Professional BoatBuilder Magazine

Mark lindsay, a life in boatbuilding.

By Paul Lazarus , Nov 11, 2019

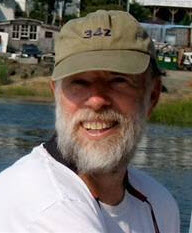

Boston BoatWorks master builder Mark Lindsay works the trapeze of an International 505 racing dinghy as sailcloth manufacturer Bob Bainbridge handles the helm, at the class’s East Coast championships off Newport, Rhode Island, in 1979. (Mark and his wife, Sally, won the North American championship the year before.) Lindsay’s expertise in advanced composites and construction processes began with high-performance one-design small craft like the 505, a class he considers “the best boat ever.”

In Professional BoatBuilder No.182, Paul Lazarus noted the September 6 passing of Mark Lindsay, and included a personal appreciation of his work and influence in the boatbuilding industry and on this magazine over the years. What follows is an excerpt from Lazarus’s 2015 article about Lindsay’s Boston BoatWorks ( PBB No. 157 ) that provides a more thorough account of the builder’s resume—a full and remarkable career in our industry. —Ed.

Mark Lindsay’s boatbuilding career goes way back, to his teens, spanning several one-design and rule boats, and producing numerous champions—Sailfish, Stars, 505s, Fireballs, Flying Dutchmans, Tornadoes, MORC, IOR, and IMS boats—plus much of the technical work on America³ , the 1992 winner of the America ’s Cup. The reason so many of his boats have been so successful is that he is always searching for strong, lightweight structures, and was among the first builders to use—in boats—what were previously thought of as exclusively aerospace materials.

Trained at MIT

It is no accident that most of Lindsay’s building career has been committed to sail, the bulk of it to very small craft, and the faster the better. His exploration of how to exploit composites to make sail-powered small craft lighter, stronger, faster began at Massachusetts Institute of Technology, where he studied for a graduate degree in architecture and architectural engineering. (Lindsay started college at Middlebury, but dropped out to work as an “apprentice laborer” in a Marblehead boatyard that had been commissioned to build an A-Cup contender, before pursuing an undergraduate degree in architecture from the University of Pennsylvania.)

Taking information gleaned in a structures course at MIT, Lindsay would test samples to failure in the materials lab. Meanwhile, MIT’s Sailing Pavilion, a boathouse on the Charles River laying claim as the birthplace of competitive college sailing in this country, served as a test tank for him, racing so-called Tech Dinghies. The design dates to 1935, when MIT naval architecture/marine engineering professor George Owen drew the plans and the Herreshoff Manufacturing Co. produced a fleet of 30. Today’s Tech Dinghy, the design’s sixth generation, is a carbon fiber raceboat.

For Lindsay, the interaction of his MIT structures studies and sail-racing experience was formative: it taught him, he said, the important difference between stiffness and strength . Understanding that distinction enabled him, when he turned professional, to give his boats a truly competitive edge by lightening them within a class’s parameters, while making them strong enough for the crew to stress the sailing rig without destroying structure.

Tinkering and testing

After he’d set up shop as an independent builder specializing, at first, in small raceboats, Lindsay continued to experiment with materials and methods. Precisely because the product was small, he could test many iterations within a relatively short time frame. His boats’ overall success on the race course generated more and more business for him in a market niche that, though popular, was also notorious for small profit margins.

A good example of his experimental construction efforts over time came to the magazine’s attention in 1996, when he was based in Gloucester, Massachusetts, as Lindsay Custom Yachts. Responding to an article we’d recently published on switching to high-performance resin systems, Lindsay wrote in to say:

Kevlar, foam and honeycomb

“Since 1979, I have built over 50 International 505 sailboats in production female molds with polyester gelcoat and epoxy laminate, and I can attest to the challenges of innovating with construction techniques. We knew it would be hard to get a successful bond, and just kept trying until we invented a solvent and technique that usually worked. It allowed us to build very light, strong Kevlar laminates with foam and honeycomb cores, and still have a durable in-mold finish. What was a tricky process then, seems routine with today’s products.

“When we started building production boats with 250°F [121°C] epoxy prepregs in 1983, we found a whole new set of gelcoat challenges. One of the more interesting solutions was a polyurethane gelcoat developed for automotive parts. Searching for new answers is what maintains the fascination in this profession.”

Additional examples of R&D that Lindsay conducted (and this magazine reported) years ago include low-cost ways to post-cure epoxy laminates, plus innovative solutions for attaching heavily loaded rigging hardware. Little wonder, then, that Bob Johnstone tapped Boston BoatWorks for his nascent MJM Yachts venture. Lindsay’s many projects over many years feature fearless composite construction, with nearly all those projects high-performance sailboats.

A Lindsay-built Taylor 40 (12.2m) at Key West Race Week about 25 years ago with the builder, as he puts it, “driving the bus.” Scott Smith owned and campaigned another Lindsay-built Taylor 40, which helped bring the two men together in 1990, to form the business partnership that became Boston BoatWorks. They share not just a passion for fast sailing but “all operational responsibilities” at BBW as well.

And fortunately, BBW has been an excellent fit for MJM. In a marketing video for MJM we’ll review later, Johnstone, at the helm of a 40z traveling offshore at speed in tricky seas, says in a voice-over why he selected Lindsay: “The key to more responsive handling is to build an MJM not like a powerboat but like a racing sailboat. So we turned to a builder of … racing sailboats, Mark Lindsay. Mark had been working with high-tech composites for 33 years.”

Read more Construction , People/Profiles articles

- Van der Werff’s Curved Wood

A Dutch yard adopts composite panel molding technology to build boats from preshaped wooden hull sections.

- Departures: Carl Chamberlin

Passionate, competent, considerate, modest, and thoughtful is how designer and boatbuilder Carl Chamberlin is remembered by those who knew him. He died last November at age of 75 in Port… Read more »

Australia II Wing Keel Controversy – Part 2

A tank-testing laboratory team in The Netherlands convinced Australian challengers to rely on performance-prediction data and analysis that helped create the 12-Meter that made America ’s Cup history.

Recent Posts

- Find out how 3D printing can help your boatbuilding with MASSIVIT

- SAFE Boats Regains Small-Business Status with Employee Ownership

- SNAME Powerboat Symposium Is Back

- Companies (85)

- Construction (106)

- Design (161)

- Drawing Board (10)

- Education (25)

- Environment (16)

- Events (21)

- Materials (50)

- Obituary (18)

- People/Profiles (49)

- Products (16)

- Propulsion Systems (32)

- Racing (16)

- Repair (37)

- Rovings (317)

- Short Cuts (3)

- Sponsored Partner News (14)

- Systems (80)

- Task Sheet (1)

- Uncategorized (26)

- Wood to Glass (7)

ProBoat.com Archives

Solar-pioneers Heike und Michael Köhler have travelled the oceans on conventional motorboats and sailboats for 40 years. Already during the early 2000s, they came to the conclusion that there had to be a better way to supply energy to the propulsion system and the onboard appliances of yachts. After years of dedicated research, this led to the birth of the Solarwave 46 in 2009 – their first prototype of a solar powered catamaran.

Our Origins

The Solarwave 46 was the first ocean-going yacht which exclusively used solar energy, not only for actual propulsion, but also to provide energy to all household appliances on board. This included everything ranging from cooktops, stoves and the freezer to the air conditioning, washing-machine and water-maker.

In 2010, a rigorous four-year sea trial was initiated in which Michael & Heike crossed the entire continent of Europe by river, sailed the dangerous Black Sea, the stormy Aegean as well as the vast Mediterranean Sea. Throughout the journey, the Solarwave 46 not only accommodated them with convenient amenities such as on-board water production, cooling and heating, but also their eight guests with all the comfort they needed for a period of 120 weeks.

Furthermore, the 46 was able to power the engines every day in all kinds of weather: rain, cloudy sky, sun, snowfall, ice and even storms of Force 9. Crucially, during the four-year voyaging there were no maintenance or repair works required on the solar panels, the batteries or the electric drivetrain.

The generator, which had to be on board for safety reasons, was working for less than 50 hours during those 48 months – primarily to avoid it becoming corroded. By comparison, the electric motors operated for more than 2.000 hours for the same period of time with no maintenance needed.

After all those years of dedicated trials, it was clear beyond doubt that the solar electric drivetrain Michael & Heike had developed was the most effective, efficient and reliable choice for nautical propulsion and self-sufficient sailing, facilitating a fully independent on-board lifestyle.

In 2016 Silent Yachts was created. Since then the company has successfully developed several full production solar-electric yacht models. The 60, 80 and 120 Series form the cornerstones of the current Silent model range. In addition, Silent Tenders and Silent Speedboats were launched in 2022, further complementing the experience on board of our yachts. The tenders are designed to be mountable and chargeable onboard; while the speedboats provide incredible performance demonstrating that electric boating can be exhilarating as well.

Company Milestones

For five years Michael & Heike tested alternative power sources on their yachts. They measured the production and consumption of energy with a focus on self-sufficiency for propulsion and well as systems.

Solarwave 46 launch

After 5 years and 15.000 nm of sailing their test catamaran, they started with the design and construction of Solarwave 46: the first prototype of a fully self-sufficient and purely solar-powered ocean-going catamaran.

For 5 years the Köhlers crossed the entire European continent by river, sailed the Black Sea, the stormy Aegean, as well as the vast Mediterranean. A proof of concept that the reliable solar electric drivetrain was an ideal choice for a self-sufficient and emission free lifestyle on board.

Silent 64 launch

As first serial-production solar yacht in the world, the Silent 64 marked the dawn of a new electric era of sustainable yachting.

Silent 64 world record

In February, the 64 became the first solar serial-production bluewater catamaran to cross the Atlantic. From Cartagena, Spain, to Florida she effortlessly covered 5.500 nm. The crossing from Cap Verde to Barbados took only 16 days with an average speed of 6 knots.

Watch Video

Silent 55 launch

As the second serial-production solar powered yacht, the Silent 55 made her world debut at the 2018 Cannes Yachting Festival.

Silent Resorts presentation

The sustainable zero carbon luxury holiday experience. Silent Resorts combines highly efficient non-impactful solar powered residences on some of the most beautiful islands with moorings for silent yachts allowing them serve as floating villas.

Silent 60 launch

The evolution of the Silent 64, optimized with much more powerful engines, greater capacity batteries and higher solar energy output. Honoured with the 2021 German Design Awards, 2021 Gustave Trouvé Award, 2021 Best of Boats Award and winner of the 2022 Multihull of the Year Award.

Office opening - Mallorca

Designed by Philippe Starck, Port Adriano in Mallorca is one of the finest luxury marinas in the world. Silent opened its new offices in the spring.

Silent 120 Explorer presentation

As the boldest expression of solar powered yachting yet, the Silent 120 Explorer brings our signature noiseless experience the superyacht level. Designed by none other than Marco Casali.

Silent Tender 400 launch

Further extending the signature electric experience, our innovative Silent Tender powered by a jet drive made its world debut at the annual Cannes Yachting Festival.

A new e-ra of yachting

Being the first series producer of solar electric yachts, we have always been dedicated towards leading the industry with the latest technology. In today´s world, technology is progressing constantly at a very high pace. A new e-ra is upon us, where small percentage gains in solar cell and battery technologies create ever improving performance. When these gains are combined with even more efficient systems, the result are future-proof yachts which rather than becoming outdated actually improve over time.

This is due the central ability that all Silent designs can be upgraded with ease when better architectures become available. Original used units can also be repurposed for domestic or commercial use. The integration of such circularities is of the key benefits our approach.

In addition to designing and making the world’s most efficient and effective solar boats, our brands longer term ambitions centre around the establishment of a Silent World and Community, where wider lifestyle infrastructure seamlessly integrates with the Silent yachting and living experience. The first important step in this agenda was the partnership with Silent Resorts in 2020: an initiative providing ultra-sustainable residences in carefully-designed, environmentally-sympathetic environments that complement the overarching Silent experience.

In widespread recognition of the company’s expertise and achievements, Silent has received many awards honouring the research, development and expertise invested into our innovative technologies.

Published on September 9th, 2019 | by Editor

Eight Bells: Mark Lindsay

Published on September 9th, 2019 by Editor -->

Mark Lindsay

Few people touched the full range of the sport as Mark Lindsay, 75, who passed away unexpectedly on September 6 in Gloucester, MA. From dinghies to keelboats, from powerboats to America’s Cup boats, Mark was a high-tech boat-building pioneer. Here Mark tells his story:

My childhood summers were spent in a small town on the coast of Connecticut. Although the town beach attracted the crowds, the best-kept secret was in an old weathered boat shop at the foot of Waterside Lane.

I spent hours there, watching the local lobster boats take shape under the practiced eye and knowing hands of a septuagenarian craftsman who worked the oak and cedar with little more than a half model to guide him. The process that brought all the pieces together to create the flowing lines of sea-kindly hulls fascinated me. It was the innocent beginning of a lifelong passion.

At 14 my father helped me buy a kit to build my first boat, a Sailfish. His enjoyment in helping me as we drilled and set the bronze screws in the mahogany, planed and sanded, taught me the value of putting your energy into something you love. I also learned how much fun it is to share that process with others who are just as excited as you are.

Two summers later, away from home and working at my first job on Cape Cod, that Sailfish won a season championship for me, and I was hooked on learning what makes boats go faster.

I left college in the middle of my sophomore year to build boats, and landed a job in Marblehead at the yard where the 12 Metres Nefertiti and Easterner were being fitted out for the America’s Cup.

On my first day at work, in the depths of a New England winter, they handed me a pickaxe and shovel and said, “Dig a ditch three feet deep from this shed to that one and come back when you’re done.” After that I was assigned to building fiberglass Formula V race car bodies, in a cramped corner under the eaves of the lofting floor. I was beginning to learn there is a lot of hard work in boat building. Back at college a year later, I studied architecture at the University of Pennsylvania and then architecture and architectural engineering at MIT. The structures classes opened my mind to the important distinctions between stiffness and strength, and the materials testing lab provided a fascinating opportunity to load the structures and watch how they failed.

I also found myself inevitably drawn to the MIT Sailing Pavilion where the Charles River was a test tank for all our ideas on what makes boats go faster.

The next diversion in my education was several years of building Olympic Class Star boats with World Champion Joe Duplin. Joe has always loved the cross-fertilization of ideas in completely diverse areas like hydrodynamics, sports psychology, and materials technology.

Our coffee breaks were like graduate seminars as we stretched our minds to encompass Joe’s images such as, “If I were a water molecule.” In that shop we built our first epoxy boat 30 years ago, and the exceptional strength and weight characteristics were immediately obvious.

In the early ’70s, Dick Carter’s yacht design office north of Boston attracted an eclectic group of international clients and young designers. When the future America’s Cup designer Doug Petersen left Carter’s office to start his own business, I brashly applied for the job and won it.

I shared an office with Carter’s computer expert, Chuck Paine, and soon afterward we hired another young aspiring designer, Bob Perry, who had a few years previously given up a career as a rock musician.

At the time I was racing sailboats in the very lightweight and overpowered International 505 class. The contrast between the high-performance composite construction of those sailing dinghies and the typical aluminum or wood construction of offshore racing boats lead me to wonder if boats could be built even lighter, stronger and, therefore, faster.

I found a chance to test out those ideas when the Carter yacht design staff was laid off in the winter of 1975, and a friend asked me to build him a sailboat to compete in a World Championship. I rented a loft in a barn on Boston’s North Shore, and designed and built an International Fireball Class sailboat, the first of many launchings for Mark Lindsay Boatbuilders, Ltd.

That summer Joan and Art Ellis took the boat to France and our first boat won. As skipper, Joan became the first woman to win a double-handed Worlds, and the first American in this class.

With its unique structural design, the boat was able to carry much higher rig tension giving better sail shape control. We kept the boat exceptionally light by using aircraft plywood. Puzzled by the boat’s speed, the class measurers even drilled exploratory holes in the hull to try to uncover its secrets.

The following year Steve Benjamin took his new boat from our shop to win the World Championship in Canada.

We turned next to a class that attracted many of the best sailors in the world, the International 505. It was firmly believed that after these lightweight, 16-foot dinghies were more than a year old, they would begin to break down and become uncompetitive. Many of the winning boats were as much as 10% over the minimum weight in an attempt to keep them from falling apart.

We changed the materials and construction process to use vacuum-bagged epoxy, carbon-fiber and Kevlar with Nomex honeycomb cores. Our 505 hulls were dramatically lighter, both stiffer and stronger, and provided World Championship wins for Steve Taylor, Steve Benjamin, Gary Knapp and Cam Lewis. One of my great thrills was winning a North American Championship among that crowd. Twenty-five years later, many of these same boats are still winning.

When two of our 505 owners decided to campaign for the Olympics in the Flying Dutchman, they asked us to design and build the fastest possible boats for them. The prototypes were built with the same carbon, Kevlar, honeycomb, and epoxy technology of the 505s, but it was clear that we could push the technology further.

In the early 1980s, we proposed and won a grant from the U.S. Olympic Committee to design and build a high-temperature-cured, pre-impregnated epoxy Flying Dutchman. With technological support from Sikorsky Aircraft, DuPont, and Hexcel Corporations, and our own hull design and structural engineering, we were able to build the hulls for this 20-foot boat that weighed in at 75 pounds and decks at only 25 pounds.

In 1984, Jonathon McKee and Carl Buchan sailed our boat to the United States first Flying Dutchman World Championship and Olympic Gold Medal. The Lindsay Flying Dutchman became a world standard and sailors came from Europe, South America, Asia, and Australia to purchase the magic boat speed.

Yacht designer Bruce Farr came to us with a design for a 38-foot Lake Garda racer for a Swiss customer. The laminate was the same Kevlar and honeycomb as our 20-foot Flying Dutchman which had been rejected as unworkable by several European builders.

Only five feet wide at the waterline, 16 feet wide on deck and with a towering 45-foot mast, the boat weighed only 2,000 pounds and carried seven crew on trapezes. Launched the day before the first race, this lightweight flyer bested the other 500 boats in the 100-mile race up and back the length of Switzerland’s Lake Geneva, beating multihulls and boats half again her size.

In the early 1980s, Lindsay Boatbuilders began building ocean racers, starting with MORC and IOR boats. Our first keel boat, a Graham and Schlageter 27 won the MORC Internationals. More orders followed and the boats grew in size. In the late ’80s, the IMS rule gave a new opportunity to use our vacuum-bagged epoxy Kevlar construction with the Taylor 40. These boats combined the technology of the latest racing designs with a layout and sail control systems that were easy for the crews of families and friends who sailed the boats.

The Taylor 40 gave several local sailing teams their first successes at the national level, with one overseas boat winning the Japan Cup for its new owner. In 1992 our recently launched Schumacher 40 fulfilled her owner’s dreams by winning her class in the Bermuda Race. I was privileged to join owner Shep Poor and designer Carl Schumacher on that long thrash to weather in the rain that left us with several sea stories and some great memories.

Over the years, many young and old sailors developed an affinity for Lindsay rudders. From Optimist prams to Dennis Conner’s America’s Cup boats, these foils had developed a mystique for successful performance.

In preparation for the 1992 America’s Cup, we were invited to build the rudders for Bill Koch’s America 3 team and to bring our boatbuilding expertise to Hercules Aerospace for the construction of their first hull.

I took a team to Hercules in Utah for two and half months where we helped build the radical autoclaved and glued construction carbon and honeycomb AC boat “Jayhawk”. Later we took another team to Detroit and set up a prepreg carbon mast building shop to assemble the America 3 spars. Back in Massachusetts we built more rudders and mast components. It was a thrill to see them on the winning boat in the 1992 America’s Cup.

Our next undertaking was a series of Bruce Farr designed lightweight IMS racing boats. The Farr 39 ML was built to order for a select group of owners who came from such diverse sailing areas as the East Coast, Great Lakes, Europe, and Japan.

These boats won the Japan Cup, the King’s Cup in Palma de Majorca, Antigua, Block Island and Key West. Their lightweight cored epoxy glass and Kevlar hulls were also subjected to the test of many miles of ocean passages, including one reported peak speed of 30 knots while fleeing the leading edge of a hurricane.

In 1996 I joined Scott Smith in forming the new venture, Boston BoatWorks, at the site of the former Bethlehem Steel Shipyard in Boston, MA. We were very excited to be bringing boatbuilding back to the East Boston waterfront where Donald McKay had built and launched his famous clipper ships such as the Flying Cloud.

In addition to our custom IMS ocean racers, we began using the same pre-impregnated epoxy construction to build both power and performance-oriented cruising boats.

Hydra Powerboats had built a reputation for racing catamarans and asked us to build molds, hulls and decks for their new 50-knot production boat. Vacuum-bagged in cored Kevlar and epoxy, these boats were employed for such diverse uses as sport fishing and high-speed shuttle service on the Panama Canal. Engineering the construction for unusually light weight and high speed was a fascinating challenge.

Designer Chuck Paine had stayed in touch over the years since we shared an office at Dick Carter’s in the ’70s, and brought us an opportunity to build the hull and deck for a custom Kevlar/epoxy 47-foot sailing cruising yacht with interior and fit-out to be completed by Morris Yachts in Maine. This lovely pilothouse design based on an IMS racing hull shape, was the first of several of Paine yachts, up to 62 feet in length, which we built this way.

These projects lead to our building the Boston BoatWorks 46, a Chuck Paine pilothouse performance cruiser for a customer from Seattle, WA. We constructed “Lustrous” for self-sufficient world cruising or exploration of the Pacific Northwest, with a finely detailed varnished cherry interior, a full complement of systems, carbon spars and gleaming custom finish. It was hard to part with her when we were finished.

Our latest project with MJM Yachts is the realization of a longtime dream. I first met Bob Johnstone at a 505 regatta in the early ’70s. We have always appreciated each other’s work and I am delighted at this opportunity to work with such a creative contributor to the profession and to the enjoyment of boating. And when I can’t wait to get to work in the morning, I know I have chosen the right occupation.

A celebration of his life will be held on Saturday, September 21, from 12 – 3 at the Shalin Liu Performance Center, Rockport, MA. Contributions in his memory may be made to Courageous Sailing, Charlestown, MA. www.courageoussailing.org

Tags: Eight Bells , Mark Lindsay

Related Posts

Eight Bells: John B.B. Whitton →

Eight Bells: Allegra Mertz Torrey →

Eight Bells: Tony Morgan →

Eight Bells: Marcel Beaudin →

© 2024 Scuttlebutt Sailing News. Inbox Communications, Inc. All Rights Reserved. made by VSSL Agency .

- Privacy Statement

- Advertise With Us

Get Your Sailing News Fix!

Your download by email.

- Your Name...

- Your Email... *

- Name This field is for validation purposes and should be left unchanged.

- Nautic Shows

- America’s Cup

- Classic Yachts

- Motor Yachts

- Sailing Yachts

- Superyachts

- Yachts News

- Destinations

- Yacht Clubs

- Boat Racing

- Meta Yachts

Headlining the news is the announcement that Austrian-owned Silent-Yachts has been restructured as Silent Group comprising several distinct divisions.

Silent-Yachts: Offering fully electric, solar-powered catamarans from 60-120 feet for noiseless, zero-emission cruising. In addition, from now on a new sub-division will also build hybrid yachts that make use of both conventional propulsion and renewable solar energy. The first hybrid yacht is an 82-foot model to be built in partnership with VisionF Yachts.

Through the cooperation with VisionF, Silent-Yachts aims to support the Turkey based shipyard towards making their catamarans more sustainable. The extended hardtop flybridge of the so-called Silent VisionF 82 is fitted with a large solar array and a powerfull battery bank in order to provide sufficient energy to power all household and comfort appliances on board. As a result, guests will be able to enjoy the noiseless Silent experience without compromises when anchoring in a bay or docked in a marina. The alliance showcases the willingness of Silent-Yachts to assist other manufacturers to reduce their vessels dependency on fossil fuels by incorporating the proven solar technology of the Austrian pioneer.

Silent-Tenders: Offering a new range of electric Silent tenders, starting with a model of 4 metres in length. Further models will be announced during 2022.

Silent-Management: Offering the full spectrum of management services for Silent clients, from documentation, flag registration, certification and inspections to crew hiring, charter and yacht management, maintenance and servicing.

Silent-Charter: Offering Silent yachts for charter from the fleet base in Port Adriano, Mallorca and around the world.

Silent-Brokerage: Offering brokerage services for pre-owned vessels for sale by Silent and its clients.

Silent-Resorts: Stunning zero-carbon, ultra-sustainable resorts with luxurious beachfront solar-powered residences.

Silent-Shop: A web-based outlet for electric water toys, smart electric gadgets as well as Silent merchandising products.

New production sites The Silent Group can draw on three production facilities around the world. Its shipyard on Italy’s Adriatic coast has five construction sheds with 22,000 m² of covered space and about the same area outside for building the Silent 60 series & and the Silent 80 series.

The Swiss-owned and managed PMG Shipyard in Thailand builds the Silent 60 series. The yard has a 20,800-m² facility in Rayong with dedicated areas for each stage of the production process.

A new partnership with Coşkun Bayraktar in Turkey, founder of the Viaport Group has opened up more production opportunities. Bayraktar, who also owns VisionF Yachts in Istanbul, has invested considerable manpower in recent months to start up production of the Silent 60 series, Silent 80 series, SILENT 100 series as well as the new Silent VisionF 82. Boats of each series are already being built in Turkey. Including the Tuzla Viaport Marina, the copperation with VisionF Yachting provides access to more than 100,000 m² of production area.

Record sales in 2021 – the current order book 2021 was a record-breaking year for the brand with 21 yachts sold. There are 17 yachts currently in build at different stages of production, among them eight Silent 60 series, six Silent 80 series, two Silent VisionF 82 and the first Silent 120 (ex-Silent 100).

Upcoming new launch The next unit to be launched will be a Silent 60 – Front Exit version. The solar electric catamaran will touch the water this month February 2022 and will head straight to the US where the owner is waiting. Another Silent 60 Front Exit will be launched by April and will be followed by more yachts later this year.

“I’m immensely proud of what Silent-Yacht has achieved over the years,” says Silent-Yachts founder and CEO Michael Köhler. “After beginning our research into solar yacht technologies in 2004, the company has evolved and expanded and last year’s sales show that we continue to grow. We are now a truly international Group with diverse interests requiring more extensive resources and production space. This enables us to collaborate with other shipyards such as VisionF to assist them in harnessing solar technology as a step towards a more sustainable future.”

- Silent Yachts

RELATED ARTICLES

Damen yachting introduces the xplorer 80, vision turns view: the first unit of the widercat 92 hits the water, most exciting new yachts at the venice boat show, rossinavi to present futuristic catamaran oneiric, what to know about hydrogen-powered yachts, innovative yachts and superyachts of the 21st century.

Subscribe to our newsletter

To be updated with all the latest news, offers and special announcements.

LATEST ARTICLES

Riccardo tosetto fourth in the global solo challenge, palmavela reaches 150 entries, unleashing potential: emirates team new zealand’s two-boat training session, nyyc american magic’s intensive training session amidst barcelona’s spring blues, editor picks, canadian beau lake introduces the tahoe ’14 and lugano ’14 electric runabouts, underwater adventure and exploration with deepflight’s super falcon 3s, driving performance on land and on water: 41′ amg carbon edition, popular posts, young designer of the year 2022: ioana valentina corcodel reveals 65m ophelia concept, mirabaud sailing video of the century: celebrating 2 decades of passion, superyacht the flying fox seized in the dominican republic, popular category.

- Regatta 811

- America's Cup 386

- Motor Yachts 263

- Boating 215

- Superyachts 183

- Sailing 178

- Yachts News 174

- Sailing Yachts 162

- Cruising and Chartering

This Zero-Carbon, Solar-Powered Yacht Club Is in the Works

- By Yachting Staff

- June 23, 2022

Silent-Resorts and EcoIsland Development are building Club Ki’ama Bahamas , a zero-carbon, solar-powered yacht and residence club on Elizabeth Island near Great Exuma.

According to Silent-Yachts , Club Ki’ama Bahamas will be the world’s first equity club to offer “ultra-sustainable solar residences and carbon-neutral solar yachts as a co-ownership model.”

Construction on the 36-acre property is scheduled to start in June, with design of the community, residences and facilities by Silent-Resorts CEO and founder Victor Barrett. There will be 16 four-bedroom residences and eight 60- to 80-foot yachts, in addition to eight whole-ownership residences that include a share of a Silent-Yacht.

Owners can access at least five weeks of annual vacation time, including 10 yacht days. The location will have a 2-acre marina, six private beaches and mostly undeveloped land to create a natural habitat for guests.

The introductory ownership price is $525,000.

“Club Ki’ama represents the future for sustainable residential and resort development,” Steve Dering of EcoIsland Development stated in a press release. “It’s incumbent on us to protect Elizabeth Island’s ecologically sensitive environment while thoughtfully creating comfortable spaces where our owners and their guests can enjoy the best of the Bahamas. Our equity club provides abundant owner use while consuming less land with fewer homes and adds an incredible yacht experience.”

Will these eco-friendly residences be ready for hurricane season? The developers say yes. Residences will be single-story structures designed to withstand Category 4 storms.

Take the next step: Go to silent-resorts.com

- More: Bahamas , Cruising & Chartering , Silent-Yachts

- More Cruising and Chartering

Bruce Kessler Dies at 88

New to the Charter Fleet

Sanibel Rising

Yacht Charter Your Way

Top Helm Technology For 2024

For Sale: 2017 Tiara Yachts 53 Coupe

For Sale: 2009 Sabre 42’ Hard Top Express Yacht

10 Used Yachts Under $1 Million Available Now

- Digital Edition

- Customer Service

- Privacy Policy

- Email Newsletters

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

- Yachting World

- Digital Edition

Review: Silent 55, the extraordinary solar powered yacht

- January 18, 2019

Silent Yachts is tapping into the solar zeitgeist and creating a new meaning for the term ‘powercat’. Sam Fortescue reports

There is a slow, silent revolution under way in the yachting world. It is a revolution that is introducing tonnes of lithium and a sprinkling of silicon to the spec list of new boats. Holding out the promise of silent mobility, plus limitless domestic power on board, it made a big splash at the last Cannes Festival of Yachting – not least thanks to the new Silent 55 catamaran which debuted there.

From the pontoon side, the Silent 55 looks like a typical modern catamaran, with a big coachroof studded with windows and a flybridge helm. Except there’s no mast. Now, bear with me here. I realise that this is a sailing magazine, but we will shortly get back to more familiar territory. The unique qualities of this catamaran only become apparent from up top, where an expanse of solar panels stretches away fore and aft, embedded into the coachroof. The hard top itself carries yet more panels, and can be folded down flush to give an unshaded solar array of 49m2. During the heat of a summer day in the Med, this is capable of generating 10kW of power and up to around 60kWh in the course of the day.

But to make a solar system work in reality, Köhler had to go back to the drawing board on yacht design. The saloon and hulls have extra thermal insulation to keep air-con losses down, and the use of carbon and aramid in key areas helps reduce the overall weight to a decent 17 tonnes (a Lagoon 52 weighs 22.5 tonnes). He has tried to keep windows out of the direct sun with long overhangs and in contrast to the Lagoon’s 12 deck hatches, the Silent 55 has just two.

Holistic design

On the other hand, it has lots of opening windows, to allow a natural draught to do its job. “It’s a holistic approach – you can’t take the batteries and the drivetrain and drop it into another boat.”

Of course, using the propulsion system quickly takes its toll of the boat’s 140kW battery bank. The model on display at Cannes had two 135kW motors, giving you just half an hour of silent motoring flat-out, albeit at a top speed of over 20 knots. More reasonable 30kW engines and a single-digit speed give you greater range. Nonetheless, the electric drive alone isn’t going to allow you to outrun a storm, or race home after a day at anchor, so the boat is designed to work with a generator hidden in the heavily insulated transom of its starboard hull. At cruising speed of around 5-6 knots, Köhler says there is rarely any need to use the generator, citing an owner who has just emailed him triumphantly about a second year totally generator-free. “In the end, you have to compare it to the performance of a sailing boat,” Köhler says. “It is as fast as a sailing boat in similar conditions – after all, there is no wind without sun.” He went so far as to tell me during the sea trial in Palma, Mallorca, that he believed the majority of sailors would happily dispense with the hassle of sails and a rig if only they could enjoy silent motoring and anchoring. “As soon as people realise the incredible concept of this boat, they won’t understand why they ever did anything else.”

The market does not seem to agree with him – yet. Sales of the boat have been good – they have already sold six, five of which are already in the water. But of those, four customers have taken the sail option, which means planting a 19.7m tall mast complete with boom and rigging slap bang in the middle of the coachroof solar array. “I was a bit amazed,” Köhler admits. “The shade from the rig reduces the energy generated by the solar area, while it costs more and is heavier, so consumes more fuel. Maybe it is for optical reasons.” In fact, the shade of the rig slashes the average yield of the solar panels in half. In the Med, that means around 30kWh per day. But perhaps it figures. The typical profile of buyers is an environmentalist who has a Tesla electric car and is “an early adopter who likes to have things before others”. And at low speeds, with modest use of the air-con, the reduced energy generation should still cover daily consumption.

The performance under sail should be reasonable because of the lightweight build of the boat, its broad 8.47m beam and stub keels added to each hull. Control lines are led back via conduits in the coachroof to the flybridge helm station, to make single-handing under sail a possibility.

More interesting, I think, is a sort of halfway-house option using a kite rig. This optimises the performance of the solar panels and gives plenty of propulsion. On the smaller 55 and the 64, Silent Yachts currently recommends a 19m2 kite that costs around €25,000 – a fraction of the cost of a new mast, boom, shrouds and sails. “The sail automatically makes a figure of eight above the boat, and you can steer it with a joystick or an app on an android phone,” Köhler explains. “It can propel the 55 at up to 6 knots, even in light winds.” Perfect for an Atlantic crossing, then.

For the bigger Silent 79, which will hit the water in the summer, a commercial grade Sky Sail system needs to be used – a smaller version of the ones used on cargo ships. This kite can propel the boat at ten knots, but it costs more than ten times as much as its smaller cousin. Both are capable of pulling the boat upwind. So far, so new. But outside the novel energy and propulsion system, the Silent 55 aims to do what many other cruising catamarans are trying to achieve. “Most of our clients order for circumnavigation and long-term cruising,” Köhler says. So the boat is aimed to be as comfortable and capable as possible with watermakers, TVs and an induction hob that all capitalise on the boat’s abundant energy. A flexible configuration allows owners the choice of between three and six cabins – the latter designed for charter. The owner’s cabin lies forward of the saloon, under the windows of the coachroof, which provide magnificent views and abundant natural light. There’s a walk-around bed and steps down into the starboard hull give access to an en-suite shower room and heads.

In my view, the best cabin lies aft of this, accessed in the traditional manner down steps out of the saloon. The king-sized bed lies athwartships and the shower is larger than that of the master cabin. There’s more space down here, better headroom and still plenty of light courtesy of the many hull lights.

When I had the chance to sea trial the Silent 55, albeit in motorboat format, I jumped at it. It was a contrary autumn day on Mallorca with 15 knots breeze – just a shame, then, that this wasn’t one of the sailing configured versions.

To start with, getting on board is made really easy courtesy of deep boarding platforms on the skirts. She feels rather square because of that vast, glazed saloon with its deep overhang, and perhaps because of the utilitarian nature of the hard top, which is really about supporting more solar panels. Nevertheless, the side decks are broad and uncluttered. The space up top is designed to concertina down flat, hence the hydraulic rams, fold-down seat back and lowering console. It makes a great sailing position, though, with all round visibility, and is also perfect for sundowners at anchor. When the rain comes down, this feels quite exposed, but there is a fully sheltered helm at the front of the saloon, and it is also possible to drive the boat from anywhere using a tablet thanks to smart electronics. Under power, the handling is superb. The quietness of the motors is astonishing, and I gather they’ll be inaudible on the next boat, which will do away with the gearbox. Even in the aft cabins, directly above the motors, there is no more than a distant hum. The boat responds instantly to the power and the wind seemed to have no impact at all. As with any propulsion system, the power consumption jumps as you pile on the speed – it was sobering to see. At 6 knots, both motors drew 10kW but at 8 knots it was closer to 30kW. I liked the huge saloon with its raised table for 360º views. And the sliding door and window gives great access aft, connecting the saloon and cockpit in fine conditions. The finish was smart and in muted tones, feeling more Scandinavian than German.

Intriguingly, at least it seems to me, Köhler has tapped into something with the concept behind Silent Yachts – but not entirely for the reasons that he expected. Buyers are opting for the sail or kite versions of the boat because they want a comfortable wind-powered craft with abundant, quiet energy on tap. It brings a whole new meaning to the term ‘powercat’

Multihulls: new yacht reviews

Yes, the racing world is stretching the boundaries, with 100ft foiling maxi trimarans tearing around the globe and F50s, the…

Multihulls: owners’ experiences and reviews

They have two different boats, different sailing plans and two very different sets of experience. But what these cruisers have…

The Builder Under the Bridge

Professional boatbuilder magazine.

Boston BoatWorks co-owners Mark Lindsay and Scott Smith have been delivering complex, lightweight, fuel-efficient power cruisers in wet-preg epoxy composites for the last dozen years— production-built for Bob Johnstone’s MJM Yachts.

In late February of 2015 Boston was digging out from a record winter; large snowbanks impinged on miles of aging turnpike just north of the city. I exited this roadway after crossing the Mystic River on the Tobin Memorial Bridge, headed for Charlestown. Proceeding past the Navy Yard and the USS Constitution’s berth, I followed Scott Smith’s directions through the grit of industrial Charlestown, most of it vintage brick buildings, since there was no signage identifying Boston BoatWorks’ stillunfinished shop.

I parked my car beside a Marine Travelift with Boston BoatWorks’ name on the crossbeam. A tugboat steamed by. Light snow fell from a gray sky. To my right, people wearing hoodies parked factoryfresh imported cars on a waterfront staging area, queuing them for further transit aboard a ferry barge soon to appear. Off to my left, municipal workers in bucket loaders and dump trucks attacked piles of old plowed snow. And literally overhead was the tallest and longest bridge in New England. Tobin’s doubledeck, threespan, cantilevertruss steel structure, 2 miles (3.2 km) in length, dates to 1950; its lower deck arcs 135′ (41m) above the river. There was no doubt that I had arrived at an increasingly rare phenomenon: an urban industrial waterfront boatbuilding shop, and this one was new.

BBW’s masonryandglass main building, which houses production and assembly on the ground floor with administrative offices above, sits on a strip of land alongside the steel uprights of the looming bridge. Between the plant and the auto staging area, the builder keeps a row of tooling and assorted boats stored under shrinkwrap.

MJMMore significant than its site, though, is what BBW has accomplished to date and continues to improve upon. While numerous boatshops here and abroad build sophisticated wetpreg epoxy composite yachts, those are typically oneoff projects. Only two shops, in this country at least, can be said to be in production using wetpreg epoxy composite construction: Outerlimits Offshore Powerboats (Bristol, Rhode Island), and Boston BoatWorks. Of these two companies, only BBW is turning out product in real volume: oceancapable performance motoryachts ranging in size from 29′ to 50′ (8.8m to 15.2m).

Professional BoatBuilder’s prior visit to BBW, in the spring of 2005, was to the company’s original location not far from this one, in East Boston on the same waterway. My visit a decade later was to see the new facility, and meet with Smith and Lindsay to discuss notable changes and upgrades to their operation. But before stepping inside the main building, let’s restate some relevant background on the BBW–MJM relationship, and the rationale behind the boats’ wetpreg construction.

In the mid1970s Bob Johnstone, then vice president of marketing for AMF Corporation, a major American conglomerate at the time, was unable to persuade AMF to produce the performance keelboat he and his brother Rod had in mind. So the Johnstone brothers—both of them passionate about sailboat racing—went into business to build their idea themselves, and subsequently developed J Boats into one of the great international success stories in modern production boatbuilding (see “J Is for Johnstone,” PBB No. 98).

MJMBy the early 2000s Johnstone and his wife Mary, life partners and boat mates, with a shared preference for racing sail, had shifted from sail to power, as have many other cruising and racing sailors of a certain age. The Johnstones owned a Dyer 29 (28.5’/8.7m), an able and versatile fiberglass powerboat in production continuously since the mid1950s. However, the powerboat the Johnstones really wanted, one that met their fairly reasonable requirements, did not exist. So Bob Johnstone once again created a company to build the exact boat he sought.

The wish list? A goodlooking boat Mary could handle alone; fuel efficient but a performance vessel able to safely venture offshore; spacious enough for comfortable socializing with guests; and easy to maintain—in roughly that order of importance. Ever the mastermind and certainly no stranger to the recreational marine industry, Johnstone set about identifying and assembling the technical talent necessary to make Mary Johnstone’s Motorboat (the origin of the initialism “MJM”) a reality. Johnstone, as he told Professional BoatBuilder, had no interest in starting another powerboat company for its own sake (see PBB No. 99 for stories, by Dan Spurr and Bruce Pfund, on MJM Yachts and Boston BoatWorks).

The crucial design/build team that Johnstone put together consists of designer Doug Zurn (Marblehead, Massachusetts; he’s the “z” following each MJM model number in the product line), and master builder Mark Lindsay.

Johnstone—and his son Peter, whom Bob consulted—held Zurn’s design aesthetics in high regard. Johnstone also had every reason to expect reliable performance throughout the speed range, given Zurn’s impressive portfolio in power and sail.

As for build, Johnstone knew from the outset that any prototype of a production MJM would have to be made of strong, lightweight composites, precisely the construction medium that Mark Lindsay had been expertly working in for more than 30 years at that point, always evolving with advances in materials technology. Lindsay had built not only a number of winning sailboats, but atypically for a builder, he’d also been a champion sailor in several onedesign classes, and the technical manager for a successful America’s Cup campaign.

MJMLindsay and Scott Smith formed Boston BoatWorks a halfdozen years before Johnstone approached them with his MJM Yachts proposal. (BBW is the sole builder of these boats, whereas J Boats has had more than one licensed manufacturer globally.) Smith brings to BBW a remarkably varied résumé that includes biomedical engineering, financial services (mutual funds), and banking, all in the Boston area. Like Johnstone and Lindsay, Smith too began racing sailboats as a kid; a Lindsaybuilt competition 40footer (12.2m) is what initially whet Smith’s interest in Lindsay’s work.

Besides managing BBW’s financial affairs, Smith has been active in Bostonarea civic affairs, particularly East Boston’s—its Chamber of Commerce, its Economic Development Council, as well as a nonprofit youth sailtraining program, which he started and serves as a trustee. It was Smith’s sustained participation in the Boston Redevelopment Authority’s planning advisory committee for the municipal harbor that fortuitously led to BBW’s new location. The BoatWorks qualifies as a bona fide modern marine business on a venerable commercial waterfront where there was none. BBW does not own the property it occupies, but its new production plant and administrative offices were built to Smith and Lindsay’s specifications by the property owner. (BBW’s earlier shop, in East Boston, was a leased, repurposed facility formerly part of Bethlehem Steel.)

MJMStill another critical player for executing Johnstone’s vision of a lightbutstrong MJM motoryacht is Steve Burke, a graduate naval architect specializing in structural design, who’d already engineered limitededition, highperformance models in the J Boat line. Beyond designing the structure for MJM’s prototype—a “pocket” motoryacht at 34′ (10.4m), currently discontinued—Burke was charged with securing for later, larger models (at 40’/12.2m and 50’/15.2m) the highest possible standards for small craft, as established by ISO, the International Organization for Standardization. These standards, said Burke, “are the emerging worldwide regulations governing the design and construction of vessels, both power and sail, of up to 24m [79′ ] in length.” It’s noteworthy that the MJM 40z is the only plan- ing powerboat of its size to achieve ISO’s CE mark for “ocean” certification. According to Johnstone, the 40z’s structure is built to withstand 21′(6.4m) ocean waves at speeds over 40 knots. There are no guarantees as to how the people onboard would fare running at speed in such conditions.

Let’s get back to Lindsay. His handson experience in composite construction complements Burke’s engineering expertise. Lindsay’s boatbuilding career goes way back, to his teens, spanning several onedesign and rule boats, and producing numerous champions—Sailfish, Stars, 505s, Fireballs, Flying Dutchmans, Tornadoes, MORC, IOR, and IMS boats—plus much of the technical work on America3, the 1992 winner of the America’s Cup. The reason so many of his boats have been so successful is that he is always searching for strong, lightweight structures, and was among the first builders to use—in boats—what were previously thought of as exclusively aerospace materials.

Taking information gleaned in a structures course at MIT, Lindsay would test samples to failure in the materials lab. Meanwhile, MIT’s Sailing Pavilion, a boathouse on the Charles River laying claim as the birthplace of competitive college sailing in this country, served as a test tank for him, racing socalled Tech Dinghies. The design dates to 1935, when MIT naval architecture/ marine engineering professor George Owen drew the plans and the Herreshoff Manufacturing Co. produced a fleet of 30. Today’s Tech Dinghy, the design’s sixth generation, is a carbon fiber raceboat.

For Lindsay, the interaction of his MIT structures studies and sailracing experience was formative: it taught him, he said, the important difference between stiffness and strength. Understanding that distinction enabled him, when he turned professional, to give his boats a truly competitive edge by lightening them within a class’s parameters, while making them strong enough for the crew to stress the sailing rig without destroying structure.

MJMAfter he’d set up shop as an independent builder specializing, at first, in small raceboats, Lindsay continued to experiment with materials and methods. Precisely because the product was small, he could test many iterations within a relatively short time frame. His boats’ overall success on the race course generated more and more business for him in a market niche that, though popular, was also notorious for small profit margins.

A good example of his experimental construction efforts over time came to the magazine’s attention in 1996, when he was based in Gloucester, Massachusetts, as Lindsay Custom Yachts. Responding to an article we’d recently published on switching to highperformance resin systems, Lindsay wrote in to say:

“Since 1979, I have built over 50 International 505 sailboats in production female molds with polyester gelcoat and epoxy laminate, and I can attest to the challenges of innovating with construction techniques. We knew it would be hard to get a successful bond, and just kept trying until we invented a solvent and technique that usually worked. It allowed us to build very light, strong kevlar laminates with foam and honeycomb cores, and still have a durable inmold finish. What was a tricky process then, seems routine with today’s products.

MJM”When we started building production boats with 250°F [121°C] epoxy prepregs in 1983, we found a whole new set of gelcoat challenges. One of the more interesting solutions was a polyurethane gelcoat developed for automotive parts. Searching for new answers is what maintains the fascination in this profession.”

Additional examples of R&D that Lindsay conducted (and this magazine reported) years ago include lowcost ways to postcure epoxy laminates, plus innovative solutions for attaching heavily loaded rigging hardware. Little wonder, then, that Bob Johnstone tapped Boston BoatWorks for his nascent MJM Yachts venture. Lindsay’s many projects over many years feature fearless composite construction, with nearly all those projects highperformance sailboats.

And fortunately, BBW has been an excellent fit for MJM. In a marketing video for MJM we’ll review later, Johnstone, at the helm of a 40z traveling offshore at speed in tricky seas, says in a voiceover why he selected Lindsay: “The key to more responsive handling is to build an MJM not like a powerboat but like a racing sailboat. So we turned to a builder of…racing sailboats, Mark Lindsay. Mark had been working with hightech composites for 33 years.”

O’Meara’s List Rich O’Meara—whose Rhode Island–based Core Composites company was the source of Boston BoatWorks’ new fabric impregnator—offered eight good reasons why wetpregs are advantageous for composite boatbuilding.

1. You can build a lighter boat. That’s because the core in a wetpreg lamination is not completely filled with resin, as it is for infusion processing.

2. You optimize the fiber-to-resin ratio. This is often expressed as “glasstoresin” ratio; at BBW, that figure is 60:40. With wetpregs you can also vary the ratio depending on the particular plies, from very dry (30% resin content by weight) to wetter for, say, core bonding. 3. You control that ratio to true prepreg quality. The deviation with BBW’s new and old fabric impregnators is ±3% or better.

4. You can run a range of fabric reinforcements. From very light weight (5 oz/yd2, or about 175 g/m2) up to 50 oz/yd2, or 1,700 g/m2.

5. You can run a range of resin viscosities. From 500 cps to 15,000 cps—versus infusion, “where you’re pretty much obligated to use lowviscosity resins, less than 300 cps being best.”

6. You can build a boat faster than with infusion. “By the time you load the mold with dry fabric for infusion, you can put a wetpreg laminate in place, and the resin is just where you want it. You know it’s there. And, you use the same vacuumbagging process.”

7. You do not require near-perfect molds, whereas

infusion does. If a wetpreg mold “leaks,” it’s not going to produce a laminate with a lot of voids. “I don’t say this to encourage lowquality tooling. Rather, it’s a matter of not having to justify infusionquality molds for the potential unit volumes out there.”

8. You get very good core-to-skin bonds, once bagged. That’s because the wetpreg process offers good penetration of the resin into the core “with a laminate that—I’ll say it again—has the resin right where you want it.”

If the list above represents O’Meara’s advantages of wetpregs, is there a second list…of disadvantages? Yes, but it’s shorter.

1. Infusion is superior if you want to fill the core kerfs to prevent water ingress.

2. Polyester resin for wetpregs is not yet optimized by many suppliers. But that’s coming, O’Meara said, because the marketplace’s growing desire for lighterweight parts requires a greater variety of fillers and of resin qualities to make them. Currently, the marine industry is “fully geared up” with lowcost styrenated infusion resins. Printthrough remains an issue, so skincoats are needed.

3. Being under a vacuum bag for the infusion process is cleaner (in terms of odor and VOCs). But odor is minimized with epoxy, as is skin contact—so long as proper technique is maintained with the wetpreg process. “Spray adhesive applied to the dry stack is still the least pleasant aspect of making an infused part. That step is eliminated with wetpregs.” —Paul Lazarus

MJMLindsay and Smith recently purchased a new impregnator for BBW. The machine, designed by Rich O’Meara, head of Core Composites, a division of his Newport, Rhode Island–based ROM Development Corp., and built by Art Armellini, who operates A & E Machine Shop in Cocoa, Florida, replaces one designed and built by Bruce Pfund that Lindsay bought in 1991. (Incidentally, Pfund’s article in PBB No. 99 is arguably the most detailed analysis in print, anywhere, of an impregnator at work in a boatshop. Granted, it’s an impregnator from an earlier era, but by way of his objective text and richly captioned photos shot on site, Pfund tells PBB readers what the machine does best, what its limitations are, and how the BBW crew maximizes its efficiency.)

O’Meara’s company, which distributes composite materials and manages composites programs, has sold more than 250 fabric impregnators into various industries since 1987, when he first witnessed an impregnator in action—in Australia, while visiting there to watch the America’s Cup.

Over the next few years O’Meara tried, “with very limited success,” he said, to interest production boatbuilders in the United States, among them Sea Ray and Wellcraft, in converting from sprayup to wetpreg construction. The problem, O’Meara said, was “drip issues” due to fastcuring polyester resins, and the reluctance of laminators to change away from sprayup. At the same time, “the epoxy oneoff business was booming. We sold units to just about every oneoff boatbuilder, it seemed, in the U.S. and Canada.” O’Meara also sold impregnators to snowboard manufacturers, to outfits wrapping bridge columns, to a firm wrapping water pipes at nuclearpower plants, and to another making rocketmotor cases.

MJMImpregnator machine design and complexity vary with the application. In the beginning O’Meara and Pfund would “compare notes on how best to build these machines,” and O’Meara adopted some of Pfund’s ideas into his design. O’Meara’s early impregnators for the marine industry were made by Binks, best known for its spray finishing equipment.

The Core Composites machine purchased by Boston BoatWorks has the following characteristics: a 60″ (154cm) working width; pneumatically actuated operation (via foot pedals, to keep the operator’s hands free); a safety slip clutch on the drive roll (to keep fingers safe, “especially while cleaning up”); supply and takeup reels on castors; drip tray and tool trays. According to O’Meara, it’s “a popular machine,” and because the basic design is “simple, it has proven to be a longlasting workhorse. Art Armellini and I have debugged it over the years, thanks to plenty of customer input.”

I might add that the documentation O’Meara supplies with an impregnator is thorough and well illustrated. It covers setup, calibration, operation, and cleaning, along with a parts list and drawings. That paperwork—written in plain English—reflects O’Meara’s lengthy history with these machines: he’s dealt with enough impregnators to anticipate frequently asked questions, and therefore what is needed in the way of a proper owner’s manual and technical support.

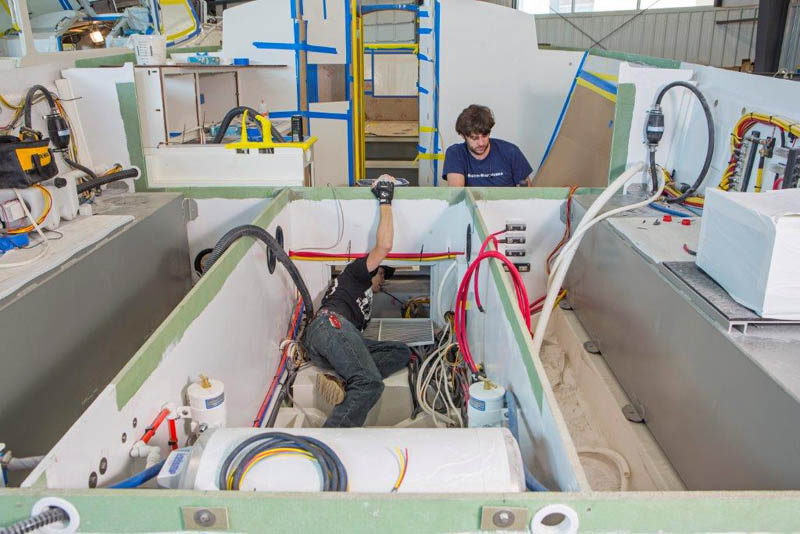

MJMThe top of the concrete ramp, where BBW’s Travelift is parked, levels off to form a raised ground floor for the new main building. I step inside a glasswalled entryway and stairwell, open an interior door, and find myself in BBW’s highceilinged production space. The shop is humming with assembly and construction activity from one end of the building to the other.

In the old facility, Lindsay and Smith’s MJM production was manageable—until sales volume, coupled with Bob Johnstone’s expanded product line, reached a critical mass at the upper end of the model size range. Those boats became too big for the space available, given other boats of different sizes in various stages of construction and assembly. To build a 40footer, for example, Lindsay and his crew had to move hulls out of the way, even out the door, and then roll them back into the shop, sometimes to a different slot on the floor. All of which amounted to unavoidable and effectively wasted time and motion. A larger shop was a necessity, not just a convenience.

In the new facility, wetpregging is done in a dedicated climatecontrolled room/oven, whose controls are located in a dedicated mechanicals room one flight up. No need anymore to choreograph the shuffling of hulls and tooling. The rest of the build process occurs in the main space mentioned above. Lindsay likens it to the openclassroom concept in elementary education; that is, he wants BBW shopfloor personnel to be aware of what their colleagues are doing, to get a better visual idea of the many procedures involved in producing a goodsize boat. He thinks of this buildinghall space as fundamental to crosstraining the crew, and for developing supervisors among them.

MJMDuring one of two walkthroughs in this area, the first by myself and the second accompanied by Lindsay, I could see a systems installation in progress on a 36footer (11m), two men preparing a wiring harness (one was teaching the other), another rounding a portion of the edge of a chine flat to reduce the sound of slapping water at anchor, and several people taking delivery of a preassembled deckrailing system that had been driven from Maine, where it was fabricated by a subcontractor. Each of these tasks was likely a line item on a production wall chart in an upstairs office. Taking up the most space on the floor this morning was an infusion shoot of the monolithic internal grid to be installed on a hull was still in the oven, undergoing postcure. The collective noise level throughout the large room was low. Similarly, there was virtually no sanding dust in the room, or fumes in the atmosphere from coatings or resin.

Indeed, Bob Johnstone promotes MJM boats, in part, on the basis of BBW’s “green” manufacturing practices. Regarding the latter, Boston BoatWorks easily meets and exceeds the U.S. Environmental Protection Agency’s Maximum Achievable Control Technology standard. Lindsay’s longheld reliance on epoxy resins and closedmolding techniques not only ensures superior laminates, it eliminates the VOC problems associated with styrenated resins (in the boatshop as well as earlier in the supply chain). Locally, BBW’s “record and practices related to employee health and safety” have earned it an invitation to apply for certification under the state’s Safety and Health Achievement Recognition Program.

“Side benefits” to a robust safety program that qualifies a manufacturing company for the SHARP initiative, as enumerated by Johnstone, consist of lower workers’ comp rates, lower product costs through higher productivity and morale, better employee retention, and lower training costs. All of which, according to Johnstone (who, let us remember, is a true master of marketing) “improves the value of MJM Yachts to their owners.”

MJMWhile we’re on this theme, Johnstone is, I believe, sincere in his belief that MJM Yachts are “ecofriendly”— particularly in terms of energy efficiency. Text on the website for MJM Yachts points out that the 29z (8.8m), for example, “gets about 3 nautical miles per gallon [0.8 nm/l] of diesel when cruising at 25 knots. This is about half the fuel consumed by a twinoutboard centerconsole of the same size.” Similar fuelefficiency numbers continue up the current MJM product line to the 50z—versus other companies’ production boats: trawleryachts, express or cabin cruisers, and tripleor quadoutboard centerconsoles of comparable size.

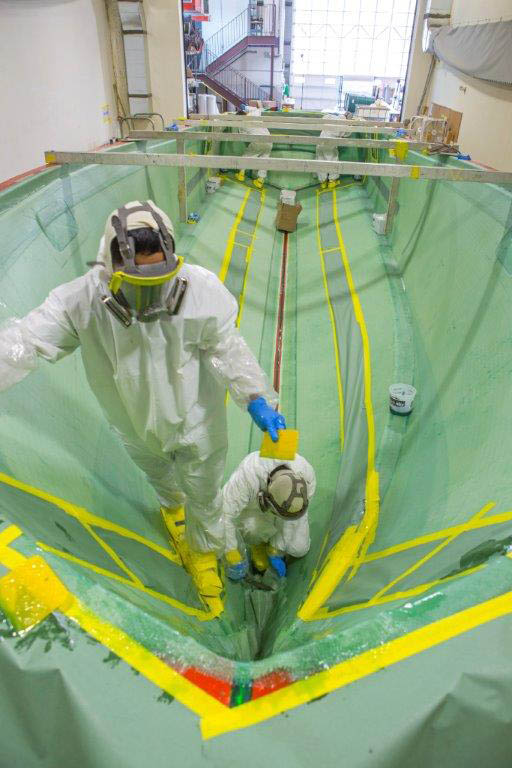

Central to the laminating of MJM hulls and decks is the fabric impregnator. Hull laminate schedules call for continuousstrand biaxial and triaxial glass reinforcement, run through the impregnator’s highpressure rollers, saturating the fibers while limiting resin content to a precise 60:40 glasstoresin ratio. They are split hull molds, affording easy access to each half.

PVC takeup tubes loaded with the preset calibrated length of saturated fabric are carried to the tooling and manually rolled out in one piece inside the mold, the full length of the hull. After applying the outer structural laminate of fiberglass and kevlar, crew members fit precut (by a computer numerically controlled machine) panels of waterproof structural foam (Corecell) to the wet skin. The core panels, Lindsay said, vary by physical properties according to their respective location in the hull; that is, highload and lowload areas.

Wet-Preg Pointers Boston BoatWorks coowner Mark Lindsay has been nothing less than generous about sharing his technical knowledge with attendees at IBEX. He was a principal speaker at two sem inars specifically on wetpregs in pro- duction boatbuilding (at IBEX 2006 and IBEX 2007), and at a third seminar, in 2009, on process materials for closedmold construction in general. Here, I’ve distilled the second of his wetpreg presentations to talking points

Lindsay employed during his half of the 90minute session. (In both wetpreg sessions he shared the podium with Joe Parker, longtime product manager for ProSet Inc., whose epoxy resin system BBW uses for building MJM Yachts. Parker is now retired.)

• BBW chose wet-preg epoxy lami- nation because: epoxy gives us the highest-strength resin matrix; the wet- preg process keeps the weight low; the relatively low cost and simplicity of a wet-preg resin system in materials and process are an advantage over manu- factured prepregs; and a mechanized wet-preg system provides consistent, predictable results.

• Higher material costs imply the need to engineer the product to gain value through the use of more advanced materials. Combining the different chemistries of epoxy lami- nates with polyester in-mold coatings demands careful craftsmanship and sound technology. Achieving the engineered strength properties and superior cosmetic results requires extra attention to process technology.

• When we looked at production efficiency, we discovered that the mold turnaround time was less of a concern than the total production cost of the part. Unlike the rest of the boat, the labor for the laminated parts costs more than the materials, so reducing labor hours was a primary focus.

• Resin-mixing equipment is expensive but gives us reproducible accuracy and reduces labor. A high volume pneumatic impregnator that can keep up with the lay-down team is at the heart of our process. Precut and prelabeled core and cloth ensures accuracy and reduces layup time.

• Another opportunity was to reduce cosmetic finishwork on the parts. If you want lightweight, high- strength laminates, you don’t want to waste those properties by using a resin-rich mat layer backing up the gelcoat to maintain the cosmetics.

• In addition, you’ll want to cure the parts under a vacuum bag, and post- cure them at high temperature to gain the full strength of the resin system. Both of these processes, if not done right, can cause prerelease of the parts from the mold, which then means cosmetic rework.

• Vacuum-bagging demands careful attention to detail. Any place there is a bridge in the bag or the peel ply or the breather material is an invitation to causing prerelease of the part.

• The part has to reach full temperature to complete its cure. The temp must ramp up and down evenly and gradually so that the part does not pull away from the mold, or apply unwanted stresses on the laminate.

• If each step delineated above is done correctly, the result is a flaw- less part that will hold its shape and cosmetic perfection essentially indefinitely.

MJMWith the outer skin and core installed, the crew then applies the inner layer of preimpregnated structural glass, and bags it. Under vacuum, the laminate is compressed by a pressure of 2,000 lbs/sq ft (9,765 kg/m2), “compacting the glass for ultimate strength,” said Lindsay. “Then the hull halves are joined, and with 14 layers of triaxial glass we create a solidglass centerline.” Finally, the entire hull is baked for 48 hours at 150°F (65°C) before unbolting the mold halves and releasing the hull shell.

What I’ve written above is only an overview. Again, for a detailed description of an impregnator—and a BBW team—in action laminating a 34z, I encourage you to read Bruce Pfund’s article titled “Smooth Operators,” in PBB No. 99. Though the MJM 34z is no longer being built (replaced by the 36z [10.9m]), and the impregnator in that article has been supplanted by a new machine (the older one remains in use as a secondary unit), BBW’s laminating process of a representative MJM hull and basic fabricimpregnator technology have changed relatively little since that article was published.

For a full discussion of the technology itself, circa 1990 but still pertinent, see PBB No. 5 for a feature article I wrote titled “Fabric Impregnators,” intended as an introduction to and primer on these machines. Frankly, it surprises me that, 25 years later, so few production boatbuilders acquired them, and altered construction practices accordingly.

MJMDuring my second walkthrough of the shop floor, with Lindsay, he indicated that the boats were likely to be semisurrounded soon by movable staging in lieu of a more permanent perimeter mezzanine system to enhance production efficiency during finishing and fitout. We stopped at a 50z, ascended to a wooden landing, and stepped aboard by way of a door in the hull side. The largest model in the MJM product line, a 50z has proportionally larger windows in the house—necessitating beefier hardware for opening the windshield segments than the openers installed on smaller MJM models. Lindsay wanted to examine for himself the ergonomics of a potential conundrum: Would an older owner find it too difficult to open the windshield outward?

That task completed (but an Internet search for sources of appropriate hardware yet to be made), he showed me a barely discernible structural detail directly beneath us, as we sat and talked under the housetop amidships. When the 50z prototype was put through builder’s trials, Lindsay’s experienced and educated sense of structure told him the big hull needed further stiffening. He surmised that the topside door we had passed through to board, interrupted the boat’s engineered resistance to twist along the sheer. His solution was to fabricate a pair of tall, wide, lightbutstrong cored composite Ibeams, or webs, installed as far outboard as possible in the engineroom, extending from bulkhead to bulkhead below, and beyond the break in the sheer at port and starboard topside doors. When painted to match the rest of the machinery space, this structural element resembled a traditional ceiling down below.

MJMIn a voiceover for a video made three years ago to market MJM Yachts, Bob Johnstone identifies himself as the founder, CEO, and chief boat driver. His baritone voice is pleasant, the pacing unhurried. In my opinion, no elder executive since Lee Iacocca, or Frank Perdue, has been as effective selling his product.

Johnstone is alone in a 40z, offshore, in 6′ –8′ (1.8m–2.4m) seas, driving the boat at different speeds on different headings, while Billy Black—who took the photographs of Boston BoatWorks for this article—shoots video from a helicopter, like a door gunner. The boat’s performance in these conditions is mesmerizing. And convincing.

Johnstone: “That’s me, driving. You don’t see many powerboat companies showing videos of their boats in rough water. In fact, you don’t see any other boats out here today….”

And elsewhere: “When a seventysomething like me can drive a 40z from Northeast Harbor, Maine, to the Cape Cod Canal alone, in these conditions, 200 miles in eight hours, 20–30 miles offshore, you know it’s easy, and safe….”

The still frame shown here from a similar video (shot offshore, in South Florida waters) provide visual confirmation of what Johnstone is describing in his narrative. His vision for an MJM Yacht—in terms of design, construction, and performance, without compromising any of those three criteria— sold boats straight through the Great Recession, as if it weren’t there. At IBEX during each of those painful years (the recreational marine industry is only now emerging from its longest and deepest slump since the Depression), Scott Smith and Mark Lindsay and Doug Zurn would attend seminars and walk the exhibit hall— smiling. Because Smith learned that while the three of them were at the show, still another newly built MJM had sold.

We’ve come this far in the narrative without some vital statistics. They’re numbers that Mark Lindsay doesn’t need to look up; the data are in his head. More important for our story, these stats testify to Boston BoatWorks being a true production builder—in wetpregs—as distinct from the many shops turning out custom boats by the same composite process.

MJMHaving settled into its new space, specifically the 35,000 sq ft (3,252m2) of constructionandassembly areas, BBW has seven or eight MJM yachts under way on the shop floor at any one time, depending on orders for different size models in the product line. The range in completion span between smallest, a 29z, and largest, a 50z, is three to six months. As of July 1st, Boston BoatWorks had delivered a total of 189 MJMs. Current production tempo, according to Lindsay, is about twodozen boats per year, or “a new boat every three weeks.”

Is there a longrange business plan? “As a company we’re trying to maintain sustainable growth,” he said. “We don’t want to overinflate—and explode.” Concurrent with building boats, Lindsay said that among shopfloor personnel in particular, he is attempting to buildin an awareness of key precepts guiding quality control and best practices. (The company employs 75 overall.)

The success of the MJM Yachts relationship, coupled with and predated by BBW’s reputation for highquality construction, has enabled Scott Smith and Lindsay to slowly develop what Smith refers to as a serviceandsupport component. Meaning, a growing percentage of MJM buyers have begun returning to Boston BoatWorks to store, repair, upgrade, or sell their boats. The phenomenon is by no means rare; several wellknown East Coast yacht yards provide historical precedent, among them Rybovich, Hinckley, and Hood, to name three. This type of aftermarket activity helps account for the physicalplant expansion BBW is undertaking out back, along the riverfront beyond the rear door of the main production spaces.