- Outremer 45

- Outremer 4X

- Outremer 4.zero

- Outremer 52

- Outremer 55

- Outremer 51

- Outremer 5X

- All the Outremer Fleet

- Personalized support

- Blue Water Sailing Seminars

- Our concept

- The Outremer team

- Our commitments

- Construction principles

- Our catamaran services

- After-sales customer service & Quality control

- Offshore Connected Catamaran Maintenance

- Concierge Services

- Our owners’ stories

- FAQ – Outremer catamarans

- Brokerage: used catamarans for sale

- Privacy Policy

- Legal Notice

- Grand Large Yatching

Building expertise: our catamaran construction principles

At Outremer every specification has to be precise and consistent with what the naval architect has drawn. During catamaran construction, he or she works in close collaboration with the designers and engineers to reach a harmonious end result.

Safety, reliability, performance, comfort, and pleasure are the key words throughout the design of an Outremer blue water catamaran.

Peace of mind no matter the weather conditions.

An absolute priority for all sailors! We can accept that for racing boats, risks are knowingly taken into account, but for cruising catamarans, a very big safety margin is fundamental. For this reason, the daggerboards are essential to guarantee good upwind sailing, even in difficult situations (storms, rough seas, etc.). We don’t always choose to find ourselves in such situations, but Outremer will bring you back to port, in all conditions.

Resisting the test of time and continuous improvement

Every Outremer will without doubt cover several hundreds of thousands of miles across oceans or around the world during its lifetime and it is crucial that every system is proven and reliable. To achieve this, Outremer takes particular care with the standard of finish, with its choice of technologies and the selection of brands of equipment they install on their boats. What’s more, every year we conduct a survey among all new Outremer owners to help us consistently improve our liveaboard catamaran construction techniques. This feedback is especially important: it allows us to get closer to building the “perfect boat”!

Combining comfort and pleasure of sailing

Multihulls from the Outremer yard are of course, not racing yachts, but they are among the fastest of cruising boats! Performance is both a source of pleasure for any sailor and also an essential safety factor allowing the crew to have more options when facing weather risks, especially single-handed.

Unparalleled quality of life onboard

One of the keys to successful cruising! The quality of life on board depends essentially on comfort at sea. All the elements which go into making an Outremer are combined to achieve an incomparable quality of life with a comfortable interior: more gentle movement allows for quality sleep, no slamming under the bridgedeck, and reduced pitching, leading to good cooking conditions for whoever is in the galley. Silence on board, the absence of any creaking or groaning, so often found on a sailing catamaran, guarantees unrivaled peace and quiet.

Easy sailing and fun for all

Because the pleasure shared between the crew is the guarantee of harmonious life on board during a blue water sailing journey, Outremer takes everyone’s needs into account: skipper, crew, children, guests… Everyone can enjoy 360° visibility, perfect ventilation, and great ergonomics. And of course, the enjoyment of sailing, feeling a boat which goes fast and well, as seen when using the tiller which is available on Outremer boats, an incomparable way to feel a multihull slipping effortlessly through the water!

Loïck Peyron, 4X sponsor: “The point of sailing is the point of departure and the destination. Between the two, the sailing part is fun, of course, but it’s often too long!”

Architecture

Designing the ideal boat

Naval architects translate specifications into lines and volumes:

- Hull designs carefully studied and optimized; long, to carry the required load and reduce forward resistance. Fine hulls demand, in effect, little power to make the move and allow them to maintain high average speeds under way. Not just that, but also to be able to use only one motor when there is no wind, reducing the amount of noise in the hulls when some of the crew are off watch, and also doubling the range under power.

- Windage is limited for maneuvers in port and for better holding at anchor.

- Centering the weight: a very low center of gravity, and weight distribution around that center of gravity – all these unseen elements add to the quality of sailing and reduce pitching movement.

- Fine bows absorb pitching and help produce high levels of comfort under way.

- Daggerboards for sailing to windward, going faster when close-hauled and being able to reach otherwise inaccessible anchorages. Sailing close-hauled on an Outremer catamaran is worthy of the best monohulls, even in the hardest of conditions.

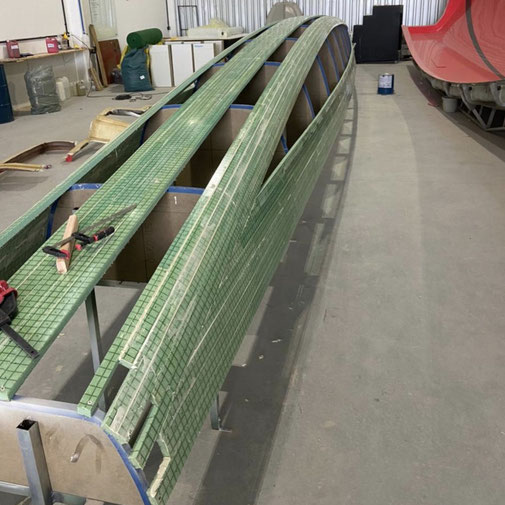

Catamaran construction principles: how are Outremer multihulls made?

The methodology of the Outremer boatyard: putting forward a blend of high-tech technologies and know-how. Blue water cruising programs require significant safety margins: you need to be able to count on your boat in all circumstances!

Even though the philosophy of the yard of is to reduce weight, this must never be done to the detriment of the structure, and our designers are committed to reinforcing the essential areas: the bows are protected by several watertight crash-boxes, the lower part of the hulls are resistant to collision and knocking, the daggerboard wells are indestructible as the daggerboards act as a fuse, making it insubmersible as a result.

Even though modern composites such as those found in sandwich construction are essential materials for saving weight, an Outremer always has the lower part of the hull built in a very thick monolithic laminate: in the event of collision, no structure in sandwich construction could compete with the strength of an Outremer hull. The structure is completely laminated in the hull, and not simply glued on: there is no backing mold interfering with access to any part of the underwater hull, and all the systems remain visible and accessible.

The stiffness of an Outremer catamaran is incomparable

The main bulkheads are of large dimensions, and so are able to take much greater loads than a cruising multihull might encounter. Inserts in carbon fiber, closed-cell foam, isophthalic resins and high-resistance polyester: everything is designed to guarantee your safety for offshore sailing.

For the furnishings, sandwich panels are used to reduce weight, with wood veneer for warmth and aesthetic appearance. The furnishings do not add to the rigidity, and are insulated from the structural parts to reduce unwanted noise, creaks and groans. Aluminum structures support the floors, which don’t squeak either. No more wedged doors or drawers that won’t shut. For the equipment, we choose brands and makes for their quality, their reliability and their suitability with the boat’s program.

An Outremer is designed to be around for over fifty years

Owners change over time, all with ambitious projects and wanting to replace or add certain equipment to their cruising catamaran! In this respect, we apply four golden rules: every part of the boat and every system installed must be documented, be accessible, able to be checked and be replaceable.

Today, more than three million miles have been sailed by our multihulls on every ocean, most of them cruising tropical seas, though many have seen extreme conditions, ranging from Alaska to Patagonia. The huge amount of experience accumulated by Outremer has allowed us to refine and consolidate our principles of catamaran construction.

Catamaran Design Guide

Spectacular sunsets in the Pacific turn the horizon into a brilliant spectrum of gold and orange colors.

Copyright © 2006, 2008 by Gregor Tarjan. Click here for terms of use.

performance, yet desire high daily averages and passage times, which should be as short as possible. When choosing a large multihull, sailors look, above all else, for safety and comfort, long before the consideration for flat-out speed comes into the discussion. Nevertheless, performance is a highly important design consideration. No catamaran sailor wants to sail slower than a same length ballasted keelboat. Below are some EVALUATION & COEFFICIENTS useful coefficients, which will help compare monohulls and multihulls objectively.

Bruce Number (BN)

below "Indigo," a magnificent Wormwood 70, sailing in sparkling Caribbean waters.

Various multihull characteristics and design features can be expressed in mathematical formulas. Their results are crucial and will give prospective owners a basis of comparison between different types of catamarans. These numbers are important, as they eliminate ambiguity and clearly display various advantages or concessions of a design, which would be hard to quantify any other way. Mathematical coefficients not only will provide insight into a boat's performance in varying conditions, they also reflect concerns about loads to be carried safely, speed and stability.

We have already mentioned the Displacement/Length and Sail Area/ Displacement ratio in our chapter on Multihull Advantages, illustrating the point of a multihull's efficiency. Let's look at some other coefficients that give us an indication of a boat's performance.

What is performance and how do we really measure it? Most people who buy a cruising catamaran are not really interested in racing

The Bruce Number is very similar to the Sail Area to Displacement ratio although the formula is slightly different. It is the square root of the sail area in feet, divided by the cube root of the boat's displacement in pounds:

SA = upwind sail area (mainsail and 100% jib)

Displ = weight of the boat in pounds

Similar to the Sail Area to Displacement ratio, the higher the coefficient the faster the boat and better is its performance in light air. Typically a BN of 1.1 will be the threshold between fast and more sluggish multihulls. A heavy displacement monohull might have a BN of .7, whereas a modern cruising catamaran shows a BN of 1.3. Offshore multihull racers can have BNs of 2.0 and higher. The BN will also tell us about a catamaran's ability to withstand stronger winds before reefing. A boat with a higher BN is usually overcanvassed in strong conditions and will have to be reefed earlier than one with a lower coefficient.

On the other hand, they will be able to produce more "power" than their counterparts in lighter winds and perform better.

Sail Area to Wetted Surface (SAWS)

SA/WS = Sail Area Wetted Surface Coefficient

SA = upwind sail area

WS = total underwater surface area (hull and appendages)

This formula simply divides the upwind sail area of the boat (mainsail and 100% jib) by the wetted surface. This coefficient will give us a statistical indication of the multihull's lightair performance since in low wind conditions skin friction becomes an important factor. Monohulls can have coefficients of at least 7% more than multihulls.

Hull Fineness Ratio (HFR)

The Hull Fineness Ratio, known as the hull's beam-to-length ratio, is an interesting number. It is derived by simply dividing the waterline length of the hull by the waterline beam of the hull.

Max. WL/Max. Beam WL = Hull Fineness Ratio Max. WL = length of the hull at waterline in ft. Max. Beam WL = beam of the hull at the waterline in feet.

Monohulls, when compared to multihulls, have low hull/fineness ratios. In Part 1 of this

book, discussing "Efficiency," we saw that ballasted keelboats are limited to Archimedes' principle of hull speed (1.34 x VWL). Multihulls do not have these theoretical barriers, because their hulls are narrower.

The thinner the hull the faster it will be able to travel through the water. But, attention! It will also carry less unless you are on a mega cat. Typically, a 40' cruising catamaran's HFR will range from 8:1 to 10:1. Dennis Conner's above While sailing under spinnaker and experiencing virtually no roll at all, guests will always find a comfortable spot to relax on the foredeck, an impossibility on a monohull.

There are various methods of calculating the transverse stability of a catamaran. One of the simplest and most utilized techniques is establishing a relationship between the height of the Center of Effort (CE), displacement, beam and sail area. Multihull designer, James Wharram added safety factors of 20% to compensate for gusts and the dynamic environment of the ocean. Another method is described in the text below.

Multihull Stability & Capsizing Moment d - Displacement (kg) x half beam (m) max ~ Sail Area (sq m) x Height of Center of Effort (m)

P max = maximum pressure exerted onto sails

Multihull Stability & Capsizing Moment

height of sailplan CE

half overall beam (half hull beam)

racing cat "Stars and Stripes" had a 16:1 HFR. Of course, the larger the boat, the narrower the hulls will become in comparison to its length. For example, the HFR of a 100' luxury catamaran may be 12:1, providing it with a high speed potential. However, monohulls can show HFRs of 3:1, though the comparison is complicated as their angle of heel affects the measurement.

One has to be very careful when analyzing the Hull Fineness Ratio of a cruising catamaran, because other factors such as the actual shape of the hull cross sections (Prismatic Coefficient, PC) can throw the analysis off balance. Go-fast sailors like to think that fine hulls are always fast. That is not necessarily true because a slim hull could have a large underwater volume, thus slowing it down. Consequently, a wide waterline-beam hull could have less drag than a narrower one. It could have a shallow underbody (low PC), which would be beneficial to load carrying (Pounds Per Inch Immersion Number, PPI) and early surfing characteristics at speed.

Stability Coefficient (SC)

This mathematical formula has been devised by the distinguished catamaran designer and sailor James Wharram and his team. This coefficient analyzes a multihull's ability (in a static environment) to resist capsizing due to wind.

( 0.682 VW x (.5 Boa) ) x .555 = CW .00178 x SA x h

W = Wind speed, apparent, in mph CW = Critical Wind Speed to capsize in mph SA = upwind sail area in sq ft. h = height of Center of Effort (CE) of total sail area

Boa = Beam overall

This formula will tell us how much wind it will take to overturn our multihull. By instinct we will know that a catamaran with a wide stance and a conservative sail plan will be very stable offshore. The SC formula will inevitably illustrate that a wider beamed catamaran with a tall sail plan will be as resistant to wind induced capsize as a short-rigged, narrower boat. This is not so if one considers the chaotic environment of waves and the real world of heavy weather sailing. It is interesting to note that a wide beamed boat (regardless of the SC) is more resistant to capsize in seas due to the effects of a higher moment of inertia. In an open-ocean environment, which is everything but static, the SC formula has little meaning. Nevertheless, it serves as a good basis to evaluate stability as a factor of wind force.

below When the wind suddenly comes up, all that is needed is a couple of turns on the jib furler to quickly reduce the headsail size. The catamaran will hardly sail any slower, but feel more comfortable.

Wide hulls and a large overall beam will increase the overall righting moment of a catamaran. A word of caution: Excessive beam will reduce the fore and aft stability. Designers strive to compromise hull fineness ratios, place heavy weights towards the CG (Center of Gravity), and engineer hull and overall beam to achieve a seaworthy balance, which is safe, yet provides ample liveaboard accommodations.

Catamaran Stability Considerations

Diagonal Stability & Beam-to-Length Ratio (BLR)

Stability of a multihull, or the resistance to capsize, should be seen as three components. Athwartship Stability is one well-publicized type and the one often talked about. The other much more important types are Fore and Aft and Diagonal Stability. Fore and aft stability is established by the relationship between the boat's waterline length and the distance between the hull centerlines. It will reflect the catamaran's resistance to tripping. This relationship should be in the vicinity of 39% to 42%. For a seaworthy cruising multihull it is important maintain the proper ratio between length and beam, which, in turn, balances equal amounts of athwartship with diagonal stability. The goal should be to prevent the possibility of a sudden discrepancy of powers between fore and aft and sideways resistance. Most of today's multihulls keep these two component forces in equilibrium, making them extremely seakindly and safe.

Some early design multihulls were very narrow, partly due to the material limitations of that time. But things have changed. Contemporary composite construction allows designers to build wider boats without compromising stiffness. Production catamarans of today have a wide stance and have the benefit of greater safety margins in gusty wind conditions than their older cousins. Multihulls are sophisticated structures and true modern miracles. They provide a more comfortable ride and more interior room. Thanks to modern materials they weigh less and perform better than catamarans built only 10 years ago.

Some catamarans, especially production boats, which are very popular in the charter fleets, are growing wider by the year. The businesses who rent these beamy monsters adore them. Lots of room plus open decks are ideal for clients and the bigger (wider) the boat, the more paying guests can share the fees. But there certainly is a limit as to how wide is too wide. Extreme beam can be dangerous. It can lead to instability fore and aft and to excessive bridgedeck slamming, as the relative distance from the bridge deck to the water will decrease with an increase in width. A vessel with excessive beam might seem stable athwartships, but it will compromise overall stability.

We know that multihulls can, in extreme cases of seamanship error in wild storms, be thrown over from any side - front, back and beam-on. The best examples of this phenomenon are racing multihulls, especially Formula 1 trimarans, which have fine hulls for speed and huge sailplans to provide driving power. They are initially extremely stable athwartships (High Beam-to-Length Ratio), but have a tendency to become unstable fore and aft. They will surf down waves and reach a point where the power of the sails, and speed, will exceed the ability to keep the bows out of the water and the boat will pitchpole. This is the reason why catamaran designers usually draw their multihulls with a Beam-to-Length relationship of between 50% and 55%. The longer the vessel the lower that percentage becomes.

I am currently involved in the "Gemini" project, which presents an example. It very well might become the world's largest sailing catamaran. She will have an overall length of 145 feet, yet her beam will "only" be 54.4'.

Please, don't worry. "Gemini" will not be tender and tip over in the slightest breeze. On the contrary, this monster will be one of the most stable craft afloat, although the beam-to-length relationship is only 37%. The relatively low beam-to-length ratio also involves the fact that the boat would be too heavy and building costs would be prohibitive if she were to have a standard 52% BL relationship. Most importantly, could you imagine turning a 75-foot-wide boat?

above Asymmetric spinnakers on furlers are great inventions. They add instant sail area, yet can be doused in a matter of seconds when the wind picks up strength.

above Although this Edel 35 was a good-looking and popular catamaran, it suffered from excessive bridgedeck pounding, which was caused by only several inches of clearance between the saloon's underwing and the sea.

Obviously there is a sweet spot in the beam vs. stability question. Designing too beamy a boat will also necessitate more freeboard to preserve bridgedeck clearance which, in turn, will increase windage and complicate maneuvering. Unless sophisticated aramid construction methods are utilized, more beam will also add more weight and stress to the structure. Adding more mass will, to a certain point, help make the boat more stable, but where do we stop? Is it better to add weight or width to make a boat stiffer? Of course, both characteristics are interrelated as a beamier boat normally is also heavier. Just adding weight to a catamaran simply to make her more stable will not pay off. Consequently, making a boat too wide might increase living space yet it will also burden the structure, require a beefier manufacture, and yield an even heavier boat. Needless to say, a boat which is too wide will also create practical restrictions such as maneuvering, the ability to haul the vessel and much higher building costs.

Beam has a great effect on bridgedeck clearance, which is one of the most vital characteristics of a good cruising catamaran. As standard practice, the well-known rule of 1" of bridgedeck clearance for each foot of beam was a safe way to prevent excessive wave slap. The wider the beam the more the relationship changes and the necessary height of 1" per foot of beam needs to be increased to 1.3" or more. In the extreme case of overly square boats, that number will have to be closer to 1.8" per foot of beam. This will have a negative effect on any seaworthy multihull that has a bridgedeck saloon. The wide beam will necessitate a high cabin sole to remain a safe distance from the waterline. In order to provide standing headroom, the coachroof might be higher than practical, which could result in a boxy, high-windage multihull. Not only will this be unattractive, but also raise the Center of Gravity (CG) which really should be kept as low as possible.

More overall beam on the other hand (given that there is still sufficient bridgedeck height) has a less known benefit, as it reduces the possibility of hull-wave interference, which is particularly important for fast designs. The wave interaction between the hulls can lead to additional resistance, and especially in an agitated sea state, the formation of wave crests can pound the bridge deck. Most early narrow-beamed catamarans suffered from this phenomenon,

Ultimately, a boat's design has a major influence on its ability to stand against the forces of nature, and to keep occupants safe. Manufacturing excessively wide catamarans is like trying to market monohulls with super deep-draft keels. Both are totally impractical. We designers have to make sensible compromises and learn from past experiences of what has worked at sea by balancing the benefits of a wide boat with its disadvantages.

below This narrow-hulled Outremer 64 Light has completed her third circumnavigation with the same owners. Note the smooth underwing clearance, lacking any protrusions or steps.

"A great cape, for us, can't be expressed in latitude and longitude alone. A great cape has a soul, with very soft, very violent shadows and colors. A soul as smooth as a child's, and as hard as a criminal's. And that is why we go!"

~ Bernard Moitessier

Dinghies, windsurfers and every imaginable type of water toy can be stored conveniently on large catamarans and easily launched from the wide transom steps for shore-side pleasures. Note the twin life rafts located in special compartments on the massive aft crossbeam.

Continue reading here: Hull

Was this article helpful?

Related Posts

- Design Dynamics - Catamarans Guide

- Hull Construction - Ship Design

- Geometry - Ship Design

- Heavy Weather Tactics - Catamarans Guide

- Configuration Types - Catamarans Guide

Readers' Questions

What length should a stub keel be to waterline length on a catamaran?

There is no set rule for the length of a stub keel on a catamaran in relation to its waterline length. The length of the stub keel will depend on various factors, such as the size and design of the catamaran, intended use, and specific requirements of the boat builder. Generally, the stub keel on a catamaran is designed to provide stability and improve sailing performance, so it is important to consult with a naval architect or boat designer to determine the appropriate length for a specific catamaran.

What is a 16 passenger catarmarn like?

A 16-passenger catamaran is a type of boat or vessel specifically designed to carry 16 people comfortably. Catamarans are multihull boats with two parallel hulls, which are connected by a deck or a structure. They offer stability, speed, and efficiency in the water. A 16-passenger catamaran can vary in size and design, but generally, it will have enough seating or lounge areas for all passengers. It may have indoor cabins with beds or seating areas, as well as outdoor spaces for relaxation or socializing. These boats often come equipped with amenities such as bathrooms, kitchens or galleys for meals, and sometimes even entertainment systems. The catamaran's size can influence its specific features. Some catamarans are designed for day trips or shorter excursions, while others are built for longer journeys or overnight accommodations. Additionally, they can be used for various purposes, such as whale watching, diving trips, ferry services, or private charters. Overall, a 16-passenger catamaran provides a comfortable and stable platform for small groups or gatherings, allowing passengers to enjoy the beauty of the water while ensuring safety and comfort.

Is the catamaran hull floor always on the waterline?

No, the hull floor of a catamaran is not always on the waterline. The design of a catamaran allows for the hulls to be elevated above the waterline, reducing drag and increasing speed. The position of the hulls in relation to the waterline can vary depending on factors such as the weight distribution, load, and sailing conditions.

How close to a catamarans design reefing points should you go?

You should always be careful when approaching reefing points on a catamaran and stay as far away as possible. Generally, you should aim to stay at least 10 meters away.

What keel to length ratio for catamarans?

The keel-to-length ratio for catamarans typically ranges from 0.1 to 0.25.

Is 70% length to beam ok for a catAMARAN?

Yes, it is generally accepted that a catamaran should have a length to beam ratio of between approximately 6:1 and 8:1. Therefore, a 70% length to beam ratio would be within an acceptable range.

What is the waterline length to baem ratio of a typical cruising catamarans?

This ratio will vary depending on the type and size of the catamaran. Generally, the ratio should be between 1:1.5 and 1:2.5, with 1:2 being the most common.

A Trusted Source For Boating Information Since 2019

A complete catamaran guide.

- Post Written By: Boater Jer

- Published: January 26, 2020

- Updated: November 27, 2020

Disclaimer: You might notice that we recommend products in some articles. We may earn a commission for referring you if you click the link and buy a product.

We only recommend products we’ve tried/tested/own (that’s why you won’t find thousands of affiliate links on my site). If you have experience with one of the products we’ve mentioned, please share your experiences in the comments at the end.

Advertisement

There you are, out on the water when a strange craft approaches. Is it a sailboat? It sure looks like one until it turns to face you. That’s when you notice this boat doesn’t have just one hull. It has two hulls and it’s called a catamaran.

Catamarans are unique, and highly stable watercraft. We’ll explore all the ins and outs of sailing the waters in one of these weird, and awesome multi-hulled craft. Join me as we explore the wild world of sailing catamarans.

A History Of The Catamaran

It is believed that the first people to use a catamaran design were those living in Australasia.

The succession of boat design in this region was actually very interesting. The beginning of boats in the area was simple, albeit conventional rafts. These were fashioned from logs strewn together with plant fiber lashings such as those formed using bamboo fiber.

Catamaran Evolution

The conventional raft gave way to a minimal raft. This design was basically a conventional raft with two cross beams added in the form of logs. These would be eventually hollowed out to improve buoyancy.

The next step in the evolution of boats in the Australasian region was the double canoe. This proved to be the first real catamarans.

After some time, the form evolved further into the asymmetrical double canoe design. In this design, one canoe was large and the other attached canoe was smaller.

The asymmetrical design quickly evolved into the single-outrigger boat like the one shown in the photo below.

The final stage of the evolution of the catamaran in the region was to gain a second outrigger. This in effect created the trimaran with the single central hull and dual outriggers.

Eye Witness Accounts Of Catamarans

In 1697, William Dampier wrote of witnessing a type of seafaring vessel off the coast of Coromandel. He noted how the locals called the type of boat a catamaran. He also noted that it had multiple hulls (logs) and that they were small vessels that the person operating would have to hang partway into the water, straddling the hull (log).

The name catamaran came from the Tamil. And yet, it was easily applied by the European visitors to the two hulled sailing vessels that sped across the water in the region.

Although Dampier may have described the catamaran in the 1690s, the type of boat was actually used as early as the 5th century by the Tamil Chola dynasty. They used boats to move their troops from one island to another. Using this design of boat allowed them to travel heavy, travel quickly and was partially responsible for the conquering of neighboring Burma, Malaysia, and Indonesia.

Building A Boat – Basics Of Catamaran Construction

A boat is usually thought of as being a single-hulled vessel that travels along the surface of the water. It can have multiple types, shapes, and designs of the hull. However, it is often only thought of as having a single hull. But, what if it had two hulls? Would that be like taking two separate boats, and making a raft over both of them? In essence, that is exactly what a catamaran is: two boats made into one.

Advantages Of Multiple Hulls

- More stability than a monohull

- Wide supporting base allows for larger sails than monohull craft of the same length

- Hull does not require the deep-running keel of a standard monohull sailboat

- Less hull drag in the water than a monohull

- Less power required to drive a catamaran forward than a monohull boat

Disadvantages Of Multiple Hulls

- Due to multiple hulls, construction is more expensive than a monohull design

- Catamaran speed relies on lightweight materials to make a lightweight craft. This also drives up the cost of construction.

- Extra engineering requirements for multi-hull craft also increase the cost of construction.

Conclusion? Well, it looks to me like everything about catamarans points towards superiority over monohulls in nearly every way. But, you get what you pay for. I think the same thing likely applies to cars too. For instance, I have a performance car that cost me about 10k more than the equivalent non-sports car within the same class.

Yet to drive the vehicle, it performs so much better than the normal version of the car, it really speaks volumes to the difference between a common vehicle, and a performance one.

Speaking of performance vehicles, let’s take a look now at the different kinds and uses of a catamaran.

Catamaran Types

Commercial catamarans – ferries.

One of the most common uses for a catamaran is the commercial use of the vehicle design when it comes to ferries. This is likely due to the wide, flat deck possibilities of a catamaran versus a monohulled boat. Not only that, but the catamaran is also a much more stable bodied vessel. This again makes it a superior design for transporting larger land vessels like trucks and so forth. They can easily drive on the ferry without fear of the ferry tipping over.

Some ferries are designed for taking vehicles, like the one you might find in the city of Toronto. Where it transports cars from the mainland to Toronto Island. Others are designed specifically with the sole purpose of transporting people. I took a look at one such ferry that operates in Germany. Take a look at the following case study.

Commercial Use Case Study – The Ferry

The FRS Helgoline is a ferry catamaran operating out of Flensburg, Germany, close to the Danish border.

According to the ferry company’s website, the ferry runs using four main engines which are run to a capacity of 12,182 hp combined. This blasts this ferry at a speed of 35 knots or 65 km/hour. This is equivalent to 40 miles per hour. That’s pretty good considering the size and weight of the ship body this catamaran can carry.

Speaking of capacity, the ship can carry 680 passengers. At 56.4 meters long (185 feet) by 14 meters wide (45.9 feet), that’s a decent passenger capacity.

Catamaran Passenger Capacity Versus Monohull Boat Passenger Capacity

The general rule for calculating passenger capacity for a boat is as follows.

Length x Width / 15 = Passenger Capacity

Therefore, the FRS Helgoline should have a calculated capacity calculated as follows.

185 x 45.9 / 15 = 566

But it actually has a capacity of 680 which is a 20% increase in capacity over a standard monohull.

For comparison, let’s look at a superyacht. A 48.5m (159 feet) long by 10.7m (35 feet) beam (width of the boat) Palmer Johnson Supersport 48 (valued at about $28.5 million dollars) should have a capacity calculated as follows.

159 x 35 / 15 = 371

In short, 26 feet of difference in length equates to 309 fewer passengers. It is almost half of the capacity of the catamaran at 26 feet longer length.

Photo courtesy of https://sysyachtsales.com/

Commercial Catamarans – Service Vehicles

Although Catamarans are typically used as ferries due to their stability and ability to carry wide loads on their flat decks, there are many different service catamarans out there as well. From a support vessel to a crew transfer or search and rescue, catamarans are a solid and stable platform to build a ship on.

This is the Ardea which is a 20 meter (65.6 feet) catamaran to be used for crew transport and as a support ship. This ship was built by the Echo Marine Group and delivered to Western Australia in early 2019. This particular vessel is in the service of the Cape Preston Sino Iron Project.

Catamarans are used all around the world, for a variety of tasks, not just ferries or support craft.

Commercial Catamarans – Cruise Lines

Now these are the catamarans we all want to be aboard, aren’t they? Due to the wide stance, these ships can feature massive halls and wide-open interior areas. These ships are stable, and some would say even more stable and safer than monohull design ships.

There are many cruise ship catamarans in use today around the world. Some of the more ‘famous’ catamaran cruises are those which investigate the Galapagos Islands. There are several high-end, small fleet, cruise lines operating to the Galapagos which utilize catamaran design vessels as their primary ship type.

These ships can be extremely comfortable and stable and often offer some reprieve to those who may otherwise feel seasick. It won’t stop the feeling, but the more stable the hull, the less the boat rocks around.

Military Catamarans

Catamarans make excellent military transport vessels. They are stable and the potential to have a large, flat and wide deck for transporting land craft, troops or acting as a landing pad for vertical take-off aerial craft. The stability of the two hulls makes the vessel an excellent candidate for military use, and thus it is used for said purpose.

As you can clearly see in the image of the USNS Spearhead, the rear of the vessel has a moveable ramp that can be used for loading and unloading land vehicles. The interior bay of the craft is visible in the image as well, a large area for storage of vehicles, supplies and more. The crane arm on the back of the ship also shows how it is a versatile craft, set up to act as an excellent support craft with a helicopter landing pad and ample storage and freight capacity.

Recreational Catamarans

Catamaran Personal WatercraftThe wind is in your hair, the warm spray from the hull cutting over the edge of each wave as you skip over the water. That is life, let me tell you. Personal watercraft have come a long way over the years and the small one, two, three and four-person catamarans have come a long way as well.

Depending on the options, you can get a small one or two-person catamaran for as little as $1500 new. That might be an inflatable though. There are some very nice, rigid hull designed catamarans for 1-4 people that range from $3500 to $15000. And these are basically open, personal watercraft like that shown in the image below.

Using a small catamaran can be quite challenging to learn at first. Sailing is not for the faint of heart. It requires skill, technique, knowledge of the wind and sea, and a bit of hard work. But it can be fun, rewarding and a great way to catch some sun and fresh air out on the water. It’s a relatively GREEN sport as well. Given the use of sails over gas-powered motors that is.

‘Sailing Cats’ – Sailing Catamarans – Yacht & Luxury Class

Here’s where we get into the dreamy boats of the rich and famous. I priced out a small 43’ luxury Leopard 40 sailing catamaran. Even before I added any extras at all, the base price was $399,000 USD. I imagine if I added a few of the multiple extras available, and some tax, freight and that sort of thing, I’m easily in half a million dollars. And that’s the smallest base model.

There are all kinds of luxury catamaran shipbuilders across the world. From Asia to Europe and The Americas, it seems any major boating country has at least one company building luxury catamarans. It’s weird that you don’t see more of them on the water though, don’t you think?

Being sailing vessels, these luxury cats require some training in sailing before you get behind the wheel. And considering the price point, I would definitely want to be at least a semi-decent sailor with some good few years experience under my belt before I would comfortable at the helm of a half-million-dollar sailing cat. It’s all relative I suppose. I imagine a billionaire might bat an eye at the prospect of wrecking a half-million-dollar boat. But to me, and most of you reading this, that’s likely a lot of money.

‘Power Cats’ – Powered Catamarans

The powered catamaran is one of my favorite boats. They have sort of a muscle car appearance with the wide and often tall front end of the boats. I find it to be reminiscent of a large air intake on the front hood of a rally race car like the Subaru WRX, for instance. These boats are fast, they are stable and handle very well. Catamarans are often considered the boat of choice for long sea voyages due to their stability.

A powered catamaran will definitely cost more than a powered monohull boat of the same length. Why? Well, the powered catamaran has one crucial downside. That is, it needs two engines. One for each of the two hulls. Otherwise, it’s off balance for propulsion. These two engines or motors have to be in sync with each other or again, the propulsion will be off-balance. Because they have two motors, they have double the maintenance when it comes to maintaining the propulsion system.

More components also means a greater chance of things breaking down. In essence, it doubles the chances of the ship having a motor break down. The saving grace is that should one motor break, they have a backup, even if it does mean very unbalanced propulsion. In contrast, a monohull vessel of the same length may only have half the chance of motor failure due to only having one motor, but if that one motor breaks, then what? Call for help, that’s what. A cat would have a struggling chance to get itself back to port. A monohull would be dead in the water unless it was carrying spare parts or another motor onboard somewhere.

Catamaran Frequently Asked Questions

What is a catamaran cruise.

A catamaran cruise is simply a cruise on a dual hull design boat. Often used for river cruises, the catamaran which is used as cruise ships are often considerably smaller than their giant monohulled counterparts.

What is the purpose of a catamaran?

A catamaran is a design for a boat that utilizes two hulls. Due to the flat, platform-like-potential for the deck of the boat, the catamaran is often purposed with transporting materials, vehicles, and people. For instance, catamarans are quite often used as ferries.

Is catamaran safe?

Catamaran are very safe water craft. The design of riding on two hulls separated by a gap in between, in essence is like giving a car a double-wide wheel base. The wider the stance, the more stable the craft, from side to side anyway. And if the length of the boat is proportional to the width, then it becomes an extremely stable craft. That is why catamarans are often considered the best to be used for long voyages. Yes, catamaran are safe.

What is the difference between a catamaran and a sailboat?

A traditional sailboat is a deep, monohull vessel that has at least one mast extending high into the air above the deck to hold sails. A catamaran refers to the design of a dual-hull boat and really has nothing to do with sails. Although, catamaran do make excellent sailing boats as well, they are quite capable of acting as power boats and do not require sails if they have the correct amount of powered motors to propel them. Sailboats, although also able to be powered if a motor is provided, are traditionally monohull and wind-powered exclusively.

Do catamarans have small interiors?

The size of an interior cabin on a boat is typically proportional to the size of the boat itself. If a catamaran has above-deck cabins, they will likely be able to be of a larger design than those you would find on deck of a monohull boat. This is because a catamaran has a much wider footprint than a monohull boat of the same length. This extra width would allow for larger on deck cabins.

How much does a catamaran cost?

A personal watercraft (1-2 person) inflatable catamaran will run you anywhere from $1500-$12000 USD, depending on the quality and features. The rigid hull catamarans of the same size start at about $4500 USD.

A small cabin cruiser type of catamaran will typically start at about $60000 for a small base model and the price just goes up and up depending on size and features.

For Instance, a 40’, 3 cabin with 1 washroom cat will cost you about $500,000 USD for the base model. They are considerably more expensive that a monohull of the same length. However, the trade-off is greater stability and a smoother, more comfortable ride.

Is a catamaran more work to maintain?

Technically yes. Due to having two hulls and if powered, two motors and likely also water jets, this means you have double the oil changes of a boat that would have a single motor. Once you get past the basic engine and hull maintenance, a catamaran is not that much more work than a monohull ship of the same length.

The trouble with catamarans in terms of maintenance, is that once they reach a certain length, the width becomes more than a standard lane on the road. That being said, if you ever need to transport the boat via land, it can be quite the challenge. Especially if you need to pay to have a police escort for an extra-wide trailer. And special licensing might be involved as well.

What is the difference between a catamaran and a trimaran?

A catamaran is a dual hull boat. In other words, it has two hulls. A trimaran has three hulls.

Is a catamaran considered a yacht?

According to Oxford dictionary, a yacht is a medium-sized sailboat equipped for cruising or racing. A catamaran, on the other hand, is a boat with two hulls. Therefore, a catamaran can most certainly also be a yacht. And likewise, if a yacht has two hulls, then it is a catamaran as well.

Can you get seasick on a catamaran?

Seasickness occurs when a person feels nauseous from the swaying motion of a rocking ship. These feelings may be lessened on a catamaran, due to their extra stability. However, a catamaran may be slightly more stable than a monohull of the same length, but it is still a boat. And it will still make someone who experiences seasickness continue to feel the ill effects.

Are catamarans more stable in rough seas?

Catamarans are known to be more stable than monohull ships of the same length. This is why catamarans are often the ship type of choice for long sea voyages due to their stability.

Why do catamarans capsize?

Catamarans are not known for capsizing. The larger vessels that is anyway. But, it does happen from time to time. Catamarans are known for their stability, so typically if a capsize event should occur, it is typical for them to be extreme circumstances.

Personal watercraft catamarans are a different story though. These are in fact known for tipping over. Not because they are less stable than their monohull counterparts of the same length. But instead, because they are able to go considerably faster than monohull personal watercraft of the same length (not including powered craft though). This is due to the sailing cats being able to have a larger sail than a small monohull sailboat of the same length.

Due to the extra sail, they are able to travel faster than monohull sailboats of the same length. This allows them to whip around on the water and at higher speeds, whipping your cat about quick can easily send it over sideways. Extra speed means fast turns carry momentum in the direction of travel and that extra speed equates to tipping over if turned too fast. To sum up, they capsize due to user error or extreme events.

Which is safer, a catamaran or a monohull?

Due to the extra stability of having a wider footprint than a monohull, a catamaran of the same length is the safer vessel.

Are catamarans safer than sailboats?

The same rule applies to stability versus the length of the hull. A cat will always be the more stable length for length. However, due to their ability to go much faster than a monohull sailboat, this kind of cancels out some of the added safety due to stability. With that in mind, they may just be about the same but there is one generalization we can make when comparing the safety of catamarans vs sailboats: At the same speed, and of equal length, sailing or power catamaran will be safer than a monohull sailboat.

How fast can catamarans go?

The speed a catamaran can go is entirely dependent upon the hull design, weight of the vessel, the strength of propulsion (be it wind or powered) and so on. The general rule is that in terms of sailing cats vs monohull sailboats, a cat of equal length can typically go faster than a sailboat.

In terms of powered cats vs powerboats, a powered catamaran will typically require less energy to move forward than a monohull of the same sort of hull design (but monohull of course) and thus a cat should, in theory, be able to go faster than a monohull when both are using propulsion that is equal in power.

Bibliography

- Wikipedia – Catamarans

- Mahdi, Waruno (1999). “The Dispersal of Austronesian boat forms in the Indian Ocean”. In Blench, Roger; Spriggs, Matthew (eds.). Archaeology and Language III: Artefacts languages, and texts . One World Archaeology. 34 . Routledge. pp. 144–179. ISBN 0415100542 .

- Wikipedia – Spearhead -class expeditionary fast transport

- https://www.tiki-toki.com/timeline/entry/169516/Origin-of-the-catamaran/#vars!panel=1620923!

- https://www.austal.com/ships/passenger-express-56

- https://www.adventure-life.com/galapagos/galapagos-catamaran-cruises

Boating Gear

Take a look at our Recommended page for a variety of items. Here are some of the things you can expect:

- GPS And Fish Trackers

- Hitch And Trailer Supplies

- Lifejackets And Specialty Clothing

- Boating Books And More!

Crab Island by Pontoon: A Fun Watery Boating Guide Destination in 2024

Upgrade Your Boating Experience: Adding a Third Pontoon Made Easy!

How Long Does It Take A Canoe To Go… (Canoe Calculator Here)

In-Depth Review of the Pelican Sentinel 100X Fishing Kayak: Pros, Cons, and Performance

How To Put A Kayak In The Water – The Ultimate Guide For New Kayakers

Best Cruising Catamarans For Couples

More from boating guide magazine.

- Pontoon Boat Basics

- The Complete Runabout Boat & Trailer Towing Guide

- Winterizing Your Boat

- Boating Gear Requirements For Canada And USA Waters

- Aluminum vs. Fiberglass Bass Boats

- Better Boating At Night & How To Survive The Darkness

- Staying Safe On A Catamaran: 24 Essential Tips

- Can A Catamaran Capsize?

- 4 Common Types Of Propulsion For Boats

Return To Home * About Boating Guide * About The Author

fakewatches.is

Share this post with your friends

- Tags: boat type , catamaran , catamaran basics , catamaran essentials , sailing

Subscribe to our Newsletter

Join us in our love for all things water. And Adventure.

The Complete Guide To Replacing Boat Flooring

Advertisement Now that you’ve decided replacing boat flooring is the way to go, it’s always a good idea to take the help of some excellent and valuable guides. You can hire a professional to redo your boat flooring as several professionals in the market can do the job at a reasonable price. On the other

The Eyoyo Portable Underwater Fish Finder and Camera Review

Advertisement A fishing trip is something that can excite any man (and some women too). You get to enjoy good times outside with your friends. Nevertheless, the pain of being unable to catch any fish may be yet to come. If you’re one such unlucky person, who is having a hard time catching even a

A Wizard of Technology – The PowerEgg X Wizard Waterproof Drone

The PowerVision PowerEgg X Wizard Drone – A Waterproof, water-landing aerial drone of the future, today. This thing is just plain awesome.

Boat Propeller Anti-Fouling Paint, Grease, And Awesome Tips

Advertisement Boat Propeller Anti-Fouling Paint questions? You’re in the right place. Boat propellers often develop subaquatic organisms, hindering their performance and degrading their longevity. Antifoul paints and grease slow down the growth or detach these organisms. These products are available commercially, and their application is effortless. However, most people still ask for the best tips

Qysea Fifish V6 Underwater Drone Review

Advertisement Are you an aspiring Youtuber who needs to use an underwater drone while shooting? Do you need an efficient underwater drone for professional purposes? Or are you simply a drone enthusiast who likes nothing but the best? Whatever may be your specific need for an underwater drone, we have a fantastic recommendation for you-

AQUAROBOTMAN Magic Jet Sea Scooter – Almost Too Much Fun

Advertisement In the world full of anxieties and worries, water sports have proven to be one of the best cures for the human mind. People like to go in the water to swim, dive, or snorkel around to find relief from the perplexing life we all face if only to gain peace of mind. And

Boat Information By Type

© 2023 Boating.Guide, A Hyperwave Media Group Ltd. Publication.

Privacy Overview

Connection denied by Geolocation Setting.

Reason: Blocked country: Russia

The connection was denied because this country is blocked in the Geolocation settings.

Please contact your administrator for assistance.

[email protected]

Category: Our Catamaran Build Kits

Recommended equipment.

Quality suppliers & manufacturers

The schionning team have a lot of contact with equipment suppliers and manufacturers, and hear feedback on certain brands or systems from our many customers. there are many schionnings cruising the world and testing products longevity and the customer service offered by the manufacturer., on this page we will list products and companies that we know to provide above average quality and service. it is always growing, and if your company provides equipment used on our designs and you would like to be included - please contact us., engines & drive systems.

Visit: https://oceanvolt.com

Batteries, Power Management

LITHIUM POWER (VIC)

Back in 2013 I knew that my boat batteries were reaching the end of their lives, I had been researching LiFePO4 cells for a few years and decided that I should install them. Unfortunatly I was unable to find a local supplier. So Lithium Power was established.

Technical Information

The technical information page is a collection of documents (mostly in pdf format) on the materials and systems used in schionning catamarans. including data sheets, engineering information, strength comparisons of each core material and informative articles from jeff outling the design of certain system such as engine choices and main sheet systems., detailed engineering data for your research, we understand that getting your head around the process of building your own boat, or having one built, can take a little while. to gain a greater understanding of the materials used in our designs, the below data sheets have been supplied by atl composites, and contain all of the technical data you could need regarding the composites we use. in addition are articles or documents written by jeff about certain systems used on our designs and why., all technical information and data sheets on west system/duflex/durakore provided courtesy of atl composites. for more information please see the atl composites website here., documents library.

Information Sheet – CE CERTIFICATION PROCESS

- Mainsheet Systems for Catamarans

- Motor Choices for Schionning Designs

- Weight and Weight Distribution Schionning Designs

- Schionning Designs Sailing Performance and Tips

- Hull Shapes and Performance – Power Designs

- Outboard Engines VS Diesels – Written by Ross McCombe

- An Outboard Installation That Works – Ross McCombe Follow up

- Data Sheet – DUFLEX BALSA for Catamaran Kit Builds

- Data Sheet – DUFLEX FOAM

- Data Sheet – FEATHERLIGHT Paper Honeycomb

- Data Sheet – WEST SYSTEM R105

- Data Sheet – PUMP SYSTEMS

- Data Sheet – MICROFIBRE BLEND 403

- Data Sheet – MICROLIGHT 410

- Data Sheet – MICROSPHERES 411

- Information Sheet – USING FILLERS

- Data Sheet – KINETIX RESIN Thixotropic

- Information Sheet – DURAKORE PLANKS 413

- Data Sheet – DURAKORE PLANKING 414

Kit Materials Contents

Kit materials' contents, so if you order a schionning kit, what exactly is going to arrive see an overview of the materials you will receive, and what each is used for during the build process. fibreglass cloth or tapes microspheres, microballoons or microfibers take a closer look and you can answer these questions., our schionning kits are a no nonsense, common-sense approach to building a boat. we offer great service, fast delivery and access to anything you could need for your boat straight from the supplier to your door. our construction plans and kits are sold with 100% professional boatbuilder support via phone and email, any time you're unsure or just need a second opinion, we're here..

Our kits contain all of your basic materials to build your boat to a faired shell stage, ready for painting and fit-out. We have sail-away costing estimates available for all of our standard designs, and this will give you an accurate idea of the overall cost of your project. This costing varies depending on your level of finish, as you can imagine different options vary greatly in price.

Below is a quick glance at what your Schionning Kit will include and what each item is primarily used for, we hope this is helpful and if you should require more detailed information please don’t hesitate to contact our office.

What do I actually receive?

DUFLEX PRE-LAMINATED PANELS

DuFlex pre-laminated panels are the main and most important material used in our kits, predominantly in the flat panel designs, however they are used in Strip-planked designs also, though to a lesser extent. These panels are 2400mm x 1200mm and are CNC routed to speed up build time on our Wildernes X Series, as well as some of our power designs. For internal furniture, a paper honeycomb core is used instead of the end-grain balsa wood core that is used for main structural areas. The use of this is purely to save weight in the shell and therefore produce a faster, more responsive catamaran.

KINETIX LAMINATING RESIN & HARDENER

WEST SYSTEM EPOXY RESINS

FIBREGLASS TAPES (DOUBLE BIAS)

CARBON FIBRE CLOTH

FIBREGLASS CLOTH

The kit process, building your own boat can be a daunting prospect, however to demonstrate each step in the kit assembly process, we've created this guide for you to study. as you can see our kits are the ultimate in building efficiency and have been streamlined over 30+ years to ensure that you're on the water faster and with less effort., how does it all go together.

The first step to building your dream catamaran begins with a strongback – this is a square frame used to position the temporary frames that will be used to form the hull shape. This frame will be set up and must be square and accurate, a string or laser level can be used to achieve this.

The forebeam is now installed along with the striker attachment fitting, as shown above. The bridgedeck is installed shortly after and taped onto the bulkheads with webs installed, this now completes what is a quite stiff and strong platform to work on.

Now that the bridgedeck is in place, the forward webs and dash will be fitted. At this stage, all furniture and internal work begins, with the main panels left off for ease of access when working.

Material Choices

Schionning material choices, solutions that work best for catamarans & why, our designs are based on cored composite construction techniques using west system epoxy resin and knitted fabrics. but given the range of today's composite technologies, which solution works best for catamarans and why written by jeff schionning, selecting the correct materials, resin choices.

It also fully protects the boat against water absorption and it can not develop the dreaded Osmosis.

We choose ATL Composite’s resin systems for their superior quality, reliability and value for money.

Having worked closely with the ATL Composites team and their products for many years, we know we can stand by their material solutions, and rely on great service should something unexpected happen.

This may not seem important but when working with a material for an extended period of time, the small things make all the difference.

CORES Which One to Use?

- End-Grain Balsa – 150kg per cubic metre

- Superlight Balsa – 94kg per cubic metre

- Western Red Cedar – 360-380kg per cubic metre

- Foam – 80kg per cubic metre

BALSA END GRAIN (150 kg/cubic metre)

Balsa has very good values and we can produce a shell using a very light laminate. It will be very stiff and very resilient to fatigue.

It has exceptional qualities including very high compression strength, extremely good sheer capabilities and fantastic sheer stiffness.

Compressive strength is the resistance to collapsing when pressure is applied perpendicular to the surface as when pushing directly onto the material with the point of your finger. Balsa is far stronger than Foam (80kg/cubic metre) in compression.

Balsa is also very strong in shear. This is when the core sample is held flat between your hands, one hand slid one way and the other slid the opposite way, when the core tears through the middle the core has failed in sheer. The amount of stretch you feel before the core shears is shear stiffness. To compensate for sheer weakness the core is made thicker. So 13mm Balsa may be equal in sheer to 19mm Foam.

(80 to 200 kg/m³)

There are many boats sailing that are built from foam as it’s mechanical properties are good for boat building.

- Initially one would expect this cat shell to be lighter as it is ½ the weight of Balsa. We do have to compensate for its weaknesses and will then add to the reinforcement the reinforcement on the outside to spread that compression load over more core and need a triaxial type weave to compensate for the veneer content that runs fore and aft on the Durakore.

- Secondly, we need to increase the Core thickness to compensate for the shear value, usually neutralizing the weight advantage.

- We only use structural foam core that is closed-cell and cross-linked.

The end result using foam core amounts to a very similar total boat weight. Professional builders can achieve a good result but usually use vacuum bagging and very good molds to achieve this.

Secondary Issues

Balsa can absorb water. It needs extreme neglect to rot (very unusual). Water soaks along the end grain quickly. It travels very slowly across the grain. We use balsa under the waterline especially because of it’s high compression strength for beaching etc. any core type must be sealed. Damage to all cores results in the same sort of repair. Notice a damp spot remaining when drying out to anti-foul… simply grind back the surface glass exposing the core, dry it out and re-glass – it’s that easy.

Timber cores are cheaper than Foam in most cases.

A light, high tech cat returns a far better (often 2 – 3 times) re-sale than lower tech materials. Often saving $10,000 on materials initially, loses $200,000 on re-sale – a serious reality.

Our boats can be built using Balsa, Foam or Western Red Cedar. Combine strength, stiffness, lightness and cost, with ease of use – it just makes good sense!

STRIP PLANKING GUIDE

Above: The plug for the Chincogan 40 catamaran, entirely planked in western red cedar, with the plug later becoming the first boat after molds had been made.

IT'S NOT THAT HARD

Strip planking a boat hull is very straight forward process that doesn't take a great deal of skill or technical capability. But there's a few basic principles to follow. The most important one is the orientation of the planks which we've covered under "Planning the Planking".

PLANKING PROFILE

If you follow the techniques of the strip plank canoe and kayak builders (Pinterest is one good source) you'll notice a lot of them machine the strips to a concave/convex profile so they fit really snuggly on the mould frames and a minim of glue is used.

I've seen this done on offshore sailing catamarans as well but unless you're fanatical about detail it's probably overkill for larger boats. There is more cost for the machining and more wastage in the lost timber. Rectangular planks work fine.

PLANKING WIDTHS

The wider the strips the less glue joins you have to make. However wider planks create wider flats and higher ridges on the joins creating more work to fair the hull. A good compromise is wider planks on the keel plank and on the flatter hull sides, and narrower planks on the bilge curve.

For a hull bottom in the 40' to 50' size range I suggest a plank width of about 45mm for about two thirds of the area, and scale down to about 30mm for the bilge curve.

If you're going all the way up to the gunnel with the planks you could increase the planking widths to 70mm, 90mm or more if the topsides are flat enough.

GLUING TECHNIQUE

One method I've seen used is dry planking - whereby all of the planks are simply laid up dry and then the glue is screeded into the gaps when the planking is all done. This method relies on getting the consistency of the glue just right. If it's too thin its going to run through the cracks onto the shop floor below. If it's too thick it's not going to fill all the voids. Keep in mind that the width of the gaps between the plans will vary as the curvature changes so no consistency is going to be absolutely perfect for every part of the hull.

My advice is not to use this technique unless you "know what you're doing".

Another way of speeding up the gluing process is to clamp several planks side by side and run a squeegee or a cartridge gun down the line covering them all at once. Be careful not to apply glue to more planks than you can carefully lay before the epoxy begins to set.

The strip planking work can proceed very quickly with an efficient team of two or three workers. If I remember correctly we were able to plank the hull side of a 40' catamaran in two days with three workers. But don't be tempted to rush the job. Keep the planking neat and tidy. Clean up as you go, especially on the inside as much as you can. A bit of extra clean up work can save a lot of sanding later.

SELECTING MATERIALS FOR THE STRIPS

Western Red Cedar is forgiving and easy to work with. The main downside is that it's more expensive than it used to be in the 1980's and 90's when strip planking was probably the most popular method for building one off sailing boats.

Another relatively light timber that appears to be rot resistant is Pawlownia which is readily available in South East Asia and possibly in some western countries as well.

Strip planking with foam/glass strips has become a very popular method of creating round bilge hulls while retaining the light weight and durability of the PVC foam/fibreglass combination.

Typically full size foam sheets (1.2m x 2.4m) are joined up to the full length of the hull (the foam can be simply but joined with an epoxy glue) and laid up with unidirectional glass in the x axis (along the hull) both sides of the core. . The panels are then ripped into strips of the required width.

A possible compromise between the solid timber and the foam glass strips is to us ATL's Durakore with a PVC foam core and Hoop Pine veneers on each face. This is probably slightly more expensive but the panles dont need a glass laminate prior to planking and the timber faces are easier to fair than glass/epoxy.

PLANNING THE PLANKING

This is pretty basic, but it's important to a tidy job and if you don't get it right you can create a lot of hard work for yourself. Quite simply; Don't cross the bilge curve. Plan your planking operation so that your planks will run parallel with the tightest curve in the hull. Crossing the bilge curve at an angle will force the planks to twist and this can cause a lot of extra fairing work.

A great shot of the hull shoe planking on Raku 48 Mint. There are different ways you can approach the planking operation and I don't know exactly how it was approached on this hull; but here is one way it could have been done:

1. A marking plank was laid along the bilge curve, not glued in placed but used to mark the lay of the bilge planks.

2. A second marking plank was laid parallel I guess about 300mm further down the hull side. This determined where the lower planks (on the mould) would be trimmed off.

3. A plank is then rebated into the mould frames on this line and covered in plastic to provide a solid backing for the saw when it comes time to trim these planks.

The same can be done on the keel line to assist with trimming the keel planks.

4. The bottom planking is completed and then trimmed off as planned. Note that it would have been reasonably easy to clean up excess glue on the inside face while this was being done. Not quite so easy for the upper planks when doing the second side.

The narrower planking on the bilge and hull bottom can now begin and proceed up to the keel where once again it is trimmed along the keel line.

It is recommend to partially plank each side concurrently to avoid putting a lot of twisting load on the mould frames and strongback.

5. When closing in the final planks on the second side it will be necessary to fit some of the planks by spiling the ends to meet the keel line.

Bottom planks on a Barefoot 40 hull, ready to be trimmed off where they meet the marking plank. No backing plank has been provided for the trimming operation in this example.

Barefoot 40 detail and the stem. The planking is 20mm thick and the final planks at the keel line have been cut down to about 25mm wide.

Biaxial Glass at ±45˚ has been laid across the hull over the finished planking. The joins in the glass do not need to be overlapped. The laminators are pulling excess resin from the laminate with squeegees.

Laminating of the external hull surface completed.

Two extra coats of epoxy have been applied to ensure the hull is well sealed.

Construction of R42 Trimaran Venom. Panels of PVC foam with unidirectional carbon skins are being joined up to the length of the boat using a heat press supplied by ATL Composites. The heat press greatly speeds up the joining operation but if you don't have access to the heat press you can also join the panels using screws and clamping boards. (see this link)

Strip planking the outriggers for R42 trimaran Venom.

Two shots of the first hull for the Raku 44 trimaran under construction in Brazil. You watch progress of the construction for this boat on this link.

Join the Newsletter

- Scroll to top

New Boat Construction Techniques

- By Capt. Ken Kreisler

- Updated: October 2, 2018

Boat construction and materials have come a long way since ancient mariners first hollowed out a fallen tree and floated downstream. Many of us remember the early builds from Hatteras — think back to the 1960 introduction of Knit Wits; at 41 feet in length, it is considered to be the first fiberglass production boat over 30 feet, and one that is still running to this day. But did you know that the use of composite materials dates back to antiquity?

In the Beginning

According to scholarly research, the earliest record of composite use is generally attributed to the ancient Mesopotamians around 3400 B.C. Using their own homegrown sticky stuff, they glued strips of wood placed at different angles to one another, and voilà : plywood was born.

The use of composites grew by leaps and bounds, and by around A.D. 1200, those rascally Mongols figured out that by using a combination of wood, bamboo, animal tendons and bones, all wrapped in silk and bonded together with pine resin, their bows were much more effective. So effective, in fact, that the weapon ruled their world in both hunting and warfare well into the 14th century, when firearms first appeared.

Fast-forward to the 1930s, when resin development took a giant step forward, paralleling the introduction of fiberglass by the Owens Corning company. Fiberglass-reinforced polymer was given a patent, and it would only be a matter of time until the automobile industry designed and produced a totally composite car body. After the introduction of the 1953 Corvette, the marine industry caught on.

In the next decade and onward — with the patent of carbon-fiber material for commercial use, technologically advanced resins and epoxies, new fabric weaves, better strength-to-weight ratios and the advent of Everett Pearson’s Seemann Composites Resin Infusion Molding Process (SCRIMP) system of vacuum bagging — other innovations have brought us right up to today’s high-tech, state-of-the-art construction methods, ones that have given us some of the most beautifully built and functional fishing machines known worldwide.

To get a handle on just how all this has affected high-level tournament-ready sport-fishing boats from the custom sector, I went right to the source with several well-known builders to get their input.

A Flair for Innovation

“We put a lot of engineering into our boats, and each one, from a 60-footer to a 90-footer, gets the same attention,” says Gary Davis, superintendent of new construction at the sprawling Jarrett Bay Boatworks facility in Beaufort, North Carolina. “You can’t just add more horsepower to make the boat go faster. The only way to skin that cat is to look for ways to improve the hydrodynamics and eliminate weight. Those are the challenges that new technology addresses.”

We put a lot of engineering into our boats, and each one, from a 60-footer to a 90-footer, gets the same attention.

The Jarrett Bay approach looks at the whole build to ensure all of the critical structural parts, as well as all of the boat’s systems, work in harmony in order to exceed expectations. “For example, with our 90-footer, the owner wanted the boat to be not just fast but as quiet as possible,” Davis says.

With the research done, they determined that while a full carbon-fiber package would yield the best speed, with the level of sound-dampening material needed to achieve the desired decibel levels, the weight savings would be eliminated, and the boat would actually be heavier. “We came up with a hybrid method for the hull skin, sides and transom by building them out of the relatively same lightweight material we have been using over the past 15 years — a cold-molded product made out of plywood and epoxy,” Davis notes. “The wood acts as a fairly good sound insulator too.”

After that, the similarities go away. For example, all the stringers, bulkheads, decks and everything from there on are foam-cored, with carbon-fiber-infused skins. “In the case of all the topside stuff, we’ve taken the E-glass out and replaced it with carbon fiber,” Davis says. “On the hull itself, we do have the E-glass laminate on the hull, inside and out, but after that, and with a few exceptions, everything else is a carbon-infused lamination.”

Carbon, research and manufacturing for the production of cars and aircraft

As far as mounting those new high-horsepower engines, one of the headaches with carbon fiber is the absolute need to isolate it from metals to prevent galvanic corrosion. The main stringers where the engines sit have a higher-density foam core and an overlay of carbon fiber. Over that is a welded aluminum cap that is properly sized to accept the motor mounts. To isolate it all, a layer of E-glass was applied before the paint. And to make sure the through-bolts would not come in contact with the carbon fiber, a compression sleeve was inserted. “Everything you see mounted on that boat, and everywhere that particular material is used across the board, we use a compression or grip sleeve to make sure there is no chance of any contact with a screw, bolt or metal component to set up galvanic corrosion,” Davis says. “This does complicate the build, but we made it happen.”

With the blessings of technology and new materials come a host of ills that must be addressed. “With the new processes, we are always looking for weight-saving opportunities, and in the final analysis, it all adds up. To make it happen, everybody involved has to be in the same mindset,” he adds.

The Bayliss View

“We are big believers in the triple-ply Okoume hull, and I think, universally, everyone can agree that nothing compares to the sound-deadening capability, the ride and the performance of this hull,” says John Bayliss, whose boatbuilding facility in Wanchese, North Carolina, bears his name.

While the hulls at Bayliss Boatworks are glass inside and out, and use epoxy resin throughout the build, the construction process will vary with the building materials used. During wood construction, for example, a specific West System epoxy will be applied. “When we get to the cabin, superstructure, flybridge and console, we use Core-Cell foam that is glassed on both sides,” Bayliss notes. “We still use Philippine mahogany for the framework in the overhead of the cabin, which provides room for air ducts, wiring bundles, lighting and so on.”

Bayliss and I discussed the all-important notion of being weight-conscious throughout his builds. While that is essential in today’s horizon-chasing fishing boats, his personal stamp on every boat that leaves the facility also comes with a pedigree that pays special attention to the ride. “I believe there is such thing as getting too light and high-tech, where a solid glass or core boat tends to resonate the sound more. That’s why we stick with cold-molding and the wood hull,” he says.

Learn more about The Anatomy of a Modern Sport-Fisher .

To further weight savings, Bayliss has replaced his decking material with a very durable 3M honeycomb core, and all bulkheads are a combination of marine plywood and Core-Cell, glassed on both sides. “Our boats are really quiet, ride very well and fish like they are expected to,” he says. “As far as all these new materials are concerned, and while we’ve adopted some of them into our builds and construction process, like CNC [computer numerical control], in-house design and the use of carbon fiber in certain areas for stiffening, we like to think that we have the kind of consistency to keep doing things the way we’ve always done them.”

Spencer’s Take on Tech

“We’ve been on the forefront of new technology for some 18 years now, with resin infusion, composite construction, Core-Cell, Divinycell and incorporating carbon fiber,” says Paul Spencer, of the Wanchese, North Carolina-based Spencer Yachts . “And we’re always looking for new ways to make things lighter and stronger on our boats.”

We’ve been on the forefront of new technology for some 18 years now, with resin infusion, composite construction, Core-Cell, Divinycell and incorporating carbon fiber.