben Ainslie Racing Technologies (yes – Ben Ainslie – one of the most successful Olympics sailors of all time!) and legendary Italian car designers, Pininfarina.

This yacht can reach a top speed of 50 knots. Only the fastest swimming fish in the world could keep up with the R Class yachts.

To confuse the eye and help conceal its design until its official launch, the prototype R35 was actually covered in dazzle camouflage which was created by Plymouth College of Art student, Katie Sheppard. Take a look at the sea trial of the prototype R35 in its dazzle camouflage design here.

SEE INSIDE PRINCESS

If you would like to see more inside Princess Yachts, watch some of their manufacturing processes, find out how the yachts are tested on water and understand the company’s amazing history and craftsmanship – visit the Princess Yachts webpage here “Inside Princess” and scroll down to watch their interesting video.

Explore Other Exciting Companies

Kawasaki Precision Machinery UK

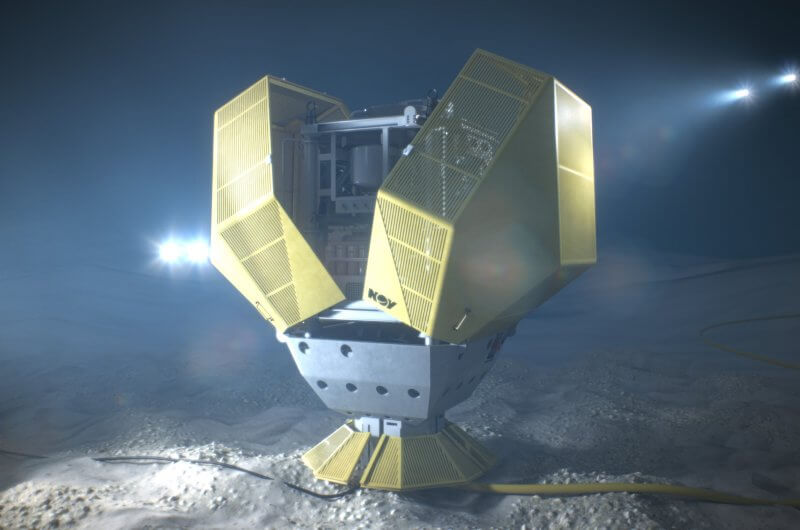

NOV Fiber Glass Systems

Composite Integration

Babcock International

- Select Language

Inside Princess Yachts: How are they built

Saturday 30th November 2019

The sports boat and motoryacht market is by no means deficient in boat buying options. The modern buyer is now able to explore a vast range of designers, builders and brands in a bid to tailor his boat to his favoured marine application before committing to a decision. In terms of choice and accessibility, that certainly has its merits, but as we continue to see established brands taking ever greater advantage of the production efficiencies offered by third-party suppliers, overseas workforces and shared construction facilities, a builder like Princess Yachts stands out as markedly different.

Based in Plymouth at the traditional maritime hub of England’s southwest, Princess Yachts expanded fast after the original founder moved into a rental shed on an offshoot of the River Tamar back in 1965. By the time the company had reached its 40 th anniversary in 2005, it boasted 81,000 square metres of space, 1,450 employees and global sales in excess of £140 million. And following its entry into the superyacht sector in 2011 with the first of the new M Class yachts, it continued to expand. The company we see today employs more than 3000 people across seven manufacturing plants and has raised production from 230 boats a year to more than 300. And yet the story of yacht production at Princess is not defined by scale of operations or speed of production. It’s defined by culture, process and mindset…

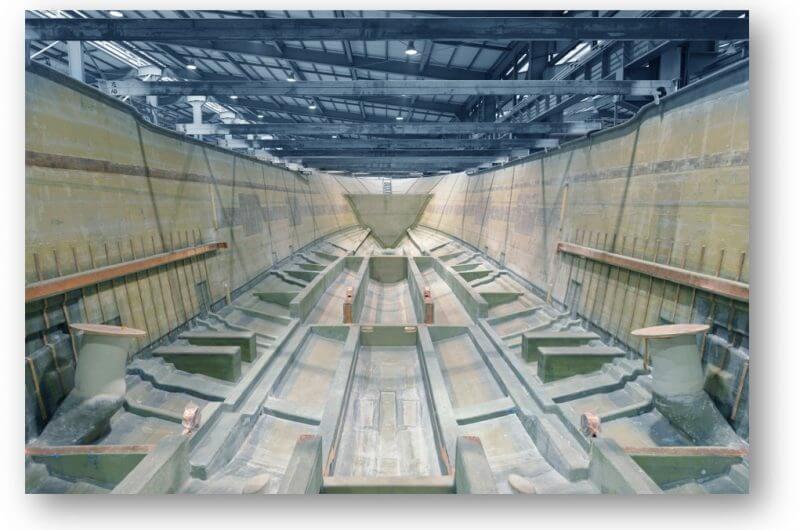

Keeping it in-house One of the most fundamental differences at Princess Yachts is the fact that the company designs and builds 80% of its components in-house. There’s an argument that the yard’s relative geographical isolation has compelled it to become self-sufficient over the years but whatever the truth might be, Princess now runs dedicated in-house departments for a variety of specialist tasks that most builders are compelled to outsource. For instance, Princess operates its own mould shop, where it builds its own plugs with a pair of five-axis cutting machines and uses resin infusion to create everything from its decks and structures to the hull of its 40-metre flagship. The fact that the process is controlled by computer and put under vacuum helps ensure exact fibre-to-resin ratios for greater consistency, stiffness and strength. And in addition to reducing weight for uprated on-water speed and efficiency, the absence of cumbersome stiffening beams helps optimise internal volume for increased space and versatility. Princess also runs a dedicated metal shop, where all the stainless steel fittings are built, as well as its own specialist loom shop. Here, specialist technicians pre-assemble all the required wiring harnesses in preparation for the fit-out of a yacht – and while that gives Princess the ability to alter designs mid-build, it also enables them to incorporate customer requests with far greater flexibility than other yacht builders can achieve. One of the yard’s most impressive assets, however, is its furniture shop. This bustling department is responsible for building all the timber elements of a Princess yacht, including the structural pieces, bulkheads, sidelinings and headlinings. And whether fixed or freestanding, it also builds the furniture from scratch, enabling it to optimise continuity throughout each yacht by using timber of precisely the same grain texture, pattern and colour. As Paul Bailey, Commercial and Technical Manager at Princess Motor Yacht Sales, points out: “This stuff is not sourced off the shelf at the same impersonal third-party plant that other manufacturers might use. It’s designed and built by Princess’s own craftsmen, so whether a customer chooses to spec up his boat or buy the ‘standard’ package, a Princess yacht will always have the feeling of something special; something unique; something much more artisan and bespoke than you might experience from other builders.”

Creating a culture of quality One of the key drivers behind Princess’s fastidious approach is the Chairman, Anthony Sheriff. Having come from an automotive background, he invested heavily in a quality management system based around a process known as ‘No Fault Forward’. This involved rooting out any faults early on in the build process, so they could be remedied before the issue was passed forward onto subsequent production stages. Its effective integration would require a very structured and transparent approach to problem solving, so he established a dedicated Quality Control Division that has since grown from six people to around 30. The idea behind this investment was to transform ‘quality’ from a formal manufacturing protocol into a culturally ingrained attitude inhabited by everyone at Princess Yachts – and to help achieve that, the quality division is involved throughout the entire process, from the moment a build begins right through to a yacht’s entry to market. The division’s personnel go out on the boats themselves; they talk to the test engineers and the boat management professionals; they do everything they can to understand the customer experience because getting things completely right is the means by which Princess aims to differentiate itself from the competition. The team have an inspiring approach to the yacht design, the most striking exponents being the company’s full-scale mock-ups. To ensure that a new design works properly, the entire boat is built from plywood in exhaustive detail, enabling the designers to step on board and examine it first-hand – to explore head heights, door openings, spatial arrangements and furniture; to think about materials and real human usability. It enables them to inhabit the space and get a genuine feel for it in a way that a 3D CAD drawing can never achieve. Things can then be tweaked before the final design is put into production and while it does of course involve a highly skilled and labour-intensive process, its value in terms of the end product is fundamental to what Princess does.

Equipping the customer Princess makes a point of encouraging customers to come to its Plymouth headquarters and witness first-hand how its boats are put together. It urges them to take an active role partly because it is proud of its standards and partly because a customer who is properly equipped to collaborate in the detailing of his yacht is likely to end up with something much better tailored to his needs. To that end, Princess has a team of designers dedicated solely to helping customers navigate their way through the options and select the choices that will be of greatest benefit to their favoured cross-section of boating activities. The company’s fastidious in-house approach has an impact on the long-term quality of the ownership experience in other ways too. For instance, in addition to safeguarding the standard of each finished yacht with exhaustive sea trials encompassing more than 3,000 checks, every part of the build process is archived and traceable. That enables the yard to examine original engineering diagrams for each yacht and to identify the ‘who, how and when’ of every individual element. It can then leverage its distributor network to provide bespoke support for a customer’s yacht throughout its lifetime, even after that yacht is sold on to new owners. As the industry’s appetite for international third party construction plants continues to gather traction, that degree of care, accountability and control looks set to become even more special than it is today.

Sign up to our newsletter

Sign up now to be the first to hear about our news and updates.

You can amend or withdraw consent at any time here or by emailing us . Further details regarding how we process your personal data can be found in our privacy policy .

- Comments This field is for validation purposes and should be left unchanged.

Our Sister Brands

Princess Yachts’ new manufacturing facility in Plymouth

- Inspiration

Related News

Popular news this week, popular news this month, latest news.

- Yacht Charter & Superyacht News >

Written by Chelsea Smith

Plymouth based Princess Yachts International has won financial backing from the Government’s Regional Growth Fund (RGF) for a major investment in Plymouth’s Devonport dockyard.

Plans to create a world leading boat building facility at the company’s South Yard site were approved by Plymouth City Council last year, following which the company sought a Government contribution to help secure approval for this major investment from its French parent company.

Princess Yachts receives Government support for new manufacturing facility in Plymouth

The new production site will be used to build Princess M Class yachts, a range of 100-foot plus vessels developed to meet the growing global demand for craft of this size. The new facility is planned to be operational by early 2013 and will create or secure over 1,000 jobs both directly and indirectly in the wider Plymouth economy.

Princess Yachts exports 90 per cent of its production and has built a global reputation for quality and craftsmanship. It is already Plymouth’s second largest private sector employer, with just under 2,000 employees, and supports several hundred supply chain jobs.

Last month Princess Yachts completed the purchase from Defence Estates of a freehold interest in the 18-acre South Yard site within the historic Devonport Naval Base.

Chris Gates, Managing Director of Princess Yachts, said:

“I am delighted that the Government has decided to back our investment in a new production facility to meet the global demand for larger vessels. This recognises the fantastic work being achieved by our company as it competes on a global stage from its Plymouth base. We are extremely grateful for the local support given to us during the application process, including our local MP’s, the leaders of the Council and the numerous business and community leaders, all of whom clearly recognise the significant contribution we bring to the City of Plymouth as a strong local employer.”

Vivien Pengelly, Leader of Plymouth City Council, said:

“We are delighted that Princess Yachts has won support from the Regional Growth Fund. The company is one of the biggest employers in Plymouth and is a local success story. Their ambitious plans will kick start the regeneration of South Yard within Devonport dockyard and create a focus for excellence in marine engineering.”

Princess entered the superyacht market this year with the launch to wide acclaim of the Princess 32M long range cruising yacht at the London Boat Show in January 2011. The company is already working on the new flagship Princess 40M, a 130-foot tri-deck yacht to be launched in 2012 and with a strong forward order book the company is confident of further growth in this market.

Please contact CharterWorld - the luxury yacht charter specialist - for more on superyacht news item "Princess Yachts’ new manufacturing facility in Plymouth".

- Charity & Fund Raising

- CharterWorld News

- Classic Yachts

- Coronavirus

- Cruise Ship

- Ecological Yachts

- Expedition Yachts

- Expert Broker Advice

- Feature Superyachts

- Interior Design

- Legal & VAT Yacht Issues

- Luxury Catamarans

- Luxury Gulet

- Luxury Phinisi

- Luxury Trimarans

- Luxury Yacht Design

- Luxury Yachts

- Marinas & Harbours

- Marine Ecology

- Marine Electronics

- Marine Equipment

- Mega Yachts

- Modern Yachts

- Motor Yachts

- New Launch Yachts

- New To Charter

- Open Style Sports Yachts

- Private Jets

- Sailing Yachts

- Social Media

- Sports Yachts

- Superyacht Crew

- Superyacht Photographers

- Superyacht Products & Supplies

- Superyacht Refits

- Superyacht Reviews

- Superyachts

- Uncategorized

- Yacht Builders

- Yacht Charter

- Yacht Charter Destinations

- Yacht Charter Picks

- Yacht Charter Specials

- Yacht Delivered to Owner

- Yacht Designers

- Yacht Events & Boat Shows

- Yacht Fashion

- Yacht Industry News

- Yacht Photos

- Yacht Racing

- Yacht Racing & Regattas

- Yacht Safety Equipment

- Yacht Support Vessels

- Yacht Tenders

- Yacht Videos

- Yachting Associations

- Yachting Awards

- Yachting Business

- Yachts For Charter

- Yachts For Sale

Quick Enquiry

Superyacht news:.

Email Your Yachting News to: news @ charterworld.com

Princess Yachts

Princess Yachts look forward to superyachts up to 70m

Princess Yachts’ New Superyacht Facility Gets Government Seal of Approval

Princess Yachts International welcome Richard Lambert as new member of the Board

Princess Yachts unveil latest M Class motor yacht Princess 30M

Ferretti Custom Line Navetta 30 series motor yacht GINDUNGO hits water in Italy

50m luxury motor yacht BEL1 launched in Pisa by Rossinavi

Luxury yacht UNIQUE S is brand new to the charter market in the Western Mediterranean

44m superyacht EXTRA TIME new to charter around the Western Mediterranean

Superyacht KISMET – the 122m Lurssen motor yacht the charter market has been waiting for

37m luxury yacht LEGEND offering unparalleled comfort on charters in the Western Mediterranean

Discover our Top 10 brand new yachts available for charter worldwide this year

Florida charter yacht REAL SUMMERTIME offering 10% discount

Discover summer in New England aboard a luxury charter yacht: Escape to this beautiful northeast corner of the USA

Last minute yacht charter deals in the Bahamas

Westport announce the first hull of their 36m W117 range is nearing completion

49m sailing yacht ANIMA MARIS is offering discounted rates for the remaining summer weeks in Croatia

Superyacht LAUNCHPAD previously Feadship 1010 delivered

Take advantage of the exceptional 15% discount by 44m charter yacht BLISS in Greece

- Seller Market Analysis

- Trade Your Yacht

- Vessel Donation

- Sold Yachts

- We Buy Boats

- Exclusive Listings

- Yachts for Sale

- New Yacht Builds

- Nautor Swan Yachts

- Sichterman Yachts

- Luxury Yacht Charters

- Search Charter Yachts

- Charter Management

- Luxury Events

- Team Members

- Boat Show Events

- North Report Magazine

- Testimonials

- +1.954.900.9988

Experienced Brokers Princess Yachts

Founded in Plymouth, England, in 1965, the Princess Yachts shipyard now occupies 1.1 million square feet in the heart of Great Britain’s maritime industry. In fact, more than 80 percent of every Princess yacht is crafted in-house across six local manufacturing sites. Today, Princess Yachts is deeply focused on sustainability, offering hybrid power plants, eco-friendly upholstery, energy-saving technologies, low-emission building techniques and more. They were also the first major European yacht-builder awarded the ISO 14001 in recognition of their reduced environmental impact.

Our team has worked with Princess Yachts on new custom builds and resales since 2011 . We are excited by the company’s green thought leadership and environmentally friendly initiatives, as well as the exceptional design and build quality of every yacht they produce.

Are you interested in Princess Yachts? Contact 26 North Yachts to learn more about Princess custom builds and resale opportunities.

Talk to us Contact Our Team

I understand that by signing up I agree with 26 North’s Privacy Policy .

Welcome aboard!

We have added you to the newsletter.

We have received your information and an agent will get back to you ASAP

Sign up for Yoga On the Docks Tuesdays at 8 AM

We have received your registration. See you on the docks!

Plymouth's Princess Yachts reveals record billion dollar order book

UK's largest luxury boat builder says it is selling yachts faster than it can make them as it recovers strongly from Covid hit 2020

- 11:21, 1 OCT 2021

We have more newsletters

The UK’s largest luxury boat builder Princess Yachts has revealed a US$1bn order book and said production is struggling to keep up with demand.

The Plymouth manufacturer’s financial update has revealed a “record-setting commercial performance” with sales rate surpassing production rate, driving record low distributor stock levels.

It said almost all production through to the end of 2022 and more than 60% of 2023 production is already covered by orders. This year it has already sold 20 of its flagship Superfly X95 and has 57 orders for the new Y72 model which launched this summer.

More about Princess Yachts

The company is now poised for further growth with the new Y95, X80,and V50 already in production, as well as five further new model launches by the end of 2022.

And, despite being in a Covid-19 recovery phase, intensive recruitment continues with increased investment in skills training and award-winning apprenticeship programmes.

The firm, which employs about 3,200 people in Plymouth, said it has faced challenges from the Covid-19 pandemic and the ongoing supply chain issues affecting the UK. Turnover and profits dipped in 2020 as the company was affected by a temporary Covid-related closure.

But it has bounced back strongly and despite ongoing challenges retail sales have grown to the highest levels in the history of the company, with an order book exceeding US$bn.

With record low distributor stock levels globally - equivalent to one to two weeks of stock - and production almost completely covered by orders into the second half of 2023, the company said it is in a unique commercial position.

Antony Sheriff, Princess Yachts executive chairman and chief executive, said: “As expected, in a Covid-19 year when we stood down our 3,200 strong team for Q2 2020, turnover reduced to £244m from 2019’s full year turnover of £314m.

“The combination of our unique vertically integrated manufacturing process, the investment required to make it Covid-19 compliant and our decision to not cut new product development or make staff redundant resulted in an understandable drop in profits during 2020.

“However, these decisions have put us in an excellent position during 2021 and onwards. Although Covid-19 continues to bring interruptions in the supply chain and government mandated self-isolation of staff, we significantly improved financial performance in 2021 compared to 2019 and 2020 and we expect even stronger results in 2022 .”

How to contact William Telford and Business Live

Business Live's South West Business Reporter is William Telford. William has more than a decade's experience reporting on the business scene in Plymouth and the South West. He is based in Plymouth but covers the entire region.

To contact William: Email: [email protected] - Phone: 01752 293116 - Mob: 07584 594052 - Twitter: @WTelfordHerald - LinkedIn: www.linkedin.com - Facebook: www.facebook.com/william.telford.5473

Stay in touch: BusinessLive newsletters have been re-designed to make them even better. We send morning bulletins straight to your inbox on the latest news, views and opinion in the South West. Get our breaking news alerts and weekly sector reviews too. Sign up now - it's free and it only takes a minute. To sign up for Business Live's daily newsletters click here .

And visit the Business Live South West LinkedIn page here

He added: “We continue to move forwards with an ambitious new product launch plan and innovative new ways to engage with our customers . The company now has a retail order book worth over US$1bn with the sales success of new models such as the X95, X80 and Y72 exceeding expectations. We have had over 20 orders for the X95, and 57 orders for the new Y72 model, the majority of these orders received off plan. All production slots are now filled for 2021, over 95% of 2022 production and over 60% of 2023 production is covered by orders.”

A return to many of the global boat shows this calendar year saw Princess Yachts attend Palm Beach International Yacht Show in March 2021; Cannes Yachting Festival 2021; Southampton International Boat Show 2021; with plans being finalised for the Fort Lauderdale Boat Show in October 2021 and the much-anticipated return to Boot Düsseldorf in January 2022.

- Engineering

- Company Results

- Manufacturing

- Most Recent

- THE PRINCESS PASSPORT

- Email Newsletter

- Yacht Walkthroughs

- Destinations

- Electronics

- Best Marine Electronics & Technology

- Boating Safety

A Day in the Life of Princess Yachts’ Manufacturing Engineering Director

- By By Princess Yachts America

- Updated: October 12, 2020

Originally published in Watermark Extra, Princess Yachts’ lifestyle magazine for owners.

This content is also featured on our Princess Passport. To return or learn more, visit: The Princess Passport

“As Princess Yachts’ manufacturing engineering director, I head up a team of 30 people and together we are responsible for current manufacturing engineering and future product launch co-ordination between the development and production departments.

I joined the business – then Marine Projects – as a 16-year-old engineering apprentice in 1997 and gained several years’ experience in boat building before becoming a manufacturing engineer tasked with integrating more efficient manufacturing principles and improving the operational process. A couple of years later, I became a production manager in charge of the fitout assembly for a number of boat models, and later took on the role of operations manager and head of engineering – at the time, the youngest person to have been promoted to that level.

Then in 2014 I took a sabbatical, indulging my passion for offshore powerboat racing in Florida, followed by a period in the Defense sector supporting our Royal Navy platforms. I then returned to Princess in an exciting role heading up the newly-formed advanced operations team, which 12 months later morphed into my current role when a number of engineering functions were consolidated under one ‘Man Eng’ umbrella.

The role includes supporting new product projects, visiting the various sites, reviewing new product strategies and supporting operations with engineering and build sequence direction. Because of my background, I also like to get involved and support the day-to-day problem-solving decisions with current builds. We consistently have between five and 10 new model projects ongoing at any one time and, once a product is launched, the team analyses what could have been done more efficiently on site and factors this into future projects as part of the ‘lessons learnt and continuous improvement’ process.

When it comes to product design, Princess has always had strong traditional roots and this has led to a large number of returning customers who trade up over years of ownership. We have some extremely talented designers who are keen to push the boundaries in terms of innovation – you only have to look at the R35 and X range – and part of my team’s job is to manage how far we can go within the ‘design for manufacture’ parameters of build sequence, cost, quality and validation of weight affecting fundamental performance and stability characteristics.

I enjoy all the different aspects of my job and I think my 20-plus years at the company helps greatly in my current role. My professional experience, from shop floor to senior management, gives me the tools to empathize and communicate with people at all levels, as well as the practical skills to back up our engineering strategy and return on investment (ROI) projections.

The excitement of working with the latest product designs and playing a key role in mapping the future boat production pipeline is something that I thrive on. I continue to feel privileged that I get to work with such talented people, and I look forward to strengthening the department with further talent as we progress towards achieving the goal of a ‘Flawless Launch’.

To learn more about Princess Yachts’ craftsmanship, visit their website .

- More: Princess , Princess Yachts , Sponsored , Sponsored Content

Meet The Italia Yachts Veloce 43

For sale: ocean alexander 78 sport bridge, for sale: ferretti yachts 750, for sale: 2007 96′ hargrave.

- Digital Edition

- Customer Service

- Privacy Policy

- Email Newsletters

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

Optimizing 50 years of yacht-building expertise with Siemens Digital Industries Software portfolio

Princess elegantly balances attention to detail and speed with NX and Teamcenter

Princess Yachts

One of the world’s leading luxury motor yacht manufacturers, Princess Yachts International has more than 2,300 employees across five manufacturing sites in the southwest of England. With a reputation for high standards and engineering excellence, Princess offers a superb range of sports yachts, flybridge motor yachts and super yachts ranging from 39 to 130 feet.

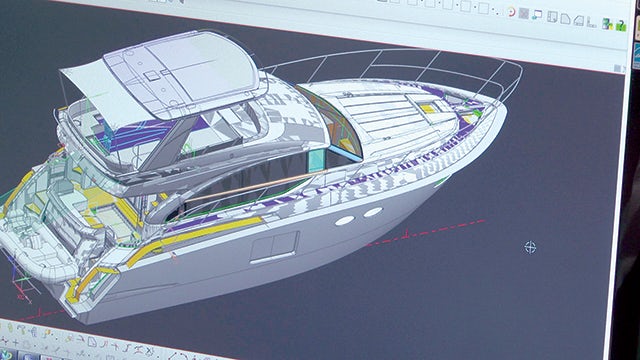

Data delivered direct to the 5-axis machine gives accuracy and a better surface finish.

Effortless and exhilarating elegance

As Princess Yachts International (Princess) marked its 50th anniversary with the launch of three new class-leading products across its S Class, V Class and M Class ranges, it simultaneously revealed the lovingly restored Project 31, one of its original 1965 models. The company sympathetically restored original features, yet incorporated modern materials and production techniques for a new level of luxury.

The combination of bold technical innovation and detail-oriented craftsmanship epitomizes Princess. After five decades of designing and manufacturing motor yachts, the company is renowned for graceful hulls that are both agile and efficient, and interiors that exude quality and style and are cleverly resolved. One of the largest employers in the southwest of England, the company has more than 2,300 staff members across five sites in and around Plymouth. Not only does Princess embody the maritime heritage of the area, it exemplifies the international standards of excellence set by the LVMH (Louis Vuitton Moët Hennessy) family of companies to which it belongs.

The extensive range of sport and flybridge motor yachts features custom-made furniture, beautiful textiles and bespoke lighting. Founder David King explains the appeal of a Princess yacht: “We have a product that performs in all conditions and is timeless in its good looks. For Princess, every aspect of a boat has to be thought through and resolved, with elegance and without compromise.”

Passionate about producing the best

King is involved right from first concept, working closely with the company’s Head of Design, Andy Lawrence, and its naval architect studio for 35 years, Bernard Olesinski Limited. Together, they establish the hull form, structure, performance criteria and unique features of each new design. “It is all about allocating space and headroom yet retaining a low, sleek profile,” says King. “That means attending to every detail, from the performance of the hull to the way in which a shower drains, or the crockery drawer layouts.”

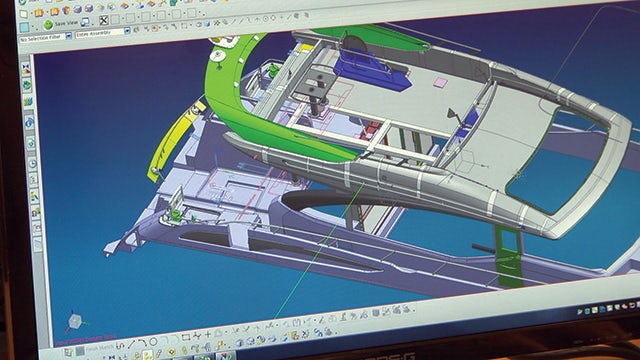

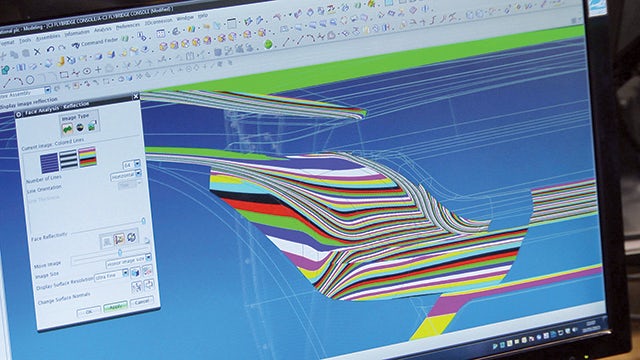

Between three and six yacht designs are brought to market each year, and as the first of a new design begins sea trials, the second is ready to commence fit-out. “We schedule a gap between hull number one and hull number two, but this often gets compressed, and with the first six boats already sold with allocated delivery dates, the production teams frequently face pressures,” King explains. The only way to maintain this rate of production and advance the highest standards of quality is to utilize technology to facilitate the development process. Princess has a long-standing partnership with product lifecycle management (PLM) supplier Siemens Digital Industries Software, and uses NX™ software for computer-aided design (CAD) and Teamcenter® software for storing information and managing workflows.

Facilitating attention to detail with NX and Teamcenter

When a new design is confirmed, the NX model files of the hull and deck are placed in Teamcenter, which acts as the hub controlling all data in and out of the product development department. At this point, the design team takes responsibility for the general arrangement, which includes the final exterior and interior layouts. Careful thought goes into the detail of each item as well as the look and functionality. Although the work starts in 2D for simplicity and speed, the final result is a fully detailed 3D model of the entire boat showing how all components work together, and includes third-party supplier items. “With this complete NX assembly, designers can review different aspects of the boat in context and finesse tiny details well before the production stage,” Lawrence notes.

David Hough, head of the company’s development engineering, leads the team responsible for mechanical and electrical systems, ranging from fuel and water tanks to hydraulic bathing platforms. “We design electrical circuits in a dedicated software program, then we use NX to measure the looms and show how they fit into the overall design,” he explains.

Andy Hay, head of naval architecture at Princess, is responsible for compliance with safety regulations and shipping class rules. “My team uses NX to ensure that the design meets structural and performance standards and will meet expectations right down to the allowance of light switches and window blinds in the structure,” says Hay.

Meanwhile, Rob Coleman, the company’s development operations manager, organizes schedules and coordinates different processes. “NX gives us speed, efficiency and design freedom, and Teamcenter enables us to control information,” says Coleman. “We can all view a complex product design and make sense of it.”

Siemens Digital Industries Software provides ongoing technical support and guidance as required, for example, assisting with a major upgrade of the company’s database and working with Princess to review and improve in-house skill levels and working practices. Siemens Digital Industries Software also delivered customized training that enabled everyone to follow consistent methods of design. “This resulted in a significant efficiency improvement, which has enabled us to reallocate resources to allow more complex surface modeling of interiors and improved designs,” says Coleman.

An effortless passage from design into manufacturing

Princess has several 3- and 5-axis numerical control (NC) machines. The company uses the advanced computer-aided manufacturing (CAM) capabilities of NX to drive the advanced equipment on the shop floor. The NC programmers use NX CAM to create and validate 5-axis operations needed to machine the complex geometry of plugs from which molds are made. Besides NC programs, NX CAM enables Princess’ engineers to generate complete work packages, including setup sheets and tool lists. When the mold is ready, resin infusion techniques are used to create a hull that is strong, light and thin, maximizing internal volume. “Data delivered direct to the 5-axis machine gives increased accuracy and a better surface finish,” comments Coleman.

Direct output from NX CAM to production machinery maintains precision, yet attention to detail is taken even further with the construction of a physical mockup so that subtle details can be verified and refined; for example, King sits at the console, checking sight lines and the layout of the console. Team leaders in the factory have access to the latest digital information for boat fit-out and furniture, and also use it for production planning and various technical systems within the boat design.

Navigating with knowledge

Princess Yachts uses Teamcenter to manage information on hundreds of thousands of parts and provide visibility and traceability across the company. Everyone can see the evolution of a structure or component, its production status and any background data. In addition to storing design, analysis and performance data, Teamcenter holds all due-diligence and compliance documentation and can be used to create business reports.

“We always know where we are in our virtual world because Teamcenter is infinitely searchable,” says Hay. “When I go to Teamcenter to locate a part, I can see every revision and who is working on the latest release.”

Princess Yachts uses Teamcenter to manage a library of standard parts, each with associated analysis and performance data. These range from nuts, bolts and washers to generators and larger items such as tenders. The company enables re-use of items and establishes standard process and protocols using Teamcenter, supporting the smooth development of boat designs that are unique. “There is very little straight re-use,” comments Hough. “One object may be used in various ways to create an end result that is different each time.”

Rob Dewe, who is responsible for NX in development and Teamcenter as an information hub, notes: “We previously used Teamcenter workflows simply to release subassemblies. Now we use them to ensure consistent standards of quality and communication.”

A focus on product

“Through the use of NX and Teamcenter, Princess has increased efficiencies across all processes and is building bigger and better boats,” says Coleman. With a constant focus on improvement, the company is now looking at enhancing the way in which it exchanges data with Bernard Olesinski, and improving procurement through closer communication between Teamcenter and its manufacturing resource planning (MRP) system.

“We are fundamentally a product company,” comments Chris Gates, Princess’ managing director. “We work with like-minded partners around the world who focus on customer care, and we put all our passion into the product because we believe that the customer will decide which product is best. The quality of our product grows ownership, and our greatest achievement is the fact that the vast majority of the Princess family of owners upgrades within their product range.”

King concludes: “It takes two years to develop a boat, which typically has a fiveyear lifecycle. That means we are always looking ahead, for example, to what engines and new materials are in development. It really is all about details, just as Leonardo da Vinci said: ‘Details make perfection, and perfection is not a detail.’”

We always know where we are in our virtual world because Teamcenter is infinitely searchable.

Press Releases

KPS Capital Partners to Acquire Controlling Ownership of Princess Yachts

Investment will Accelerate Company’s Growth and Innovation

New York, NY (February 13, 2023) -- KPS Capital Partners, LP (“KPS”) announced today that it has entered into a definitive agreement to acquire a controlling equity interest in Princess Yachts (Holdings) Limited, (“Princess Yachts” or the “Company”), a leading global manufacturer of luxury motor yachts. Existing stockholders will retain ownership in the Company. Completion of the transaction is expected in the first quarter of 2023 and is subject to customary closing conditions and approvals.

Princess Yachts is a leading builder of luxury motor yachts and is recognized for its timeless design, hand-crafted quality and exceptional seakeeping. Headquartered in Plymouth, England, the Company’s unparalleled level of vertical integration – including on-site design, engineering and manufacturing – has helped position Princess Yachts as one of Britain’s most iconic luxury brands. Princess Yachts serves a global customer base through its best-in-class international dealer network. The Company has approximately 3,200 employees and operates five manufacturing facilities in Plymouth, England.

Ryan Harrison, a Partner of KPS Mid-Cap Investments, said, “We are excited to make this significant investment in Princess Yachts, a leading company in the luxury global yachting industry with an iconic brand grounded in British tradition, a remarkable and growing product range and worldwide reputation for quality and innovation. KPS’ investment will accelerate Princess’ growth trajectory and fund numerous investments for its future. We look forward to working with Princess’ existing stockholders, Chief Executive Officer Antony Sheriff, the senior leadership team and the talented employee base at Princess Yachts.”

Antony Sheriff, Chief Executive Officer of Princess Yachts, said, “We are thrilled to partner with KPS for this exciting new chapter for Princess Yachts. KPS and the Princess Yachts team are deeply committed to investing in the Company’s future while continuing to further strengthen our portfolio of best-in-class motor yachts. With a current order book nearing a record $1 billion and many model lines sold into 2025, we have never been in a stronger commercial position. Together with KPS’ tremendous track record of manufacturing excellence and investing in leading brands, we are now positioned to take Princess Yachts to the next level of industry leadership in quality and innovation. Under KPS’ ownership, we will accelerate a range of growth and operational initiatives to build upon our long and successful history.”

Paul, Weiss, Rifkind, Wharton & Garrison LLP served as legal counsel to KPS. Macquarie Capital and Latham & Watkins LLP served as financial advisor and legal counsel, respectively, to Princess Yachts.

About Princess Yachts

Princess Yachts is a leading builder of luxury motor yachts and is recognized for its timeless, understated design, unique craftsmanship and exceptional seakeeping. Headquartered in Plymouth, England, the Company’s unparalleled level of vertical integration – including on-site design, engineering and manufacturing – has helped position Princess Yachts as one of Britain’s most iconic luxury brands. Princess Yachts serves a global customer base through its best-in-class international dealer network. The Company has approximately 3,200 employees and operates five manufacturing facilities in Plymouth, England. For additional information, please visit www.princessyachts.com .

About KPS Capital Partners

KPS, through its affiliated management entities, is the manager of the KPS Special Situations Funds, a family of investment funds with approximately $21.4 billion of assets under management (as of December 31, 2023). For over three decades, the Partners of KPS have worked exclusively to realize significant capital appreciation by making controlling equity investments in manufacturing and industrial companies across a diverse array of industries, including basic materials, branded consumer, healthcare and luxury products, automotive parts, capital equipment and general manufacturing. KPS creates value for its investors by working constructively with talented management teams to make businesses better, and generates investment returns by structurally improving the strategic position, competitiveness and profitability of its portfolio companies, rather than primarily relying on financial leverage. The KPS Funds’ portfolio companies generate aggregate annual revenues of approximately $20.3 billion, operate 222 manufacturing facilities in 26 countries, and have approximately 48,000 employees, directly and through joint ventures worldwide (as of December 31, 2023). The KPS investment strategy and portfolio companies are described in detail at www.kpsfund.com.

← Back to Press Releases

One Vanderbilt Avenue, 52nd Floor New York, NY 10017 T: 212.338.5100 | F: 646.307.7100

- Investments

- Investor Login

Cookie Consent

This website uses cookies or similar technologies, to enhance your browsing experience and provide personalized recommendations. By continuing to use our website, you agree to our Privacy Policy

How Princess Yachts use WFM software to streamline manufacturing across multiple sites

Princess Yachts International, a division of luxury brand family LVMH, are one of the UK’s leading luxury yacht manufacturers, with a reputation for producing craft of the highest quality. The company wanted to replace its labour-intensive, clunky and ageing time and attendance system with one that would address their management needs well into the future.

Read on to discover why Crown Time and Attendance was chosen as the perfect solution for Princess Yachts’ needs, and how it has helped the company streamline manufacturing across multiple sites, boost efficiency and improve processes around payroll and workforce activity.

Latest blogs

Journey of empowerment through a 186-mile hike for mnd awareness, inclusive strategies in working time for navigating ramadan, crown strengthens security confidence by joining risk ledger, crown are here to help you drive efficiency and business growth.

- Destinations

- Trip Planner

- In the Spotlight

- Scandinavia

- Switzerland

- UK & Ireland

Set off to Europe on one of the fully-customizable private tours

Join a petite group of travelers during your exploration of Europe

Select one of the greatest itineraries to Spain for your trip

Have an unforgettable journey to the biggest country in the world

Discover Norway, Sweden, Finland, Denmark, and Iceland's best

Plan Your Tour to Europe

Treat yourself to an unforgettable getaway to the European destination of your choice

Interested in the unmissable sights of the top cities in Scandinavia?

Travel to Scandinavia

Go on a trip of a lifetime to gorgeous Norway, Sweden, Denmark, Finland or even Iceland

- My itineraries

- Trip survey

- For Suppliers

+1 (800) 884-1721

- Oceania and Australia : +61261888118

You are here

Top 10 moscow tourist attractions.

The majestic capital of Russia , Moscow is the perfect destination for those seeking to explore the culture, history, and architectural heritage in the country. An extensive Moscow tour is arguably the best way to get acquainted with the one-of-a-kind city, as there is an abundance of sites to visit, such as the Kremlin, the Red Square, the State History Museum, Zaryadye Park, numerous churches and theatres and more! Don't miss the chance to enjoy Moscow sightseeing and explore the bustling hub yourself! Below we offer a list of the best places in Moscow not to miss.

- Call us now

- Request a call

- Chat on WhatsApp

- Start Live chat

- Contact via email

Why Us Firebird Tours Reviews Triptile Blog Reservation Policies Terms of Service Privacy Policy

Italy Small Group Tour

Venice, Florence & Rome

From Venice to Amalfi

Paris, Munich & Rome

Norway Private Tour

Scandinavia in Small Group

Sweden Private Tour

Finland Private Tour

Best Tours to Spain

Best Tours to France

Best Tours to Germany

Best Tours to Russia

All Rights Reserved © 2024 Terms & Conditions | Privacy Policy

Moscow major projects

Since launching modern Russia’s largest construction program in 2011, Moscow has more than doubled its territory. To catalyze the full potential of this rapidly-growing metropolitan area of 19.5 million people, the City of Moscow’s government pays significant attention to infrastructure as one of the key pillars of urban development—with a current focus on projects that create livable and comfortable urban spaces for both citizens and tourists.

Following its first five years of projects, Moscow was given special recognition for “demonstrating outstanding strategic commitment and ambition” by the International Association of Public Transport (UITP). That period saw 50 million square meters of real estate developed, 370 social infrastructure objects built, and the metro expanded by 30 percent—including 101 kilometers of metro lines and 55 new stations. Innovative finance solutions, necessitated by the city government’s debt-free approach to development, enabled all this whilst maintaining a budget surplus and remaining a net donor region within Russia.

On 30-31 May 2018, the City of Moscow and Mosinzhproekt—a large Russian engineering, construction and project management company—hosted an Innovation Site Visit to showcase Moscow’s major projects to the Global Infrastructure Initiative (GII) community. Through roundtable discussions and site visits with project executives, participants explored where innovation and technology have enabled the step-changes that have allowed Moscow to deliver major projects on a short timeline—and how to apply these lessons to other cities and major projects.

The following insights emerged during GII’s Innovation Site Visit in Moscow:

- Establish a structure for citizen involvement. Major urban infrastructure projects are an extremely visible expenditure of taxpayer funds while also often being large disruptors of daily life. A foundation of citizen support is essential for success and requires a thoughtful engagement program. In Moscow, citizens are encouraged to participate in the planning process by steering major initiatives through the “Active Citizen” application—a portal for online referendums on topics appropriate for democratic decision-making. To date, almost 2 million citizens have cast more than 90 million votes on over 3,000 issues through the platform. The purpose of this structure is to increase the opportunity for citizen engagement and involvement with their city’s major investments.

- Manage the disruption ‘cost’. Major urban projects cannot be delivered without disrupting daily life. While citizens can be enrolled to accept the disruption as a necessary investment for a better outcome, equal attention needs to be given to managing the disruption ‘cost’ as to managing real expenditures. For example, MyStreets, a project to upgrade and enhance Moscow’s urban environment through reconstruction of streets and building façades, was disruptive to many citizens and commuters. However, through staging and swift execution, the disruption was minimized and the intended lifestyle improvements were quickly delivered to Muscovites and tourists who traverse newly styled pedestrian streets every day.

- Invest in technology to optimize sequencing. Moscow’s cohesive vision for urban transformation has allowed early investments in technology to assist future delivery. One of the first projects completed was the centrally-controlled traffic management system which can monitor traffic conditions and urban movement through more than 2,000 traffic cameras and 160,000 CCTV cameras installed across the city. Data collected on current conditions, and knowledge of planned activities, allows real-time rerouting of traffic through the city’s dynamic signage. It also allowed identification and analysis of permanent traffic flow changes that could further ease disruptions like those created by the major construction projects.

Moscow traffic speed increased over 13% in 201.

- Maximize utility of brownfield sites. A key reason the Moscow Central Circle (MCC), a new light-rail system integrated into the Moscow Metro, was completed in a record four-year period was the repurposing of existing brownfield networks which allowed the installation of modern technology on existing rail transport routes. The MCC’s 31 new stations will revitalize formerly abandoned industrial areas when its next stage of development builds an expected 300,000+ square meters of hotels, 250,000+ square meters of retail, and 200,000+ square meters of offices. This will give districts with historically poor infrastructure access a chance to develop at the same pace as the rest of the city.

- Leverage PPPs to enhance basic services. To manage public cost and investment while delivering world-class infrastructure, municipalities need access to additional financing tools. Based on a structure that took an act of federal legislation, the MCC is an example of enhancing publicly developed foundations with private services. The tracks and land are owned by the Moscow Metro, with the rolling stock subcontracted to Russian Railways under a life cycle contract with a guaranteed buyback. The innovation is that Moscow Metro is licensing the development rights of its individual stations to private investors. Though all stations will exist under the same covenants, individual investors will assume their station’s construction cost and operational risk and rewards.

- Create citizen-centric spaces. In addition to serving as open spaces, today’s city residents expect their parks to provide for entertainment and consumer services too. Many modern parks offer architectural features, charismatic vistas, and social, educational, and artistic spaces for all ages. When Zaryadye Park, an area of prime real estate next to the Kremlin was converted to parkland, an international contest resulted in 10 hectares being densely designed for this multi-function purpose. The outcome was two concert venues, restaurants, a parking garage, an entertainment complex, and a biological education center, all neatly camouflaged into a natural landscape that represents Russia’s ecological diversity.

- Innovate where needed but not excessively. Moscow’s planners and builders did not shy away from technological innovation. The MCC used weldless joint rails to create a smoother and quieter system that is easier on riders and less disruptive to residents living near the railway tracks. The retrofit designs for Luzhniki Stadium were fully modeled in building information management (BIM)—a step which identified more than 100,000 conflict points before they could escalate into project delays. However, the project teams were also careful not to force innovation where it could create unnecessary risk and complications. Instead, they delivered the massive project portfolio by tactically melding innovations with highly-proficient execution of well-known and proven methods.

Related Articles

Building smart transport in Moscow

Making the consumer case for major infrastructure

Learning from experience: How hosting the Olympics can leave a positive legacy

- CruiseMapper

- Cruise Ports

- Russia Rivers Cruise Ports

Moscow (Russia)

Cruise port schedule, live map, terminals, news.

Region Russia Rivers

Local Time 2024-04-05 20:30

Moscow is a Volga River cruise port, Russia's capital and largest city (population over 12,2 million, metro 17 million). Moscow City covers a total area of approx 2610 km 2 (970 mi2). By population, the city is ranked the world's 14th largest. Moscow is one of the Russian Federation's all 3 federal cities - together with St Petersburg and Sevastopol .

Being Russian Federation's capital, Moscow is a major economic, political, scientific and cultural center, as well as Europe's biggest city.

According to Forbes 2013, Moscow has been ranked as the 9th most expensive city in the world by Mercer and has one of the largest urban economies, being ranked as an alpha global city according to Globalization and World Cities Research Network. It is also one of the fastest-growing tourist destinations in the world according to MasterCard Global Destination Cities Index. Moscow is the northernmost and the coldest megacity and metropolis on the Earth. It's home to Ostankino Tower, the tallest free-standing European structure; the Federation Tower, the tallest European skyscraper; and the Moscow International Business Center.

Moscow is situated on Moskva River in the Central Federal District of European Russia, which makes it the most populated inland city in the world. Moscow city is well known for architecture, particularly its historic buildings like Saint Basil's Cathedral. With over 40% of its territory covered by greenery, it's one of the greenest capitals and major cities in Europe and the world. Moscow is the seat of power of the Russian Government, being the site of Moscow Kremlin, a medieval city-fortress that is now the residence of the President of Russia. Moscow Kremlin and Red Square are among the several World Heritage Sites in the city.

Moscow has 2 passenger terminals, North River Terminal (Rechnoy vokzal) and South River Terminal. The regular ship routes and cruises along Moskva and Oka rivers are used mostly for entertainment. North River Terminal (1937-built) is currently the main hub for long-range routes along the river. There are 3 freight ports that serve Moscow.

In late-July 2021 the city announced plans to incorporate a fleet (unspecified number) of fully electric passenger ferries into its public transportation network from summer 2022, the goal being to reduce the dependence on cars.

- The boats are designed with length ~22 m (72 ft), passenger capacity 42, modern amenities (Wi-Fi, USB charging points, tables for working commuters), spaces for storing scooters and bicycles.

- Moscow Transport confirmed that two routes (with max daily capacity ~16,000 passengers) have already been mapped out.

- Passengers will be able to pay via bank cards, the city’s Troika card (smart card for travel by any public transportation) or biometric payment cards. Those with monthly/yearly public transit tickets will use the boats at no extra cost.

- The new electric ferry service is up to 5 times faster (in comparison to other city public transports) and ~2 times faster than by car.

Moscow cruise terminal

Moscow's cruise terminal is called North River Terminal or River Station ("Rechnoy Vokzal" / "ÑеÑной вокзал").

The terminal was opened in 1937 and is one of 2 passenger terminals (the other being South River Terminal) of the city's river transport. North River Terminal is the main hub for long-range (including cruise) shipping routes.

South River Terminal (above photo) was opened in 1985.

Moscow launches electric ferry service in 2022

Russia's capital city Moscow plans to incorporate a fleet of fully electric passenger ferries into its public transport network from summer 2022...

Vodohod’s first Project PV300 river ship departs on maiden cruise

Project PV300 built by United Shipbuilding Corporation's Krasnoye Sormovo Shipyard (Sormovsky-Nizhny Novgorod, Russia) and recently delivered to...

Emerald Waterways opens bookings for 2021 Russian River Cruises

The premium brand Emerald Waterways opened bookings for its 2021 Russian river cruise season. Voyages will feature a newly chartered...

Vodohod’s Mustay Karim cruise ship to be delivered by July 10

Russia's largest cruise company and tour agency Vodohod expects its newbuild cruise ship MS Mustai Karim (currently under construction at Nizhny...

2018 FIFA World Cup Games to Be Shown Aboard Princess Cruises Ships

Princess Cruises passengers sailing all over the world will spectate and cheer on their favourite teams during the single largest tournament of the...

- show more news

Moscow - user reviews and comments

15 Top-Rated Tourist Attractions & Things to Do in Moscow

Written by Diana Bocco Updated Dec 23, 2023 We may earn a commission from affiliate links ( )

Moscow is one of Europe's most enigmatic destinations, home to a fascinating history and colorful, awe-inspiring architecture you won't find anywhere else in the world. Moscow might be one of the most populous cities in the world with over 11 million inhabitants, but this hasn't changed its strong cultural and social traditions.

Walk the cobblestone streets of the Red Square or the banks of the Moskva River early in the morning, and it's hard to tell what century you're in.

Tsarist architecture, must-see churches, and glamorous shopping opportunities blend together for a visual experience you won't forget. For ideas on what to see and do while visiting Russia, here's our list of top tourist attractions in Moscow.

1. Marvel at the Size of the Kremlin

2. catch a performance at the bolshoi theatre, 3. shop at the luxurious gum, 4. make your way into lenin's mausoleum, 5. spend an hour (or three) at red square, 6. discover history at the museum of cosmonautics, 7. ride the stunning moscow metro, 8. explore the moscow state integrated museum-reserve, 9. spend a rainy day at the tretyakov gallery, 10. walk up and down arbat street, 11. stop by the vdnkh all-russian exhibition centre, 12. wander around gorky park, where to stay in moscow for sightseeing, map of tourist attractions & things to do in moscow.

Moscow's most recognizable structure is without a doubt the Kremlin, a 15th-century fortified complex that covers an area of 275,000 square meters surrounded by walls built in the 1400s.

The Grand Kremlin Palace -which has over 700 rooms- was once home to the Tsar family and is now the official residence of the president of the Russian Federation, although most heads of state choose to reside elsewhere.

The massive complex also includes many other buildings, some of which are open to the public and can be visited regularly. Aside from three cathedrals (including one where the Tsars were once crowned) and a number of towers, the Kremlin is also home to the Armory building, a museum holding everything from the royal crown and imperial carriages to the ivory throne of Ivan the Terrible and Fabergé eggs.

The Bolshoi Theater is home to the largest and one of the oldest ballet and opera companies in the world . While the theater has undergone several major renovations over the past century-including a recent one in 2011 to restore some of the imperial architectural details-it still retains all of its Neoclassical grandeur.

The Bolshoi Theater you see today opened in 1824, after several older versions burned down. Inside, red velvet, a three-tiered crystal chandelier, and gilt moldings give the place a Byzantine-Renassaince grandiose feel like no other.

Catching a show from the resident ballet and opera troupes is a treat, as the theater often presents a number of classic performances, such as Tchaikovsky's Mazeppa and Rachmaninoff's Francesca da Rimini, both of which originally premiered here.

Moscow's oldest and most upscale shopping center is an architectural marvel. GUM (short for Glávnyj Universálnyj Magazín or "Main Universal Store") was built in the late 1800s in neo-Russian style to showcase a beautiful mix of a steel skeleton and 20,000 panels of glass forming an arched roof.

This was a unique construction at the time, since the glass had to be strong enough to support the snow-heavy Russian winters. The building is just as impressive outside, with all three levels covered in marble and granite.

While GUM is no longer the largest shopping center in Moscow, it's still by far the most beautiful. Home to brands like Gucci and Manolo Blahnik, this might not be the ideal destination for most budget-conscious visitors, but the beauty of the building itself is worth a visit.

On the third floor, there are also great dining options, including a Soviet-style canteen that serves traditional Russian food, and a stand selling ice cream made by hand using an original 1954 recipe originally approved by the Soviet government.

Lenin's Mausoleum, the final resting place of Soviet leader Vladimir Lenin, occupies a central spot in Red Square. His body has been in the mausoleum since his death in 1924-and although the original plan was for him to be buried after a short period of public display for mourning, the plan quickly changed.

After over 100,000 visited the tomb over a period of six weeks, it was decided that a new sarcophagus and a more permanent display space could actually preserve Lenin's body for much longer than expected-and Lenin's Mausoleum was built.

Over the years, the mausoleum and its marble stairs also became the main spot from where Soviet leaders would watch parades and events happening in Red Square.

Lenin's embalmed body can still be seen today, lying down in a bulletproof glass sarcophagus as if he's sleeping. While a visit to the mausoleum is certainly unusual, it has become a must-do for history buffs looking to understand how Lenin's legacy truly changed the nation. Come ready to wait, though -there are usually lines to get in.

All of Moscow's main streets start at Red Square, so it's easy to see why this is considered the heart of the city. A massive space of 330 meters by 70 meters, the square is flanked by the Kremlin, Lenin's Mausoleum, two cathedrals, and the State Historical Museum.

In 1945, a massive Victory Parade was held here to celebrate the defeat of Nazi Germany by the Soviet Armed Forces.

St. Basil's Cathedral , one of the most recognizable buildings on the square, was built in 1555. The unique cathedral has architectural details inspired by Byzantine and Asian design, as well as details that resemble those found in famous mosques. There are nine individual chapels inside the church, all decorated with colorful mural art.

Both the square itself and the Kremlin are recognized as UNESCO World Heritage Sites . On weekends, there are sometimes stalls selling souvenirs and traditional items here, such as matryoshka (Russian nesting dolls), at the entrance of the square.

At one point, Russia and the US were toe-to-toe when it came to space exploration. While that might no longer be the case, the museum's amazing collection-which includes over 85,000 items-is still awe-inspiring.

Main exhibits include the space capsule used by Yuri Gagarin , the first human to travel into outer space; a USSR flag with moon fragments; a Soviet spacesuit; and a rocket propulsion unit from the 1960s. A special two-story hall showcases sections of the Mir space station interior, and there are also models of the first sputniks and a replica miniature spaceship.

English-language tours are available, and there's also a Cinema Hall showing subtitled short films about the history of space exploration programs and the first manned space flight.

The museum is located inside the base of the monument to the Conquerors of Space, which was built almost 20 years before the museum opened.

Riding the Moscow metro is an experience all in itself, but even just heading underground to walk through the stations is something no visitor should miss. With 223 stations and 12 metro lines crosscutting through Moscow, however, this can be tricky, so visiting at least a few of the most impressive ones is a good start.

Arbatskaya station was designed by a skyscraper architect, so it's no surprise that it features multicolored granite slabs and impressive bronze chandeliers.

Park Kultury station , located next to Gorky Park, is covered in marble and features reliefs of people involved in sports, while Teatralnaya station is decorated with porcelain figures dancing and wearing traditional Russian costumes.

The metro is open between 5:30am and 1:00am but it's very crowded in the early morning and after 4pm, so it's better to visit in the late morning or early afternoon to really appreciate the architecture without the crowds.

The Moscow State Integrated Art and Historical Architectural and Natural Landscape Museum-Reserve is a cultural open-air museum complex comprised of four different historical sites.

The most important site, the Kolomenskoye Estate, was once the summer residence of Tsars as far back as the 14 th century. The complex, which covers almost 300 hectares, is home to fairy-tale wooden palaces; a tent-roof stone church built in the 1500s; a water tower; fort towers and structures; and the 24-room Museum of Wooden Architecture , which includes the restored dining room of Tsar Alexei I.

Beautiful manicured gardens , riverside picnic areas, and a massive collection of both artifacts and structures make this a great destination to help you see what medieval Russia looked like. English-language tours are available, but you're also free to wander the grounds on your own.

The largest collection of Russian art in the world sits here, with over 180,000 paintings, sculptures, and religious art dating back to over a millennia ago. The gallery, built using beautiful red and white colors from classical Russian architecture, is located near the Kremlin and it was built in the early 20 th century.

Significant art pieces include the Vladimir Mother of God; a Byzantine icon of the Virgin and child dating back to the 1100s; Andrei Rublev's The Trinity icon from the 15 th century; and several works by Ilya Repin, the most famous realist painter in Russia.

On the grounds of the museum, there is also an 86-meter-tall statue of Peter the Great, as well as a number of Socialist Realism sculptures.

Moscow's one-kilometer-long pedestrian street has been around since the 15 th century. Originally a trade route in the outskirts of the city, Arbat Street is now very centrally located, home to posh buildings and lots of places to eat and shop.

Beautiful street lamps and two significant statues-one of Princess Turandot (from Puccini's last opera) and one of Soviet-era poet Bulat Okudzhava-adorn the street, which fills up with both locals and tourists on evenings and weekends.

A great place to pick up souvenirs or sit down at an outdoor café, Arbat Street also offers a chance to visit the former home of poet Alexander Pushkin and the café both Anton Chekhov and Leo Tolstoy used to visit.

Although it was originally designed as a general-purpose trade show venue, this park complex now houses amusement rides , ice rinks , and a number of galleries and other attractions for all ages.

The park's most famous landmarks are the Moskvarium, a marine biology center home to over 8000 species of marine animals, the Garage Museum of Contemporary Art, and a shopping center selling traditional products from former Soviet countries.

There's even a film museum showing Soviet cartoons or even a full-length film (for an extra fee) and an education center offering masterclasses on everything from becoming a barista to video montage (call or write in advance to find out which ones are English-friendly).

Soviet-era pavilions, sculptures, and fountains abound here as well, including the famous Friendship of the Peoples Fountain, which features statues of women dressed in costumes from different former Soviet countries.

Named after the famous Russian writer Maxim Gorky (who was nominated for the Nobel Prize in Literature five times but never won it) and sitting right across the Moskva River, Gorky Park covers 120 hectares of beautiful ponds and green spaces.

Popular with both locals and tourists, the park offers a variety of things to enjoy-from sunbeds, hammocks, and drinking fountains to free yoga classes and children's playgrounds. There's free Wi-Fi and sockets for charging your phone, as well as many food stands and plenty of wild animals, including deer, rabbits, and pheasants.

Visitors can rent paddle boats and bicycles to explore the park-and from May to October, there is also an open-air movie theater, as well as scheduled presentations by street performers, musicians, and artists. Gorky Park attracts the young and old, so don't be surprised to see a mix of people exercising, playing chess, and sunbathing.

Luxury Hotels :

- Lotte Hotel Moscow is one of the top 5-star properties in Moscow offering the largest Royal Suite in Russia. The trendy rooms and suites here all have contemporary style and great city views. On-site amenities are plentiful. There are two restaurants: one serving contemporary Italian fare, and the other Japanese. There is an impressively lit indoor swimming pool, a well-known spa, and a state-of-the-art gym.

- Another excellent luxury hotel is the Ararat Park Hyatt Moscow . The residential-style property is in the heart of Moscow just next to the Bolshoi Theatre and within walking distance of the Kremlin and Red Square. The rooms and suites have been opulently designed by Tony Chi. The on-site restaurant serves a mix of European and Armenian specialities. There is also a Japanese sushi bar and a rooftop lounge with fabulous city views.

- The St. Regis Moscow Nikolskaya also has a central location just a few minutes from the Kremlin and Red Square. The 5-star property has a mix of elegant rooms and suites, including interconnecting room options for families with kids. There are multiple restaurants on-site including an Italian bistro. Other amenities include the fabulous Iridium Spa, which does a full range of treatments and has an indoor swimming pool, sauna, and steam room.

Mid-Range Hotels :

- Palmira Business Club is a top mid-range choice. The contemporary lifestyle hotel offers well-appointed rooms and suites, including options for families. Suites are quite spacious and have kitchenettes. Amenities here include a complimentary breakfast at the on-site restaurant, a hot tub, sauna, and spa. There is also a fitness center.

- The trendy Mercure Moscow Baumanskaya offers a mix of rooms and suites with contemporary decor. The mid-range hotel can arrange airport transportation and offers baggage storage. Other amenities include a restaurant and room service. The front desk is open 24 hours.

- Boutique Hotel Brighton is about 10 minutes from the city center in a leafy park area. It offers excellent value for money and has charming rooms and suites with sound-proof windows and doors, as well as blackout curtains. A complimentary breakfast is served, and there is also an indoor swimming pool.

Budget Hotels :

- Hotel Ibis Budget Moscow Panfilovskaya is about a 15-minute drive from Moscow's downtown, and it's within walking distance from a metro station that will take you there. The soundproof rooms at this budget property are clean, comfortable, and can sleep up to three people. The hotel is pet friendly, has paid parking available on-site, and also has a salon.

- If you just need a budget hotel near the airport then check out Aviator Hotel Sheremetyevo . Located right at the airport, it has soundproof rooms, including options for families. Amenities include an indoor play area for kids, a sauna and swimming pool, and a free breakfast.

More Related Articles on PlanetWare.com