Professional BoatBuilder Magazine

Folding multihulls.

By John Marples , Jan 28, 2023

Folding multihulls and their beam-reduction strategies.

A Farrier 33R trimaran with amas folded and secured on a road-legal trailer exem- plifies the advantages of adjustable- beam multihulls, which are easy to trans- port and store out of the water.

“I’ll be surprised if you can find space in the harbor for that thing,” I heard him say as my new 37 ‘ (11.3m) trimaran was about to be launched. I hadn’t given it much thought, but now this legitimate question was raised, and where to moor was the next issue at hand. Space, particularly width of a slip, becomes the limiting requirement. But then, space also is one of the attractive features of multihulls—deck space to move around on, free from the confines of the cockpit.

Step aboard any multihull and it is obvious how much real estate they offer. Even small models seem expansive. The beam of the typical catamaran is half its length, and trimarans are even wider, sometimes as wide as they are long. Aside from increasing space, beam also boosts stability without adding ballast. The early Pacific Islanders created these form-stable craft for fishing and interisland commerce and voyaging where natural island harbors were few, so the boats had to be light enough for crew to carry them up the beach. Today’s modern multihulls are still lighter than contemporary monohulls, but the larger ones preclude the option of dry sailing them from the beach. They require more marina space than monohulls, and the limited number of slips to accommodate them can be a problem. As someone once put to me, “Multihulls have a poor ‘stacking factor.’”

With catamarans and trimarans becoming more popular, they demand mooring solutions. Some marinas offer shallow-water slips to multihulls, typically at the inboard ends of docks, next to the seawall, because multihulls either have shallow keels or retractable boards. Some marinas also designate the end ties as multihull slips in areas not used for transients. Even though these boats protrude farther into the channel than monohulls, the extra space their beam occupies is relatively small. With multihulls crowding waiting lists for marina slips, builders were prompted to consider folding systems to “improve their stacking factor.”

Without ballast, smaller multihulls up to about 30 ‘ (9.1m) can be dry-stored on a trailer, and most launch ramps easily accommodate over-width boats. If the boat’s beam can be reduced to the legal highway width of 8.5 ‘ (2.6m), the owner can store the boat at home. Today, folding trimarans and catamarans are common sights on trailers in storage yards and backyards. Various folding systems have evolved to support this need, especially for the backyard builder. Some beam-reduction systems allow the boats to be folded and stored in the water in conventional-size marina slips, while other systems facilitate efficient storage or provide street-legal trailering.

Folding Systems

Basic folding systems are separated into several categories:

- take-apart akas, the simplest beam-reduction method

- telescoping akas (sliding beams)

- simple horizontal hinge

- complex horizontal hinge systems

- vertical hinges (swing wing)

- complex swing wing

The following overview of folding systems illustrates how these mechanisms work. It is not intended to be an exhaustive listing of available folding designs. I’ll address two-hull boats (catamarans and proas) first, followed by trimarans. Each type has its challenges and advantages. All are separated into two more categories: transportable boats and trailerable boats. The characteristic distinguishing between them is the time and effort required to launch, starting from an on-the-trailer folded condition. Trailerable implies the possibility of daily launching, requiring less than an hour from trailering to sailing. Transportable denotes a road-legal trailer package but with a longer assembly time to sail away. It might even take more than one trailer load, and considerable assembly time. Legal width in this category could extend to 10 ‘ (3m) wide if OVERSIZE LOAD signs are used (consult local laws). Transportable boats usually require seasonal transport with storage in the water during sailing season and dry storage in the winter. Both categories benefit from the ability to “go to weather at 65 mph” to reach any suitable launching site, even hundreds of miles from home. This opens the possible sailing venue to any water body with a launch ramp and road access, and some trailerable and transportable boats can be delivered anywhere in the world in standard shipping containers.

Catamarans and Proas

The WindRider 17′ trima- ran’s telescoping tubular akas are secured with pins

Hobie Cats and other beach cats are familiar sights around lakes, beaches, and harbors. They are usually built to 8 ‘ (2.4m) beam and do not need folding systems. The 19 ‘ (5.8m) Tornado class catamaran at 10 ‘ wide uses a side tilt-up trailer to reduce beam. Larger catamarans needing folding systems have greater challenges than trimarans of the same length, for a few reasons: The hulls are normally bigger (and heavier) than amas for the same length trimaran; the mast is stepped on the center of an aka, midway between the hulls, which means the aka must be extra strong; and there is no easy means of supporting the hulls while the beam is being expanded to the sailing position, requiring that the trailer have an expanding-beam function. As a result, folding systems are less common on cats and are usually of three types:

- folding akas along the centerline or to a center pod

- telescoping akas

- take-apart akas

On this Wharram cat, the akas are securely lashed into “deck alleys.”

Designers have used telescoping akas, but production boats generally avoid the associated complexity and cost. The mechanically straightforward take-apart feature has successfully been used by many boats, like the 27 ‘ (8.2m) Stiletto Cat and others. Generally, the assembly of these boats takes some time and muscle, which relegates them to the transportable category. Stiletto Cat advertising suggests a four-hour setup time, but in reality, it is much longer. All the James Wharram–designed catamarans up to 63 ‘ (19.2m) are held together with rope lashings and can be dismantled for transport. The required time and effort are generally proportional to the length of the boat.

Note that the Gougeon 32 ‘ (9.7m) sailing catamaran is unique, at 8 ‘ wide, without folding capability but with a water ballast system to make up for the lack of form stability.

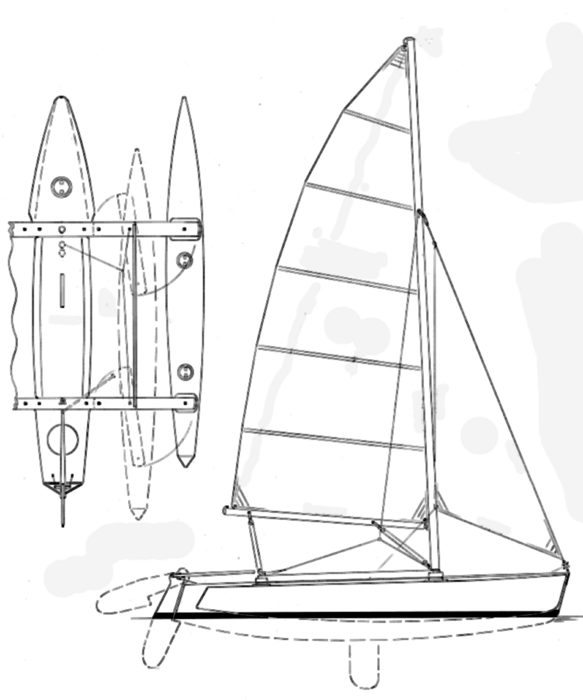

The large main hull of a typical smaller trimaran offers a larger interior space than a comparably sized catama ran, a deep footwell in the cockpit for comfortable seating, and a folding system for trailering with the amas connected to a well-supported main hull. In addition, the mast is stepped on the main hull, with the headstay attached to the bow, not to the akas.

Trailerable trimarans come in all sizes to about 32 ‘ long, with transportable designs somewhat longer. The latter types tend to have larger interior spaces and less complex connectives. To a certain extent, manufacturers were willing to add cost to the folding system to reduce setup time. Folding capability on or off the water also adds to the design challenges.

Take-Apart Aka Systems

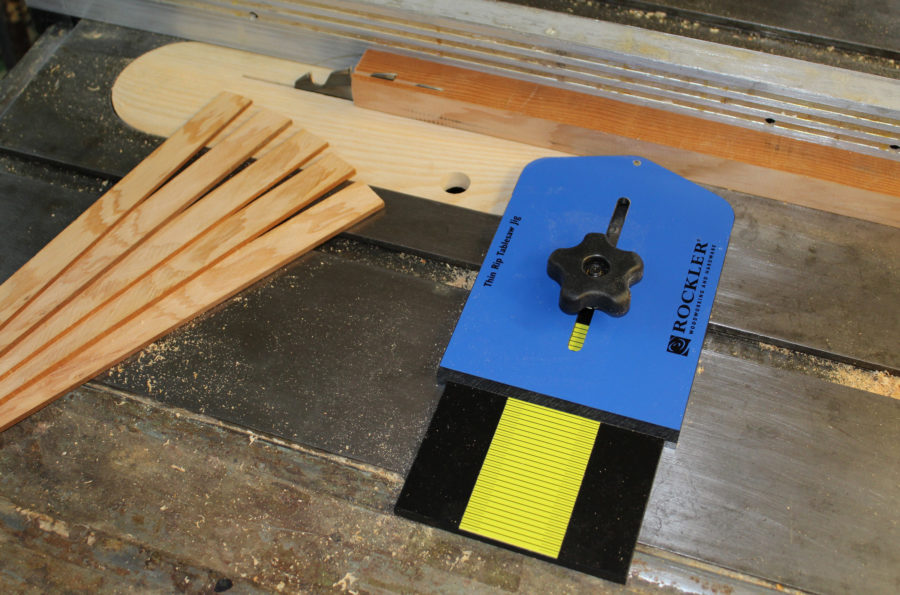

This is the least expensive method and easiest to achieve for the home builder or the manufacturer. The akas may be built-up wood box beams or tubular metal. Each beam is secured to the hulls by through-bolts, bolted straps, plug-in sockets, or lashings. Tubular aluminum beams are the lightest but most expensive. Regardless of attachment method, the hulls must be supported in their respective positions for the akas to be installed. In small vessels, this can be an abbreviated procedure, but larger vessels will require a special trailer to hold the disconnected amas while on the road.

The Chesapeake Light Craft 15′ single outrigger canoe akas lash into saddles on both hulls.

Telescoping Aka Systems

The telescoping option is limited to boats where the total stack-up width and length dimensions of the hulls and fully retracted akas do not exceed the legal road limits. The WindRider 17 is a good example. The boat is supported on “high bars” on the trailer, leaving the amas free to be moved in or out. The simplicity of the akas and trailer-support system reduces cost and launching time.

In larger vessels, this system has been applied to reduce width for storage in marina slips. For these boats, the sliding system is large and complex, usually requiring some sort of power to make the telescope slide. Because the sliding mechanism requires a small clearance between the sliding members, the akas will move slightly during sailing, which is difficult to avoid.

The 1970s-vintage Telstar 26 features a simple hinge-down system with a bolted con- nection on deck and a bolted strut below.

Simple Horizontal Hinge Systems

Early trailerable trimaran designs often incorporated a simple hinged beam-reduction system to fold both sides down. Boats to about 25 ‘ (7.6m) with a 16 ‘ (4.9m) beam could be made to fold to 8 ‘ . At the ama end, lifting the hull, sometimes with attached wing deck, could require substantial muscle or a mechanical lift. Even for smaller boats this task may be beyond one person’s capability. Normally, bolts and plates between the members secure the hull for sailing. On the Searunner 25 and Constant Camber 26 (7.9m), double-hinged tubes are bolted to tangs on the main hull.

The Searunner 25 trimaran has a hinge mechanism on its metal-tube A-frame akas that secures with bolts at both ends.

Commonly, simple hinge systems require that the main hull be positioned rather high on the trailer so the amas clear the trailer wheels beneath. A disadvantage is that the trailer must be submerged more deeply than usual for the boat to float off. Compared to the Telstar system, the Searunner 25 offered some improvement by positioning the hinge point at the top of the cabinside, raising the folded ama slightly.

Complex Aka Hinge Systems

A complex system for folding multihulls, much like a garage door lift linkage, was developed and patented by Ian Farrier for his trailerable trimaran designs. It allows one person to fold or unfold the boat while it’s afloat. Before launching, the mast is stepped and secured with lower stays. Note that folded storage in the water for long periods is not practical because the immersed ama’s topsides will gather marine fouling. In addition, the arrangement of the support linkage arms has a very shallow angle with the aka, causing them to be highly stressed, which adds significant weight and cost.

Unfolding it requires help from friends.

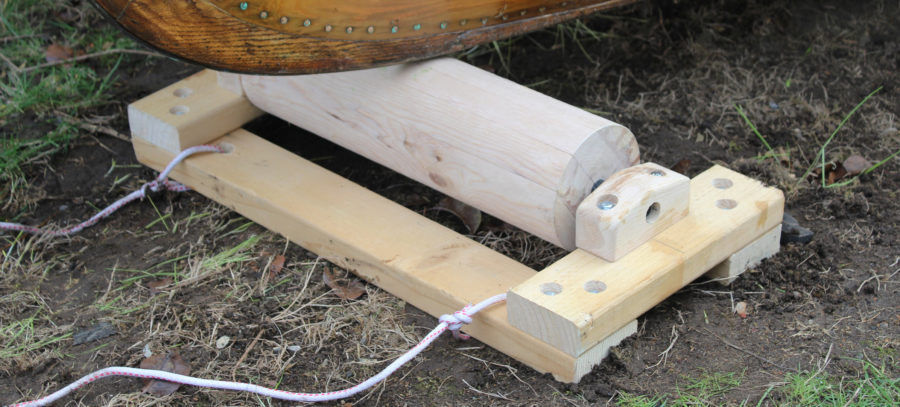

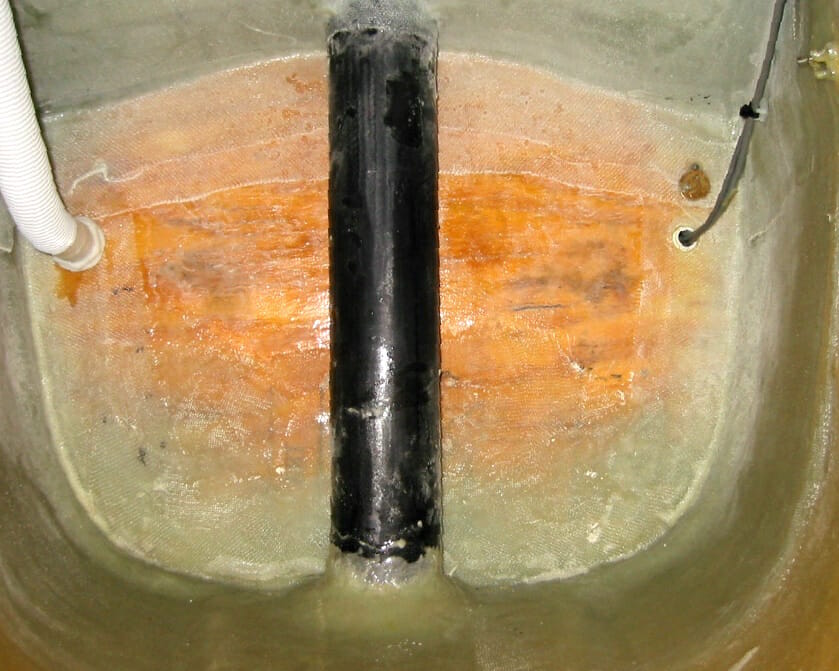

A complex folding system I developed has only four attachment bolts and a wide-angle strut brace. It is very light but requires folding prior to launching. It relies on a simple roller dolly on a beam attached to the trailer to support the ama during folding and unfolding.

Swing-Wing Systems

In-water storage of folding trimarans is generally limited to swing-wing designs, where the hulls all float on their respective waterlines, either folded or unfolded. Many variations have been used in production boats, and among the most successful is the Quorning-designed Dragonfly. It has hinged arms supported by a “waterstay”— a diagonal cable under the arm to counteract cantilever aka loads. The outer end of the arm, on the ama deck, pivots on a single pin. The waterstay becomes slack when the boat is folded, leaving only the hinge to support the ama in the folded configuration. I’ve seen one folded boat that was damaged while moored at the dock in strong harbor waves when the ama climbed onto the dock. Swing-wing designs stored in the water must provide strong vertical support for the ama in the folded condition

A swing-wing aka system on the Borg Quorning–designed Dragonfly 32 is further supported by a waterstay when rigged for sailing. The akas can be adjusted in and out while in the water and for storage at the dock.

The main challenge of the swing-wing system is to get all the pivot axes parallel because they must rotate about 90° without binding. If there is any depth to the structure, this accuracy is critical, as the pins or pivot axles could be quite long, so even a small inaccuracy will make the system difficult to assemble, let alone pivot smoothly.

Folding Multihulls with Flat Swing-Wing Akas

The most basic swing-wing system is the flat aka configuration developed by Jim Brown. He avoided the need for perfect parallel alignment of all hinge axes because the beams are not very thick, and the pivot-pin holes can have additional clearance. For the swing system to operate without binding, spacing of the pivot points must be identical on all the swing arms. The system’s downside is strength, because the aka must support all the heeling loads in a relatively narrow beam. For some boats, a waterstay may need to be added to increase cantilever strength and reduce deflections when sailing.

The Seaclipper 16 flat swing- wing akas are made from common dimensional lumber and pivot using steel bolts.

A logical improvement in strength for swing arms is to add a truss, with triangulated strength that will easily bear all the heeling loads from the ama. Here again, it is essential that pivot axes be in perfect alignment to avoid binding. To my eye, open trusses in sleek yachts are never beautiful, but they offer higher strength for lower weight.

Complex Swing-Wing Systems

If the akas are not flat along their full length, it is more difficult to achieve a smoothly pivoting system. My latest boat, Syzygy (pronounced, sis-a-gee), is a case in point. Flat akas offer little variation in styling—flat is flat. To add underwing clearance and more attractive aesthetics, many designers favor the arched aka. This configuration allows the aka to approach the ama hull from above and connect through the deck for more usable immersion of the ama buoyancy, and to keep the aka above the wavetops.

This system has arched akas with an upward angle (dihedral) as they extend from the main hull and descend with a smooth curve onto the ama deck. The pivot axis must also be inclined, normal to the surface, to allow it to pivot. To make life simple, the vertical centerline of the ama is inclined inboard at the top by the same amount, which aligns all the pivot axes with the ama vertical centerline. If the beam is level fore-and-aft, when the ama is folded inboard, it is positioned rather low, due to the arch. To compensate, the akas must be given a negative angle of attack to make the folded ama arrive in the same position as a simple flat aka system. It’s a good challenge for any boatbuilder to get it right and a good use of a digital level. The angles in Syzygy were 8° dihedral, and a nega tive 5° angle of attack. The aka pivot surfaces must be perfectly parallel on both ends—at the inboard aka pivots and the ama deck pivot tables.

Jan Gougeon designed and built strings, a 40′ swing-wing catamaran with carbon- tubular-truss swing akas built over foam mandrels.

A late iteration of the Telstar 26 became the Telstar 28 with a vertical-axis swing-wing system. This production boat is no longer manufactured but was unique for its faired wing and attempt to hide the folding system from view. It also featured an electric linear drive to fold/unfold the heavy akas.

For transporting folding multihulls on the highway, road trailers must have some specific attributes to properly support the hulls. Most models use transverse cradle supports under the hull at major interior bulkhead positions. It is important to install bow guides on the trailer to get the hull to settle in exactly the right place when retrieved from the water. Rollers beneath the hull are not recommended, as they tend to distort it and potentially cause damage. The amas require enough support so the folding mechanism is not carrying the load when being towed.

For swing-wing boats, there is a significant change in the center of gravity between folded to unfolded configurations. Normally, the amas swing back when folded and swing forward for the sailing position. If the trailer has the proper tongue weight for towing on the hitch with the boat folded, the weight will increase when unfolded. For trailers with telescoping tongues, tongue design must accomodate that weight; otherwise, the extended tongue may bend severely during launching or retrieval.

Homebuilt wooden trailers are popular for these specialized boats, and some designers provide plans for them. Without much metal in them, they will probably float, which sometimes leads to difficulty at launching. Adding some steel channel to the bunks can solve that. However, floating is not an undesirable feature if a trailer floats level but is submerged enough to maneuver the hull into the bunks, and the hull settles into the right place automatically. Floating trailers also never run off the end of the ramp.

Conclusions

There’s truth in the humorous claim that “the new family yacht has to look good behind your SUV.” But while many of the latest small boats are daysailers, folding multihulls have expanded the trailerable and transportable boat size to include those with weekend cruising capability, up to about 32 ‘ . As we’ve seen, those essential folding or retraction mechanisms are not simple and must be carefully designed and engineered, even by the home builder. But for owners of these boats, seasonal storage and slip availability are no longer problems. And the overall reduction in total cost can bring owning a boat within reach for many more people. What’s not to like about that?

About the Author: John Marples has designed, built, and rigged many sail- ing vessels. His portfolio includes doz- ens of wood-epoxy composite sailing and power multihulls to 110′ (33.5m). He operates Marples Marine , a multihull design and engineering firm in Penobscot, Maine

Dieter Loibner | Professional BoatBuilder Magazine

Nomenclature

Multihull designers have developed some useful, specific names for components, mostly derived from the Pacific Islander language.

Aka (ah-kah) refers to the crossbeam structure of any multihull. Designers used to call them “cross-beams,” but writing that on hand-drawn plans took up too much space and time, so this shorter Polynesian name became the standard.

Ama (ah-mah) is the Polynesian name for the outer hull of a trimaran or proa. They were formerly named “floats” or “outer hulls” (never pontoons), but again, ama is shorter.

Vaka (vah-kah) is the Polynesian name for the main (largest) hull of a trimaran or proa. Since it can be confused with the other names and is not very descriptive, most designers have opted for the term main hull.

Waterstay is a diagonal stay, metal or synthetic rope, below the aka, between the main hull near the waterline and aka near its outboard end. This stay counteracts the upward load from ama buoyancy when the ama is immersed.

—John Marples

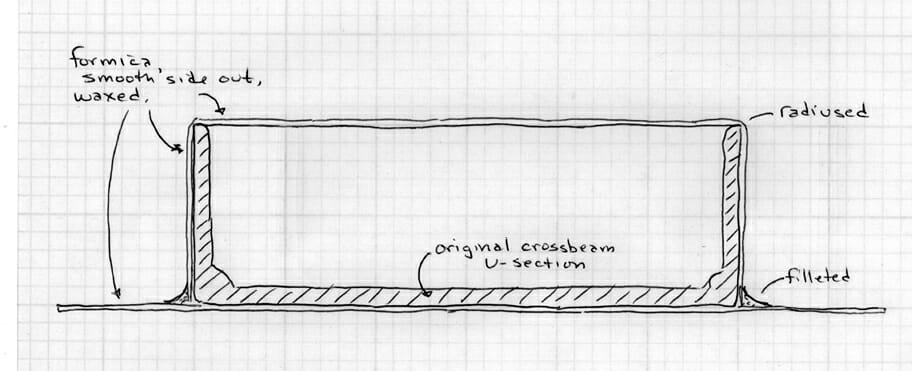

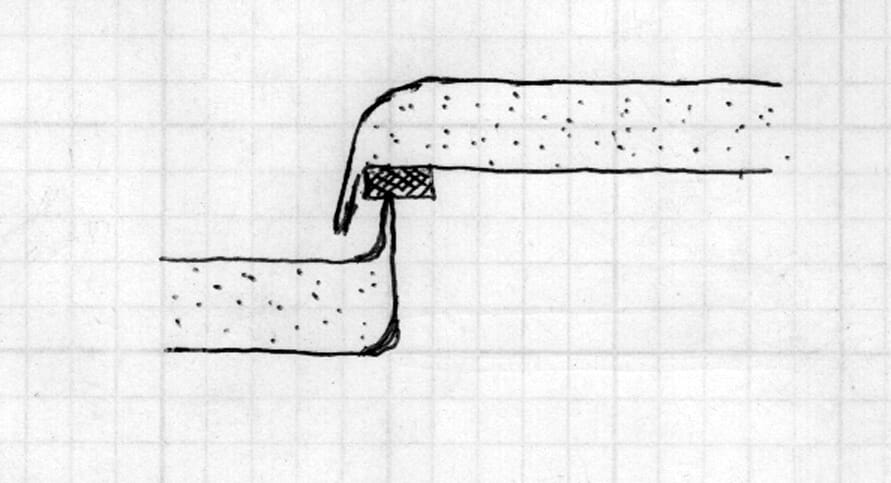

The Crossbeam (Aka) Structure

T he essential function of any crossbeam (aka) system on a multihull is to structurally connect the hulls in a way that resists all the forces generated when sailing. Heeling forces from lift on the sails must be transferred to the leeward hull by the aka structure. The forces on the akas are complex, composed of cantilever bending due to heeling loads, twisting of the structural platform, and horizontal bending caused by drag from the ama’s forward motion through the water. The heeling force, resisted by the buoyancy of the ama, pushes up, causing cantilever bending loads in the akas similar to the forces on an airplane wing. Torsion is created when the sails’ lift pushes the leeward ama bow down, while the shrouds supporting the mast pull the weather-side ama stern up. Drag from the leeward ama tries to bend the akas toward the stern, and forces from the windward shroud tend to pull the aka forward as well as up. These forces all act together at the attachment points on the hulls. In most cases, torsion is resisted by the tubular hull and cabin structure itself. Heeling is countered by the cantilever strength of the aka beams and is sometimes strengthened by diagonal waterstay cables beneath. Drag forces can be resolved by the fore-and-aft strength of the akas or by adding diagonal cables between the akas. Each folding system must accommodate these loads through all the pivoting components in the structure.

Of key interest in aka design are the loads imposed on the ama hulls by the seaway when sailing to windward. These hulls are subject to significant loads on the outboard sides. The windward ama is pummeled by wavetops, and the leeward ama is pushed sideways due to leeway. Since the aka system is characteristically attached through the ama deck, these forces are trying to rotate the ama keel inboard, toward the main hull, in either case. The same is true for catamarans, concerning the aka loads where they emerge at the hull inboard sides. These loads can be calculated to estimate the strength required for any configuration and should be part of the design’s stress analysis. If centerboards or daggerboards are located in the amas, those rotating forces are significantly increased.

Of further interest in swing-wing designs is the clearance between pins and brackets in vertical pivot mechanisms. When sailing, the forces at the hinge pins can change from positive to negative repetitively, creating noise and wear. The wear will eventually elongate the holes, reduce pin diameter, and become a maintenance problem. Designs like the flat wing can be tightened to eliminate movement, which will eliminate wear. Amas with waterstays tend to put the akas in compression and stop the vertical deflection that would be normally carried through the hinge pins. In that case, the pins would be loaded in only one direction and not be subject to cyclic ± loads. —J.M.

Read more Construction , Design articles

- Departures: Carl Chamberlin

Passionate, competent, considerate, modest, and thoughtful is how designer and boatbuilder Carl Chamberlin is remembered by those who knew him. He died last November at age of 75 in Port… Read more »

- SNAME Powerboat Symposium Is Back

The Society of Naval Architects and Marine Engineers (SNAME) Technical and Research Program, in cooperation with the Hampton Roads, Virginia Section of SNAME, will host the Sixth Annual Powerboat Symposium… Read more »

- Candela’s Faith in Foiling Ferries

In the rarefied world of fully foiling electric boats with carbon hulls and appendages, sensor-based digital ride control systems, and hefty price tags, Candela grabbed the spotlight by delivering on… Read more »

Recent Posts

- SAFE Boats Regains Small-Business Status with Employee Ownership

- Australia II Wing Keel Controversy – Part 2

- Companies (84)

- Construction (105)

- Design (161)

- Drawing Board (10)

- Education (25)

- Environment (16)

- Events (21)

- Materials (49)

- Obituary (18)

- People/Profiles (49)

- Products (16)

- Propulsion Systems (32)

- Racing (16)

- Repair (37)

- Rovings (317)

- Short Cuts (3)

- Sponsored Partner News (13)

- Systems (80)

- Task Sheet (1)

- Uncategorized (26)

- Wood to Glass (7)

ProBoat.com Archives

- You are here

- Everything Explained.Today

- A-Z Contents

- Polynesian multihull terminology

Polynesian multihull terminology explained

Polynesian multihull terminology , such as "ama", "aka" and "vaka" (or "waka") are multihull terms that have been widely adopted beyond the South Pacific where these terms originated. This Polynesian terminology is in common use in the Americas and the Pacific but is almost unknown in Europe, where the Anglo-Saxon terms "hull" and "outrigger" form normal parlance. Outriggers, catamaran s, and outrigger boat s are a common heritage of all Austronesian peoples and predate the Micronesian and Polynesian expansion into the Pacific. They are also the dominant forms of traditional ships in Island Southeast Asia n and Malagasy Austronesian cultures, where local terms are used. [1] [2]

See also: Waka (canoe) and Outrigger boat . The term vaka or waka means "boat" or "canoe" in most Polynesian languages. It comes from Proto-Austronesian *abaŋ, meaning "ship" or "canoe". Cognate s in other Austronesian languages include Ivatan Awang , Tagalog and Visayan bangka , Malay wangkang , and Fijian waqa . [3]

"Ama", "aka" and "vaka"

The term ama is a word in the Polynesian and Micronesian languages to describe the outrigger part of a canoe to provide stability. Today, among the various Polynesian countries, the word ama is often used together with the word vaka ( Cook Islands ) or waka ( Māori ) or va'a ( Samoa Islands , Tahiti ), cognate words in various Polynesian languages to describe a canoe.

The Polynesian term vaka is the main hull , the ama is the outrigger, and the aka or iako (Hawaiian) is the support connecting the two (not three) hulls. The term ama and aka have been widely applied to modern trimaran s.

In modern sailing, the term is sometimes used to refer to the outrigger on double-outrigger canoes ( trimaran s), or the two sections of a catamaran . However, calling the two sections of a catamaran by the word ama is not technically correct since they are of equal size. A catamaran is technically a wa'a wa'a or double canoe connected by an aka . [4]

On a proa, the ama may provide lift or ballast , depending on whether it is designed to be used to leeward or windward ; on a trimaran it is designed primarily to provide lift. There are many shapes of ama; those used in proa s are generally laterally symmetric, as the proa is designed to sail with either end forwards, while trimaran ama are one-directional and may have no axis of symmetry.

The most advanced ama are composed of highly curved surfaces that generate lift when driven forward through the water, much like an airplane wing. This lift may be directed to the windward, used to counter slipping to leeward , or may be oriented vertically to counter heeling forces from the sailing rig. These highly curved structures are much more difficult to manufacture than traditional ama and are therefore more expensive. The Bruce foil is an example of a type of leeboard often attached to an ama to assist in producing lift.

Use of the term in other cultures

Even though double-outrigger ships ( trimaran s, sometimes informally referred to as "proas" historically) of other related Austronesian groups in Island Southeast Asia , Island Melanesia , and Madagascar didn't reach Polynesia or Micronesia, they may also sometimes use Polynesian terminology in modern times, especially when used in sport sailing. [5]

The US Navy tri-hull Independence -class littoral combat ship refers to their outboard hull sections as an "Amah". "An Amah tip is the leading edge of the all-aluminum, trimaran-type vessel’s outrigger, or amah, and is more than seven feet across and weighs 850 pounds." [6]

- Polynesian navigation

- Bangka (boat)

- Waka (canoe)

- Outrigger canoe

- Hōkūleʻa

- Beheim . B. A. . Bell . A. V. . Inheritance, ecology and the evolution of the canoes of east Oceania . Proceedings of the Royal Society B: Biological Sciences . 23 February 2011 . 278 . 1721 . 3089–3095 . 10.1098/rspb.2011.0060. 21345865 . 3158936 .

- Hornell . James . Was the Double-Outrigger Known in Polynesia and Micronesia? A Critical Study . The Journal of the Polynesian Society . 1932 . 41 . 2 (162) . 131–143.

- Dempwolff . Otto . Vergleichende Lautlehre des austronesischen Wortschatzes . Zeitschrift für Eingeborenen-Sprachen . 1934–1938 . Special Publication . 15,17,19.

- Web site: Story: Canoe navigation - Waka – canoes' . Rāwiri Taonui, Te Ara . The Encyclopedia of New Zealand . 4 March 2009.

- Web site: The Tridarka Raider . 2007-10-30. https://web.archive.org/web/20071020045916/http://www.tridarkaraider.com/. 20 October 2007. dead.

- Alcoa Provides Aluminum Amah Tips to Austal for Littoral Combat Ship USS Jackson (LCS 6) . 16 April 2012 .

This article is licensed under the GNU Free Documentation License . It uses material from the Wikipedia article " Polynesian multihull terminology ".

Except where otherwise indicated, Everything.Explained.Today is © Copyright 2009-2024, A B Cryer, All Rights Reserved. Cookie policy .

- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Customer Service

- Free Newsletter

Ericson 34-2 Finds Sweet Spot

How to Sell Your Boat

Cal 2-46: A Venerable Lapworth Design Brought Up to Date

Rhumb Lines: Show Highlights from Annapolis

Solar Panels: Go Rigid If You have the Space…

Leaping Into Lithium

The Importance of Sea State in Weather Planning

Do-it-yourself Electrical System Survey and Inspection

When Should We Retire Dyneema Stays and Running Rigging?

Rethinking MOB Prevention

Top-notch Wind Indicators

The Everlasting Multihull Trampoline

What Your Boat and the Baltimore Super Container Ship May Have…

Check Your Shorepower System for Hidden Dangers

DIY survey of boat solar and wind turbine systems

What’s Involved in Setting Up a Lithium Battery System?

The Scraper-only Approach to Bottom Paint Removal

Can You Recoat Dyneema?

How to Handle the Head

The Day Sailor’s First-Aid Kit

Choosing and Securing Seat Cushions

Cockpit Drains on Race Boats

Re-sealing the Seams on Waterproof Fabrics

Safer Sailing: Add Leg Loops to Your Harness

Waxing and Polishing Your Boat

Reducing Engine Room Noise

Tricks and Tips to Forming Do-it-yourself Rigging Terminals

Marine Toilet Maintenance Tips

Learning to Live with Plastic Boat Bits

- Sailboat Reviews

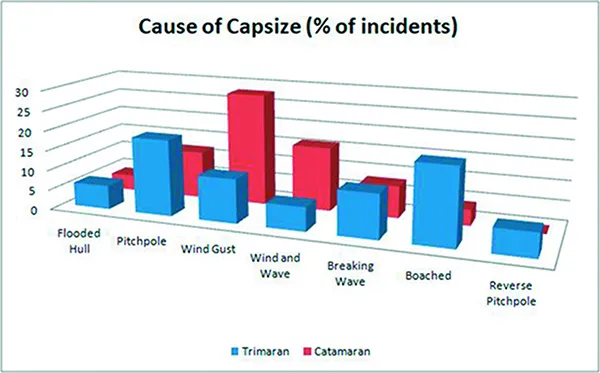

Multihull Capsize Risk Check

Waves, squalls, and inattention to trim and helm contribute to instability..

In recent years we’ve seen a surge in interest in multihulls. Thirty years ago, when my experience with cruising multihulls began, nearly all of the skippers served an apprenticeship with beach cats, learning their quirks by the seat of their pants. They hiked out on trapezes and flew head-over-heels past their pitch-pole prone Hobie 16s, until they learned the importance of keeping weight way aft on a reach and bearing off when the lee bow began to porpoise.

By contrast, the new generation of big cat buyers skipped this learning process, learning on monohulls or even choosing a big stable cat as their first boat. Heck, nobody even builds real beach cats anymore, only pumped up racing machines and rotomolded resort toys. So we’re guessing there are a few things these first-time cruising multihull sailors don’t know, even if they have sailed cruising cats before.

It is extremely hard to capsize a modern cruising cat. Either a basic disregard for seamanship or extreme weather is required. But no matter what the salesman tells you (“none of our boats have ever …”), it can happen. A strong gust with sail up or a breaking wave in a survival storm can do it. And when a multihull goes over, they don’t come back.

Trimarans tend to be more performance oriented than catamarans. In part, this is because it’s easier to design a folding trimaran, and as a result Farrier, Corsair, and Dragonfly trimarans had a disproportionate share of the market.

In spite of this and in spite of the fact that many are raced aggressively in windy conditions, capsizes are few, certainly fewer than in equivalent performance catamaran classes. But when they do go over, they do so in different ways.

Trimarans have greater beam than catamarans, making them considerably more resistant to capsize by wind alone, whether gusts or sustained wind. They heel sooner and more than catamaran, giving more warning that they are over powered.

Waves are a different matter. The amas are generally much finer, designed for low resistance when sailing deeply immersed to windward. As a result, trimarans are more susceptible to broach and capsize when broad reaching at high speed or when caught on the beam by a large breaking wave.

In the first case, the boat is sailing fast and overtaking waves. You surf down a nice steep one, into the backside of the next one, the ama buries up to the beam and the boat slows down. The apparent wind increases, the following wave lifts the transom, and the boat slews into a broach. If all sail is instantly eased, the boat will generally come back down, even from scary levels of heel, but not always.

In the second case a large wave breaks under the boat, pulling the leeward ama down and rolling the boat. Catamarans, on the other hand, are more likely to slide sideways when hit by a breaking wave, particularly if the keels are shallow (or raised in the case of daggerboards), because the hulls are too big to be forced under. They simply get dragged to leeward, alerting the crew that it is time to start bearing off the wind.

Another place the numbers leave us short is ama design. In the 70s and 80s, most catamarans were designed with considerable flare in the bow, like other boats of the period. This will keep the bow from burying, right? Nope. When a hull is skinny it can always be driven through a wave, and wide flare causes a rapid increase in drag once submerged, causing the boat to slow and possibly pitchpole.

Hobie Cat sailors know this well. More modern designs either eliminate or minimize this flare, making for more predictable behavior in rough conditions. A classic case is the evolution of Ian Farrier’s designs from bows that flare above the waterline to a wave-piercing shape with little flare, no deck flange, increased forward volume, and reduced rocker (see photos page 18). After more than two decades of designing multihulls, Farrier saw clear advantages of the new bow form. The F-22 is a little faster, but more importantly, it is less prone to broach or pitchpole, allowing it to be driven harder.

Beam and Stability

The stability index goes up with beam. Why isn’t more beam always better? Because as beam increases, a pitchpole off the wind becomes more likely, both under sail and under bare poles. (The optimum length-to-beam ratios is 1.7:1 – 2.2:1 for cats and 1.2:1-1.8:1 for trimarans.) Again, hull shape and buoyancy also play critical roles in averting a pitchpole, so beam alone shouldn’t be regarded as a determining factor.

Drogues and Chutes

While monohull sailors circle the globe without ever needing their drogues and sea anchors, multihulls are more likely to use them. In part, this is because strategies such as heaving to and lying a hull don’t work for multihulls. Moderate beam seas cause an uncomfortable snap-roll, and sailing or laying ahull in a multihull is poor seamanship in beam seas.

Fortunately, drogues work better with multihulls. The boats are lighter, reducing loads. They rise over the waves, like a raft. Dangerous surfing, and the risk of pitchpole and broach that comes with it, is eliminated. There’s no deep keel to trip over to the side and the broad beam increases the lever arm, reducing yawing to a bare minimum.

Speed-limiting drogues are often used by delivery skippers simply to ease the motion and take some work off the autopilot. By keeping her head down, a wind-only capsize becomes extremely unlikely, and rolling stops, making for an easy ride. A properly sized drogue will keep her moving at 4-6 knots, but will not allow surfing, and by extension, pitch poling.

For more information on speed limiting drogues, see “ How Much Drag is a Drogue? ” PS , September 2016.

Capsize Case Studies

Knock wood, we’ve never capsized a cruising multihull (beach cat—plenty of times), but we have pushed them to the edge of the envelope, watched bows bury, and flown multi-ton hulls to see just how the boat liked it and how fast she would go. We’re going to tell you about these experiences and what can be learned from them, so you don’t have to try it.

First, it helps to examine a few examples of some big multihull capsizes.

Techtronics 35 catamaran, John Shuttleworth design

This dramatic pitchpole occurred in a strong breeze some 30 years ago. In order to combine both great speed and reasonable accommodation, the designer incorporated considerable flare just above the waterline, resulting in hulls that were skinny and efficient in most conditions, but wide when driven under water in steep chop.

The boat was sailing fast near Nova Scotia, regularly overtaking waves. The bows plowed into a backside of a particularly steep wave, the submerged drag was huge, and the boat stopped on a dime. At the same time, the apparent wind went from about 15 knots into the high 20s, tripling the force on the sails and rapidly lifting the stern over the bow. Some crew were injured, but they all survived.

PDQ 32 Catamaran

On July 4, 2010, the boat’s new owners had scheduled time to deliver their new-to-them boat up the northern California coast. A strong gale was predicted, but against all advice, they left anyway. The boat turned sideways to the confused seas and a breaking wave on the beam capsized the boat. There were no injuries, and the boat was recovered with only moderate damage a few weeks later. Repaired, she is still sailing.

Another PDQ 32 was capsized in the Virgin Islands when a solo sailor went below to tend to something and sailed out of the lee of the island and into a reinforced trade wind.

Sustaining speed with wider tacking angles will help overcome leeway.

Cruising cats can’t go to windward. That’s the rumor, and there’s a kernel of truth to it. Most lack deep keels or dagger boards and ex-charter cats are tragically under canvassed for lighter wind areas, a nod to near universal lack of multihull experience among charter skippers. Gotta keep them safe. But there are a few tricks that make the worst pig passable and the better cats downright weatherly. Those of you that learned your craft racing Hobies and Prindles know most of this stuff, but for the rest of you cruising cat sailors, there’s some stuff the owner’s manual leaves out.

“Tune” the Mast

Having no backstay means that the forestay cannot be kept tight unless you want to turn your boat into a banana and over stress the cap shrouds. Although the spreaders are swept back, they are designed primarily for side force with just a bit of pull on the forestay. The real forestay tension comes from mainsheet tension.

Why is it so important to keep the forestay stay tight? Leeward sag forces cloth into the luff of the genoa, making it fuller and blunting the entry into the wind. The draft moves aft, the slot is pinched, and aerodynamic drag increases. Even worse, leeway (sideslip) increases, further increasing drag and sliding you away from your destination. Sailing a cruising cat to windward is about fine tuning the lift to drag ratio, not just finding more power.

How do you avoid easing the mainsheet in strong winds? First, ease the traveler instead. To avoid pinching the slot, keep the main outhaul tight to flatten the lower portion of the main. Use a smaller jib or roll up some genoa; overlap closes the slot. Reef if need be; it is better to keep a smaller mainsail tight than to drag a loose mainsail upwind, with the resultant loose forestay and clogged slot. You will see monos with the main twisted off in a blow. Ignore them, they are not cruising cats. It is also physically much easier to play the traveler than the main sheet. Be glad you have a wide one.

Check Sheeting Angles

Very likely you do not have enough keel area to support large headsails. As a result, you don’t want the tight genoa lead angles of a deep keeled monohull. All you’ll do is sail sideways. Too loose, on the other hand, and you can’t point. In general, 7-10 degrees is discussed for monos that want to pinch up to 40 degrees true, but 14-16 degrees makes more sense for cruising cats that will sail at no less than 50 degrees true. Rig up some temporary barber haulers and experiment. Then install a permanent Barber-hauler; see “ Try a Barber Hauler for Better Sail Trim ,” Practical Sailor , September 2019.

The result will be slightly wider tacking angles, perhaps 105 degrees including leeway, but this will be faster for you. You don’t have the same hull speed limit, so let that work for you. Just don’t get tempted off onto a reach; you need to steer with the jib not far from luffing.

Watch the fore/aft lead position as well. You want the jib to twist off to match the main. Typically it should be right on the spreaders, but that depends on the spreaders. If you have aft swept shrouds, you may need to roll up a little genoa, to 110% max.

Use your Tell-Tales

On the jib there can be tell-tale ribbons all over, but on the main the only ones that count are on the leech. Keep all but the top one streaming aft. Telltales on the body of sail are confused by either mast turbulence (windward side) or pasted down by jib flow (leeward side) and won’t tell you much. But if the leach telltales suck around to leeward you are over sheeted.

Keep Your Bottom Clean

It’s not just about speed, it’s also pointing angle. Anything that robs speed also makes you go sideways, since with less flow over the foil there will be less lift. Flow over the foils themselves will be turbulent. Nothing slows you down like a dirty bottom.

Reef Wisdom

Push hard, but reef when you need to. You will have the greatest lift vs. windage ratio when you are driving hard. That said, it’s smart to reef most cruising cats well before they lift a hull to avoid overloading the keels. If you are feathering in the lulls or allowing sails to twist off, it’s time to reef.

Don’t Pinch

Pinching (pointing to high) doesn’t work for cats. Get them moving, let the helm get a little lighter (the result of good flow over the rudder and keel), and then head up until the feeling begins to falter. How do you know when it’s right? Experiment with tacking angles (GPS not compass, because you want to include leeway in your figuring) and speed until the pair feel optimized. With a genoa and full main trimmed in well, inside tracks and modified keels, and relatively smooth water, our test PDQ can tack through 100 degrees with the boat on autopilot. Hand steering can do a little better, though it’s not actually faster to windward. If we reef or use the self-tacking jib, that might open up to 110-115 degrees, depending on wave conditions. Reefing the main works better than rolling up jib.

Boats with daggerboards or centerboards. The comments about keeping a tight forestay and importance of a clean bottom are universal. But the reduction in leeway will allow you to point up a little higher, as high as monohulls if you want to. But if you point as high as you can, you won’t go any faster than similar monohulls, and quite probably slower. As a general rule, tacking through less than 90 degrees, even though possible, is not the best strategy. A slightly wider angle, such as 100 degrees, will give a big jump in boat speed with very little leeway.

Chris White Custom 57

In November 2016, winds had been blowing 25-30 knots in stormy conditions about 400 miles north of the Dominican Republic. The main had two reefs in, and the boat was reaching under control at moderate speed when a microburst hit, causing the boat to capsize on its beam. There were no serious injuries.

Another Chris White 57 capsized on July 31, 2010. It had been blowing 18-20 knots and the main had a single reef. The autopilot steered. The wind jumped to 62 knots in a squall and changed direction so quickly that no autopilot could be expected to correct in time.

Gemini 105mC

In 2018, the 34-foot catamaran was sailing in the Gulf of Mexico under full sail at about 6 knots in a 10-15 knot breeze. Squalls had been reported on the VHF. The crew could see a squall line, and decided to run for cover. Before they could get the sails down, the gust front hit, the wind shifted 180 degrees, and the boat quickly went over.

38-foot Roger Simpson Design

The catamaran Ramtha was hit head-on by the infamous Queen’s Birthday storm in 1994. The mainsail was blown out, and steering was lost. Lacking any control the crew was taken off the boat, and the boat was recovered basically unharmed 2 weeks later. A Catalac catamaran caught in the same storm trailed a drogue and came through unharmed. Of the eight vessels that called for help, two were multihulls. Twenty-one sailors were rescued, three aboard the monohull Quartermaster were lost at sea.

15 meter Marsaudon Ts

Hallucine capsized off Portugal on November 11 of this year. This is a high performance cat, in the same general category as the familiar Gunboat series. It was well reefed and the winds were only 16-20 knots. According to crew, it struck a submerged object, and the sudden deceleration caused the boat to capsize.

Multihulls We’ve Sailed

Clearly seamanship is a factor in all of our the previous examples. The watch needs to be vigilant and active. Keeping up any sail during squally weather can be risky. Even in the generally benign tropics, nature quickly can whip up a fury. But it is also true that design choices can impact risk of capsize. Let’s see what the numbers can tell us, and what requires a deeper look.

Stiletto Catamaran

We’ve experienced a number of capsizes both racing and while driving hard in these popular 23-foot catamarans. The combination of light displacement and full bow sections make pitchpoling unlikely, and the result is very high speed potential when broad reaching. Unfortunately, a narrow beam, light weight, and powerful rig result in a low stability factor. The potential for capsize is real when too much sail is up and apparent wind is directly on the beam. The boat can lift a hull in 12 knots true. This makes for exciting sailing when you bring your A-game, but limits the boat to coastal sailing.

Corsair F-24 MK I trimaran

Small and well canvased, these boats can capsize if driven hard (which they often are), but they are broad beamed, short-masted, and designed for windy sailing areas. F-24s are slower off wind than the Stiletto, in part because of greater weight and reduced sail area, but also because the main hull has more rocker and does not plane as well. They are faster to weather and point considerably higher than a Stiletto (90-degree tacking angle vs. 110 degrees). This is the result of greater beam, a more efficient centerboard design, and slender amas that are easily driven in displacement mode. The boat is quite forgiving if reefed.

Going purely by the numbers, this boat seems nearly identical to the F-24. In practice, they sail quite differently. The Dash uses a dagger board instead of centerboard, which is both more hydrodynamic and faster, but more vulnerable to damage if grounded at high speed.

The rotating mast adds power that is not reflected in the numbers. The bridgedeck clearance is higher above the waterline, reducing water drag from wave strikes. The wave-piercing amas create greater stability up wind and off the wind. The result is a boat that is slightly faster than the original F-24 and can be driven much harder off the wind without fear of pitchpole or broach.

Without proper testing, calculating stability yields only a rough picture.

Evaluating multihull performance based on design numbers is a bit more complicated than it is with ballasted, displacement monohulls, whose speed is generally limited by hull form. [Editor’s note: The formula for Performance Index, PI has been updated from the one that originally appeared in the February 2021 issue of Practical Sailor.

The following definitions of units apply to the adjacent table:

SA = sail area in square feet

D (displacement) = weight in pounds

LWL = length of waterline in feet

HCOE = height of sail center of effort above the waterline in feet

B = beam in feet

BCL = beam at the centerline of the hulls in feet.

Since a multihull pivots around the centerline beam, the overall beam is off the point and is not used in formulas. Calculate by subtracting the individual hull beam from the overall beam.

SD ratio = SA/(D/64)^0.66

This ratio gives a measure of relative speed potential on flat water for monohulls, but it doesn’t really work for multihulls.

Bruce number = (SA)^0.5/(D)^0.333

Basically this is the SD ratio for multihulls, it gives a better fit.

Performance index = (SA/HCOE)^0.5 x (D/1000)^0.166

By including the height of the COE and displacement, this ratio reflects the ability of the boat to use that power to sail fast, but it understates the importance of stability to the cruiser.

Stability factor = 9.8*((0.5*BCL*D)/(SA*HCOE))^0.5

This approximates the wind strength in knots required to lift a hull and includes a 40% gust factor. In the adjacent data sheet, we compare the formula’s predicted stability to observed behavior. Based on our experience on the boats represented, the results are roughly accurate.

Ama buoyancy = expressed as a % of total displacement.

Look for ama buoyancy greater than 150% of displacement, and 200 is better. Some early trimaran designs had less than 100 percent buoyancy and would capsize well before flying the center hull. They exhibited high submerged drag when pressed hard and were prone to capsize in breaking waves.

Modern tris have ama buoyancy between 150 and 200 percent of displacement and can fly the center hull, though even racing boats try to keep the center hull still touching. In addition, as a trimaran heels, the downward pressure of wind on the sail increases, increasing the risk of capsize. The initial heel on a trimaran is more than it is on catamarans, and all of that downward force pushes the ama even deeper in the water. Thus, like monohulls, it usually makes sense to keep heel moderate.

These numbers can only be used to predict the rough characteristics of a boat and must be supplemented by experience.

This is the first real cruising multihull in our lineup. A few have capsized. One was the result of the skipper pushing too hard in very gusty conditions with no one on watch. The other occurred when a crew unfamiliar with the boat ignored local wisdom and set sail into near gale conditions.

Although the speed potential of the PDQ 32 and the F-24 are very similar, and the stability index is not very different, the feel in rough conditions is more stable, the result of much greater weight and fuller hull sections.

Like most cruising cats, the PDQs hulls are relatively full in order to provide accommodation space, and as a result, driving them under is difficult. The increased weight slows the motion and damps the impact of gusts. Yes, you can fly a hull in about 25 knots apparent wind (we proved this during testing on flat water with steady winds), and she’ll go 8-9 knots to weather doing it, but this is not something you should ever do with a cruising cat.

Stability by the Numbers

The “stability factor” in the table above (row 14) is based on flatwater conditions, and ignores two additional factors. Unlike monohulls, the wind will press on the underside of the bridgedeck of a multihull once it passes about 25 degrees of heel, pushing it up and over. This can happen quite suddenly when the boat flies off a wave and the underside is suddenly exposed to wind blowing up the slope of the wave. A breaking wave also adds rotational momentum, pitching the windward hull upwards.

Multihulls by the Numbers

Autopilot is a common thread in many capsizes. The gust “came out of no place…” No it didn’t. A beach cat sailor never trusts gusty winds. The autopilot should be disengaged windspeeds and a constant sheet watch is mandatory when gusts reach 30-40 percent of those required to fly a hull, and even sooner if there are tall clouds in the neighborhood. Reef early if a helm watch is too much trouble.

“But surely the sails will blow first, before the boat can capsize?” That would be an expensive lesson, but more to the point, history tells us that well-built sails won’t blow.

“Surely the rig will fail before I can lift a hull?” Again, that could only be the result of appallingly poor design, since a rig that weak will not last offshore and could not be depended on in a storm. Furthermore, good seamanship requires that you be able to put the full power of the rig to work if beating off a lee shore becomes necessary.

Keeping both hulls in the water is up to you. Fortunately, under bare poles and on relatively flat water even smaller cruising cats can take 70 knots on the beam without lifting … but we don’t set out to test that theory, because once it blows for a while over even 40 knots, the real risk is waves.

Everything critical to safety in a blow we learned on beach cats. Like riding a bike, or—better yet—riding a bike off-road, there are lessons learned the hard way, and those lessons stay learned. If you’ve been launched into a pitchpole a few times, the feeling you get just before things go wrong becomes ingrained.

Perhaps you are of a mature age and believe you monohull skills are more than enough to see you through. If you never sail aggressively or get caught in serious weather, you’re probably right.

However, if there’s a cruising cat in your future, a season spent dialing in a beach cat will be time well spent. Certainly, such experience should be a prerequisite for anyone buying a performance multihull. The statement might be a little pointed, but it just makes sense.

Capsize by Wind Alone

Capsizing by wind alone is uncommon on cruising multihulls. Occasionally a performance boat will go over in squally weather. The crew could easily have reefed down or gone to bare poles, but they clung to the idea that they are a sail boat, and a big cat feels so stable under sail—right up until a hull lifts.

Because a multihull cannot risk a knockdown (since that is a capsize), if a squall line is tall and dark, the smart multihull sailors drops all sail. Yes, you could feather up wind, but if the wind shifts suddenly, as gusts often do, the boat may not turn fast enough. Off the wind, few multihulls that can take a violent microburst and not risk a pitchpole. When a squall threatens, why risk a torn sail for a few moments of fast sailing?

You can’t go by angle of heel alone because of wave action. Cat instability begins with the position of the windward hull. Is it flying off waves?

A trimaran’s telltale is submersion of leeward ama. Is the leeward ama more than 30-40 percent under water? The maximum righting angles is a 12-15 degrees for cats and 25-30 degrees for trimarans, but that is on flat water. Once the weather is up, observation of motion becomes far more important. Is the boat falling into a deep trough, or is at about to launch off a steep wave and fly?

Just as monohulls can surprise a new sailor by rounding up and broaching in a breeze, multihulls have a few odd habits that only present themselves just before things go wrong. Excuse the repetition, but the best way to learn to instinctively recognize these signs is by sailing small multihulls.

Sailing Windward

Because of the great beam, instead of developing weather helm as they begin to fly a hull, multihulls can suddenly develop lee helm, causing the boat to bear away and power up at the worst possible moment. This is because the center of drag moves to the lee hull, while the center of drive remains in the center, causing the boat to bear away.

If the boat is a trimaran, with only a center rudder, this rounding up occurs just as steering goes away. This video of a MOD 70 capsize shows how subtle the early warning signs can be ( www.youtube.com/watch?v=CI2iIY61Lc8 ).

Sailing Downwind

Off the wind, the effect can be the reverse. The lee hull begins to bury, and you decide it is time to bear off, but the submerged lee bow acts like a forward rudder. It moves the center of effort far forward and prevents any turn to leeward. Nearly all trimarans will do this, because the amas are so fine. The solution is to bear away early, before the ama buries—or better yet, to reef.

Conclusions

We’re not trying to scare you off multi-hulls. Far from it. As you can probably tell, I am truly addicted. Modern designs have well-established reputation seaworthiness.

But multihull seaworthiness and seamanship are different from monohulls, and some of those differences are only apparent when you press the boat very hard, harder than will ever experience in normal weather and outside of hard racing. These subtle differences have caught experienced sailors by surprise, especially if their prior experience involved only monohulls or cruising multihulls that were never pressed to the limit.

Although the numbers only tell part of the story, pay attention to a boat’s stability index. You really don’t want an offshore cruising boat that needs to be reefed below 22-25 knots apparent. Faster boats can be enjoyable, but they require earlier reefing and a more active sailing style.

When squalls threaten or the waves get big, take the appropriate actions and take them early, understanding that things happen faster. And don’t forget: knockdowns are not recoverable. It is satisfying to have a boat that has a liferaft-like stability, as long as you understand how to use it.

Technical Editor Drew Frye is the author of “Rigging Modern Anchors.” He blogs at www.blogspot/sail-delmarva.com

RELATED ARTICLES MORE FROM AUTHOR

22 comments.

It’s interesting to read the report of the Multihull Symposium (Toronto, 1976) regarding the issues of multihull capsize in the formative years of commercial multihull design. There were so many theories based around hull shape, wing shape, submersible or non submersibe floats, sail area and maximum load carrying rules. My father, Nobby Clarke, of the very successful UK firm Cox Marine, fought many a battle in the early Sixties with the yachting establishment regarding the safety of trimarans, and I am glad that in this modern world technolgy answers the questions rather than the surmises of some establishment yachting magazines of the time.

Thank You Mr.Nicholson and Thank You to Practical Sailor for this great read superbly shared by Mr.Nicholson God bless you and our great Sailing Family.

Great read! Multi hulls are great party vessels which is why companies like Moorings and Sunsail have larger and larger numbers in their fleets. More and more multihulls are joining the offshore sailing fleets. Dismasting and capsizes do happen. Compared to mono hulls I know of no comparative statistics but off shore and bluewater, give me a mono hull. That is probably because I took one around with zero stability issues and only minor rig few issues. Slowly though; ten years.

Great read! Multi hulls are great party vessels which is why companies like Moorings and Sunsail have larger and larger numbers in their fleets. More and more multihulls are joining the offshore sailing fleets. Dismasting and capsizes do happen. Compared to mono hulls I know of no comparative statistics but off shore and bluewater, give me a mono hull. That is probably because I took one around with zero stability issues and only minor rig issues. Slowly though; ten years.

What’s an ama? Those who are new to sailing or even veteran sailors who have never been exposed to a lot of the terms simply get lost in an article with too many of those terms. I would suggest putting definitions in parentheses after an unfamiliar term to promote better understanding.

Vaka is the central, main hull, in a trimaran.

Ama is the “pontoon” hull at the end of the aka, or “crossbeam”, on each side of a trimaran.

I’m a geek, and therefore live in a dang *ocean* of the Jargonian & Acronese languages, and agree with you:

presuming 100% of audience is understanding each Jargonian term, and each Acronese term, is pushing credulity…

( and how in the hell “composition” means completely different things in object-oriented languages as compared with Haskell?? Bah. : )

As I understand it: Cats have an advantage in big beam seas because they will straddle a steep wave whereas a Tri can have its main hull on the wave crest with the windward ama’s bottom very high off the water and acting as another sail. Also, rig loads on a mono hull are calculated to be 2.5-3x the righting moment at a 45 deg heal; the reason being at 45 degrees the boat will still be making headway and feeling the dynamic loads in the seaway but beyond 45 degrees is a knockdown condition without seaway shock loads. A multihull rig on the other-hand can experience very high dynamic shock loads that are too short in duration to raise a hull.

Though I agree with much of the article content, the statement: “… this is because strategies such as heaving to and lying a hull don’t work for multihulls.” does not ring true in my experience. I have sailed about 70,000nm on cruising catamarans, a Canadian built Manta 38 (1992, 39ft x 21ft) with fixed keels and my present boat, a Walter Greene Evenkeel 38 (1997, 38ft x 19ft 6″) with daggerboards. I came from a monohull background, having circumnavigated the world and other international sailing (60,000nm) on a mono before purchasing the Manta cat. I owned that catamaran for 16 years and full time cruised for seven of those years, including crossing the Arctic Circle north of Iceland and rounding Cape Horn. I usually keep sailing until the wind is over 40knots, then the first tactic is to heave-to, and have lain hove-to for up to three days with the boat lying comfortably, pointing at about 50 to 60degrees from the wind and fore-reaching and side-slipping at about 1.5 to 2knots. Usually once hove-to I wait until the wind has reduced to 20knots or less before getting underway again. Lying ahull also works, though I have only used that in high winds without big breaking waves, as in the South Atlantic in the lee of South America with strong westerlies. I have lain to a parachute sea anchor and it is very comfortable, though lots of work handling all that gear and retrieving it and was glad to have deployed it when I did. I heave-to first, then deploy the sea anchor from the windward bow while in the hove-to position. The daggerboard cat will also heave-to well, though takes some adjusting of the boards to get her to lay just right, though I have not experience being at sea on this boat in as high of winds as with the Manta (over 60 knots). Catamaran bows have lots of windage and have little depth of hull forward. Thus you need mostly mainsail and little jib to keep her pointing into the wind. I aim for the wind to blow diagonally across the boat, with a line from the lee transom to the windward bow pointing into the wind as an optimum angle. As per taking the boat off autopilot when the wind gets near 20 knots is just not practical. The longest passage I have made on my catamarans has been from Fortaleza, Brazil, to Bermuda, nearly 3,000nm and across the squall prone doldrums and horse latitudes, taking 20 days. The autopilot steered the whole distance. I have never lifted a hull nor felt the boat was out of control despite having sailed in some of the most dangerous waters of the world.

I believe that your Techtronics 35 should be Tektron 35 (Shuttleworth) and as far as I know the capsize that occurred off Nova Scotia was, in fact, a Tektron 50 (Neptune’s Car I believe) sailed by the Canadian builder Eugene Tekatch and was reported as being off PEI. This capsize was well documented under a thread in “Steamradio” that I can no longer find. It appears that Steamradio is now, unfortunately, no longer operating. The report of the capsize was along the lines of the boat being sailed off wind with all sail in a gale. I think Shuttleworth indicated that they would have been doing about 30 knots. They then hit standing waves off PEI, the boat came to a standstill and with the change in apparent wind to the beam, over they went. Reading between the lines, Shuttleworth was pretty unhappy that one of his designs had been capsized in this manner, unhappier yet that some of the findings of I believe an american committee/ board were that the design was somehow at fault. Given Shuttleworth’s rep it seems unlikely. As I say these are recollections only.

Shortly afterwards Neptune’s Car was up for sale for a steal price.

I think Jim Brown (Trimaran Jim) when speaking of the Tektron 50 referred to it as weighing less than similarly sized blocks of Styrofoam. Admittedly, blocks of solid foam weigh more than one might imagine, but still a vivid point. Though Tektron 50 was light, we have far more options to build lighter boats today, than in the past.

Good that Practical Sailor is looking at this issue and I agree with much of it, so thanks PS for that. Also fun to see Nobby Clark’s son chip in …. I met Nobby at the ’76 World Symposium in Toronto, when I was just starting to get interested in Trimarans. I have since owned 4 and as a naval architect, builder and sailor, now specialize in their design and ‘all things related’, with a quasi-encyclopedic website at: http://www.smalltridesign.com . So as a trimaran guru, I’d like to add a few things here. In my experience (now 45 years with multis) there is really too much difference between catamarans and trimarans to compare them on the basis of the same formulas. For example, lifting a hull on a cat brings about a major reduction in reserve stability ….. lifting an ama on a trimaran, certainly does not. Using 30-40% immersion of an ama is hardly a guide to limit or prevent a capsize on a trimaran as that’s not even close to normal operating immersion . I would recommend a reduction of ama bow freeboard to about 1-2% of the boat length (depending on a few size factors) is a better guide as the ‘time to really ease up’. This visual indicator is great on my boats but is very hard to judge on hulls with reverse bows where there is no deck up forward. For a number of reasons, I am against this shape but as I’ve already made my case on line about this, I’ll not repeat it here. Over 80% of the capsizes we see on line, show that mainsails were never released .. and that includes the capsize of the MOD70 in the YouTube referenced in the PS article. As several trimaran owners I deal with have also capsized or near-capsized their boats (particularly those between 22 and 40ft that ‘feel’ more stable than they really are, I am developing a few models of EMRs to help solve their issue, (EMR=Emergency Mainsheet Release) and these will be operated wirelessly by punching a large button under the skippers vest, as I am not in favor of any fully automatic release. This HAS to be a skippers decision in my opinion for numerous reasons. The first two units of this EMR dubbed ‘Thump’R, will be installed this Spring … one in Europe and the other in Australia, but one day, perhaps Practical Sailor will get to see and test one for you 😉 In a few words, my advice to all multihull sailors is to be very aware of the way your stability works on your specific boat and sail accordingly. We learn this instinctively with small beach boats, but is harder to ‘sense’ as boats get heavier and larger. I have sailed cats from a 60ft Greene cat to a 12ft trimaran and although some basics apply they are of course very different. But you still need to ‘learn the early signs’ of your boat, as these must be your guide. IMHO a good multihull design will be fairly light and easily driven which means that it will still sail well with less sail. This means that the use of a storm mainsail in potentially high wind can add much reserve stability and safety to your voyage. To give an example from my small W17 design that sets a rotating wingmast, the boats top speed to date is 15kts with 200 sqft, but with the storm mainsail and a partly-furled jib I can get the area down under 100sqft without losing rig efficiency. In fact, the tall narrow storm main with a 5.5:1 aspect ratio is now even MORE efficient as the wingmast is now doing a higher percentage of the work. In 25-30t storm conditions, I have now sailed 8kts upwind and 14.4kts down, and feel very dry and comfortable doing so … even at 80+. So get the right sails, and change down to small more efficient ones when it pipes up. A multihull storm sail should look nothing like a mono’s trysail … with our narrow hulls, we are sailing in a very different way. Happy sailing Mike

In the old days, low displacement, short and narrowly spaced amas were the design of choice. One was supposed to back off when they started to submerge. It was a visual indicator. Modern amas are huge. If a 24 foot tri like the Tremolino could be designed to use Hobie 16 hulls in the 70s, today it would carry Tornado hulls. The slippery shape of designs catches the eye, and their supposed less grabby when submerged decks, but these amas also carry 1.5-2x main hull displacement. The chance of burying them is significantly reduced.

The original intent of these slippery ama designs was to shake off wind. Though low drag shapes for reducing pitch pole risk are a consideration, it should be balanced against maintaining ama deck walkability. This is important in allowing one to service the boat or rig drogues or anchors, not to mention to position live ballast. I am thinking here of the smaller club and light crusing tris. You aren’t going to be able to do a lot of these things on monster luxury boats that are a different scale entirely. But they mater on the kinds of boat most people are likely to own.

Poring over tri design books, one will notice that the silhouette of, say, a 40 foot tri, and the smaller 20 foot design are very similar This yields a doubling of the power to weight ratio on the smaller boat. This difference can even be greater as the smaller boats are often nothing more than empty shells, yet may carry higher performance rig features like rotating masts. Smaller tris are often handicapped by the requirements of being folded for trailering which both limits beam and ama displacement, though it may tend to increase weight. On top of that, mainsail efficiency is much higher, these days, with squared shapes, and less yielding frabrics. And, of course, much larger sail plans. All the better, just so long as people realize what they have by the tail.

Excellent article…thank you!!!!!!!!!

Good article. One thing that concerns me about modern cruising cat is how far above water level the boom is. I first noticed this looking at Catana 47’s for hire in New Caledonia and recently saw large Leopards 48 & 50 footers visiting Fremantle Sailing Club, here in Australia, and in all cases the boom seems to be at least 20 feet (6 metres) above the water. This seems to greatly increase the heeling moment and reduce the amount of wind required to capsize the vessel. Mind you at 20+ tons, the weight of the Leopards probably makes them a bit more resistant to capsize. But why does the rig need to be so far off the water?

Notice to Moderator After having read this article a couple or days back, I emailed naval architect mike waters, author of the specialist website SmallTriDesign to read the article and perhaps comment. Nearly a day ago, he emailed me back to say that he had, yet there’s been nothing posted from him and now I see a post with todays date. With his extensive knowledge and experience I would have thought his insight to be valuable to your readers and I was certainly looking forward to seeing his input. What happened?

Yes, PS .. what’s cookin ? Thought readers would be interested to know that capsize control help maybe on the way 😉

Yes PS, what’s cookin’ ? Thought your readers would like to know that some anti-capsize help maybe on the way 😉

Great article! I’ve read it twice so far. Recently in Tampa Bay I sailed my Dragonfly 28 in 25 knots breeze and found that speed was increased (drag reduced?) after I put in one reef in the main. I think I should have reefed the Genoa first?

Absolutely Tim. Slim hulls, as for most trimarans and the finer, lighter catamarans will often sail more efficiently with less sail .., especially if with a rotating mast, and you can indeed get proportionally better performance. The boat sails more upright for one thing, giving more sail drive from improved lift/drag and less hull resistance .. and its certainly safer and more comfortable and can also be drier, as an upright boat tends to keep wavetops passing underneath more effectively. Even my W17 design has been shown to achieve over 90% of its top speed with only 1/2 the sail area, by switching to a more efficient, high-aspect ratio ‘storm mainsail’ set behind its rotating wingmast …, a far cry from a monohulls storm trysail in terms of upwind efficiency. Yes, wind speed was higher, but the boat sailed far easier and its definitely something that slim hulled multihulls should explore more, as they will then also be less likely to capsize. More here if interested http://www.smalltridesign.com

Darrell, is there some reason for blocking replies that hold opinions contrary to those of PS ? I am still hoping to read the expertise of those who actually study design and sail multihulls. The written target of PS is to accurately present facts and that implies the input of experts. Over the last 10 years, I have come to appreciate a few experts in the field of multihulls and right now, I see at least one of them is not being given a voice here. Your article made a lot of fine points but there are some issues needing to be addressed if PS it to remain a trusted source for accurate information. First, I have been told by a reliable source, you need to separate trimarans from catamarans and use different criteria to compare their stability as they do not respond the same and neither can you judge their reserve stability in the same way. I would also like to know what NA Mike Waters was hinting at when he said “capsize control help may be on the way” .. would you know anything about that? If not, then please invite or allow him space or the promise of PS fact-finding accuracy is heading down the drain for me. thanks

As a new subscriber to PS, it is a little disquieting to see no response to the two comments above by Tom Hampton.

LEAVE A REPLY Cancel reply

Log in to leave a comment

Latest Videos

40-Footer Boat Tours – With Some Big Surprises! | Boat Tour

Electrical Do’s and Don’ts

Bahamas Travel Advisory: Cause for Concern?

Island Packet 370: What You Should Know | Boat Review

- Privacy Policy

- Do Not Sell My Personal Information

- Online Account Activation

- Privacy Manager

Free Shipping in the US on Orders $75+

- 1-888-609-2827

Item added to your cart

The complete list of trimarans.

There is no single trimaran that is best for everyone. Where some prefer luxury cruisers for long trips with family and friends, others might opt for a high performance racing tri for thrilling rides at breakneck speeds. With the recent spike in trimaran popularity, these days there is a perfect tri for every sailor. So to help prospective trimaran owners decide which boat is just right for them, we here at WindRider have put together a comprehensive list of the best trimarans on the market today! Read through for simple at-a-glance trimaran comparisons of boats both big and small, exhilarating and relaxing, and for all price points.

Jump to a specific sailing trimaran: Neel Weta Corsair WindRider Dragonfly Catri Astus Hobie Sea Pearl Farrier Sea Cart Multi 23 Triak SeaRail Warren Lightcraft Diam Radikal Challenger

Known for their award-winning luxury trimarans, NEEL is based in La Rochelle, the capital city of sailing in France. NEEL trimarans are built for fast cruising with an average cruising speed of about 10 knots, and are even configured to facilitate that sustained speed under motor propulsion. The NEEL 45 was notably named Cruising World’s Most Innovative Vessel in 2013, and by all accounts is an easy-to-sail, high performance boat that is just plain fun.

At a glance:

Models: NEEL 45, 65

Length: 45’ – 65’

Cost: $$$$$

Use: Luxury cruiser

A fan favorite, Weta trimarans are fast, stable, and remarkably easy to rig. This single-sailor tri has a capacity of up to three, and the ease with which it can be transported and stored makes this a great, versatile boat for beginners. The Weta was named Sailing World’s 2010 Boat of the Year, and one ride is enough to know why: simply put, the Weta is an absolute ton of fun to sail regardless of skill level.

Models: Weta

Length: 14’5”

Cost: $$ $$$

The high-end Corsair trimaran definitely holds its own in the categories of versatility, performance, and convenience. Boasting a rigging time of 30 minutes from trailer to sailor , the Corsair 42 – whose convenient folding amas makes trailering possible – is a simple option even for single sailors, though cabin space is suitable for two adults. These boats are wicked fast, capable of reaching speeds of 20+ knots, and were made for skilled sailors seeking solid construction and high performance vessels, not for beginners.

Models: Pulse 600, Sprint 750 MKII, Dash 750 MKII, Corsair 28, Cruze 970, Corsair 37, Corsair 42

Length: 19’8” – 37’

Cost: $$$$ $

Use: Sports cruisers