Step-By-Step Guide: How to Build a Wooden Sailboat – Complete DIY Tutorial

Alex Morgan

Building a wooden sailboat is a rewarding and fulfilling endeavor that allows you to create your own vessel for sailing adventures. Whether you’re a seasoned sailor or a woodworking enthusiast, constructing a wooden sailboat requires careful planning, attention to detail, and a love for craftsmanship. This comprehensive guide will take you through the step-by-step process of building a wooden sailboat, from choosing the right design and gathering the necessary materials to assembling the framework, building the deck and cabin, and installing the sails and rigging. We will also discuss the finishing touches and regular maintenance required to keep your wooden sailboat in optimal condition for years of enjoyment on the water. Let’s dive into the world of wooden sailboat construction and embark on this exciting journey together.

Key takeaways:

Key takeaway:

- Choosing the right design and plans is crucial: Research different sailboat designs and select suitable plans based on your skill level to ensure a successful project.

- Gather the necessary materials and tools: Pay attention to wood selection and preparation, as well as acquiring the tools and equipment needed for building your wooden sailboat.

- Attention to detail in the construction process is important: Prepare and assemble the framework carefully, focusing on lofting, laying out the keel, constructing the ribs, and the hull structure to ensure a sturdy and reliable sailboat.

Choosing the Right Design and Plans

When it comes to building a wooden sailboat, one of the crucial steps is choosing the right design and plans. In this section, we’ll take a deep dive into the world of sailboat designs and explore the vast array of options available. From researching different sailboat designs to selecting plans that match your skill level, we’ll guide you through the exciting process of bringing your wooden sailboat dream to life. So, hop aboard and let’s set sail on this exhilarating journey of craftsmanship and adventure.

Researching Different Sailboat Designs

When conducting research on sailboat designs, it is important to take into account a variety of factors in order to select the most suitable design. One of the primary considerations is whether you prefer a monohull or a multihull sailboat. Monohulls are more commonly found and offer superior performance when sailing upwind, whereas multihulls provide both stability and speed.

Another aspect to consider is your level of sailing experience. If you are a beginner, it is advisable to seek out designs that are easier to handle and forgiving. On the other hand, experienced sailors may gravitate towards performance-oriented designs that are ideal for racing or long-distance cruising.

It is crucial to think about how you intend to use the sailboat. Are you looking for a day sailer , a cruiser , or a racing boat ? Each design comes with its own set of distinctive features and characteristics.

Determining the appropriate size of the sailboat is another crucial step, which should be based on the number of people and activities you plan to have on board. You must also decide whether you prefer an open cockpit or an enclosed cabin .

To find the perfect sailboat design that aligns with your sailing goals and preferences, it is imperative to thoroughly research various options and take into consideration all of these factors. By doing so, you will be able to make an informed decision and select the ideal sailboat design.

Selecting Suitable Plans for Your Skill Level

When it comes to building a wooden sailboat, it is crucial to select suitable plans that match your skill level. This is important as it ensures that you have the necessary knowledge and expertise to effectively complete the construction. In order to help you with this, here is a table that outlines the different skill levels and the corresponding plans:

Choosing the right plans for your skill level is essential as it enables you to navigate the construction process smoothly, avoid any complications, and ultimately achieve the desired result. It is crucial to honestly evaluate your woodworking skills and then select plans that align with your abilities. Keep in mind that building a wooden sailboat demands patience , attention to detail , and a willingness to learn and improve your woodworking skills.

As a pro tip, if you are a beginner, it is advisable to start with simpler plans and gradually work your way up to more complex projects. This allows you to gain experience and confidence in your woodworking abilities over time. So always remember to select suitable plans for your skill level and enjoy the process of building your wooden sailboat.

Gathering the Necessary Materials and Tools

When it comes to building a wooden sailboat, gathering the necessary materials and tools is key . In this section, we’ll dive into the exciting world of selecting and preparing the right wood for your sailboat, as well as the essential tools and equipment you’ll need to bring your project to life. So, start sharpening your creativity and let’s sail away into the realm of wooden boat construction!

Wood Selection and Preparation

Incorporating the provided keywords naturally in the provided text:

1. Conduct research on the different types of wood used in boatbuilding, such as mahogany , teak , or oak . This will help you make an informed decision regarding the most suitable wood for your sailboat.

2. Determine the specific requirements of your sailboat design in order to guide your wood selection process. Each design may have different needs and preferences when it comes to the type of wood to be used.

3. Take into consideration the durability and resistance to rot of the wood options available. This is crucial to ensure the longevity and overall quality of your sailboat. Choosing a wood that can withstand exposure to water and other elements is essential.

4. Look for straight , dry , and defect-free wood. This will contribute to the structural integrity of your sailboat. Any defects or irregularities in the wood may compromise its strength and performance.

5. Calculate the amount of wood needed based on the specific design and measurements of your sailboat. This will help you estimate the quantity of wood required for the construction process.

6. Mill or cut the wood into the required dimensions and shapes as outlined in the sailboat design. This step is crucial for achieving the desired structure and appearance of your sailboat.

7. Prior to assembly, it is important to sand the wood surfaces thoroughly. This will remove any rough edges or splinters, ensuring a smooth and safe finish.

8. Apply a protective coating or sealant to the wood in order to prevent water damage. This will help preserve the wood and extend its lifespan .

By following these steps, you can ensure that the wood selected and prepared for your sailboat construction is suitable and of high quality.

Tools and Equipment Needed for the Project

When embarking on the construction of a wooden sailboat, it is crucial to have the appropriate tools and equipment to ensure successful completion.

To accurately measure and obtain precise alignment and dimensions, essential measuring tools such as a tape measure , combination square , and level are indispensable.

For shaping wooden components, cutting tools like a circular saw or table saw , jigsaw , and hand saw are necessary.

Joinery tools, including a chisel set , mallet or hammer , and drill with different-sized bits, are vital for smoothly joining parts together.

To achieve a polished finish, sanding and finishing tools such as sandpaper with varying grits, sanding blocks , and a random orbital sander are crucial.

Additionally, brushes and rollers are required for the application of finishes.

When it comes to safety, it is imperative to prioritize the use of safety goggles , ear protection , a dust mask , and work gloves to ensure personal protection during the construction process.

When selecting tools and equipment, it is essential to invest in high-quality items that are specifically designed for the tasks involved in wooden sailboat building.

By doing so, not only will efficiency be maximized, but the overall quality of the finished boat will also be greatly enhanced.

Preparing and Assembling the Framework

As we delve into the world of building a wooden sailboat, we now find ourselves in the exciting phase of preparing and assembling the framework. In this section, we’ll discover the essential steps that go into setting up the lofting and laying out the keel , as well as the intricacies of constructing the ribs and hull structure. Get ready to immerse yourself in the hands-on process of bringing this magnificent vessel to life!

Setting Up the Lofting and Laying Out the Keel

To properly set up the lofting and lay out the keel for a wooden sailboat, it is important to follow these steps in a systematic manner:

- Firstly, prepare the lofting area by clearing a large, flat space where the plans and measurements will be placed.

- Next, securely attach the keel stock to the lofting platform, making sure it is both level and aligned with the boat’s centerline.

- Using battens, rulers, and pencils, transfer the measurements and lines from the boat plans onto the lofting platform.

- Ensure the accuracy of the waterlines, buttock lines, and other reference lines on the lofting platform by drawing them according to the measurements provided in the boat plans.

- Utilizing the dimensions indicated in the plans, measure and mark the positions of the keel, stem, and transom on the lofting platform.

- Thoroughly examine and adjust all lines and measurements to guarantee their accuracy.

- Identify the locations where any additional frames, bulkheads, or structural elements will connect to the keel, by marking them accordingly.

- Prior to proceeding, double-check all marks and measurements to ensure their accuracy.

The process of setting up the lofting and laying out the keel is an integral step in the construction of a wooden sailboat. It serves as the foundation and reference points for the boat’s overall structure. It is crucial to pay close attention to detail and maintain accuracy throughout the build. By following these steps, you will be on your way to constructing your very own wooden sailboat.

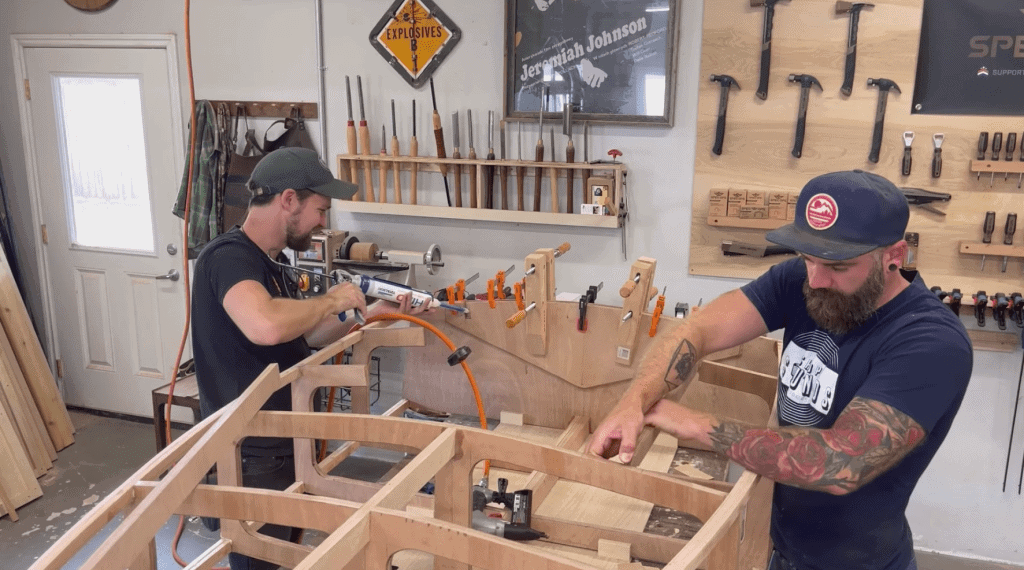

Constructing the Ribs and Hull Structure

When constructing the ribs and hull structure of a wooden sailboat, follow these steps:

– Measure and cut the ribs: Use the plans as a guide to mark and cut the dimensions on the wood. Cut the ribs accurately.

– Attach the ribs to the keel: Position and attach the cut ribs evenly along the keel using marine epoxy and screws.

– Install chines and stringers: Attach the chines to the bottom edge of the boat and install the stringers along the sides for strength.

– Attach the planking: Cut and fit planks to cover the rib and stringer structure, securing them tightly.

– Reinforce the joints: Apply epoxy and fiberglass tape over the joints to strengthen the structure.

– Shape the hull: Use tools to shape and smooth the hull, paying attention to fairing for optimal hydrodynamics.

– Apply a protective finish: Coat the hull and ribs with marine-grade varnish or epoxy for durability.

– Perform a thorough inspection: Check for defects, cracks, or imperfections and make necessary repairs before moving forward.

The process of constructing wooden sailboats has evolved over time, combining traditional techniques with modern materials and tools. Craftsmanship, attention to detail, and an understanding of wood’s properties are still essential in constructing the ribs and hull structure. This blend of artistry and engineering ensures sailboats can withstand the demands of the sea while providing a smooth and enjoyable sailing experience.

Building the Deck and Cabin

Let’s dive into the exciting world of building a wooden sailboat! In this section, we’ll focus on the crucial element of constructing the deck and cabin. Get ready to explore the process of creating the deck framework and adding those essential interior features . From laying the foundation to crafting a cozy cabin space , we’ll uncover the key steps and considerations for bringing your wooden sailboat to life. So, grab your tools and let’s set sail on this exhilarating construction journey !

Creating the Deck Framework

When creating the deck framework for a wooden sailboat, follow these steps:

- Measure and mark the desired deck size and shape on the boat’s frame.

- Cut and shape the wooden planks or panels to match the marked measurements.

- Align the planks or panels horizontally across the frame, ensuring they are straight and evenly spaced.

- Secure the planks or panels to the frame using screws or nails, ensuring tight fastening.

- Add additional support beams or joists underneath the deck for added strength and stability.

- Sand the deck surface to create a smooth and even finish.

- Apply a weather-resistant sealant or paint to protect the deck from moisture and UV damage.

- Install necessary features or fixtures on the deck, such as hatches, cleats or railings.

Pro-tip: Enhance the deck’s strength and durability by adding epoxy or marine adhesive between the joints before securing the planks or panels.

Installing the Cabin and Interior Features

When building a wooden sailboat, it is important to pay attention to every step, including the installation of the cabin and interior features. To install these features, follow the following steps:

1. First, measure and cut the materials for the cabin walls, floor, and ceiling.

2. Next, securely fit the cabin walls in place.

3. Then, attach the floorboards to the cabin base using screws or nails.

4. Align and install the cabin ceiling.

5. If desired, add insulation for extra comfort.

6. Attach interior features such as cabinets, storage compartments, and seating areas.

7. Install windows and hatches to allow for natural light and ventilation.

8. Properly wire the cabin for electricity, ensuring that lights and outlets are installed and functioning.

9. Finish the interior by sanding and applying a protective coat of varnish or paint.

10. Ensure that all installations meet safety standards.

Precision and attention to detail are key when installing the cabin and interior features of a wooden sailboat. By carefully measuring, cutting, and fitting each component, you can ensure a secure fit. It is important to optimize the layout and functionality of the interior features to create a comfortable living space with ample storage. The addition of windows and hatches will enhance comfort and enjoyment by providing natural light and ventilation . If electricity is needed, proper wiring is essential to ensure necessary lighting and power outlets. Finishing the interior with a protective coat of varnish or paint will not only enhance aesthetics but also provide durability.

Remember, the goal is to create a cozy retreat for sailors, so it is important to put in the necessary effort to install the cabin and interior features correctly.

Installing the Sails and Rigging

Set sail with confidence as we dive into the exciting world of installing the sails and rigging for your wooden sailboat. Discover the key considerations in choosing the perfect sails and master the art of setting up and adjusting the rigging. With expert tips and tricks , this section will equip you with the knowledge to navigate the waters with ease and experience the thrill of sailing your wooden masterpiece .

Choosing the Right Sails

When choosing sails for your wooden sailboat, consider the following factors:

– Type of sailing: Determine if you plan to cruise , race , or do both. Different sails are designed for specific purposes.

– Boat size: The size of your sailboat determines the size and number of sails you need. Larger boats require bigger sails , while smaller boats may need fewer and smaller sails .

– Wind conditions: Consider the typical wind conditions in your sailing areas. Different sails perform better in light winds , heavy winds , or various wind conditions.

– Sail material: The material of the sails affects durability and performance. Material choices include Dacron , laminate , and nylon . Each material has different trade-offs between longevity, performance, and cost.

– Reefing options: If you sail in varied or unpredictable wind conditions, choose sails with reefing options. Reefing allows you to adjust the sail area for stronger winds, improving control and safety.

– Manufacturer reputation: Research sail manufacturers for their reputation and reliability. Read reviews, seek recommendations, and consider warranty and customer support.

By considering these factors, you can make an informed decision when choosing sails for your wooden sailboat. Remember, the right sails greatly impact your sailing experience, so take your time and choose wisely.

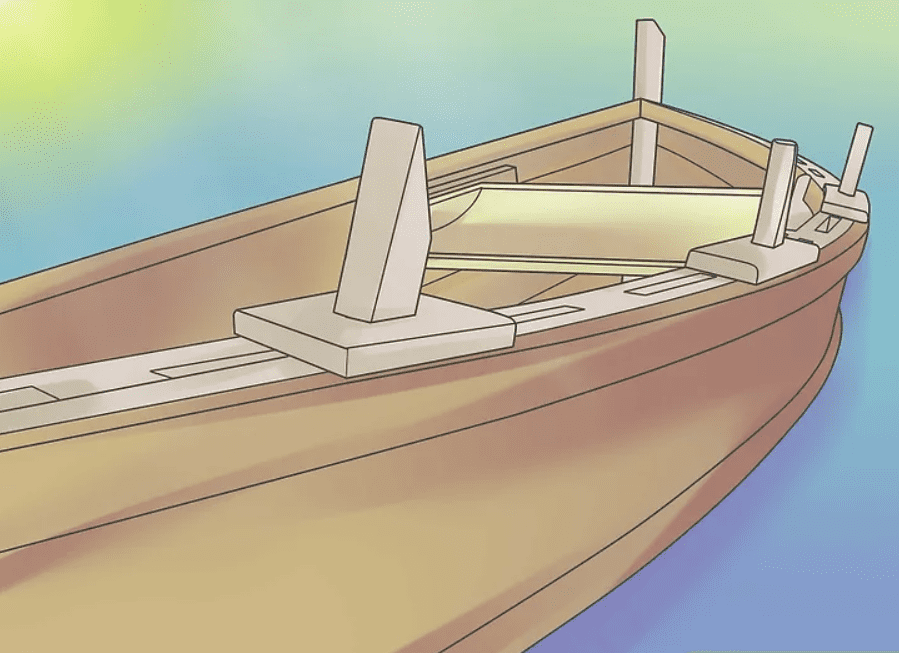

Setting Up and Adjusting the Rigging

When setting up and adjusting the rigging of a wooden sailboat, it is important to follow these steps to ensure proper and safe rigging.

To start, attach the mast to the deck using a mast step or mast partner for stability and support. This will provide the foundation for the rigging.

Next, secure the standing rigging , which includes the shrouds and stays , to the mast. This will help distribute the forces from the sails and ensure the stability of the mast.

Connect the forestay to the bow of the sailboat. This will keep the mast in line and control the position of the headsail.

To counteract forces from the headsail and maintain rigging tension, attach the backstay to the stern of the boat.

Use turnbuckles or rigging screws to adjust the tension in the standing rigging. This will ensure proper alignment and support of the mast.

Install the running rigging , including halyards and sheets , to control the position and tension of the sails.

Before and during sailing, it is important to regularly check the tension in the rigging to ensure performance and safety.

Make any necessary adjustments to the rigging during sailing in order to optimize the shape of the sails and enhance the performance of the boat.

By following these steps, you will be able to properly set up and adjust the rigging of your wooden sailboat, allowing for safe and enjoyable sailing experiences.

Finishing Touches and Maintenance

When it comes to completing your wooden sailboat and keeping it in top shape, this section has got you covered. We’ll dive into the art of applying exquisite finishes to the hull and deck, giving your sailboat a stunning appearance. And don’t worry, we won’t neglect the nitty-gritty details of regular maintenance and care, ensuring your wooden vessel remains seaworthy for years to come. So, let’s get ready to add those finishing touches and keep your sailboat sailing smoothly !

Applying Finishes to the Hull and Deck

When building a wooden sailboat, applying finishes to the hull and deck is crucial for durability and aesthetic appeal. Here are the steps to follow:

1. Prepare the surfaces: Sand down rough spots, fill in cracks and imperfections, and ensure a smooth and clean surface.

2. Choose the right finish: Consider the type of wood and desired look. Varnish provides a glossy and traditional appearance, while paint offers different colors and styles.

3. Apply the primer: Enhance adherence and create an even surface for the final coat by applying a primer.

4. Apply the finish: Use a brush or roller to apply the chosen finish coat to the hull and deck. Follow the manufacturer’s instructions for drying times and application techniques.

5. Allow for drying and curing: Follow the manufacturer’s instructions for drying and curing to ensure the finish is fully set and provides maximum protection.

6. Inspect and touch up: After drying, inspect the hull and deck for missed spots or imperfections. Touch up any areas that require additional finish for a seamless and polished look.

By following these steps and applying finishes properly, you can protect and enhance the hull and deck of your wooden sailboat, ensuring it looks beautiful and lasts for many years.

Regular Maintenance and Care for Your Wooden Sailboat

Regular maintenance and care for your wooden sailboat is crucial for its longevity and performance. Here are the steps to follow:

1. Inspect the hull and deck for damage like cracks or rot. Promptly repair any issues to prevent further damage.

2. Clean the boat regularly with mild detergent and freshwater to remove dirt, salt, and grime that can accumulate over time.

3. Apply a protective coating to the hull and deck using marine-grade varnish or paint to prevent water penetration and protect against UV damage.

4. Check the rigging and sails for wear or damage. Replace worn-out lines or rigging components for safe sailing.

5. Inspect wooden components such as the mast, boom, and rudder for rot or decay. Replace or repair as necessary to maintain structural integrity.

6. Keep the interior of the sailboat clean and dry to prevent mold and mildew growth. Use a dehumidifier if needed.

7. Regularly check and maintain the boat’s systems , including electrical, plumbing, and navigation equipment. Address any issues promptly.

8. Store the wooden sailboat in a suitable location, such as a covered boat dock or boatyard, when not in use. Protect it from extreme weather conditions.

Pro-tip: Establish a regular maintenance schedule and keep a detailed record of all maintenance and repairs. This will help you stay organized and ensure your wooden sailboat remains in optimal condition.

Some Facts About How To Build A Wooden Sailboat:

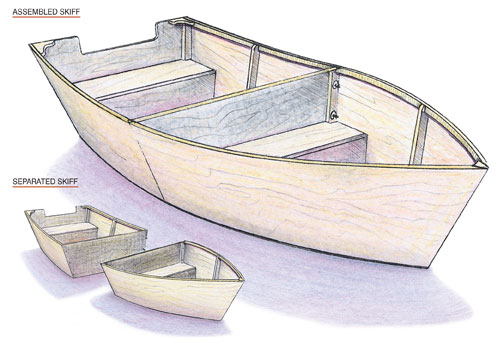

- ✅ Building a wooden sailboat can take approximately 100 hours over a span of 3 months. (Source: Instructables)

- ✅ A wooden sailboat can cost around $1,000 to build. (Source: Instructables)

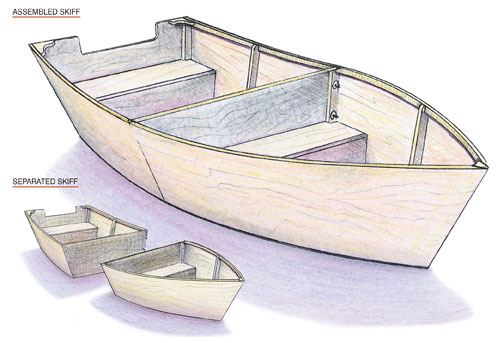

- ✅ The boat is typically built from 4×8 sheets of plywood and measures 8 feet in length. (Source: Instructables)

- ✅ Various tools such as a pull-saw, table saw, router, sander, and drill are needed for building a wooden sailboat. (Source: Instructables)

- ✅ Fiberglass cloth, epoxy resin, screws, and other materials are used to reinforce and waterproof the wooden sailboat. (Source: Instructables)

Frequently Asked Questions

1. how long does it take to build a wooden sailboat.

Building a wooden sailboat typically takes about 100 hours spread over approximately 3 months.

2. What materials are needed to build a wooden sailboat?

To build a wooden sailboat, you will need 4×8 sheets of plywood, epoxy resin, oak plywood, various tools (such as a pull-saw, table saw, router, etc.), fiberglass cloth, screws, fasteners, and other supplies like glue, clamps, and mixing cups.

3. How much does it cost to build a wooden sailboat?

The estimated cost of building a wooden sailboat is around $1,000, including the materials and tools needed for the project.

4. Can I learn to build a wooden sailboat if I have no prior experience?

Yes, building skills can be learned gradually, and mistakes can be avoided along the way. With patience and guidance from boat building plans, even beginners can successfully build a wooden sailboat.

5. How long is the wooden sailboat described in the reference?

The wooden sailboat described in the reference is an 8-foot long pram, featuring classic lines and made from 4×8 sheets of plywood.

6. Can I launch the wooden sailboat in any body of water?

Yes, the wooden sailboat is designed to be light enough to fit in a small pickup truck or be rolled to a local lake on a dolly, making it suitable for various bodies of water.

About the author

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Latest posts

The history of sailing – from ancient times to modern adventures

History of Sailing Sailing is a time-honored tradition that has evolved over millennia, from its humble beginnings as a means of transportation to a beloved modern-day recreational activity. The history of sailing is a fascinating journey that spans cultures and centuries, rich in innovation and adventure. In this article, we’ll explore the remarkable evolution of…

Sailing Solo: Adventures and Challenges of Single-Handed Sailing

Solo Sailing Sailing has always been a pursuit of freedom, adventure, and self-discovery. While sailing with a crew is a fantastic experience, there’s a unique allure to sailing solo – just you, the wind, and the open sea. Single-handed sailing, as it’s often called, is a journey of self-reliance, resilience, and the ultimate test of…

Sustainable Sailing: Eco-Friendly Practices on the boat

Eco Friendly Sailing Sailing is an exhilarating and timeless way to explore the beauty of the open water, but it’s important to remember that our oceans and environment need our protection. Sustainable sailing, which involves eco-friendly practices and mindful decision-making, allows sailors to enjoy their adventures while minimizing their impact on the environment. In this…

How to Build a Boat

Classic boat plans from a 1937 issue of Popular Mechanics , updated for the 21st century.

It was a long time since anyone in my family had built a boat. The last was my Uncle Paul. He was a shipbuilder who learned his trade beginning at age 14 in Hamburg, Germany. Every morning, the boy rowed from the family's dock out across the shipping lanes of the Elbe River, which flows into the North Sea.

The trip to the shipyard where he was apprenticed took an hour and a half, longer in winter, when there was fog and floating ice on the water. After three years, Paul received a journeyman's certificate and a berth aboard a gigantic four-masted windjammer named Passat—"trade wind" in English. That was in the 1920s, before the fascists confiscated his family's own small shipyard and the Berendsohns left for America.

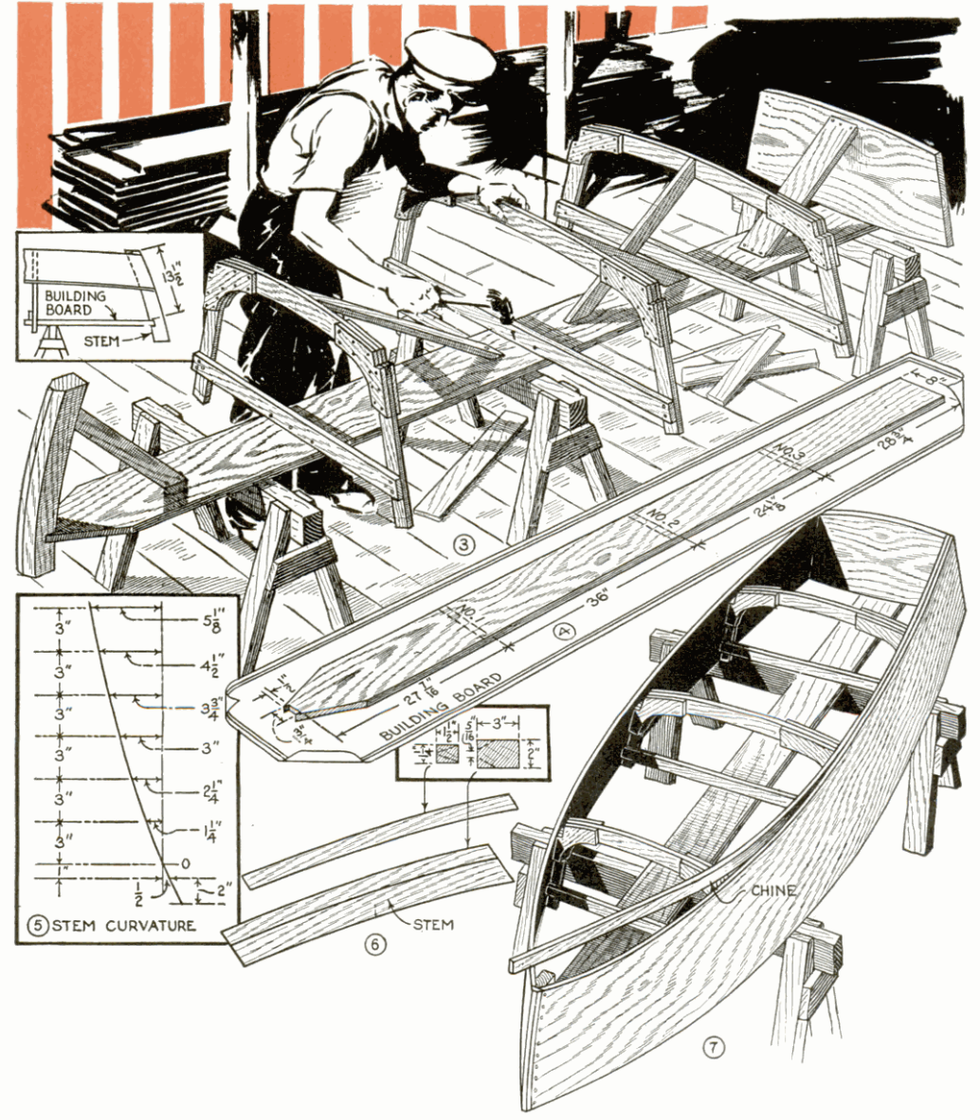

A few months ago, I decided to try my hand at the ancestral trade. I've built everything from houses to a blacksmith's forge , but there's no more evocative project than a boat, at least to me. Since before Austronesians first gazed across the Pacific, wooden vessels have stood for craftsmanship and the drive to explore. I sifted through PM's archives looking for a classic design and eventually settled on a 10-foot dinghy from our May 1937 issue . It looked elegant, yet simple enough to build on a pair of sawhorses.

It's been many years since my Uncle Paul was around to lend advice, so I ran the drawings past Timo White, a boatbuilder at Tuckerton Seaport, a small maritime museum on the New Jersey coast. It turned out that Timo was in the midst of restoring a surfboard built from plans in the July 1937 issue of PM. (It was a big year for seafaring projects, I guess.)

He confirmed that the dinghy was a good candidate for a first-time builder and agreed to lend a hand if needed.

Shipyard in the Driveway

On a wintry early spring morning I set out for Willard Brothers Woodcutters, a sawmill and lumber dealer in Trenton, N.J. You can spend hours there, roaming stacks of delicious-looking walnut, cherry and oak, some of the boards as wide as your arm is long. I bought red oak for the Sea Scout's frames (that was the name of the craft in the plans, and I chose to keep it) and a 2-inch-thick slab of white oak for the wedge-shaped stem at the bow.

Back home, I started making a racket feeding planks through a table saw. My skills were creaky--I've spent too much time in recent years fixing stuff and not enough building--but over a few days my old confidence returned. The Sea Scout began to take form.

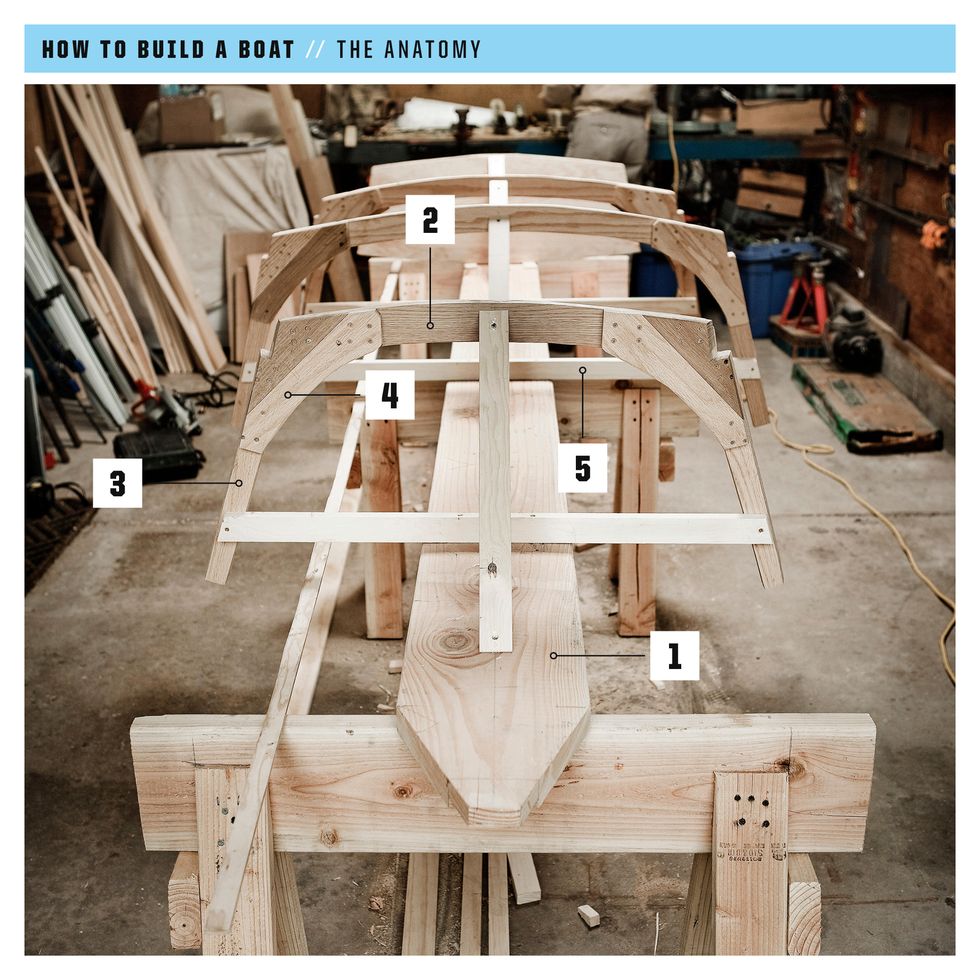

Most boats begin with the frames, the ribs that provide structure to the hull. I roughed them into shape, along with the stem and the gracefully shaped stern wall, or transom, which I cut from ¾-inch plywood. Then I braced it all to a building board--which is nothing more than a 2 x 10 with a chalk line marked down the center.

⚠️ To simplify the project, I omitted the mast and centerboard. Instead, I built the Sea Scout, named after the craft in the original article, to be rowed or powered by an outboard motor. She works well in either configuration. You can find the original plans and materials list here.

The boat's skeleton was in place, but each member still needed to be precisely beveled before I could secure the curved planks of the hull. The next step was to clamp thin strips of wood, called battens, to the frame to stand in for the planks, so I could measure and mark all those angles. Then, I took the parts off the board and finished shaping them.

Often, the weather confined me to the garage, but when the sun emerged I worked in the driveway. If you want to get to know the neighbors, start building a boat. Linda from next door asked whether the craft would be sailed, rowed or powered by an outboard motor. Others wondered where I would go with it, how I'd get it there and what I would name it. A truck driver from Tulnoy Lumber, dropping off some marine plywood, approached respectfully. "This is beautiful," he said, with an old-fashioned New York accent as broad as the hand he ran over the frames.

Anatomy of a Boat

Working the Plank

I don't know how Uncle Paul felt about it, but boatbuilding can be acutely frustrating. The bane of my weekends proved to be a small bronze screw. A No. 6 Frearson flat-head, to be exact. Like most modern DIYers, I'd been spoiled by drywall screws and other aggressive fasteners that practically plow into the lumber. Even using a specialized, tapered drill bit and a waxlike lubricant with the unlikely name of Akempucky, I managed to wreck screws by the dozen. The head on one would strip a moment before the screw was fully seated, while another would shear off on the last eighth of a turn, leaving me with a shiny Frearson-head penny.

Timo had tried to downplay the arcana I'd face--"It's more like house carpentry than fine-furniture building," he had said--but I still found myself floundering on occasion. One challenge was that the 1937 article was more an overview than a detailed set of plans. And, though it pains me to find fault with my forebears at Popular Mechanics, the sketch contained suspicious discrepancies. Timo helped me recalibrate some of the dimensions midway through the project—and I had to trim several pieces after they were assembled.

The biggest hurdle came when it was time to plank the hull. The classic way is to bend strips of solid wood to the frames. I'd chosen marine-grade fir plywood instead to save time, but now I was barely able to force the hull's 14-inch sheets into place. There was no way the half-inch plywood I'd planned for the bottom was going to work.

Timo advised me to switch to a special, wafer-thin marine-grade plywood and plank the bottom in two layers. He came swooping in one Thursday morning to show me the technique. He stepped out of his truck with a broad smile, and a block plane in each hand, and my mood lifted. He politely took a sighting down the chine logs where we'd attach the bottom, and spent a few minutes planing them to the last measure of precision. Then we got to work with staples, glue and screws--and in a couple of hours the project went from a plywood flower bed to a small craft with sensuous compound curves.

It was satisfying, but my mistakes still showed in details like the placement of screws and the shape of the stem. "You know what they say," Timo told me. "Putty and paint makes a boat what it ain't." I got out my paintbrushes.

Maiden Voyage

We launched the boat at Tuckerton Seaport on a cool, overcast day that felt more like September than June. Down at the dock, Timo produced a can of Amstel Light in lieu of champagne. "Go ahead," he said, "pour it over the bow." I popped it open and emptied the beer over the paint. "I christen thee Sea Scout," I said. Then we slid the little craft off the dock and into the water.

You might think a feeling of triumph came over me. Not so. The Sea Scout looked very small, almost helpless, as she sat bobbing at the end of the painter, the little rope that Timo had threaded across the bow. I felt humbled. A phrase from the Book of Psalms flashed in my mind: "They that go down to the sea in ships, that do business on great waters."

I wasn't aiming for any great waters myself. I eased off the dock and into the boat. Timo handed me the oars. Awkwardly, I drew the handles back, just above my hips. The craft slid forward gracefully, almost like she was on ice. As Timo watched, I braced the left oar down in the water and swept the surface with the right. The Sea Scout pivoted neatly, unexpectedly elegant and spry.

If the oars were a kick, you can imagine the thrill I felt when I mounted the 2.5-hp Mercury Marine outboard on the transom. It's a clean-running four-stroke engine, compact yet almost zippy on a boat this small. I gave the engine full throttle and cut some nice straight lines and a pleasingly tight curve complete with a crisp little wake.

With the afternoon gone, my first voyage was complete. In the end, I decided to donate the boat and engine to Tuckerton Seaport. Frankly, I needed the space in my garage and driveway: The Sea Scout was a good first foray into wooden boatbuilding, but I knew I could do better—and I'm already sifting through plans.

The Sea Scout, a Decade Later

Ask anybody who’s ever built a boat, and they’ll tell you one thing about it: you’re not the same after you’ve built one. And that goes for me, too. The little boat, which I built back in 2009, shaped me as much—or perhaps more—than I shaped it.

The Sea Scout project brought a flood of mail from our readers, some of whom had built the boat or knew someone who did. One woman still had the boat that her father built. She sent a picture of it and recalled the many pleasant hours she spent with her dad as her father taught her how to sail in it. She kindly offered to donate the boat to us, thinking that perhaps we could put it in our lobby. I wish I could have taken her up on the offer.

When you build a boat, you take your place in the long line of craftspeople—professional and amateurs alike—who have plied that trade and learned about the unique burden of building a craft upon whom someone’s safety and enjoyment will depend. Building a boat is humbling, you remember every mistake you made building the thing as it bobs up and down, and waves wash over its bow or crash into it from the side.

You feel it shudder, but it doesn’t give way as you look over the side at the murky depths. And afterward, you look at every boat with a more knowing eye, a greater respect...and you wonder if you could build it.

Roy Berendsohn has worked for more than 25 years at Popular Mechanics, where he has written on carpentry, masonry, painting, plumbing, electrical, woodworking, blacksmithing, welding, lawn care, chainsaw use, and outdoor power equipment. When he’s not working on his own house, he volunteers with Sovereign Grace Church doing home repair for families in rural, suburban and urban locations throughout central and southern New Jersey.

.css-cuqpxl:before{padding-right:0.3125rem;content:'//';display:inline;} Pop Mech Pro .css-xtujxj:before{padding-left:0.3125rem;content:'//';display:inline;}

Can AI Help Solve Math’s Thorniest Mysteries?

You Can Give Your Body Back to Nature When You Die

The History of Pi

Why the Bobcat Is Such a Badass Job-Site Machine

Can Smokejumpers Still Protect a World on Fire?

Stand-by Power: Eco Flow’s Smart Home Panel 2

Stop Wasting Lubricant

How Does UFO Footage Play Tricks on Your Mind?

Why Doesn’t the Living Human Body ‘Go Bad’?

Dealing With a Stuck Door Hinge Pin

Get to Know the Marines’ Favorite Ride

Affordable Sailboats You Can Build at Home

Last Updated by

Daniel Wade

September 13, 2023

Key Takeaways

- There are many sailboats that anyone can build from home depending on tastes

- Budget will be the biggest deciding factor on a majority of the process

- Consider kits that come with most of what you need or choose ones that are all-inclusive

- Design complexities and new materials may make the building time process longer

- Plan the best you can ahead of time to save money and your working hours

Buying a sailboat can be expensive, but building your own can save you money. So what are sailboats you can build from home?

Sailboats that you can build from home will likely be a small boat under 20 feet. These could be from many different boat suppliers such as B&B Yachts, Brooks Boat Designs, and Chase Small Craft. Boat plans will vary based on your budget and how much time you have on your hands.

Based on my previous experience, building your own boat will take much longer than if a professional were to do it. You also have to be able to study plans, consider various sailboat designs, and have tons of supplies such as fiberglass tape or fiberglass cloth. On top of that, you will also have to be good with your hands.

Table of contents

Top 10 Affordable Sailboats Anyone Can Build at Home

Building your own pocket cruiser or other styles from boat plans is an impressive feat, as this will need dedicated time and money to assure your boat sails safely. Boat building takes a lot of patience as well, especially since this will not be completed in a fast manner.

Finding boat plans and materials that fit your budget will be key to being able to complete the project. The time it takes to complete these projects will vary on your overall experience and needs. Below are 10 of the most affordable sailboats that you can build in the comfort of your home.

B&B Yachts

B&B Yachts have 14 different boat plans you can choose from to find the boat of your desires. Their shop is located along the Bay River in North Carolina where they construct all of the kits and have a 100 foot dock to show off your project once you complete it.

One popular model to check out is their Core Sound 15, as it is the perfect size for those wanting to build a modest size boat for a handful of people on board. Their website features some videos of completed projects and the plans or kits for purchase.

- 14 different models to choose from plus some dinghies

- Various monohull and multihull options

- Friendly customer service with attractive prices

- Might be too many options for some that are indecisive

- Not ideal for those wanting to have a motor sailer

Brooks Boat Designs

Brooks Boat Designs has a handful of options to consider for your next sailboat building project. They are located in Brookline, Maine and give the option to buy the kits or have them build one from scratch for you. They have plenty of knowledge, so do not be shy to ask about modifications or custom features you are looking for.

Depending on your specifics, they can attempt to accommodate some of their plans to help fit your desired outcome. By checking out their site, you can see many examples of their construction in progress and what the boats will look like when completed.

- Offers a variety of kits

- Plans vary around $50 and up, while materials will obviously add more costs

- Some plans can be rowing boats that can convert to sailboats

- Might take a while to hear back from them, as their contact section is a little outdated

- Their plans may not accommodate a ton of extras for your taste

Chase Small Craft

Chase Small Craft offers a simple process for building boats. Their kits are equipped with everything you need and will help save you time than just buying the materials outright and other parts you could need. This is arguably one of the best bang for buck instances if you want to save time and money searching for pieces to your boat.

They are located in Saco, Maine and will ship everything to your home from there. All the necessary materials are included and all you need are the proper tools and working space.

- All-inclusive kits with what you need

- Tons of knowledge on their site for boat building

- Easy process to order and customize

- Complete kits can range over $20,000 for larger boats

- Kits may take up to eight weeks to ship out

Chesapeake Light Craft

You can expect high-quality boat kits from Chesapeake Light Craft . They feature 18 different sailboat kits that vary from eight to 20 feet in length. This should be more than enough to find one for you if you are newer to boat building.

They also have a wide variety of other kits in addition to the sailboat, in the event that you wanted to order a small kayak or paddleboard in addition to your sailboat. The prices vary considerably when considering a small or larger boat, so check the complete list of options to in order to potentially fit your needs.

- Plenty of sailboat offerings to choose from

- Different beautiful hull form options to consider

- Easy to build and perfect for sailing

- Only has basic materials needed for kit, so you may need to purchase other items

- Has epoxy shipping fee no matter if you pick up item

Dudley Dix Yacht Design

Dudley Dix Yacht Design has an extensive list of plywood and single skin sailing boat options. They have plenty of sail plans and kits to consider depending on your goals. These follow a classic look for sailboats, which are aesthetically pleasing.

If you are wanting one to accommodate a small family, they have more than plenty to look through. The cost is not as bad compared to others, but keep in mind that you may need to throw in your own supplies or specific tools to get the job done.

- Plans start at $30 and range up to $7,500 or more for kits

- More than enough of options to consider

- Affordable variety of sailboat offerings

- Might be too many options for those new to sailing

- Most are wood without the use of aluminum or steel

Farrier Marine

If you are in search of a multihull to build, then Farrier Marine is what you need. They offer a unique folding catamaran that is trailerable and give you the option to build it yourself. This not only makes it an appealing option, but anyone can take this multihull boat wherever they want with ease.

It features a thorough construction guide once you receive all of the materials. These also come with stainless steel fasteners and an aluminum mast for high-quality materials. Pricing will vary since you must request which model type you are considering.

- Ability to build a unique catamaran

- In-depth construction guide to help

- Easily handled and trailerable

- Price may be too high

- Limited offerings since only a few multihull options

Glen-L Marine Designs

Building a boat from Glen-L Marine Designs can save you time and money. They feature an easy system to order and receive the kits, as well as an in-depth guide to building them. This is an appealing option compared to most boat kit sellers.

The beauty about Glen-L is that anyone can build these from scratch, so you do not have to be the best boat builder in the world to get it done. They offer guides and helpful insights from their team to point you in the right direction. Plans vary around $15, while kits can range well over $1,000 depending on boat size.

- Nearly 50 designs to choose from

- Complete guide to help anyone build it

- Plenty of price points depending on size

- Might be overwhelming with the amount of options

- Could take a while to get parts since they are popular

John Welsford Boat Designs

John Welsford Boat Designs invites new and veteran boat builders that want a taste of quality small wooden boats. The boat plans are designed to meet your specifications and are catered to your desires.

There are seven sailboat designs to choose from so you do not feel overwhelmed in the process. However, they do not sell kits all the time, so you would need to have the materials or be on the lookout for the best prices when they are available.

- Seven sailboat plans with different sizes

- Quality boat builder and supporting community

- In-depth knowledge provided to you when you order

- Might be too small of boat size

- Kits are not always available

Iain Oughtred

There are plenty of options on the wooden boat store, but you should narrow down your search for Iain Oughtred’s line of sailboat kits and plans. There are 25 different plans to choose from, which should accommodate most everyone looking to build their own boat.

While they do offer some kits, they do not routinely offer sailboat kits. You would need to purchase all of the materials if you are considering one of their sail plans. Keep this in mind if you are considering, as you would need to hunt down the parts yourself.

- 25 different sailboat plans to look through

- Various sizes to contemplate for you sailing needs

- Prices will vary but are not bad compared to market

- No sailboat kits, only plans

- Newer boat builders might find too many options unappealing

Paul Gartside Boat Builder and Designer

Gartside Boats is a boat builder company based in Long Island, New York that showcases a variety of boats from traditional and newer methods of boat building. Within that variety, they have boat plans meant for six to 50 feet in length.

With an abundance of options, you will need to contact them regarding prices and any customizable options. Kits may vary as well, as they typically design in-house and build for you.

- Experienced boat designer that can accommodate with custom plans

- Many options are trailerable

- Can have plans for up to a 50 foot boat

- You will need to contact them for prices

- Customized options may make process more complicated for new boat builders

How Much Does it Cost to Build a Sailboat at Home?

As you have likely already done so, the math between building your own boat and buying one may be a huge difference. Likewise, you may even enjoy the challenge of taking an older boat that is gutted and restoring with parts from a kit to build one new again.

But how much does it cost exactly to build a boat from the comfort of your own garage or workshop? The prices are going to vary dramatically depending on your situation and material needed to get the job done. In addition, the time that it takes to complete this will also vary.

Sail plans are rather inexpensive if you are aiming to build a small boat. These plans allow you to see the workings of the boat design and what you need to build the boat.

Without these plans, you will not know the exact details of the design and it can cause major issues with the boat’s hull or other areas of the boat. Think of these as the backbone or instructions of the boat’s infancy before being built.

Price Per Square Foot

You should assume to pay anywhere between $300 to $600 per square foot if you are interested in building a boat. Buying a kit outright can be a good way to save time, but oftentimes these do not come with everything you need.

Instead, you should try to source as much of the materials at the best price as possible. Thinking ahead is part of the process and you might be able to score a deal at a lumber yard or hardware store for parts.

Boat Designs Matter

The design of the boat will be much different from one boat to the next, regardless if they are the same size in length. If you are pondering boats that range anywhere between 16 and 20 feet, you should factor in the shape of the hull, any rigging, and various appendages.

Prices tend to increase when there are more complexities within the designs. If you are considering a kit with more details than others, you will also have to pay more for the designs on that as well.

Kits Can Differ

It is important to understand that all kits are not going to be the same. As you gander at sailboat kits online to stitch together, you need to thoroughly look over to see if you have everything you need before buying.

It would also be at your advantage to ask the seller if any additional parts or supplies are needed. This may change your dynamic on the kit buying process and you may pass up one for another if it has everything you need. An all-inclusive kit may cost several hundred, if not thousands, of dollars more to have the convenience of everything in the bundle.

Construction Approaches

Some boat plans may require you to have certain tools to get the job done. This means special saws or planers, which the average person simply does not have.

Purchasing specialty tools might be expensive upfront and hard to find depending on what it is. Your best bet would be to check locally for others trying to sell their tools or consider a boat plan that does not require extensive tools to finish the job.

How Long Does it Take to Build a Sailboat?

An easy to build sailboat could take a while to build from scratch. Many different variances come into play that are difficult to pinpoint for everyone. But how long is that exactly and how will your experience play into this?

A fun project to sail in the wind could take you several months to well over a year depending on the boat plan and how big your boat is going to be. In addition, the materials all need to be accounted for prior to starting in the event a hardware store does not have them in stock.

Time Varies

The time that passes for simple boat designs on small sailing vessels can be done in a few weeks. This is assuming you have everything you need and work non-stop around the clock.

Certain complex situations may make the process long, such as the difficulty of working with some materials. If you are a skilled laborer, it may take you half the time compared to a novice. The amount of time it can take will vary on your availability and skill level.

Planning ahead will undoubtedly offer the most time-saving features. It also helps if you can tackle parts of the project at your own pace.

Complexity of Design

The design of the boat may make the construction process longer. For example, it may take you longer to build a catamaran compared to a similar lengthed monohull.

More complex designs might require more materials, therefore making the process a bit longer to complete. Furthermore, you will also need more experience working with difficult designs and that will affect you more as a newbie.

Be sure to manage your expectations well and do not allow yourself to become too stressed over this fun project. If you can, seek expert boat building advice from a local builder or the company you purchased sail plans through.

Quality Materials

The quality of the materials will matter significantly when building a boat and will greatly affect the time it takes to construct it. Handling fiberglass or carbon fiber might require specialty tools, while wood also demands a certain level of craftsmanship.

If you are not skilled at working with the material at hand, it might affect the quality of the build and you may have to go back to fix mistakes. This will definitely add more time to your project, because mistakes are bound to happen with your first project.

To save time, consider adding the tools and materials throughout the year or as often as your budget allows. You may want to try testing your skills on fiberglass or other materials to get a feel for how to work with it.

Related Articles

I've personally had thousands of questions about sailing and sailboats over the years. As I learn and experience sailing, and the community, I share the answers that work and make sense to me, here on Life of Sailing.

by this author

Best Sailboats

Learn About Sailboats

Most Recent

Best Small Sailboat Ornaments

September 12, 2023

Best Small Sailboats With Standing Headroom

December 28, 2023

Important Legal Info

Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies.

Similar Posts

Discover the Magic of Hydrofoil Sailboats

December 11, 2023

Best Bluewater Sailboats Under $50K

Hunter Sailboats: Are They Built for Bluewater Cruising?

August 29, 2023

Popular Posts

Best Liveaboard Catamaran Sailboats

Can a Novice Sail Around the World?

Elizabeth O'Malley

June 15, 2022

4 Best Electric Outboard Motors

How Long Did It Take The Vikings To Sail To England?

10 Best Sailboat Brands (And Why)

December 20, 2023

7 Best Places To Liveaboard A Sailboat

Get the best sailing content.

Top Rated Posts

Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies. (866) 342-SAIL

© 2024 Life of Sailing Email: [email protected] Address: 11816 Inwood Rd #3024 Dallas, TX 75244 Disclaimer Privacy Policy

- The A.V. Club

- The Takeout

- The Inventory

Meet The DIY Mastermind Building A 74-Foot Sailboat By Hand In His Front Yard

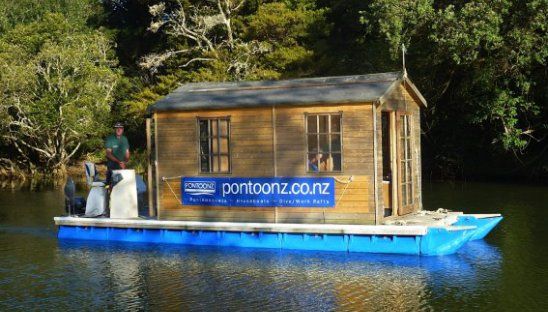

Seeing a boat in someone’s yard is not uncommon. However, when that boat is a 74 foot long, 16 foot wide steel behemoth hand-built from scratch by the owner, it begins to raise eyebrows. Doug Jackson, of Tulsa, Oklahoma has such a boat in his front yard. It’s called SV Seeker, and it’s not something you see every day.

For the past six years Doug has been working to create a boat. It’s the ultimate DIY project which he documents on his YouTube Channel, SV Seeker . He outsources practically nothing. Look at any portion of the boat and you’ll see his work. He even cast his own giant brass propeller .

This isn’t his first vessel either. He built and launched a wooden submarine and began another sub before deciding to build a sailboat.

Doug, and his girlfriend Betsy, have opened their doors to anyone who wants to come and work on the boat. Their gracious hospitality is overwhelming. There is even an apartment on the premises for people who want to stay and work a few nights in a row.

Why did Doug commit his life to building this massive craft? Scientific research, believe it or not. And because he can, because the task itself is like a mountain that demands to be climbed.

Here’s what Doug says on his website about the project:

SV Seeker not just a sailboat. She is certainly not a yacht. She is a work boat. A dream and a tool for making dreams come true. I’ve always wanted to do something grand and daring. Something that filled my passions, not just the hours of my day or a bank account. It started with building submarines, and with confidence it became building Seeker. And when completed I will have every skill I need to keep her in shape, and she will have the strength to take us to the wonders and treasures of the worlds oceans. Seeker will cater to adventurers, explorers, oceanographers, divers, wreck hunters, marine biologists and archaeologists. If you want to be a part, then allow me to welcome you aboard.

And so people from all walks of life make the pilgrimage to Tulsa to lend a hand. Some come just to see the boat in person. The first visitor arrived after driving a motor home all the way from Chicago with his family to volunteer.

Doug purchased his property for just $1500. When I asked him how, he told me a story about how he smiled pretty and talked sweetly and ended up paying twice what the lady wanted for it. Since purchasing it, he made improvements including remodeling the house, building a shop and an enclosed courtyard.

Doug’s life is built around the boat project. His home is modest but comfortable. Essentially, it’s one room with a bathroom and kitchen. The shop he built is actually larger than his house. Out back there’s a shed. In the front yard there’s a school bus body used for storage and, oh yeah, an enormous ocean-going sailboat. Photographs just don’t do it justice. It’s immense.

My fascination with the project began a couple years ago when I saw my first SV Seeker video. I saw a guy, Doug, welding together enormous sheets of quarter-inch steel plate to create the hull of a boat that would be more than 70 feet long when completed.

Building a boat of this magnitude on your own is a feat most people wouldn’t even consider possible. Since then I’ve followed the progress of the boat as Doug published each new episode.

I set out to find out what makes Doug tick. I contacted him to arrange a weekend to come up and work on the boat and then made the four-hour trek to Tulsa. Once there, I made my way through town and took a left down a sedate street. As I did I caught my first glimpse of the boat looming up from behind the other homes.

I saw a pair of huge gantries more suited to a dockyard than a residential neighborhood. And nestled beneath them is the SV Seeker, a hulking, rusty hulk adorned with twinkling Christmas lights.

Upon entering the gate and a thorough sniffing by the dogs, I was dwarfed by the bow towering above me, completely dominating the front yard of Doug’s home.

I was giddy with excitement. It was so surreal to finally see the boat in person. Not simply because I’d only seen it on YouTube, but because it’s a towering boat planted in the middle of a neighborhood.

That’s a full-size school bus sitting next to the boat.

I unceremoniously hustled up the aluminum ladder and immediately went to work with a pneumatic impact wrench in the belly of the boat. We were bolting down a hatch to prevent the rain from falling in. It wasn’t long before I was stuffed to capacity with pizza and Buffalo wings. Then it was back to work.

The rest of the weekend was spent working and talking with Doug. We welded and did a lot of grinding on deck. You can see his video featuring yours truly here . When Sunday rolled around and we sat down for a formal interview, I found most of my questions were already answered.

I asked how he has stayed so committed to one goal for so long. He said that within the span of your life you can build huge things if you’ll only commit to them. But how do you stay so committed?

When I asked him whether he ever considers not finishing the boat, his short answer was no.

He went on to say, “I would consider switching it for something better... Failure is always an option, I’m the king of failure. I love doing what I’m doing, but what I’m doing it on doesn’t particularly matter.”

Doug describes his project as “the boat the Internet built.” There’s a whole community of people online who want to see him succeed.

With such a big project there is always something to do whether it’s welding, grinding, or preparing to cast port lids. Orchestrating such a big build must be a feat in planning and organization, right? Well, to a degree it is, but mostly Doug allows the project dictate what happens next. He lets it happen organically. He tried to make a list once but he never went back to look at it.

You can’t make a steering wheel until you’ve made the rudder and all the pieces in between and you can’t fill your keels with lead until you’ve made them. This seems to be the way Doug is living his life. He forges ahead based on what knowledge is available now, and just has faith the answers will become clear the closer he gets to them.

Building the boat has convinced him that people worry unnecessarily. Making an excuse, or thinking of a reason not to do something, is easier than taking action. Doug watches no TV; he doesn’t read the newspaper and he preferred conversation to radio while we were riding in the car.

Doug suffers from dyslexia, which makes reading long texts difficult. And in the late 1980s, he found out he had a heart murmur after joining the Army. If Doug allowed himself to use these setbacks as excuses, he never would have picked up a welder to begin this project.

Even though the boat seems like a monument to a singular vision, Doug says his end goal is flexible. He doesn’t see the end of his project as merely completing the sailboat. He wants to provide a platform for conducting marine research for little or no cost. He isn’t just building a boat. He’s building a career for himself and he’s building opportunities for researchers who may not have the opportunity to go to sea otherwise.

There’s a picture on the wall in his house that says, “wear your passion.” I guess that explains the rather large tattoo of his boat on his forearm.

What makes Doug tick? The best I can come up with is that he possesses an irrepressible desire to eliminate excuses and fears that would otherwise control him and keep him from achieving his goal. He’s not scared to dream big.

I see Doug as a guy who chose live by his own rules. He isn’t grasping for that next rung. He’s not trying like hell to move up into the next social class, or give the appearance of having money. He has liberated himself from all that, and by doing so has aligned his priorities in a way that seems totally uncommon. He hopes his build will inspire more people to take on projects of a similar magnitude.

What he does have in indefatigable faith in himself to complete his goals. He has chosen to define his own criteria for success. SV Seeker is a concrete manifestation of one man’s will, a man who has taken the helm of his life firmly in both hands and stayed the course, whatever storms may come be damned.

Two years ago Aaron Vick Starnes quit his well-paying bank job to grind it out as an automotive writer. He has experience in automotive restoration, and works at a shop restoring and customizing cars. Follow him on Twitter at @AaronVStarnes and check out his blog .

- Activities for Kids

- Arts & Crafts

How to Build & Float Your Own Mini Sailboat

Crafting and outdoor exploration come together with this project—learn how to build a boat that floats and sails. The best part? You’ll only need to buy a couple of supplies because the main part of this barge is made from sticks that you find outside. Read on for the step-by-step instructions and you’ll soon have a ship to sail the high seas (or slow streams).

What You’ll Need

1 piece of paper (patterned scrapbook paper is nice, but plain construction paper also works)

2 craft sticks

string or twine

hot glue gun

14 sticks in similar sizes (5-6 inches long works well)

How to Make the Boat

1. Start by wrapping 12 the sticks together with your twine. We used Kid Made Modern Craft Twine ( target.com , $9.99) to add a pop of color, but white string would also work just fine. Tie one end of the twine to the end of one stick and wrap the string around a few more times, then move on to the next stick. Wrap the twine around that stick a few times and then use the same piece of twine to wrap the third stick and so on and so on until 12 of your sticks are connected. (You’ll use two elsewhere.) Don’t worry too much about how many times you loop around or how perfect your wrapping is. Knot off the twine on the last stick. Then, do the same thing on the opposite side of your sticks.

2. Wrap two sticks onto the bottom. Now add two more sticks, one on each end of your boat, to the bottom of your group of sticks. Again, tie a knot on one end of the stick then weave your twine in and out of the connected sticks, looping the twine around each stick and then around the stick on the bottom. Repeat for the second stick.

3. Cut 2 triangles out of your paper. Ours measured 5-inches along the side and bottom, but you may want to adjust based on the length of your sticks. We used Kid Made Modern Print Palooza patterned paper ( target.com , $7.99 for 150 sheets). However, if you have plain construction paper, ask your child to decorate it with stickers, crayons, markers, or any other way you like.

4. Add the craft sticks as your mast. Line up the craft sticks along the edge of the triangle to create your mast. Use a hot glue to secure the craft sticks.

5. Glue the triangles together. Ask your child to cover the two triangles with glue, using the glue stick. Then, press them together to complete your sail.

6. Connect the sail to the raft. Slip the craft stick in between two of the sticks in the middle of your boat. Use a piece of twine to wrap around the craft stick and around the two middle sticks until it feels fairly secure. To give it extra support, add hot glue all around the area where the craft stick and twigs come together.

7. Sail your boat. Once the glue has cooled and dried, your craft is ready for its first voyage. Fill a baby pool or other vessel (even the bath tub!) with water and watch your homemade schooner float.

8. Create some wind. Want to get your boat moving faster? Use a straw to blow it across the water.

9. Take it to the park. For further experimentation, we took our model to the park so it could sail in a real stream. Even after several sails and a few capsizes, our sailboat has held up.

Happy sailing!

Project inspired by Minieco’s handmade boats .

Have you crafted any boats with your kid? Tell us about your design in a comment.

–Julie Seguss

Need some fresh ideas?

Subscribe to our weekly newsletter for expert parenting tips and simple solutions that make life instantly better.

By subscribing you agree to Tinybeans Terms and Privacy Policy

Related reads

Why Are Gen Z Kids Covering Their Noses in Family Photos?

Screen Time for Babies Linked to Sensory Differences in Toddlerhood, Study Shows

Kids Shouldn’t Have to Finish Dinner to Get Dessert, Dietitian Explains

The Questions Parents Should Be Asking Their Pediatrician—but Aren’t

6 Better Phrases to Say Instead of ‘Be Careful’ When Kids Are Taking Risks

- your daily dose

- and connection

- Your daily dose

DIY Driftwood Sailboats

. I’ve been wanting to make driftwood sailboats for quite some time and finally I did it this week … three of them. This craft project has been formulating in my mind for awhile. I’ve combined bits and pieces of ideas from other driftwood sailboats I’ve seen in magazines, Pinterest, and at some retail stores to make these. The two steps during the process that took the most time and tested my patience were working with tiny eyelets and eyelet screws. Do not skip these steps because they gave the sailboats a clean finish. Last thing, there will be no sewing involve in this project.

The driftwood I used were collected during our recent family trip to the beach at Seabrook, Washington, click here to read more.

1. fabric pieces, slightly heavy weight fabric will hold its shape best for the sails 2. twine 3. wood glue 4. stop fabric fraying liquid 5. glue gun & glue sticks 6. paper to make sail patterns 7. eyelet screws, 15/32″ 8. eyelet tools & 1/8″ eyelets 9. scissors 10. two driftwood pieces for the boat and a mast

Instructions

step 1. Drill a hole in the center of the driftwood large enough to accommodate a long stick for the mast. Squeeze wood glue into the hole and push the stick in it and let dry.

Step 2. Use a pencil to draw the pattern on paper for the two sails (triangle shape with a right angle – see image below). Pin the pattern onto the fabric and cut it out. Apply fabric fraying liquid sparingly along the fabric edges to prevent it from fraying over time.

Step 3. Add eyelets to the corners of the two fabric sails. Cut a tiny slit close to the corner, push the back side of the eyelet through, turn the fabric over with the back of the eyelet facing up. To secure the eyelet to the fabric, place the setter over the unfinished end of the eyelet and firmly strike the top of the setter with the hammer two to three times to spread it open. Remove the setter and firmly strike the eyelet directly two to three times with the hammer to flatten the sides down around the fabric {o ptional/not required: use an eyelet finisher on the back of the eyelet to give it a smooth professional finish } .

The instructions to apply eyelets will vary depending on the tools used. The end result will be similar and it will also help to prevent the fabric from tearing and to keep it’s shape.

The two finished sails with eyelets attached to the corners.

Step 4. Attach sails to the mast. Near the top of the wooden stick, leaving enough room to glue a flag on later, screw the eyelet screw into the wood {use a pair of pliers to screw it into the wood if needed} . Cut a piece of twine about 3-4 inches long, string it through the eyelet on the large sail and the eyelet screw, tie a knot to secure them together. Repeat the process for the second eyelet screw at the bottom of the wooden stick and the third eyelet screw on the large driftwood near the end.

Attach the other smaller sail to the opposite side of the wooden stick slightly lower down from the other sail { see image below }. Snip off all the extra loose twine from the knots, leaving about a quarter of an inch, dab a little bit of fabric fraying liquid to the ends of twine to prevent unraveling.

The finished sails should spread out nicely across the driftwood.

Step 5. Add decorative flag banner. Cut 5-7 little triangle flag pieces. Cut twine long enough to go from the top of the mast down to the eyelet screw at the end of the large driftwood piece. Be sure to add about two to four inches of extra twine.

On a flat surface, lay a fabric triangle piece down and line twine along the top edge of the flag, apply hot glue, and roll the top edge of the fabric around twine and hot glue to secure together. Repeat the steps with the rest of the flag banner pieces.

Step 6. Attach the flag banner to the sailboat. Thread one end of the flag banner through the top eyelet screw on the mast and make a simple knot on the twine to keep it from slipping out of the eyelet screw hole. Thread the other end through the eyelet screw on the driftwood and make a simple knot on the twine to secure it in place.

Driftwood sailboat #1 . Step 7. Cut a triangle piece of fabric for the flag and attach it to the top of the mast with hot glue.

Driftwood sailboat #2

Driftwood sailboat #3

I couldn’t decide which one I like the most.

Hannah was assisting me.

A great summer craft project!

posted by Kay

Share this:

- Click to share on Twitter (Opens in new window)

- Click to share on Facebook (Opens in new window)

2014 , crafts , diy , driftwood sailboat

26 Responses to DIY Driftwood Sailboats

Kay, These turned out great, and your tutorial is excellent. Now the question is where to find driftwood around here. Hmmmm….

I like the light blue and white striped sail the most.

That was the first sailboat I made. The striped fabric I used for the sail came from a pair of pants 🙂

Judith, contact me with a ship to address, I would love to send you some of the extra driftwood I have left.

Kay, I adore your sailboats!!! They are cute and so clean and fresh looking and it’s such a fun idea to use driftwood. We have a sailboat and spend our summers sailing so I’m definitely going to make one {or more} of these. Thanks for the fun idea.

I’m glad you like this craft project Lori. There will be lots of driftwood waiting for you here in the Puget Sound area if you decide to come back and to do a little more sailing this summer.

We’ll be sailing the San Juans next month so I’ll definitely pick up a bag full of driftwood for this fun project.

I love these! I grew up on the Olympic Peninsula in Washington, and now that I’m landlocked in Chattanooga, TN and trying to pull off a costal living room, I really miss the ready availability of natural elements we had access to! Lovely work!

Nice to meet you April and glad you had a few minutes to visit and share with us. We try as a family to make a trip out to the Pacific coast once a year, Seabrook Wa. We drove to Forks WA once, that was a loooong drive. I hope your coastal living room is coming along nicely.

Love your little sailboats. Am making my first one now from driftwood I collected at Ocean Shores and Ruby Beach … 🙂

The Northwest beaches have such a nice supply of driftwood to choose from. I hope you had fun making the sailboat Karen.

You have inspired me! Love these boats. I live by Lake Ontario in NY so driftwood is abundant. Off to the lake…..

Hi there! I I’m so in love of these sailboat what type of fabric did you used or any suggestions? Thank you!!

Hi Carmen The fabrics I used were made of cotton with a little bit of weight to them-cotton canvas. The soft blue ticking fabric came from a pair of pants I purchased at the Gap a few years ago in hopes that I might use the fabric to make something.

I hope you have fun making these sailboats!

It’s so beautiful!!! I featured these driftwood sailboats here http://esikfloresik.blogspot.com/2016/08/beach-please-inspiration-board.html xoxo

Love these live in Littlehampton west Sussex united kingdom trying to make some little boats you have inspired me so more beautiful than shop ones

Love them, have not tried them yet but wanted to thank you for sharing instructions.

Hey I’m writing from Pakistan. I loved the whole tutorial and your work is amazing I was wondering if you can give another tutorial on how to make driftwood tiny houses! How do you shape drift wood into fine shapes I have always wondered I would really appreciate your response. Waiting for it! Love, Khizra

I love these! I was wondering if these would float? I live with a lake in my back yard. During the winter I thought it would be nice to see the sailboats floating next to our dock. I thought I would attach a sailboat to a fishing line attached to a large rock but thought it might flip over. Has anyone tried floating them?

Love these! Thank you for sharing!!

I love these sailboats! Would love it if you sold them

Loved the sailboats am going to make some for my nieces babies first birthday. Where is the best place to purchase the driftwood

Piękne, piękne, piękne … 🙂 Beautiful, beautiful, beautiful … 🙂

I love your sailboats. I live in the CA desert 6 months out of the year so the wood I collect for my sailboats is a bit more gnarled but still beautiful. Thank you for sharing.

Trackbacks/Pingbacks

[…] Driftwood Sailboats ~ Kay at White Gunpowder. I know I’m partial to sailboats but are these driftwood sailboats […]

[…] ♥ DIY Driftwood Sailboat […]

[…] helped me to develop my ideas. The favourite thing I made was the driftwood boats – I adapted a guide I found on Pinterest. I used some of Ian’s old shirts and we collected a lot of driftwood from Rest Bay. They’re not […]

[…] Vía […]

Leave a Reply Click here to cancel reply.

Name (required)

Email (will not be published) (required)

Notify me of follow-up comments by email.

Notify me of new posts by email.

How to Build a Sailboat Rudder From Scratch

Introduction: How to Build a Sailboat Rudder From Scratch

This particular rudder is built off of the original rudder for a ~20' Bayliner Buccaneer sailboat. The original had cracked and rotted pretty badly. The owner of the sailboat cut the top of the rudder off and made a wooden 'boot' to cap the rudder. However, it wasn't water sealed with fiberglass, and over time more and more moisture got in until it became so flimsy that it wasn't reliable. While this instructable is specifically for this Bayliner sailboat with a tiller-style rudder, the instructions should be general enough for you to modify it to work for many sailboats. With that said, there are many many nuances to fiberglass/composite marine construction, so this type of build will require more research beyond what is covered here.

Step 1: Previous Rudder

In these photos you can see the extent of the damage. The rudder was foam-core/fiberglass sandwich. Think of it as a Big Mac; the three buns of the Big Mac were layers of fiberglass, and the meat was the foam (the yellow stuff). The only difference was that the buns would have all been connected and fully enclose the meat. First, I cut apart the rudder along its perimeter with an oscillating saw, so that I could use the pieces as templates for the build. In the fifth image you are seeing a piece of balsa (I think) at the edge of the rudder where the mounting hardware was located so as to provide compressive stability for the tightened hardware. In the last image, if you look at the top of the image you can see where the previous owner had chopped off the top of the rudder. There was a rudimentary wooden cap on that, so you can see how easy it would have been for water to get in.

Step 2: Rebuild