ABOUT

CNC ROUTER SHOP

Composite Yacht 26'

Composite Yacht specializes in the latest technology and the 26 is no exception. Constructed utilizing modern coring materials and laminating techniques results in a lighter, stronger boat which equates to remarkable fuel economy at faster cruise speeds. An intelligently designed bottom shape aids in this while still providing a comfortable ride and stability at rest. Available in both outboard and inboard configurations, the CY26 is designed for the discerning fisherman that enjoys the performance of a sport boat.

VIEW NEXT BOAT

Specifications.

Standard Power with 2 -75 gallon fuel tanks OR Single 250 horsepower Yamaha 4 stroke with 150 gallon belly gas tank

18" with Outboard or 24" with Inboard

5,500 lbs dry

60 MPH with 500 HP

6 GPH with Yanmar option, Fuel numbers may vary depending on model and options

VIEW PREVIOUS BOAT

Please click images to enlarge

Boat models.

410-476-4414

[email protected], 1650 marina drive, unit a trappe, maryland 21673.

- Wrightsville Beach, NC 910-256-8803

- Little River, SC 843-340-0080

- Charleston, SC 843-412-6587

- Brokerage Listings

- Latest News

- Testimonials

- Videos

- Follow Us On Facebook

- Yacht Search

- WHO DAT 2007 COMPOSITE YACHT CY26CC Boats Yacht MLS #313429

WHO DAT - 2007 26' 4" COMPOSITE YACHT CY26CC

This yacht is no longer available.

This 26 Composite Yacht Center Console has been meticulously maintained with a open check book.

She is powered by a very economical, low burning Yanmar 315 HP Diesel with only 757 hours, and also has a Bow Thruster!

The 26 CYCC is built with wood free construction. The hull is molded with a propeller pocket for reduced draft, and better fuel economy

This boat was Completely Rewired in 2020, and New Electronics were added in 2020.

She is a head turner! This boat is turn key ready to go, and can be bought for a fraction of the cost of a new build.

A Double Axle Venture Trailer that was rebuilt in 2-2022 also goes with the boat.

Check out the FULL SPECS for more details and give us a call for more information, and to schedule an appointment to have a look for yourself.

Find Similar Yachts for Sale

Contact Broker

Share with your friends, composite yacht 2007, intracoastal yacht sales our offices, wrightsville beach, nc.

10 Marina Street Suite A3 Wrightsville Beach, NC 28480

Office: 910-256-8803 Fax: 888-893-9755 Email: Capt. Ric Stanley

Little River, SC

720 Hwy 17 – Suite 203, Little River, SC 29566

Office: 843-340-0080 Fax: 888-566-5886 Email: Capt. Doug Ford

Charleston, SC

Charleston City Marina 17 Lockwood Dr., Charleston, SC 29401

Office: 843-412-6587 Email: Capt. Bobby Gregory

Boats for Sale

26' composite yacht 26 express express cruiser.

ARCHIVED: This is a previously listed vessel and is no longer offered for sale If you would like assistance locating a similar vessel, Click Here to contact the listing broker.

Fabulous like new 2015 Composite 26 Express with less than 150 hours! Composite Yacht specializes in the latest technology and the 26 is no exception. Constructed using Core-Cell structural foam, it is lighter than others in its class - meaning less fuel consumption. The owner reports 31mph at 4000rpm's burning only 11.1gph! With the upgraded Yamaha 300 four stroke she'll reach 49mph! Ready to go and priced to sell.

- Specifications

- Description

Courstesy of Composite Yachts Our focus is on furnishing the best in All Composite Construction. This results in remarkably strong boats that provide wonderful speed and economy, a pleasing ride, and low maintenance durability to ensure you continue to enjoy your Composite Yacht for many years to come. Composite Yacht is made up of master craftsmen and technicians who take pride in the work we do. Our name is synonymous with using the latest technology in boat-building and fabrication.

Disclaimer While we attempt to display current and accurate data, this listing may not reflect the most recent transactions or may contain occasional data entry errors. Selling agent makes no warranties, express or implied, regarding the content or availability of the products described herein. All inventory listed is subject to availability and prior sale. Please consult selling agent for details. Hours quoted may change due to continuing use of the vessel.

Connecting with Marinesource.com

Copyright 1992-2024 MarineSource Network, Inc. All Rights Reserved.

Chesapeake Bay Magazine

The Best of the Bay

- Bay Boating

- Events & Features

A Dream Team Produces the Chesapeake’s Fastest Deadrise

by Capt. John Page Williams

Composite Yachts 55

- LOA: 55′

- Beam: 16’5″

- Draft: 2’8″

- Weight: 55,000 lb (estimated, with gear)

- Transom Deadrise: 17º

- Bow Deadrise: 48º

- Max Power: 3,880

For more information, visit compositeyacht.biz .

At 55′ long, Skinny Witch tops out at 55 knots (63.5 statute miles per hour). Some folks would say she’s the loveliest, too. That’s certainly the opinion of Jerry Murrell, her owner. He loves the graceful, traditional profile of her sheer line, tumble home and deckhouse, to say nothing of the beauty of her teak and mahogany bright work. And he loves her speed, which allows him and his family to fish her all over the Chesapeake from her home in a creek at the mouth of the Potomac River in Southern Maryland.

Commissioned in May, she has already proven that she catches fish. Two specialties to date have been trolling for rockfish, with parachute jigs behind planer boards, and for cobia, with big red surgical hose eels. She has also proven adept, under the direction of skillful skippers, at sight-casting to cobia with large orange bucktails and live eels. Since each of those techniques requires careful speed control and precise handling, their success is testimony that she is much more than just a pretty go-fast. The speed doesn’t hurt, though, since she can and does easily fish anywhere from the Potomac’s Cobb Island down to the American Mariner wreck in the Southwest Middlegrounds, Windmill Point at the mouth of the Rappahannock, and even outside the Virginia Capes off Rudee Inlet(a two-hour run, “loafing” at 48 knots). At summer’s end, she even did some bottom-fishing for spot, croakers and white perch with her three generations of the Murrell Family, and the fall season finds her jigging for rockfish. As the weather turns colder, she’ll be a natural to run-and-gun looking for gannet storms, with those big, spectacular birds diving on baitfish to signal schools of rockfish attacking from beneath.

So where did this extraordinary deadrise come from? It turns out that she’s as local as Composite Yachts, on the Choptank River, but with design consultation from as far as Ann Arbor, Mich., and twin MTU diesels from Germany. Murrell’s concept, which he came up with some five years ago, was a 55′ yacht-grade deadrise that could run 55 knots. He asked several builders about such a project, but the honest answer that most impressed him was “I don’t know. Let’s hire an architect, build it on paper, then test it.” That came from Lewis Hardy, who with his father, Martin, and brother, Rob, own and run Composite Yacht, an established firm in Trappe, Md., across the river from Cambridge, that has deep expertise in everything from traditional wooden boat carpentry to 21st-century infused Kevlar and carbon fiber construction. The architect who took on the challenge was Lou Codega—best known as the designer of Regulators, but who also has extensive experience drawing high-speed small craft for the military services.

“Jerry Murrell wanted a deadrise-style boat that’s really fast. The trick in design,” Codega told us, “forces the helm into forward position. To run soft in a Bay chop, I had to make the forefoot as sharp as possible without bow-steer. Being big buys you ride quality, especially in the Chesapeake. She measures 55′ with only 16′-plus of beam. (Thus her appropriate name: Skinny Witch . Murrell always names his boats after his wife Janie, and Skinny Witch is her childhood nickname.)

“I based the beam around the engines,” he said. “Styling cues come from traditional deadrises but she’s more streamlined, and nothing below the chines resembles a semi-displacement deadrise. She’s pure go-fast, with a 17-degree deadrise at the transom twisting to a sharp 48 degrees at the bow. The waterline is slender up forward, with high chines. There was a narrow band of design around the twin engines, 1940-hp MTU 12V 2000 M96Xs with 1.75:1 ZF V-drives, turning custom propellers through wake-adapted struts and rudders in shallow pockets, balanced with seven-degree shaft angles and three Humphree interceptors across the transom.” Codega, Murrell and the Hardys took the design to New Jersey’s Stevens Institute of Technology for the tank testing. “The model tests verified the design’s ability to achieve astounding numbers,” Lou told us.

Even so, there was more engineering to do. “The top 5% of our speed took 50% of our budget,” Lewis Hardy added. “Jerry allowed me to hire anybody I needed to make this project a success.” The team called in University of Michigan hydrodynamic specialist Dr. Brant Savander and his firm, Maritime Research, LLC, of Ann Arbor. The powerful Maritime Research computers reviewed the design, the Stevens Institute data and the hydrodynamics of the propeller shaft struts and rudders, running simulations of the bottom’s behavior at speed. “The simulations let us see pressure points,” said Lewis. “They looked like clouds, showing cavitation. Then we had to wait while the computer ran for weeks to simulate modifications that could eliminate those pressures. Al Horsmon, another Michigan naval architect, worked out all of the structural engineering for laminates and hardware in the resulting hull form. That’s how much time and detail went into this one design.”

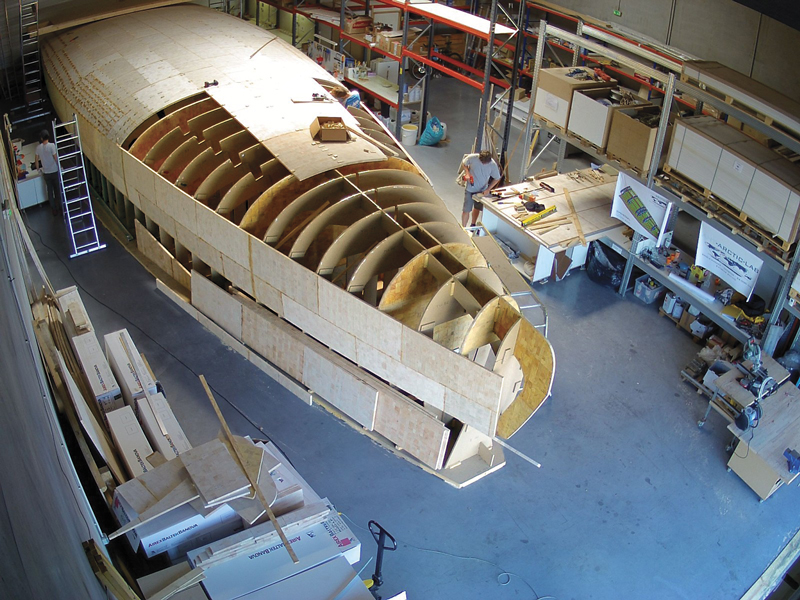

“We built test laminates,” Lewis recalled, “and then a test boat (a CY 26, the yard’s classic design), using a new build process with Scott Bader Company and composites consultant Jef Benkelman, who brought broad knowledge and experience. We had to learn our way through tricky issues like temperature spikes, viscosity changes in vacuum-bagging, adjusting films to get the precise resin mix for fiber consolidation, and then testing hardness. This is aerospace stuff.”

Construction finally began with spraying gelcoat in June 2019. Laying up the hull took a month. The outer layer of the CY 55’s hull is Kevlar, for puncture resistance. The rest is 95% cored carbon fiber with urethane acrylate resin, laminated, vacuum-bagged and cured in an oven with the temperature and resin viscosity carefully controlled during curing. The layup included fiberglass-cored panels strategically placed everywhere equipment had to be mounted. Fully loaded with engines, generator, Seakeeper and 1,900 gallons of fuel, the boat weighs only 55,000 lbs. Composite Yacht is “the best builder I’ve ever worked with,” said Lou Codega. “There’s a chemistry between Jerry Murrell as owner and the Hardys. Also, I have to mention Leon Lahman, the shop foreman, and Paulo San Juan, who are really, really good at high-tech carbon fiber laminates.”

“Everybody knew what was needed,” said Lewis. “The team gelled from the start. Jerry Murrell stuck to his concept; his project manager, Sean Durand, worked closely with us; and our Composite team looked constantly for small weight reductions that added up. On Wednesdays at 10:00 a.m., we held a full team meeting to go over everything, especially problems. The keyword every day was ‘remain disciplined’ in all facets of the build. There was no wish list, no ‘incremental weight gain.’ Lou had built the design around a weight budget. We hit it close. We were weighing the trashcans at the end of every day.

“The owner stayed with the simple accommodations necessary for fishing boat,” he continued. “He’s a genuinely nice guy, thoughtful and bright. He allowed Lou, us Hardys and the rest of the team to do what we do well.” The boat has a small generator (12.5 kW) to run air conditioning, the Seakeeper and other systems on a 220-volt system, which is lighter than 110. All raw water intakes run through a sea chest to save weight. The batteries are NorthStar lead-acid for simplicity. Ken Houle, the MTU specialist at distributor Johnson & Towers checked in to the shop frequently to make sure installation of the powertrain achieved the full power plus the design-spec balance and shaft angle. The high-performance MTUs ask for 550 gallons per minute of cooling water, so the Composite team had to design and fabricate partial bypass lines around the mufflers, all while keeping within the weight limits.”

Controlling all of that power required special MTU BlueVision controls integrated with the ZF V-drives. They’re “almost like rheostats,” Lewis said, “to ease the boat forward in close-quarters maneuvering. Add in her hydraulic bow thruster and she’s easy to handle around a dock.” Those controls also provide the precision speed control that make Skinny Witch successful at trolling lures like red hoses.

The Murrells have found they “can touch 55 knots any time we want. She cruises especially easily with a soft ride at 1,600 rpm, making 42 knots while burning 80 gallons per hour,” Jerry reported. “The wheels are one-off 34.75″ x 53.90″ Michigan Marlin Nibral 4-blades,” Lewis explained. “Brant Savander specified custom rake and cup for the blades. And yes, they’re ‘a tad out of square,’” he added with a chuckle. The boat is also “wicked quick,” accelerating from zero to 40 knots in 13 seconds and to full throttle in 18. “She’s a slippery little boat,” said Lou Codega with a smile. “She feels alive as she accelerates,” said Rob Hardy. “I’ve never felt anything like it—on the water, on land or in the air.”

Even so, “this is a family and fishing day boat, a fun boat. She’s Spartan belowdecks,” Lewis continued. (That conclusion caused Lou to comment, “She’s simple, but I don’t know if Spartan is the right word. Composite Yacht did an absolutely superb job with the joinerwork and finishes. ‘Elegant in its simplicity’ would be better.”)

“We’re really happy with everything about the boat, especially the beauty,” said Jerry Murrell. “She definitely catches fish. Our builder and naval architect have been fantastic. They all get along together. I can’t think of one thing wrong with the boat. My wife can’t believe how beautiful it is. We love looking for cobia as they move around. Everything is working well, as designed. The systems take a little getting used to, but they are performing as promised.”

So when will Composite Yacht build the next CY55? There are no orders yet, but the Hardys are already thinking about the next project. “The limited-production molds we created for this project could build more 55s,” Lewis concluded. “This design would also produce a really nice boat with a bit less power and simpler laminates.” In the end, this Dream Team of owner, designers and builders has created not only an exceptionally fast Chesapeake fishboat but also one of great beauty, strength and efficiency. It will be interesting to see what elements of the CY55 trickle out to other boats from Composite Yacht.

Pricing varies with custom options. For more info, visit compositeyacht.biz .

CBM Editor-at-Large, educator, guide and author of three quintessential Chesapeake Bay books, Capt. John Page Williams was named a Maryland Admiral of the Bay in 2013.

Related Stories

Beaver Believers

For these Bay conservationists, it’s one dam thing after another. By Marty LeGrand We’re wading

Delmarva Birding Weekends Spotlight Waterfowl, Seals & Harriet Tubman

Heading for the Maryland and Delaware beaches may not be top of mind this time

Thunder on the Choptank Roars Back to the Bay

Watch powerboats from across the country speed through the water with engines roaring to win

- The Glacier Bay

- Kayak Rentals

- Snorkel Sets

- Fishing Gear

- Boat Orientation Video

- Boat Safety

- Search for...

+1.808.879.3721

COMPOSITE 26 CC For sale

- November 15, 2022

Item Features

- Price Range: low

- Payment Type: fixed

- Item Type: sell

- Condition: new

- Warranty: yes

- Status: open

2017 Composite Yacht 26 Center Console fishing boat with inboard 6.2 liter V8 fresh water-cooled gasoline bobtail engine, direct drive, 3 blade propeller. Boat has been kept elevated on Hydrolift. Fiberglass hull, twin fuel tanks, fresh water tank, bow thruster, LENCO trim tabs, bathroom, transom mount for outboard, Set up for fishing – outrigger poles, 4 roof-mounted rod holders, Captain’s chair mounted rod holders, hull-mounted rod holders, Yeti ice box, bait bucket. Garmin xHD radar, twin Garmin 7612 GPS map MFDs, ICOM VHF, Analog gauges (2 fuel, oil pressure, RPM, temp) Engine is not working currently and is partially disasembled. Selling boat “as is” to make room for new larger boat. Asking price $20,000 for boat only; or $30,000 for boat with 4 year-old fully functioning, matching Hydrolift (see photo above) for $30,000; or selling boat, Hydrolift, and 30 foot x 20 foot dock for $60,000. Dock built by Bluewater Marine in 2018. Composite decking and 316 standees steel screws though-out. Shore abutment-to-dock gangway included with 6 stiff arms. Dock has both 120V shore power and freshwater supply. Dock built to State of HI code and HKMCA approval. Floating jet ski dock included. Owner is selling boat, hydro lift, and dock to make room for new, larger boat that requires parallel-to-shore docking.

- Sign In or Register

- Boats for Sale

- Research Boats

- Sell a Boat

- Search Alerts

- My Listings

- Account Settings

- Dealer Advertising

- Composite Yachts

Composite Yachts Boats for sale

2015 Composite Yachts Custom 26 Express

Grasonville, Maryland

Make Composite Yachts

Model Custom 26 Express

Category Saltwater Fishing Boats

Posted Over 1 Month

2015 Composite Yachts Custom 26 Express Fabulous like new 2015 Composite 26 Express with less than 80 hours! Composite Yacht specializes in the latest technology and the 26 is no exception. Constructed using Core-Cell structural foam, it is lighter than others in its class - meaning less fuel consumption. The owner reports 31mph at 4000rpm's burning only 11.1gph! With the upgraded Yamaha 300 four stroke she'll reach 49mph! The impressive list of standard and optional equipment includes:Maxwell windlass for easy anchoringHuge Garmin GPS map 1040xs Color Fishfinder & ChartplotterRaw water washdownTransom livewellDual batteriesPop up cleats all around including amidshipsHardtop with custom rocket launcher in addition to 6 rod holdersCrystal clear strataglass enclosureTwo bilge pumpsHuge cuddy cabin with a hideaway porta potty that's never been used. The owner's change of plans make this beautiful like-new vessel available at a substantial discount without the wait.

2006 Hunt Yachts Surfhunter 29

South Dartmouth, Massachusetts

Make Hunt Yachts

Model Surfhunter 29

Category Express Cruiser Boats

2006 Hunt Yachts Surfhunter 29 Extremely clean and well maintained Surfhunter 29. This boat just came in trade. She has a NEW (Jan. 2017) Volvo Aluminum out drive with warranty, which replaced the original equipment composite drive. Volvo recommended this upgrade which was performed by Volvo certified technicians. This boat is clean, inside and out and is not to be missed. A turn key yacht for your family to enjoy for years! RECENT TRADE, DON'T WAIT TO SEE THIS BEAUTY

2004 Cruisers Yachts 320 Express

Beaufort, North Carolina

Make Cruisers Yachts

Model 320 Express

Category Motor Yachts

2004 Cruisers Yachts 320 Express Original owner has taken very good care of his boat and updates have been performed as needed. The outdrives were replaced with Ocean Series composite drives in 2013. Newer electronics and a clean interior make this one the one to see.

Warwick, Rhode Island

2006 Hunt Yachts Surfhunter 29 "Total Chaos VI" is the essence of beauty combined with quality construction in a clean, professionally maintained yacht. She is powered by a low hour (347hrs) Volvo 375HP engine, has all the options and many custom upgrades. She has a NEW (Jan. 2017) Volvo Aluminum out drive with warranty, which replaced the problematic, original equipment composite drive. Volvo recommended this upgrade which was performed by Volvo certified specialists. The Surfhunter 29 is the ideal day boat with the addition of comfortable accommodations for overnighting. She features a superb deck layout with L-shaped settee and varnished wood cocktail table adjacent to the helm seat. She has a flag blue hull, oyster white boot stripe, oyster white top-sides, contrasting beige non-skid and beige canvas bimini top with 3-sided enclosure. Please see the full description for additional details and photos. This Surfhunter 29 is dry, fast, elegant, comfortable, efficient and Clean! She is built in RI with a proven deep V hull and enjoys a reputation for having the finest quality of her type. She is designed by C. Raymond Hunt, Associates, The prestigious naval architecture firm with numerous and notable pleasure, commercial and military designs to it's credit. She represents a tremendous opportunity to own an upgraded Surfhunter at a significant savings vs. a new boat and new customers can take advantage of a 50% discount for a year's summer slip and storage. There is no sales or use tax in RI. Close to 2 international shipping terminals. Why buy new?

2017 X-Yachts Xp 38

Request Price

Mystic, Connecticut

Make X-Yachts

Model Xp 38

2017 X-Yachts Xp 38 The Xp 38 delivers an unrivalled sailing experience in a dual-purpose cruiser-racer. This model after launching, quickly developed into a global fleet, with boats sold from US to Japan, Switzerland to Australia. It was nominated for Boat of the Year, with one judge commenting: The main reason you own this boat is because you love sailing. Seeing it underway, it just lights you up. (Tim Murphy, Cruising World). This enjoyment comes from the Xp 38s high level of responsiveness, thanks to high ballast ratio, light and stuff epoxy infusion construction and carbon keel structure, and controllable sail plan. High stability and ease of handling makes the Xp 38 a rapid and comfortable yacht to cruise with excellent sea-keeping in all conditions, as well as a high performance racing design for both inshore and offshore. It has scored a host of race victories under both IRC and ORC. Deck-recessed halyards and control lines, flush deck hatches and port-lights create a clutter-free and aesthetically appealing deck layout. Design details include an optional folding table concealed within the cockpit sole, with dedicated storage for all the essentials even the washboards. The twin composite wheels are offered with a range of pedestal choices, including compass and instrument mounts, together with optional electric or high-powered manual winches. The standard rig package includes an aluminium mast with discontinuous rod rigging and hydraulic back stay for efficient and repeatable tuning. The Xp 38 was also conceived with an optional deep draft keel configuration with high aspect ratio fin, carbon rig and performance deck gear. As with all the Xp models, the composite keel features a lead bulb and cast iron fin, precision molded and encapsulated in a vacuum infused GRP layer for a perfect, hydrodynamic finish. Through hull fittings are also recessed to reduce underwater drag, together with a faired S-drive engine strut. The Xp 38 includes both classic three-cabin or spacious two-cabin layout options. The three double cabin option includes symmetrical aft berths (which may have optional free board shelves or pipe cot berths added) and a master double forward. It comes as standard with the Xp sliding chart table, or an optional fixed aft-facing chart table, and a heads to starboard with shower over. The two-cabin option creates an extra large heads, with separate shower featuring hinged door and seat, and a spacious storage locker to starboard that is accessible from the cockpit and can accommodate all cruising equipment. There is

2017 X-Yachts Xp 50

Model Xp 50

2017 X-Yachts Xp 50 The Xp 50 is a high-performance cruiser-racer which offers impressive pace and ease of handling. The longer waterline length of this model allows additional cruising features to be incorporated, as well as increased straight-line speed. In line with the rest of the Xp range, the 50-footer utilizes epoxy infusion build processes for improved stiffness with reduced weight, a carbon keel structure for maximum safety and ultimate stability, and a precision-molded composite keel with iron fin and lead bulb giving a high ballast ratio. A choice of standard aluminium or optional carbon rig packages, and standard or deep draft keels, allows Xp 50 owners to optimize their yacht for cruising or racing, short-handed or fully crewed, inshore, offshore or blue water sailing. The Xp 50 bowsprit features a removable stainless steel anchor fitting, neatly integrated as standard below a removable GRP cowling. Alternative options include a carbon bowsprit with or without integrated anchor fitting, for setting large asymmetric and code sails with ease, or a flush cowling. A flush anchor deck hatch conceals a large 1500W anchor winch and also provides access to a separate sail locker with optional crew berth. Concealed control lines run aft with a Maxi-style main sheet system for a clutter-free, functional and comfortable cockpit area. There is a choice of biminis and two-pole spray hood with opening window, together with the Xp folding cockpit table for flexible entertaining space. Life raft storage is integrated under the cockpit sole, while the transom garage accommodates a small inflatable tender. An electrically operated transom door also forms a teak-topped bathing platform with stainless steel swim ladder. The Xp 50 interior is dominated by a feel of light and space, thanks to an additional skylight and unique opening coach roof window. There is ample storage (with underfloor tanks freeing up the concealed sofa storage), and 21 ft of easily accessible overhead lockers. A large U-shaped galley features an optional 22 gal front-opening fridge, larger top-loading fridge-freezer, slot for a microwave and indented worktop for safe cooking at sea. The saloon offers nearly 8 ft of extra-deep sofas in a sociable U-shape, plus an additional two-person seat. The three-cabin, twin-heads layout creates a particularly spacious forward double cabin, with the option of additional pipe berths in the aft double cabins, or fore peak crew berth.

2017 X-Yachts Xp 33

Model Xp 33

Category Racer Boats

2017 X-Yachts Xp 33 The smallest yacht in the range, the Xp 33 is designed for pure sailing enjoyment. This model is a high stability 30-footer which benefits from the same advanced construction techniques as the larger yachts in the Xperformance range for superb sailing performance and build quality. Smooth lines, ample buoyancy both fore and aft, a plumb bow for maximum waterline length and subtle chines create a hull which is fast on all angles of sail. A custom-designed double spreader aluminium mast is offered as standard, with a carbon rig available as an option. Non-overlapping head sails, a single line head sail furler and retractable bowsprit increase the sailing fun and racing potential while ensuring sail handling is stress-free, even when sailing short-handed. The Xp 33 deck layout and cockpit is designed to be highly functional. A rod linkage steering system connects to the single rudder underneath the cockpit sole and enables the tiller to be positioned aft, behind the mainsheet. This allows the skipper to easily control the boat when cruising, or to communicate smoothly with the main trimmer whilst racing. The composite tiller is fitted as standard with a Spinlock adjustable extension. The cockpit is wide and spacious. Aft of the main sheet track there are molded foot chocks integrated into the cockpit sole, with two opening lockers giving access to a generous storage compartment for fenders, mooring gear and similar. Forward of the main track, wide benches offer a comfortable cruising ride and room for race crew manoeuvres. Six Harken winches are fitted as standard, of which two may be easily upgraded to top racing spec. The Xp 33 may also be easily adapted into cruising mode, with an optional electric anchor windlass and removable stainless steel anchor arm. A self-draining anchor locker is fitted as standard, with gas bottle storage in the port aft cockpit. The Xp 33 is offered with a classic three cabin interior layout. The main saloon includes two comfortable sofas and a removable central table with integral storage, while the engine is easily accessible thanks to a removable GRP cover beneath the companionway. Aft are two symmetrical cabins, while forward there is an optional comfortable and private triangular berth. A single heads with shower is forward of the saloon. A practical galley lies to port with GRP worktops, a two-jet gimbaled gas stove and stainless steel sink. To starboard a forward-facing navigation station includes the yachts electrical switchboard as well as space for additional navigation and communication equipmen

2017 Viking Yachts 62 Convertible

Palm Beach Gardens, Florida

Make Viking Yachts

Model 62 Convertible

Category Convertible Boats

2017 Viking Yachts 62 Convertible The 62 Convertible is a showpiece in the Viking tradition with a fusion of leading edge engineering. To optimize its strength to weight ratio, the composite cored hull is resin infused with a high modulus of Dupont’s Kevlar, carbon fiber and knitted fiberglass laminates selected to reduce weight while increasing the overall physical properties of the structure. Similarly, interior stateroom and hanging locker doors, as well as cabinet fronts throughout the yacht incorporate honeycomb coring for further weight reduction. The 62 Convertible also has recessed engine cooling water pickups, refined propeller pocket entry to enhance flow to the five-bladed wheels for reduced noise with better traction, and modified architecture to the struts and rudders adding to an efficient and slippery running surface delivering speeds in excess of 42 knots with a pair of Caterpillar C32-A engines rated at 1,925mhp.

2016 X-Yachts Xp 50

Charleston, South Carolina

Category Cruiser Boats

2016 X-Yachts Xp 50 The Xp 50 is a high-performance cruiser-racer which offers impressive pace and ease of handling. The longer waterline length of this model allows additional cruising features to be incorporated, as well as increased straight-line speed. In line with the rest of the Xp range, the 50-footer utilises epoxy infusion build processes for improved stiffness with reduced weight, a carbon keel structure for maximum safety and ultimate stability, and a precision-moulded composite keel with iron fin and lead bulb giving a high ballast ratio. A choice of standard aluminium or optional carbon rig packages, and standard or deep draft keels, allows Xp 50 owners to optimise their yacht for cruising or racing, short-handed or fully crewed, inshore, offshore or bluewater sailing.

2005 Cruisers Yachts 300 Express

Model 300 Express

2005 Cruisers Yachts 300 Express Consistently maintained by her owners, Sea Ya shows very good pride of ownership in every respect. This 300 express features a comfortable interior layout with a double berth forward w/privacy curtain, fully functional galley to port, convertible booth style dinette to starboard and double aft berth with seating area and closet. A spacious head is located starboard with a Techma electric flush head, stand-up shower with curtain and molded Corian vanity with mirror.The cockpit features a nicely appointed helm with single helm seat that has a flip-up bolster and swivels. Port side has a large curved companion seat with storage below. Its wet bar is located on the starboard side with molded sink and Tundra refrigerator below. At the stern are two facing bench style seats with table and full engine room access.The exterior has sleek lines with high bow rails, remote search light, windlass, bomar hatch, bow pads, and walk-thru windshield. The stern has a generous size swim platform that includes a concealed swim ladder and hot and cold shower.OWNER HAS HAD THE ORIGINAL COMPOSITE OUTDRIVES REPLACED WITH BRAND NEW FACTORY INSTALLED VOLVO OCEAN X OUTDRIVES IN 2015.She has seen light use with under 250 total hours on the engines and has always been maintained with an open checkbook.This Cruisers 300 can be enjoyed year round with her recently installed high grade camper top package that would provide many great memories with family and friends on the water.

2008 Cruisers Yachts 300 CXi

Ponte Vedra, Florida

Model 300 CXi

- 2024 BOAT BUYERS GUIDE

- Email Newsletters

- Boat of the Year

- 2024 Freshwater Boat and Gear Buyers Guide

- 2024 Boat Buyers Guide

- 2024 Water Sports Boat Buyers Guide

- 2024 Pontoon Boat Buyers Guide

- Cruising Boats

- Pontoon Boats

- Fishing Boats

- Personal Watercraft

- Water Sports

- Boat Walkthroughs

- What To Look For

- Watersports Favorites Spring 2022

- Boating Lab

- Boating Safety

Composite Yacht 55

- By Capt. John Page Williams

- October 19, 2022

“Can you build me a 55-foot deadrise that can run 55 knots?” That’s what Jerry Murrell asked the crew of Composite Yacht located in Trappe, Maryland, on the famed Eastern Shore. Murrell loves the graceful, traditional profile of the sheerline, collar boards and deckhouse on these indigenous Chesapeake working boats.

Classic wooden “bay-built” hulls meet a variety of needs, from hauling crab pots and oystering to charter fishing. They feature sharp bows, big cockpits, forward helms, and semi-displacement, shallow V-hulls and straight-shaft inboards. They’ve never been built for efficient speeds above 20 mph, much less a soft ride at such velocities.

How did Murrell assemble a team to pull it off?

Martin Hardy and his sons, Lewis and Rob, of Composite Yacht (compositeyacht.biz) went to work. “Let’s hire an architect, build it on paper, then test it.” They signed naval architect Lou Codega, who’s drawn Regulator Boats, Cabo Yachts and others. Tank testing took place at the venerable Stevens Institute of Technology.

“The owner wanted a deadrise-style boat that’s really fast. The tricky part of this design is the forward position of the helm,” Codega says. As most boaters know, the ride gets rougher the closer that someone one sits or stands toward the bow.

“To run soft in bay chop, I had to make the forefoot as sharp as possible without inducing bow steer,” Codega explains. “Being big is a trait that buys you ride quality, especially in the Chesapeake.” The boat measures 55 feet, with only 16 feet of beam. A narrower beam helps in achieving a softer ride and higher speed goals.

“Styling comes from traditional deadrises,” Codega says. “But she’s pure go-fast, with 17-degree deadrise at the transom twisting to 48 degrees at the bow.” The waterline is narrow up forward, with high chines. The boat is designed around the twin 1,940 hp MTUs, with 1.75-to-1 ZF V-drives turning custom props through wake-adapted struts and rudders in shallow pockets, and balanced with 7-degree shaft angles and Humphree interceptors across the transom. That translates to wicked fast.

Codega lauded Composite Yacht as “the best builder I’ve worked with,” citing, “a special chemistry between boat owner Jerry Murrell, the Hardys and their team.”

Speed, as always, costs.

“The top 5 percent of our speed took 50 percent of our budget,” Lewis Hardy says. “Jerry allowed me to hire anybody I needed to make this project a success.” That included hydrodynamic specialists who used the design and the Stevens Institute data to simulate the bottom running at speed. “The simulations let us see pressure points,” Lewis explains. “They looked like clouds, showing cavitation. Then we simulated modifications to eliminate those pressures.

“We built test laminates,” he continued, “and then a CY 26 test boat. The outer layer is Kevlar for puncture resistance.”

The rest of the CY 55’s hull is 95 percent cored carbon fiber with urethane acrylate resin that is laminated, vacuum-bagged, and cured in an oven, with the temperature and resin viscosity carefully controlled, a technique borrowed from the aerospace industry.

When fully loaded with the engines, generator, Seakeeper gyrostabilizer and 1,900 gallons of fuel, the boat weighs 55,000 pounds. Keeping weight down is imperative for keeping speed goals up.

“Everybody knew what was needed,” Lewis says. “Jerry stuck to his concept, and our Composite team looked constantly for small weight reductions that added up. The keyword every day was ‘remain disciplined’ in all facets of the build. There was no client wish list, no incremental weight gain. We were weighing the trash cans at the end of every day.”

The owner stayed with the simple accommodations necessary for a dayboat’s needs. One example of this is that the boat is fitted with a relatively small 12.5 kW generator to run air conditioning, the Seakeeper and other 220V AC systems, which are lighter than 110V because of thinner cabling. Controlling all of that power on V-drives required special controls “almost like rheostats” to ease the boat forward in close-quarters maneuvering, Lewis says.

At press time, Skinny Witch was running a whisker short of the goal, topping out at 54.9 knots. “The wheels are a tad out of square,” says Lewis of the 34.75-by-53.9-inch Michigan Wheel Marlin four-blade propellers. “We still have more rpm left.”

The boat currently accelerates from zero to 40 knots in 13 seconds.

Read Next: Learning the History of Downeasters

Chesapeake Deadrise Origins

The Chesapeake deadrise got its name from the hard-chine, cross-planked, V-bottom wooden construction technique that local builders developed for sailing oyster dredge boats in the late 19th century. The term refers to the rise above dead level of the boats’ chines, originally measured in inches and now in degrees. With the advent of gasoline and diesel power, the technique morphed to produce the semi-displacement designs of today, many in fiberglass.

- More: boat building , Boats , Fishing Boats , November/December 2022

Conveniently Rent a Boat Using Boatsetter

Boat Test: 2024 Solara S-250 DC

Boat Test: 2024 Checkmate Pulsare 2400 BRX

Cox 350 Diesel Outboard

Choosing and Using a Marine Loudhailer

On Board With: Brian Grubb

Installing Clear Acrylic Livewell Lids

- Digital Edition

- Customer Service

- Privacy Policy

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

Many products featured on this site were editorially chosen. Boating may receive financial compensation for products purchased through this site.

Copyright © 2024 Boating Firecrown . All rights reserved. Reproduction in whole or in part without permission is prohibited.

Professional BoatBuilder Magazine

The quest for eco composites.

By Hans Buitelaar , Dec 2, 2020

Working with eco composites, the build crew at Innovation Yachts in Les Sables d’Olonne, France, applies Filava fiber to the balsa-cored hull of the Open 60 Ant Arctic Lab, a racing yacht intended to be fully recyclable.

Boat yards and design offices embrace new fibers and resins that promise to reduce pollution, consume less energy in production, and yield composite boats that can be recycled.

“It is going to be a big eight,” said skipper Norbert Sedlacek describing his planned solo nonstop sailing journey to prove the durability and go-anywhere quality of his new brand, Innovation Yachts. The Austrian sailor and filmmaker plans to sail from France through the Northwest Passage around Canada and Alaska, head south over the Pacific Ocean, go left around Cape Horn, circle Antarctica, come around Cape Horn again, and set course north to return to France over the Atlantic Ocean—a 34,000-nautical-mile world-record attempt.

His first attempts at this route around the Americas and Antarctica in 2018 and 2019 ended when equipment problems forced a return to France. His 2020 attempt was foiled by the COVID-19 lockdown when Canadian authorities denied permission to cross through the Northwest Passage, so Sedlacek again postponed. Fortunately, our primary interest is really in his boat, not the voyage.

Ant Arctic Lab under way. The boat has yet to make her ambitious long-distance voyage a reality.

Innovation Yachts’ First Builds with Volcanic Fibers

The boat he plans to sail on this challenging trip is the Open 60 (18.29m) Ant Arctic Lab , which he designed and built to be fully recyclable. It is Innovation Yachts ’ first build in cored-composite construction using balsa-wood panels for the core and volcanic-rock fiber—basalt and solidified lava—for the skin laminates. (The resin is a purpose-engineered epoxy.) The result is a yacht that required less energy to build and employs natural and renewable materials as much as possible. And at the conclusion of its useful sailing life, all the yacht’s composite materials can be separated and processed for reuse in another boat or some other composite construction. (See also Butterfly 46: A Yacht for 2050 )

Besides his own quest as an ocean racer, Sedlacek aims to illustrate that yacht building can be sustainable. “To start something new, you need to gain trust. I want to prove that building yachts from natural and recyclable materials results in better boats. If I can complete this immense trip, rounding the Americas and Antarctica, that will show the ruggedness of the boat,” he said.

Sedlacek and his partner, Marion Koch, founded Innovation Yachts in 2016, in the French harbor town and yachting hot spot Les Sables d’Olonne. While informed by some idealistic thinking, their plan to build oceangoing yachts from natural materials is also powered by a surfeit of practical building and sailing experience. Sedlacek’s first solo circumnavigation was in 1996 on the 26 ‘ (7.92m) composite boat Oase II he built himself. His next challenge was building an aluminum yacht to circumnavigate Antarctica through ice-fouled waters. He completed that in 2000 on Oase III . In 2009, he became the first Austrian to finish the Vendée Globe, the iconic French solo nonstop race around the world. Before he could compete in that race, he engineered modifications to the aluminum and composite construction of Austria One to bring her into compliance with International Monohull Open Class Association (IMOCA) 60 design rules.

Next, he created the concept and design and then served as project manager for the 91 ‘ (27.74m) aluminum luxury cruising yacht Bellkara , a sloop with a lifting keel built in 2016 at the Conrad Shipyard in Gdansk, Poland.

Ant Arctic Lab’s lightweight structural core of FSC-certified balsa wood from 3A Composites also provides a measure of sound and thermal insulation to the hull.

Innovation Yachts’ plan since 2016 has been to prove the concept of quality yacht building with a low carbon footprint and fully recyclable materials. Technical Director Marion Koch had written her master’s thesis on the hydromechanics and material properties of IMOCA 60 ocean-racing yachts. Together with Sedlacek and working with her company, Yacht Construction Consulting in Altlengbach, Austria, they introduced volcanic fiber into boatbuilding. The first marine application of the laminate was in the 4.9m Open 16 sloop Fipofix . Sailing this small boat in 2013–14, Harald Sedlacek, Norbert’s son, claimed three world records crossing the Atlantic from Europe to North America and back. (Fipofix, or Fiber Positioning Fixation, is a patented method of processing volcanic fibers into unidirectional fabric, explained below.)

Eco Composite Products and Processes

While modern, the design of Ant Arctic Lab is not dramatically different from other ocean-racing yachts. Recyclability comes largely from its materials. The hand-laid hull is a conventional balsa-cored composite structure. Balsa is super-lightweight, with good strength, stiffness, sound-dampening, and thermal-insulation properties. Innovation Yachts’ balsa supplier, 3A Composites , harvests from Forest Stewardship Council–certified plantations in Ecuador. Because balsa trees grow to 98.43 ‘ (30m) high and 3.28 ‘ (1m) in diameter in just five years, the planting-to-harvest cycle is so short it causes no measurable deforestation, making it a sustainable and quickly renewable resource. As it is absorbent, it also provides an excellent bond with the fiber and resin layer.

The innovation comes from the fiber, a laminate textile called Filava, made of volcanic rock and produced by the Belgian company Isomatex . Volcanic rock is melted at high heat and drawn into fibers, resulting in a strong, water-repellent, lightweight material that resists high temperatures and chemicals. Filava is available as unidirectional fiber tows and as woven fabric. Although the largest European production facility in the town of Gembloux, southeast of Brussels, opened in 2008, volcanic rock fiber has previously been used in composite windmill blades, airplane and car parts, and sports gear.

Cutting the woven Filava fiber from Belgian composite supplier Isomatex. To produce the fiber from basalt and lava rock, the raw materials are melted at high temperature and drawn into fibers that are then processed as unidirectional fibers or woven roving

Volcanic fiber has a melting point of 2,516ºF (1,380ºC), meaning that walls and doors made of Filava can be applied as fire-protection barriers. The fiber also absorbs vibrations and is highly shock resistant. Innovation Yachts considers laminates from volcanic fiber comparable in strength to carbon fiber but at a lower cost, which would make it a desirable boatbuilding material.

Made from basalt rock and other natural components, Filava’s fibers compare favorably to other more common fibers in composite construction: high impact resistance like aramid or Kevlar, better elasticity than fiberglass and carbon, resistance to acid and alkaline environments, and no galvanic corrosion where it’s in contact with metals.

In Isomatex’s proprietary process, raw materials are carefully mixed in a computer-assisted blender and transported by a pneumatic conveyor to the electric induction furnace to melt and refine the lava. The complex process requires high temperatures. The electric furnaces operate two to three times more efficiently than oxy-fuel or gas-fired alternatives. While Filava consumes less energy to produce than do most carbon fibers, it requires more than flax or glass fiber does.

Recognizing that the main disadvantage of raw volcanic fiber is its fragility, Koch’s Yacht Construction Consulting and Norbert Sedlacek, in collaboration with the Austrian telecommunications and logistics company Kapsch, developed a patented process called Fiber Positioning Fixation, or Fipofix. The technique processes the brittle, touchy volcanic fibers into rugged unidirectional fabric purpose-built for marine applications. Other conventional assembly methods (weaving, stapling, and sewing) damaged as much as 40% of the roving filaments, decreasing the product’s performance under compressive and tensile loads. Fipofix bonds the positioned fibers to the respective matrix in the mold for final processing without using foreign materials such as yarns, clamps, or other adhesives that additionally weaken the part. The Fipofix proof of concept was Harald Sedlacek’s record-breaking Atlantic crossing in the Open 16 of the same name.

Custom Epoxies

The composite’s third and final component is the resin. Innovation Yachts chose the resin supplier bto-epoxy (Build to Order, in Amstetten, Austria), an innovative company producing custom epoxies since 2012. The resin shows no shrinkage, contains no harmful solvents, and is intended to remain with the fiber and balsa beyond the end of a yacht’s life, allowing all three materials to be reused. Koch: “We will not heat the epoxy, as it will take a lot of energy to heat all of the materials to the melting point. A lot of the material will then be burnt, so will not be available for recycling anymore. Yet the remaining fibers will be shredded and only need a bit of epoxy to be applied again.” Innovation Yachts has tested the reusability of shredded fibers recovered from composite test panels for the Ant Arctic Lab by incorporating them into non-load-bearing components for new boats, including the dashboard of a yacht tender.

As bto-epoxy is processed from fossil oil, Sedlacek explains this somewhat counterintuitive choice for a yacht largely built with renewable components and materials: “We do not want to use any material that is not developed for yacht building. Yes, there are ‘green’ epoxies available, but they do not have the same properties yet as the resins made out of fossil oil. We do not want to use any construction materials in the hull that are not specially produced for maritime use, or that don’t outperform the ones commonly used in maritime applications.” In some parts of the interior, Innovation Yachts uses epoxy made of vegetable oil, but Sedlacek says it lacks the material properties to have the endurance, water resistance, and impact absorption that the bto-epoxy offers. “As soon as an epoxy resin is developed out of renewable resources that does have the right properties, we will use it,” he said.

Sedlacek is confident of his vision and the leading role his company intends to play: “When an Innovation Yachts hull comes back to the yard after its 30-year lifetime, or even longer, the owner should be getting money for the materials that can be derived from the boat. They have value because of the reusability.”

Sedlacek says he’s looking for long-term investors, because it “takes time to develop something new.” He is convinced that Innovation Yachts is on the right track ushering in an era of more sustainable materials in boatbuilding. “Our new technology is better and cheaper, and recyclable. Massproduction yards will follow. I am convinced they will need to.”

Scaled Up at Amer

Amer Yachts , builder of motoryachts from 20m to 30m (65.6 ‘ to 98.4 ‘ ) in San Remo, Italy, chose Filava for their composite hulls. As the superyacht industry requires class society certification, the yard has started a cooperation with the Italian composites company GS4C to test and further develop composites from the recyclable fiber. Class societies ENEA (the Italian National Agency for New Technologies, Energy and Sustainable Economic Development) and RINA (Registro Italiano Navale, the Italian class society for ship safety certification) are studying Filava’s properties to assess durability. As this certification takes time, the Amer yard will introduce the new fiber in small steps. First, it will be used in nonstructural components. Following successful application, more parts may be constructed from the volcanic fiber.

A rendering of the proposed sailing beach cat for La Bella Verde charter company. The final boat is intended to be sailed by a professional captain and as many as 11 guests. Auxiliary propulsion and onboard power are provided by electricity from solar panels.

An Eco Composite Beach Cat

To provide the most sustainable boats possible, the founders of the yacht charter company La Bella Verde tapped Innovation Yachts to design, engineer, and build their new 10.6m (35 ‘ ) sailing beach catamaran. The boat accommodates 11 guests and a professional captain, with ample space to relax on the trampoline. There is a head in one of the hulls, a fridge, and a sound system—requisite items for beach-hopping in the Balearic Islands, where these new catamarans will be chartered at waterside locations on Ibiza and Formentera.

La Bella Verde set out to prove that ecologically benign boating can be a modern, fun luxury experience. Maarten Bernhart, one of the three founders, explains how the company started in 2014: “We bought one open catamaran and converted it to electric propulsion for getting out and into harbors. We continued to convert more open catamarans to green electric-propelled boats [and] sold about seven refitted beach cats.” In search of a suitable day charter catamaran, Bernhart said he found a Rush 10 (32.8 ‘ ) owned by a former builder, and the company bought the molds to build and sell these cats.

Looking for a boat with an even smaller environmental footprint, La Belle Verde teamed up with Innovation Yachts’ Sedlacek and Koch. With a new design ready, the first boats started being built at the Innovation Yachts yard in 2020. They are a sandwich composite of FSC-certified balsa core—made with Filava and bto-epoxy skin laminates. “We offer the La Bella Verde cat to small charter companies that want to stand out with a nonpolluting boat,” Bernhart said. “And we will expand our own fleet with those catamarans.”

A deck detail of the port quarter of the Judel/Vrolijk-designed Flax 27 illustrates the superb aesthetic qualities of the sustainable building materials— clear-finished flax-fiber composite and cork decking—that Green- Boats (Bremen, Germany) selected for the performance daysailer.

Flax Fiber and Linseed-Oil Epoxy

Friedrich Deimann, founder of GreenBoats , a start-up boatbuilding company in Bremen, Germany, calculates that it takes five times as much energy to produce glass fiber rovings, and 20 times as much to make carbon fiber, compared to growing and making fibers from flax. “It is really not nice to work on the construction of composite yachts built in the conventional way,” he said. “The glass fiber or carbon fiber is invasive to the body. The resins and solvents are toxic. Still, after having built a lot of handcrafted wooden sailboats, I was attracted to the possibility of building strong and lightweight in composite. So, when I found flax as a possible fiber, I was eager to use it.”

The high resin absorption rate of the flax fiber makes hand lamination challenging. Resin infusion at GreenBoats allows for better control of the ultimate resin/ fiber ratio.

Next, researching a sustainable core material for sandwich composites eventually led him to cork. It is lightweight, does not absorb water, and has good impact resistance. The hardest ingredient to find was a nonpetrochemical resin. Linseed-oil-based epoxies are available, but most of them do not generally yield the watertightness, durability, stiffness, and shock absorption required in yacht construction. But after extensive testing, Deimann found the right linseed-oil-based epoxy to bind a unique composite of flax fibers and cork core together. In that quest, he said he has tried numerous epoxy resins. The tested epoxies range between 20% and 80% bio-content and are produced by multiple resin manufacturers. Some are better optimized for hand layup, while others are best for infusing, he says. In short, the best resin depends on the material qualities of the fiber and the structure it is being applied to.

The most recent tangible manifestation of Deimann’s research, the Judel/Vrolijk-designed Flax 27 daysailer, is also the boatbuilder’s most complete natural-fiber composite project to date. Finding just the right combinations of flax cloth and linseed-oil epoxy provided the solution for that build. Because flax fully absorbs the resin but is lighter than glass, the resulting laminate can be quite dense. Together with a good core material, the flax/epoxy laminate yields a composite Deimann says is good for building boats. He warns that the high resin absorption rate makes hand lamination of flax material a challenge. He prefers to use resin infusion which better controls the resin/fiber ratio. But he depends on using tightly twisted flax fibers in a dense weave that has high surface density and leaves little space for extra resin to pool between the yarns.

Because the fiber naturally absorbs wet resin, a dense textile weave of tightly twisted flax strands is best for most composite uses.

When they started building the first flax composite boat by hand in a shed with a group of friends and no budget, Deimann and his co-workers had to prove that natural materials could result in an even better composite boat than those made out of petrochemical sources. They’ve come a long way with the 2019 introduction of the much-praised daysailer Flax 27 (8.2m) weighing just 2,645.55 lbs (1,200 kg). GreenBoats offers a choice of core material: cork, or foam from recycled PET soda bottles.

While boatbuilding and sailing remain its focus, the company’s production use of natural-resource composites reaches many other industries, including power generation, automotive, architecture, and outdoor sports. “We do a lot of prototyping to introduce other companies to the use of natural-fiber-reinforced composites,” Deimann said. “The materials selected and the manufacturing process depend on the requirements for the product: life expectancy, quantities, mechanical requirements, etc. This is where the journey with our customers begins, and together we work out various options and compare them in costs, performance, and sustainability.”

GreenBoats has conducted extensive testing to determine the structural properties and the best combinations of sustainable fiber, resin, and core material, such as this flax/cork sandwich composite.

Big Companies Invest in Eco Composites

While the first yards to explore the practicality of building boats from recyclable or sustainable composite materials had to search for the right resins, the large resin manufacturers—often petrochemical companies—are now developing and introducing recyclable and bio-based resins. While I was writing this article, the French chemical company Arkema gave me a questionnaire about the need for eco-resins and the demands boatbuilders would have for such a bio-epoxy. Within weeks, the outcome of the poll and the company’s answers were shared. Arkema has been working to improve its Elium thermoplastic resins to make them recyclable. The resin, though still fossil-oil based, can be separated from the fiber and core material at the end of a boat’s service life.

In practice, composites recycling can be done in two ways: mechanical and chemical. Mechanical is grinding the composite into small pieces and reusing them as a filler material that can be bonded by adding new resin. The chemical approach is to heat the composite so the Elium resin will melt out of the fibers. The resulting crude recycled monomer can be distilled into pure recycled monomer, which can be used as a resin to build new composites.

The Flax 27 daysailer is an effective proof of the materials and build process for the flax/epoxy boats. It’s also an attractive hull and rig design that performs well, which is vital for a model intended as a production-built consumer product.

Global composites supplier Gurit has been working with Swiss high-tech start-up Bcomp, which produces flax fiber. Products now sold through Gurit’s broad distribution networks are Bcomp’s ampliTex and powerRibs. The latter is a structure of flax fibers inspired by the veins of tree leaves to create extra stiff structures at minimal weight. Gurit also sells foam-core material from recycled PET soda bottles; and in its Ampro epoxy resin line, the company offers Ampro Bio, a plant-oil-based epoxy containing roughly 40% plant oil and 60% fossil oil. While none of these fibers, core material, and epoxies are designed for recycling, after being shredded at the end a boat’s service life, the composites may have a second application as material for nonstructural parts—much like the reuse of Filava composites described by Koch.

About the Author: Freelance journalist Hans Buietlaar, who lives in The Netherlands, specializes in yachting and the maritime industry, focusing on technology and sustainable innovations.

Read more Construction , Materials articles

- Van der Werff’s Curved Wood

A Dutch yard adopts composite panel molding technology to build boats from preshaped wooden hull sections.

SNAME Powerboat Symposium Is Back

The Society of Naval Architects and Marine Engineers (SNAME) Technical and Research Program, in cooperation with the Hampton Roads, Virginia Section of SNAME, will host the Sixth Annual Powerboat Symposium… Read more »

CNC Construction on the Rise

How computer-aided design and software-controlled manufacturing technologies have reshaped custom and semi-production boatbuilding.

Recent Posts

- There was Only One Partner I’d Trust for the Refurb Project of my Life: AkzoNobel

- Citimarine Store Expands to a New State of the Art Location in Miami

- Find out how 3D printing can help your boatbuilding with MASSIVIT

- Departures: Carl Chamberlin

- Companies (85)

- Construction (106)

- Design (161)

- Drawing Board (10)

- Education (25)

- Environment (16)

- Events (21)

- Materials (50)

- Obituary (18)

- People/Profiles (49)

- Products (16)

- Propulsion Systems (32)

- Racing (16)

- Repair (37)

- Rovings (317)

- Short Cuts (3)

- Sponsored Partner News (16)

- Systems (80)

- Task Sheet (1)

- Uncategorized (26)

- Wood to Glass (7)

ProBoat.com Archives

COMMENTS

Composite Yacht specializes in the latest technology and the 26 is no exception. Constructed utilizing modern coring materials and laminating techniques results in a lighter, stronger boat which equates to remarkable fuel economy at faster cruise speeds. An intelligently designed bottom shape aids in this while still providing a comfortable ...

Composite Yacht is a yacht brand that currently has 2 yachts for sale on YachtWorld, including 0 new vessels and 2 used yachts, listed by experienced boat and yacht brokers mainly in the following countries: United Kingdom and United States. The selection of models featured on YachtWorld spans a spectrum of sizes and lengths, encompassing ...

A Composite Yacht concept drawn by Mick Price, the CY26 is designed to accept outboard or inboard power. The boat is constructed using a vacuum bagged process and modern structural foam, so she's lighter than other boats in her class. That means you won't burn as much fuel getting to the fishing grounds or the raftup.

This 26 Composite Yacht Center Console has been meticulously maintained with a open check book. She is powered by a very economical, low burning Yanmar 315 HP Diesel with only 757 hours, and also has a Bow Thruster! The 26 CYCC is built with wood free construction. The hull is molded with a propeller pocket for reduced draft, and better fuel ...

The Composite CY 26 powerboat is produced by the brand Composite Yacht since 2014. The Composite CY 26 is a 8.05 meters center console boat with a draft of 0.46 meters. The boat has a fiberglass / grp hull with a CE certification class (B) and can navigate no further than 200 miles off the coastline. The base price of a new Composite CY 26 is ...

New 2022 Composite Yacht 26' Cc Open for sale is located in Talbot County (Maryland, United States of America). This vessel was designed and built by the Composite Yacht shipyard in 2022. Hull key features 2022 Composite Yacht 26' Cc Open: hull material - fiberglass. engine: fuel type - other. 2022 Composite Yacht 26' Cc Open refers to classes ...

Composite Yacht specializes in the latest technology and the 26 is no exception. Constructed using Core-Cell structural foam, it is lighter than others in its class - meaning less fuel consumption. The owner reports 31mph at 4000rpm's burning only 11.1gph! With the upgraded Yamaha 300 four stroke she'll reach 49mph! Ready to go and priced to sell.

"We built test laminates," Lewis recalled, "and then a test boat (a CY 26, the yard's classic design), using a new build process with Scott Bader Company and composites consultant Jef Benkelman, who brought broad knowledge and experience. ... "She's simple, but I don't know if Spartan is the right word. Composite Yacht did an ...

The brand Composite Yacht produces fishing boats and lobster boats and gozzo boats. There are 7 models currently in production ranging from 8 to 17 meters. ... Composite CY 26. LOA: 8.0m. Beam: 2.9m. Draft: 0.5m. Price on request. Add to Favorites Added to favourites. Model from Catalog. Composite CY 32CB. LOA: 9.8m. Beam: 3.2m. Draft: 0.6m.

2017 Composite Yacht 26 Center Console fishing boat with inboard 6.2 liter V8 fresh water-cooled gasoline bobtail engine, direct drive, 3 blade propeller. Boat has been kept elevated on Hydrolift. Fiberglass hull, twin fuel tanks, fresh water tank, bow thruster, LENCO trim tabs, bathroom, transom mount for outboard,

Composite Yacht, Trappe, Maryland. 5,382 likes · 73 talking about this · 213 were here. Composite Yacht is a family business dedicated to innovative custom boat building while honoring the rich...

Composite Yacht specializes in the latest technology and the 26 is no exception. Constructed using Core-Cell structural foam, it is lighter than others in its class - meaning less fuel consumption. The owner reports 31mph at 4000rpm's burning only 11.1gph! With the upgraded Yamaha 300 four stroke she'll reach 49mph!

Composite Yacht 26 cc open for sale on DailyBoats.com are listed for a range of prices, valued from $135,000 on the more basic models to $135,000 for the most expensive. The boats can differ in size from to . The oldest one built in 2022 year. This page features Composite Yacht boats located in countries: United States of America.

WHO DAT - 2007 COMPOSITE YACHT 26' 4" CY26CC CONTACT Similar Listings For Sale New Search. WHO DAT is a 26' 4" (8.03m) Center Console Boat built by COMPOSITE YACHT and delivered in 2007. Photos and specifications available below. Find yachts and boats listed for sale and ones off the market in our YATCO Yacht & Boat Directory. This web page ...

Composite Yacht 26 . 11 Attachment(s) We have build slots available for our CY26. All composite construction, with large cored surfaces (deck, top, etc) being vacuum bagged. The boat runs well in inboard or outboard configuration. As a true Semi-Custom, options and deck layout are based on owner needs.

The boat measures 55 feet, with only 16 feet of beam. A narrower beam helps in achieving a softer ride and higher speed goals. "Styling comes from traditional deadrises," Codega says. "But she's pure go-fast, with 17-degree deadrise at the transom twisting to 48 degrees at the bow.". The waterline is narrow up forward, with high chines.

Find Composite Yacht for sale near you, including boat prices, photos, and more. Locate Composite Yacht dealers and find your boat at Boat Trader!

Innovation Yachts' First Builds with Volcanic Fibers. The boat he plans to sail on this challenging trip is the Open 60 (18.29m) Ant Arctic Lab, which he designed and built to be fully recyclable.It is Innovation Yachts' first build in cored-composite construction using balsa-wood panels for the core and volcanic-rock fiber—basalt and solidified lava—for the skin laminates.

26 North Yachts is pleased to assist you in the purchase of this vessel. This boat is centrally listed by Composite Yacht Sales. ... Composite Yacht: Model: CY34CC: Type: Center Consoles: Engine Information: Engine Make: Yamaha; Engine Model: F300; Engine Year: 2023; Engine Type: Outboard 4 Stroke; Power (HP): 300.00; Power (KW): 223.71;

Composite Yachts CY 55 goes 55 knots and is said to be one of the fastest yachts in her class. Today we walk the CY55 with Rob and when he opened up her engi...