Did You Know That We Offer Contract to Closing Services? Click Here to Find Out More.

Need Marine Financing? Apply Here With Our Partner, First Approval Source

- Catamaran Interviews

- Catamaran Reviews

- Buying Advice

- Selling Advice

- Woods Design Advice

- Admiral 38

- Admiral 40

- Admiral 50

- African Cats

- Fastcat 445

- Americat 3014

- Antares 44

- Aquila 44

- Aquila 48 Power Catamaran

- Aventura 37

- Balance 526

- Bali 4.0

- Bali 4.1

- Bali 4.2

- Bali 4.3

- Bali 4.4

- Bali 4.5

- Bali 4.6

- Bali 4.8

- Bali 40 Catspace

- Bali 5.4

- Bali Catsmart

- Beneteau Blue II

- Broadblue 346

- Broadblue 38 Prestige

- Broadblue 385

- Broadblue 435

- Broadblue 46

- Rapier 400

- Rapier 550

- Catalac 10M

- Catalac 11M

- Catalac 12M

- Catalac 8M

- Catalac 900

- Catalac 9M

- Catana 381

- Catana 39

- Catana 401

- Catana 40S

- Catana 411

- Catana 42

- Catana 42 S

- Catana 431

- Catana 44

- Catana 471

- Catana 50

- Catana 521

- Catana 531

- Catana 55

- Catana 581

- Catana 65

- Catathai 44

- Chris White

- Chris White 48 Voyager

- Chris White 55

- Condor 40

- Contour 34

- Corsair F28 R

- De Villiers

- Dean 365

- Dean 400

- Dean 440

- Dean 500

- Dix DH550

- Dolphin 380

- Dolphin 460

- Edel 35

- Endeavour 30

- Endeavour 35 Victory

- Endeavour 36

- Endeavour 44

- Endeavour 44 TrawlerCat

- Endeavour 50 Pilothouse Trawler

- Excess 11

- F-41

- Fastback 43

- Fisher 28

- Fisher 32

- Fortuna 36 Island Spirit

- Fortuna 401 Island Spirit

- Fountaine Pajot

- FP 32 Maldives

- FP 35 Tobago

- FP 36 Mahe

- FP 37 Antigua

- FP 38 Athena

- FP 39 Fidji

- FP 40 Isla

- FP 40 Lavezzi

- FP 40 Lucia

- FP 40 MY

- FP 40 Summerland MY

- FP 41 Lipari

- FP 42 Astrea

- FP 42 Venezia

- FP 43 Belize

- FP 44 Helia

- FP 44 Orana

- FP 45 Elba

- FP 46 Bahia

- FP 46 Casamance

- FP 48 Salina

- FP 50 Saba

- FP 56 Marquises

- FP 57 Sanya

- FP 58 Ipanema

- FP 60 Eleuthera

- FP Saona 47

- Fusion 40

- Gemini 105

- Gemini 3000

- Gemini 3200

- Gemini 3400

- Gemini Freestyle 37

- Gemini Freestyle 399 Power

- Gemini Legacy 35

- Grainger 420 Mystery Cove

- Gunboat 55

- Hirondelle 7M

- HopYacht 30

- Island Packet

- Island Packet Cat 35

- Kennex 420

- Knysna 440

- Knysna 480

- Knysna 500

- Knysna 550

- Lagoon 35

- Lagoon 37 TPI

- Lagoon 380

- Lagoon 39

- Lagoon 40

- Lagoon 400

- Lagoon 410

- Lagoon 42

- Lagoon 42 TPI

- Lagoon 420

- Lagoon 421

- Lagoon 43 PC

- Lagoon 44 Power Cat

- Lagoon 440

- Lagoon 450

- Lagoon 46

- Lagoon 470

- Lagoon 50

- Lagoon 500

- Lagoon 52F

- Lagoon 55

- Lagoon 560

- Lagoon 570

- Lagoon 620

- Lagoon Seventy 8

- Leeuwin 42

- Leopard 38

- Leopard 39

- Leopard 39 PowerCat

- Leopard 40

- Leopard 42

- Leopard 43

- Leopard 44

- Leopard 45

- Leopard 45 Classic

- Leopard 46

- Leopard 46 Lion PowerCat

- Leopard 47

- Leopard 47 PowerCat

- Leopard 48

- Leopard 50

- Leopard 51 PowerCat

- Leopard 53 PowerCat

- Leopard 58

- Lidgard 73 Executive

- Looping 50

- Maine Cat 30

- Maine Cat 38

- Maine Cat 41

- Manta 40

- Manta 42

- Matrix 450 Vision

- Matrix 760 Silhouette

- Maverick 400

- Maverick 420

- Maverick 440

- Moxie 61

- Nautitech 40

- Nautitech 40 Open

- Nautitech 44 Open

- Nautitech 442

- Nautitech 46 Open

- Nautitech 47

- Nautitech 47 Power

- Nautitech 65

- Neel 45

- Oceanlake Marine AB

- Seacart 30

- Outremer 40

- Outremer 45

- Outremer 50 Standard

- Outremer 55

- Outremer 5X

- PDQ 32

- PDQ 36

- PDQ 42 Antares

- Privilege 37

- Privilege 39

- Privilege 42

- Privilege 43

- Privilege 435

- Privilege 45

- Privilege 465

- Privilege 48 Transcat

- Privilege 482

- Privilege 495

- Privilege 510

- Privilege 65

- Privilege Serie 5

- Prout 31 Quest

- Prout 33 Quest

- Prout 34 Event

- Prout 35 Snowgoose

- Prout 37 Snowgoose

- Prout 37 Snowgoose Elite

- Prout 38

- Prout 38 Manta

- Prout 39 Escale

- Prout 45

- Prout 46

- Robertson and Caine

- Royal Cape 45

- Royal Cape 500 Majestic

- Royal Cape 530 Majestic

- Sailcraft 30 Iroquois

- Sailcraft 32 Comanche

- Sailcraft 35 Cherokee

- Sailcraft 41 Apache

- Sailcraft 44 Apache

- Scape 39

- Wildcat 350

- Seawind 1000

- Seawind 1160

- Seawind 1200

- Seawind 1260

- Seawind 1600

- Simpson 48

- Solaris 36 Sunrise

- Solaris 36 Sunstar

- Solaris 42

- St Francis 44

- St Francis 48

- St Francis 50

- Stealth 11.8

- Sunreef 60

- Sunreef 62

- Sunreef 70

- Sunreef 74C

- Sunreef 82 DD

- Sunreef 88 DD

- Switch 51

- Switch 55

- TRT 1200

- Heavenly Twins 26

- Ocean Twins 38

- Vaan R5

- Vision 444

- Voyage 380 Maxim

- Voyage 400 Norseman

- Voyage 430 Norseman

- Voyage 440

- Voyage 450 Cabriolet

- Voyage 47 Mayotte

- Voyage 480

- Voyage 500

- Voyage 580

- Voyage 590

- Kronos 45

- Wharram 38 Tiki

- AMI 320 Renaissance

- Woods 22 Wizard

- Woods 35 Banshee

- Woods 35 Flica

- Woods 36 Scylla

- Woods 36 Vardo

- Woods 38 Transit

- Woods 40 Meander

- Xquisite X5

- Xquisite X5+

Catamaran Construction – Hulls, Laminates, and Composites

- Post author By BJ Porter

- Post date October 15, 2020

- 4 Comments on Catamaran Construction – Hulls, Laminates, and Composites

It’s a given that catamarans are more sensitive to weight and loading than monohulls. Catamaran builders strive to build the lightest boats they can without sacrificing strength and stiffness, and have adapted new building techniques and materials to meet this target. Cutting weight allows more passengers and gear without sacrificing performance.

And the marketing materials reflect it–they load every review and website with polysyllabic technical jargon describing the design and production choices each builder made to deliver the best boat they can.

But when you’re reading a brochure and you come across phrases like “ hand laid bidirectional GRP ” or “ vacuumed bagged e-glass with vinylester resin over a Divinycell core ” do you know what that really means?

All modern production catamarans are made with “FRP” construction (for Fiber Reinforced Polymer). Composites aren’t new–it’s just using materials together to strengthen the whole assembly. Straw was added to bricks centuries ago, and steel reinforced concrete is a staple of construction over the last century. For boats, it’s the use of stranded fibers and cured resins which make FRP different.

The term “FRP” doesn’t get into the technical detail of which fibers and which plastics, and how they’re put together to build your hull. There’s a wide variety of fiber types which can be stranded, woven, chopped or sprayed in a varied of patterns then combined with several types of resins to make hulls with different characteristics.

Some FRP techniques produce lighter, stronger shapes, while others are quicker to build and less expensive to produce. The choice of technique is a function of many factors, from the number of hulls and parts to be built, the type of parts, the budget for the project, and many design specific requirements for weight and strength.

1. FRP Basics

The principle behind all FRP construction is the same – you lay our fibers in the shape you need, then saturate them with resin, removing all the air and voids you can. Resin is left to cure, then the piece is ready to finish and use.

The reality is more complex, since building a boat isn’t like making a flat board or a simple door. You’ve got a complex shape with a designed set of curves to build. “Tooling” is the set of shapes to make the boat parts; molds to cover with fiberglass to get the right shapes.

That’s what makes FRP so effective – you can make almost anything out of it. But to do so requires a lot of choices about what you need for the project at hand.

There isn’t a “best” all around material or technique choice for all jobs, and sometimes a lower cost technique or easier to work with material may be the better solution to the problem.

A. Fiber types

Fiber choices in the last few decades have expanded past the glass fibers used in the first mass produced boats in the 1960s. FRP construction wasn’t new even then, they built the first composite boats using modern fiberglass in the 1940s.

The major fibers used in marine construction fall into three categories – glass, aramids, and carbon. The primary differences are in the strength to weight ratios of the fibers, durability, elasticity, and cost. Some construction may use blends of fiber types to combine performance characteristics.

Glass – the most common material still, because of its low cost and versatility. The most common variety used in GRP (Glass Reinforced Polymer) is “E-glass” which refers to its strand size and mineral content. Other grades have different and sometimes better mechanical properties, but may be more expensive and less appropriate for boat building use. Fiber sizes run 10 to 25 microns for E-glass, though other grades may be smaller.

Brands like Leopard, Lagoon, and most higher production volume builders use E-glass.

Aramids – this includes brand names like Kevlar, Technora and Twaron. They have higher tensile strength than E-glass, and resistant abrasion and punctures. Kevlar is a common choice for bullet proof body armor, and can built a tough, lightweight hull. The materials can be difficult to work with, as it is very tough to cut the cloth. It is often blended with carbon fiber or other materials – Catana is known for using Twaron blends in hull construction.

Carbon – the ultimate in lightweight, strong construction material. Carbon fiber is the most expensive fiber, and is available in a variety of weights, grades and strengths. Fibers are smaller than glass – down to 5 Micron.

The lightest, most expensive hulls are made from carbon, but a catamaran builder may use carbon in places other than the hull to add strength and stiffness. Carbon boards, rudders, and reinforcing structures can enhance performance without driving the price of the boat beyond reach. Carbon is the fiber of choice for many custom builds, racing cats, and Gunboat.

B. Mats, Strands, Roving, Direction, and Weights

Fibers are woven into matting and cloth for construction. Depending on the application, different weights of cloth and cloth patterns and weaves may be more appropriate for the job.

Cloth weight refers to the weight per square yard (or meter) of the cloth. A square yard of nine ounce cloth weighs nine ounces. The heavier the cloth, the stronger it is in a laminate.

Fibers carry loads along their length, so cloth weaves have directionality to their strength. Most builders use several layers of cloth with different orientations to give good universal strength to hulls. Specific FRP applications with strict load-path requirements may have more unidirectional fiber layering – for example, a chainplate manufactured from carbon fiber may use unidirectional fiber.

Cloth – fiberglass cloth is commonly used on outer layers of composites. Cloth may have unidirectional or bidirectional strength. Bidirectional cloths have maximum load strengths in two perpendicular directions. Variations on weaves like a modified twill allow a more flexible cloth for better shaping around complex molds.

Mat – is omnidirectional strands of fiber compressed into a cloth. This is often held together with a resin soluble glue, which makes mat great at conforming to mold shapes without folding and bunching as it collapses when wetted. Because the strands do not align, fiber strength is the same in all directions.

Woven Roving – a heavier cloth made from larger bundles of strands. Woven roving allows for quicker buildup of material and strand weight.

Most FRP layups include multiple layers of different cloth and mat. Finished layers may be finer cloth over courser cloth, over woven roving and mat.

Three primary resins are in common use in marine construction – polyester , vinylester , and epoxy . All resins have materials safety concerns and require care in their use and handling.

Polyester is the least expensive and requires breathing protection because of the VOC emission (Volatile Organic Compounds…nasty, smelly fumes). It doesn’t have good bonding/gluing capability, and should only be used with glass fibers for structural building. Some polyester resins are referred to as “isophthalic” resins.

Vinylester is chemically similar to a hybrid of polyester and epoxy, and performs best with fiberglass. It shouldn’t be used in high strength applications with carbon or aramid fibers. It has some adhesive qualities which polyester lacks, it shrinks less during curing, and has better impact resistance.

The added strength of vinylester coupled with increased water resistance makes it an attractive option for many catamaran builders. It costs less than epoxy, but still has better performance than polyester.

Epoxy is the most expensive, but is three times the strength of the others. It offers the best adhesion and the only resin for building structural elements with carbon and aramid. It resists water intrusion better than the other resins, resists blisters, emits no VOCs, and shrinks less. The major drawback is it is more brittle if it takes an impact.

While epoxy is “the best” in terms of strength and ease of building, there are many applications where other resins are appropriate. Budget is a big driver – a boat made from E-Glass doesn’t need epoxy resin, and considerable cost savings to meet a construction price target may drive the choice.

They can build quality boats from all material combinations, but price and performance will drive materials choices to keep some boats more affordable.

2. Cored Construction

What’s the best way to make fiberglass strong? To a point, you can make it thicker. As it gets thicker, it gets heavier. A hollow shape can take more compressive load than a solid one of the same weight, and the same principle applies to fiberglass construction.

Consider an I-Beam used in building construction. It has the same strength (or more) as a solid rectangular beam of similar mass. The compressive load on the beam is supported by the outside edges of the material, the metal in the middle doesn’t contribute much to the strength. So we can remove metal to get the “I” shape while still keeping those sides rigid, making a lighter girder with less material.

The same principle applies to cored construction with fiberglass. Making a sandwich of two layers of fiberglass with a light core between them allows for the greater strength with weight savings.

There are drawbacks – the biggest risk is damage which breaks the skin, which can let water into the core. Earlier cored construction used materials prone to saturation and rot if they got wet. Some builders opt to do cored construction above the waterline and solid below to minimize some of these risks.

But the advantages in weight savings and increased stiffness offset the drawbacks, and there may be a few other side effects like sound and temperature insulation. Like resins and fibers, core materials offer distinct advantages, disadvantages and price points.

Most builders have adopted a hybrid approach, building solid hulls below the waterline, and cored hulls and decks above. This gives a balance of weight and safety.

A. Balsa Core

Balsa is light and inexpensive. The first cored construction used balsa, but it has the disadvantage of being wood. As a natural material, if it gets wet it can rot and break down. Builders use “end grain” balsa – shorter cross cut sections – to prevent wicking of water if there is an intrusion.

B. Foam Core

Closed cell foam cores give good strength to weight savings while minimizing water intrusion. If you get water in the core, it won’t spread very far. Divinycell is a popular PVC foam core, though there are several choices with different densities and compressive strengths.

Some foam cores are not suitable for heat treatment, but infused or vacuum bagged boats like the Outremer and PDQ do well with it.

C. Honeycomb

Honeycomb cores are often the most expensive, but also give some of the best strength to weight ratios. Honeycombed cells made from resin cured aramid papers are some of the best, but also among the most costly. They offer good stiffness, but can be hard to shape. Aluminum and other resin-infused papers are other core materials builders can choose from.

3. Construction and Resin

When building a hull, there are optimal ratios of fiber to resin saturation for target strength and weight. Too little resin and you may not have enough strength (or worse, voids and gaps), and too much, and you’re just adding weight without adding strength. Resins are also a significant material cost in building the boat, so over application not only increases weight but adds cost.

There are many ways to assemble the cores, fibers and resins to build a finished laminate hull – we’re addressing the most common in boat building. Each approach has strengths and limitations, and an impact on the bottom-line cost to build the boat. Any voids or air pockets in the laminate can be disastrous; these techniques have been developed to increase saturation and reduce the risk of voids.

A. Hand Layup / Open Molding

As the name implies, this is the application of resin by hand to cloth as it’s laid into a mold. Wetting is done with a brush, and the laminate is rolled out to remove any air pockets and voids. This is the simplest way to lay up fiberglass, but also the least precise and consistent and will use the most resin.

Skilled craftsmen have built some of the finest vessels in the world this way. Though it’s more popular with monohulls, which are less sensitive to weight, many catamarans built with hand layups on open molds are still out cruising and performing well.

B. Spraying

Using chopped-strand fiber mixed with resin, a “chopper gun” can spray the mixture into a mold to lay down the composite. A consistent thickness can be difficult, but this is a low cost construction technique which makes a very resin-rich laminate. Using sprayed fibers gives lower strength in all directions compared to meticulously laid down mat and bi-directional cloth. But it is a quick technique popular with mass produced, smaller boats.

It is an excellent technique for parts with complex geometry where weight is not an issue, but you will not see it often in catamaran construction. It’s heavy with resin without any resultant increase in strength.

C. Vacuum Bagging (Wet layup)

When an open molded component has been laid up and wetted with resin, vacuum bagging takes the process a step further. After the wetting is complete, air tight plastic bagging is secured around the wetted area, and the air is pumped out of the bag. The vacuum pulls excess resin out and collapses air pockets.

The goal is to get thorough wetting and produce as strong a laminate as possible without excess resin. Knysa and Leopard are two builders that use vacuum bagging on their hulls to reduce weight.

D. Resin Infusion

For resin infusion the cloth, matting and core is laid in place dry, then sealed in an air-tight bag. A vacuum pump attaches to one side of the bag, and on the other a feed for resin. The vacuum sucks the air out of the dry cloth stack, then pulls the resin through the stack, infusing and wetting it.

Resin infusion, when done right, gives the lightest, strongest laminates with no voids and the minimum resin weight for maximum strength. SCRIMP is a variant of the resin infusion process used by some builders, including TPI which build many early Lagoon cats.

E. Pre-preg

Using pre-preg (for “Pre Impregnated”) cloth for your laminating gets rid of the resin bucket. They manufacture cloth with a partially catalyzed resin pressed into it, then it’s chilled or frozen to stop the curing process. There is no need for seperately mixed resins, and there’s no worry your resin might “go off” and harden before you’re done wetting the cloth. Instead, the cloth is assembled, vacuumed, then heated to kick off the curing process.

There are both advantages and disadvantages to using pre-preg for your laminate work. The big disadvantage is the cost; it is most expensive material to use. You also need to chill and store the cloth until you need it, though some can be at room temperature for a couple of weeks without kicking off. And you need an oven which requires some clever tricks if you’re building a forty or fifty foot boat.

But the strength to weight ratio will always be perfect. High tech honeycomb cores are best suited to pre-preg lamination, and without racing against resin cure times, you can ensure perfect cloth placement and precise layout in the build process.

The primary use for pre-preg in boating is high performance race boats. With catamarans, pre-preg may be used high load parts, like Gunboat does for foils and rudders.

4. Industry Examples

Across the catamaran building industry you’ll find almost all the above techniques and materials used, though some are less common. You aren’t likely to find chopped strand sprayed layups in ocean going cats, and hand layups can lead to heavier hulls than weight sensitive catamaran designers prefer. Most manufacturers have moved to vacuum bagging or resin infusion, with a few of the highest end boats using pre-preg for key components.

Built by Robertson & Caine in South Africa, the hull material is vacuum bagged, end-grain balsa-cored E-glass with polyester.

Hand laid, bagged vinylester over an Airex foam core in the hulls.

Earlier Prout catamarans like the Snowgoose 34 featured hand laid solid FRP hulls and decks. Over time they switched to foam or balsa cores for decks and above the waterline.

Older PDQ boats were made from vacuum bagged vinylester – solid below the waterline and cored with CoreCell foam above the waterline and in decks. Newer PDQ models switched to epoxy resin.

All glass is vacuum bagged. Below the waterline is solid E-glass and vinylester. The rest is unidirectional, bidirectional, and triaxial cloths over a Nida-Core polypropylene honeycomb core with isophthalic and vinylester resins.

The Gemini cats are built with a solid hand layup of woven roving and fiberglass mat and polyester resin. Decks are cored with end grain balsa. The Gemini 3200 introduced vinylester resin into the layup to prevent blistering.

Older Lagoons were SCRIMP infused vinylester with and end grain balsa core above the waterline and in the decks.

Newer Lagoon catamarans use polyester and vinylester resins, also infused with balsa cores above the waterline and solid below.

With a carbon fiber inner skin, Catana also uses Twaron aramid fibers in the sandwiched hull over a foam core.

Fontaine Pajot

Primary hull construction is resin-infused vinylester with a balsa cored hull and deck.

Beneath the waterline, Outremer uses a single layer, solid vinylester laminate for safety. The hulls and deck are vinylester with a Divinycell foam core. They stiffen certain components with carbon for rigidity and durability.

Gunboat hulls are epoxy infused carbon fiber with a Nomex honeycomb core. They build dagger boards and other high load components with pre-preg carbon.

- Tags Buying Advice

By BJ Porter

Owner of Hallberg Rassy 53; world explorer.

4 replies on “Catamaran Construction – Hulls, Laminates, and Composites”

Excelent. Thank you for this I learned allot. Johan

Very straight forward information. Thankyou for doing this.

Damn…What an Amazingly Informative Article. *Cheers*

Outremer publish on their website that they use polyester. Not vinyl ester as you have stated.

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

- No products in the cart.

Catamarans and Trimarans

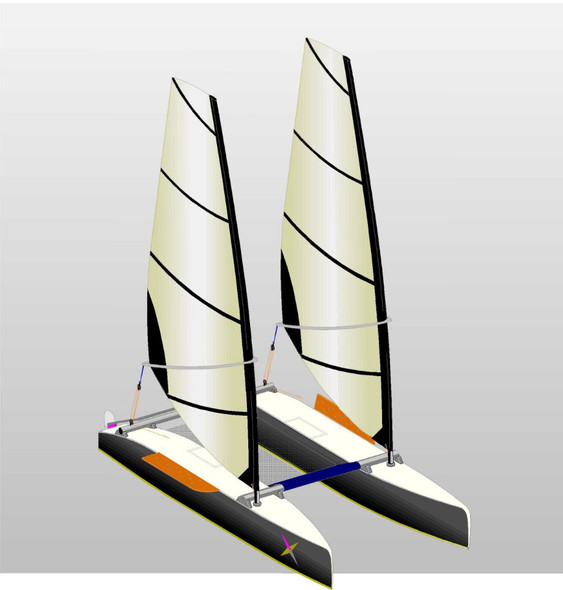

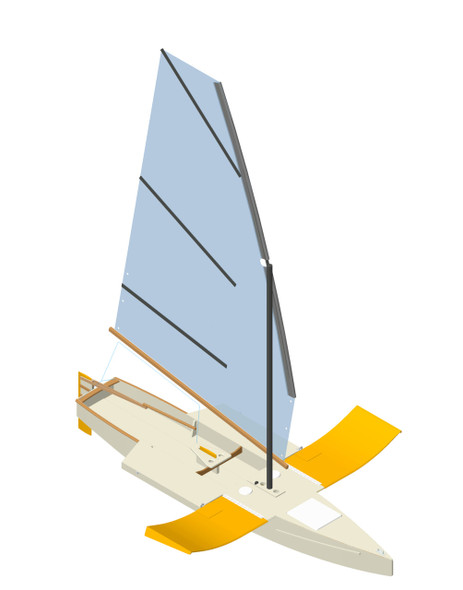

Catamaran and Trimaran Boat Plans make it a reality to build your own catamaran or trimaran. Multi-hulled sailing vessels are a special class of boat. A very different mind set is required when thinking about sailing a multi hull, let alone getting your head around building one.

There are some unique challenges building a multi-hull sail boat, the extra beam added by each hull for instance can create storage issues while under construction. Hartley boat plans make the build process straight forward for even amateur builders. However with all things considered, building a multi can be an amazing journey.

Fast Twin Catermaran

Lively 28 Cruising Trimaran

Lively 35 Cruising Trimaran

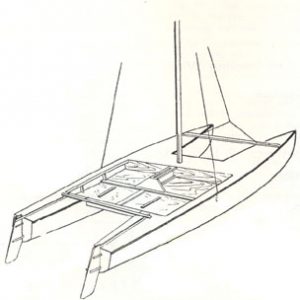

How To Create the Perfect Cruising Catamaran Layout

As an Amazon Associate, we earn from qualifying purchases. We may also earn commissions if you purchase products from other retailers after clicking on a link from our site.

More than ever before, sailing fans are gaining an interest in catamaran layouts and designs that define performance. Many others are also looking into either buying a cruising catamaran or designing and building one. While building a catamaran is no piece of cake, this article shows you how to create the perfect cruising catamaran layout.

To create the perfect catamaran layout, carefully consider factors like a good hull design, optimal helm station placement, boat stability, and adequate load-carrying capacity. Excellent galley positioning, ease of handling, and spacious living and sleeping quarters are also crucial.

The modern cruising catamaran is a far cry from the simple Polynesian double canoe of old. That’s because structural innovations and new composite materials have resulted in multihulls with impressive cruising abilities. Keep reading to learn more about exceptional catamaran layouts.

The Changing Trends in Catamaran Designs

The early cruising catamaran designs resulted in boats that could sail much faster than traditional sailing boats. In addition, they could glide with ease in shallow waters and required less wind and crew. Unfortunately, these cruising cats were heavy, had small, cramped interiors, and boasted somewhat challenging handling abilities.

Today’s cruising catamarans are different. They boast the utmost comfort, high speeds, and the safety of a well-designed cruising yacht. They are also more exciting, visually appealing, deliver the smoothest of rides, and sport more spacious interiors.

Have a look at the below video showcasing the top ten cruising catamarans:

Features To Look Out for in Catamaran Design Layouts

Cruising catamaran designers understand what most sailors look for in a cruising vessel. They, therefore, design cruising multihulls that address these pertinent issues and more. Some of the features you might want to consider having in your dream boat include the following:

- Responsive performance. Outstanding performance allows for pleasurable cruising and ensures your safety since you have more options during difficult weather.

- Excellent load-carrying ability . This allows you to have an extended cruising vacation or ocean crossing.

- Boat stability . Go for lightweight, robust construction, which results in a lot of buoyancy.

- A low center of gravity for smooth rides and enhanced performance. Centering weight around a low center of gravity improves the overall sailing quality, reduces pitching movement and reduces the risk of capsizing .

- Adequate bridgedeck clearance to reduce slamming and provide better performance in rough conditions. A high bridgedeck also means less noise and slapping action from the waves hitting the boat bottom, thus ensuring a quieter, smoother ride.

- Comfortable sailing. To enjoy a quality life on board, you need comfort while at sea. Thus, elements like gentle movement, no creaks or groans, no bridgedeck slamming, and minimal pitching are essential for quality, peaceful and restful sleep.

Now that you know what a cutting-edge catamaran features, let’s look at how to create the perfect cruising catamaran layout.

Build a Larger-Sized Catamaran

The early catamarans ranged between 36-42 feet (10.9-12.8m). At the time, this appeared to be a good size in terms of safety and ease of handling. However, the boats were heavy, and the additional drag and displacement adversely affected their performance and windward ability.

It’s now possible to make the new generation catamarans lighter, larger, and more spacious with excellent power-to-weight features. The current trend is larger-sized catamarans in the 45-50 feet (13.7- 15.2) range. Composite engineering and technologically advanced equipment such as furling systems, electric winches, and autopilot make it easier for a smaller crew to sail larger boats with confidence. And to do so without compromising safety or stability.

Get the Best Catamaran Hull Design

A cruising catamaran’s performance depends on three main aspects; its length, the sail area, and the boat’s weight. Long boats are generally fast. A light boat with more sail area is also faster than a heavier boat with less sail area. In other words, you can make a multihull faster by making it longer, lighter, or adding more sail.

However, there are exceptions to this rule; a boat with too much sail area is more likely to capsize if there are brisk winds. Also, if the boat’s design makes it too light, it’ll be unable to handle much punishment, while a hull design that’s too slim would make the vessel incapable of carrying any significant loads. But that’s not all; if the boat is too long or too large, it’ll become grossly exorbitant. Narrow hull shape might also mean smaller cabins.

Nonetheless, these three factors alone are not enough to determine a cruising catamaran’s performance. While faster boats boast finer hulls, the wetted surface area tends to increase as fineness increases; thus, fine hulls end up becoming less fast in low wind speeds. Also, very wide hulls mean a reduction in actual performance.

The Prismatic Coefficient (Cp), a measure of how full the ends of the hull get, is the most essential design hull shape factor for any catamaran. A high Cp equals high speeds, although you can still use a lower Cp if you have fine hulls. Nevertheless, the key to a good Catamaran design is a higher Cp for fast sailing.

To achieve a high Cp, there are several things you can do:

- Fit bulb bows . Unfortunately, the bulb bows tend to slam in a seaway when you do this.

- Have an extensive planning aft section . However, this can increase the wetted surface area, WSA and lead to additional challenges.

- Flatten out the hull rocker and add a bustle aft. This helps to add displacement aft.

Build Convertible Main Living Spaces

The open cockpit is now a thing of the past. Instead, pioneering designers for catamaran manufacturers like Nautitech, Gunboat, and Catana now replace traditional-style salons, cockpits, and cabins with spacious indoor and outdoor living spaces. The concept involves merging separate saloon and cockpit areas with duplicate lounge spaces and the use of hard-wearing composite materials.

You can also design the cabin to suit your preferences. You may decide to add a cabin or remove one, add a bathroom, have the forward berth in the hull or on the wing deck.

- The design enhancements boost usable space while opening up the living areas.

- It reduces time and costs for interior maintenance and cleaning.

- Large windows bring in more light, increasing visibility.

- Luxurious, spacious, and airy owners’ cabins provide more comfortable living space.

Bulkhead Helm Stations vs. Twin Stern Steering

Many catamaran owners have traditionally preferred bulkhead steering. This helm position remains popular, but twin stern steering positions come with more advantages since they provide greater sails visibility. The twin stern positions are also best suited for racing or day sailing since they often lack adequate protection for extended cruising.

Exposed helms are not ideal for a long ocean passage. Go for a safe, secure, and well-protected helm station that provides good visibility and comfortable space for long watches. Again, it’s best to have all control lines at the helm to establish a static control station. Also, have all push-button-controlled winches, instruments, windlass, and autopilot prominently located inside the cockpit.

- Twin stern steering positions give you a better view of the sails

- You get a better feel for overall sailing conditions.

- Twin stern steering positions lack the necessary protection for extended cruising.

Go for the Flybridge Design

The flybridge design is appealing because it offers excellent visibility, more comfort, and additional entertainment and lounging space for everyone on board. Unfortunately for smaller boats – those below 50 feet (15.24m), there is minimal protection from the elements. As such, you might want to consider adding enclosures to offer protection. The flybridge, thus the helm, remains cut off from the vessel, which makes communicating with the crew a challenge.

- It provides great visibility.

- It offers comfortable spacing.

- It might be unsafe to move from the cockpit to the flybridge in bad weather.

- It isn’t easy to communicate with the crew.

Daggerboards vs. Fixed Keels

Average cruising catamarans typically utilize fixed keels while high-performance cats have daggerboards . Fixed keels allow you to beach your catamaran easily, and your hull remains intact if a collision occurs. While you lose some angle when sailing upwind, you gain more interior space in the hulls that you can put to good use.

Daggerboards are essential in a performance cruising catamaran since they guarantee that the boat delivers good upwind sailing, including during difficult situations. During long passages, they allow you to point better upwind though the drawback is that they consume much interior space within the cruising catamaran’s hulls.

Since flying on foils ( hydrofoils ) isn’t that practical on cruising catamarans, designers of larger-sized boats have also come up with modified daggerboards. These daggerboards produce lift and prevent leeway, too, thereby improving performance significantly, as seen with the Catana 59’s curved daggerboards. These foil-like daggerboards lift the boat ever so slightly upon reaching higher speeds, making it feel less heavy and much faster.

At the end of the day, calculating the performance of a boat sailing in a wide range of varying seas and winds might not be easy – despite a daggerboard or fixed keel configuration. This is because upwind speed depends not only on the sails’ quality but also windage and the height of the bridgedeck beyond the water.

- The design innovations -curved daggerboards and hydrofoils- improve catamaran performance significantly.

- Daggerboards enable you to access otherwise inaccessible anchorages.

- Daggerboards take up hull space in the hulls of your vessel.

Galley Up vs. Galley Down

Galley layout are becoming more and more important as more people, including families, start sailing regularly. While at sea, your galley needs to be a safe place, well-ventilated, and functional. Everything should be well-thought-out for the sailor’s comfort, including handholds to make it safer to move around the boat.

While the galley location can either be up the bridgedeck or down in the hull, galley up appears to be the most popular trend. This makes the galley the focal point of both the living space and entertainment areas.

If you have a family, this placement is ideal since you make your meals from the galley and get to spend most of your time here. Many cruising families and couples prefer this arrangement and find separating the galley down the hull unappealing. Besides, carrying hot food up and down the staircase is unsafe.

Still, galley down is ideal for charter boats since it offers a private cooking area and uses up hull space efficiently.

- Having the galley on the bridgedeck is ideal for families and cruising couples.

- Placing the galley on a similar level with the serving area and cockpit is safer and less tiring.

- There’s better ventilation on the bridgedeck, making for comfortable cooking.

- There’s less kitchen privacy galley up.

- On smaller catamarans, this layout can impact the size of the saloon seating area significantly.

Production Catamaran vs. Custom

The choice of either a production catamaran or a custom design might seem pretty straightforward. Production catamarans from major brands come backed by proven designs, dependable construction, solid warranties, and many years of experience. The catamarans are easy to service, source for parts, and most – particularly the owner’s versions – hold on to their value, making them much easier to resell.

On their part, custom boats are fantastic in that you can tailor them to your exact needs. However, they might be more challenging to maintain or service. That’s because of parts unavailability and lack of construction knowledge.

Choose Quality Construction Materials

The best quality materials to use on your catamaran are both light and robust. While carbon fiber is great, plywood, plywood/epoxy, and strip-cedar are excellent materials too. What’s more, they are also affordable, so you don’t have to get too hung up on cutting-edge building materials. What matters is build quality; thus, a well-built plywood catamaran boat can last as long as a boat made from more high-tech materials.

Combining various materials also helps combat some of the issues that plague plywood boats in terms of resale value. At times, the design tends to make the boats appear pretty dated.

- Plywood and strip-cedar materials are affordable and provide excellent build quality.

- Plywood boats may have a lower resale value than those built with modern materials.

Consider Ease of Handling

An important factor in handling a cruising catamaran is deck layout. Most cruising catamarans sailed short-handed , so if your boat has one helm, all lines should run back here to allow for a static control station for the entire boat.

The other essential element is visibility from the helm. The 360 degrees of visibility while maneuvering, docking, or underway is crucial to your boat’s safety, as well as life and property. As such, you should be able to view both bows, or at least the pulpits and sterns, while standing at the helm. If not, you may have challenges handling the boat due to blind spots.

Consider the Load Carrying Capacity

A well-designed catamaran is enjoyable to sail in all weather conditions. It’s also much easier to handle than a monohull because of its widely spaced twin engines. But when you immerse extra hull depth, the vessel gets sluggish and moves slower, maneuvering in tight spots or when docking becomes more challenging. Furthermore, the hull submersion reduces bridge deck clearance, leading to hull slamming.

To allow for adequate load carrying capacity, you need a design that provides a generous displacement. This helps to ensure that you maintain reasonable bridge deck clearance even when fully loaded. It also allows you to avoid digging big holes in the water as you drag your transoms.

Displacement refers to the amount of buoyancy designed into the hulls, which essentially means that your boat will cruise better if its weight is less than your designed displacement.

Note that an overloaded catamaran not only loses out on performance but eventually, on safety too. To counter this, choose a lightweight catamaran with hulls bearing cored construction and interiors made of lightweight materials.

Remember, when you go cruising, you will need to carry fuel, extra water, supplies, equipment, and amenities, translating into thousands of extra pounds. Therefore, try and avoid the following design errors to ensure that your catamaran has an adequate load-carrying capacity:

- Avoid putting in place too much accommodation space.

- Avoid building a heavy boat ‐ use low-tech construction materials.

- Avoid installing inboards in a small boat.

- Lightly constructed catamarans perform faster and carry more weight.

- Cored construction makes for a strong and stiff catamaran, thus enabling good performance.

Final Thoughts

A well-designed cruising catamaran is a joy to behold. Today’s modern technological advancements mean that you can buy or build a light but strong cruising catamaran. And as you can see from this article, there are many excellent cruising catamaran layouts that you can choose from.

However, whichever layout you decide on needs to fit your sailing needs and purposes to ensure you remain comfortable and safe while at sea. Above all, ensure that you go for a vessel that you can handle with ease in all weather conditions.

Owner of CatamaranFreedom.com. A minimalist that has lived in a caravan in Sweden, 35ft Monohull in the Bahamas, and right now in his self-built Van. He just started the next adventure, to circumnavigate the world on a Catamaran!

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name and email in this browser for the next time I comment.

Recent Posts

Must-Have Boat Gear for Catamaran Sailors!

Sailing is probably the most gear-intensive activity I've ever done; there are so many decisions to be made about what gear to buy now, for tomorrow, and what to definitely never buy. The gear on...

6 Best Trailerable Trimarans For Bluewater and Coastal Sailing

Having a boat costs a lot of money, even when you are not using it, marina fees, etc. And once it is in the water most sailors never go very far from their "home marina" and sailing will be somewhat...

[email protected]

Category: Our Catamaran Build Kits

Recommended equipment.

Quality suppliers & manufacturers

The schionning team have a lot of contact with equipment suppliers and manufacturers, and hear feedback on certain brands or systems from our many customers. there are many schionnings cruising the world and testing products longevity and the customer service offered by the manufacturer., on this page we will list products and companies that we know to provide above average quality and service. it is always growing, and if your company provides equipment used on our designs and you would like to be included - please contact us., engines & drive systems.

Visit: https://oceanvolt.com

Batteries, Power Management

LITHIUM POWER (VIC)

Back in 2013 I knew that my boat batteries were reaching the end of their lives, I had been researching LiFePO4 cells for a few years and decided that I should install them. Unfortunatly I was unable to find a local supplier. So Lithium Power was established.

Technical Information

The technical information page is a collection of documents (mostly in pdf format) on the materials and systems used in schionning catamarans. including data sheets, engineering information, strength comparisons of each core material and informative articles from jeff outling the design of certain system such as engine choices and main sheet systems., detailed engineering data for your research, we understand that getting your head around the process of building your own boat, or having one built, can take a little while. to gain a greater understanding of the materials used in our designs, the below data sheets have been supplied by atl composites, and contain all of the technical data you could need regarding the composites we use. in addition are articles or documents written by jeff about certain systems used on our designs and why., all technical information and data sheets on west system/duflex/durakore provided courtesy of atl composites. for more information please see the atl composites website here., documents library.

Information Sheet – CE CERTIFICATION PROCESS

- Mainsheet Systems for Catamarans

- Motor Choices for Schionning Designs

- Weight and Weight Distribution Schionning Designs

- Schionning Designs Sailing Performance and Tips

- Hull Shapes and Performance – Power Designs

- Outboard Engines VS Diesels – Written by Ross McCombe

- An Outboard Installation That Works – Ross McCombe Follow up

- Data Sheet – DUFLEX BALSA for Catamaran Kit Builds

- Data Sheet – DUFLEX FOAM

- Data Sheet – FEATHERLIGHT Paper Honeycomb

- Data Sheet – WEST SYSTEM R105

- Data Sheet – PUMP SYSTEMS

- Data Sheet – MICROFIBRE BLEND 403

- Data Sheet – MICROLIGHT 410

- Data Sheet – MICROSPHERES 411

- Information Sheet – USING FILLERS

- Data Sheet – KINETIX RESIN Thixotropic

- Information Sheet – DURAKORE PLANKS 413

- Data Sheet – DURAKORE PLANKING 414

Kit Materials Contents

Kit materials' contents, so if you order a schionning kit, what exactly is going to arrive see an overview of the materials you will receive, and what each is used for during the build process. fibreglass cloth or tapes microspheres, microballoons or microfibers take a closer look and you can answer these questions., our schionning kits are a no nonsense, common-sense approach to building a boat. we offer great service, fast delivery and access to anything you could need for your boat straight from the supplier to your door. our construction plans and kits are sold with 100% professional boatbuilder support via phone and email, any time you're unsure or just need a second opinion, we're here..

Our kits contain all of your basic materials to build your boat to a faired shell stage, ready for painting and fit-out. We have sail-away costing estimates available for all of our standard designs, and this will give you an accurate idea of the overall cost of your project. This costing varies depending on your level of finish, as you can imagine different options vary greatly in price.

Below is a quick glance at what your Schionning Kit will include and what each item is primarily used for, we hope this is helpful and if you should require more detailed information please don’t hesitate to contact our office.

What do I actually receive?

DUFLEX PRE-LAMINATED PANELS

DuFlex pre-laminated panels are the main and most important material used in our kits, predominantly in the flat panel designs, however they are used in Strip-planked designs also, though to a lesser extent. These panels are 2400mm x 1200mm and are CNC routed to speed up build time on our Wildernes X Series, as well as some of our power designs. For internal furniture, a paper honeycomb core is used instead of the end-grain balsa wood core that is used for main structural areas. The use of this is purely to save weight in the shell and therefore produce a faster, more responsive catamaran.

KINETIX LAMINATING RESIN & HARDENER

WEST SYSTEM EPOXY RESINS

FIBREGLASS TAPES (DOUBLE BIAS)

CARBON FIBRE CLOTH

FIBREGLASS CLOTH

The kit process, building your own boat can be a daunting prospect, however to demonstrate each step in the kit assembly process, we've created this guide for you to study. as you can see our kits are the ultimate in building efficiency and have been streamlined over 30+ years to ensure that you're on the water faster and with less effort., how does it all go together.

The first step to building your dream catamaran begins with a strongback – this is a square frame used to position the temporary frames that will be used to form the hull shape. This frame will be set up and must be square and accurate, a string or laser level can be used to achieve this.

The forebeam is now installed along with the striker attachment fitting, as shown above. The bridgedeck is installed shortly after and taped onto the bulkheads with webs installed, this now completes what is a quite stiff and strong platform to work on.

Now that the bridgedeck is in place, the forward webs and dash will be fitted. At this stage, all furniture and internal work begins, with the main panels left off for ease of access when working.

Material Choices

Schionning material choices, solutions that work best for catamarans & why, our designs are based on cored composite construction techniques using west system epoxy resin and knitted fabrics. but given the range of today's composite technologies, which solution works best for catamarans and why written by jeff schionning, selecting the correct materials, resin choices.

It also fully protects the boat against water absorption and it can not develop the dreaded Osmosis.

We choose ATL Composite’s resin systems for their superior quality, reliability and value for money.

Having worked closely with the ATL Composites team and their products for many years, we know we can stand by their material solutions, and rely on great service should something unexpected happen.

This may not seem important but when working with a material for an extended period of time, the small things make all the difference.

CORES Which One to Use?

- End-Grain Balsa – 150kg per cubic metre

- Superlight Balsa – 94kg per cubic metre

- Western Red Cedar – 360-380kg per cubic metre

- Foam – 80kg per cubic metre

BALSA END GRAIN (150 kg/cubic metre)

Balsa has very good values and we can produce a shell using a very light laminate. It will be very stiff and very resilient to fatigue.

It has exceptional qualities including very high compression strength, extremely good sheer capabilities and fantastic sheer stiffness.

Compressive strength is the resistance to collapsing when pressure is applied perpendicular to the surface as when pushing directly onto the material with the point of your finger. Balsa is far stronger than Foam (80kg/cubic metre) in compression.

Balsa is also very strong in shear. This is when the core sample is held flat between your hands, one hand slid one way and the other slid the opposite way, when the core tears through the middle the core has failed in sheer. The amount of stretch you feel before the core shears is shear stiffness. To compensate for sheer weakness the core is made thicker. So 13mm Balsa may be equal in sheer to 19mm Foam.

(80 to 200 kg/m³)

There are many boats sailing that are built from foam as it’s mechanical properties are good for boat building.

- Initially one would expect this cat shell to be lighter as it is ½ the weight of Balsa. We do have to compensate for its weaknesses and will then add to the reinforcement the reinforcement on the outside to spread that compression load over more core and need a triaxial type weave to compensate for the veneer content that runs fore and aft on the Durakore.

- Secondly, we need to increase the Core thickness to compensate for the shear value, usually neutralizing the weight advantage.

- We only use structural foam core that is closed-cell and cross-linked.

The end result using foam core amounts to a very similar total boat weight. Professional builders can achieve a good result but usually use vacuum bagging and very good molds to achieve this.

Secondary Issues

Balsa can absorb water. It needs extreme neglect to rot (very unusual). Water soaks along the end grain quickly. It travels very slowly across the grain. We use balsa under the waterline especially because of it’s high compression strength for beaching etc. any core type must be sealed. Damage to all cores results in the same sort of repair. Notice a damp spot remaining when drying out to anti-foul… simply grind back the surface glass exposing the core, dry it out and re-glass – it’s that easy.

Timber cores are cheaper than Foam in most cases.

A light, high tech cat returns a far better (often 2 – 3 times) re-sale than lower tech materials. Often saving $10,000 on materials initially, loses $200,000 on re-sale – a serious reality.

Our boats can be built using Balsa, Foam or Western Red Cedar. Combine strength, stiffness, lightness and cost, with ease of use – it just makes good sense!

BUILD YOUR RAKU CAT WITH A DuFLEX KIT BY FOLLOWING THESE NINE BASIC STEPS

Step 1. Kit Design

Work with us to finalise the details of the design you have chosen including any design options or additional modules to be included in the kit.

We will determine the laminates, the number of panels required for each laminate, create the cutting files and prepare a quote for the kit if it is not already priced.

Once the design details and pricing are confirmed you are ready to place your order.

Step 2. Unpacking

2. The kit arrives at your workshop door, usually by container, as a stack of 1.2m x 2.4m routed composite panels ready to be joined. The shipment will normally include additional reinforcements, resins, and ancilary products as specified.

Unpack the shipment and stack the panels out of the way of the space where the panels will be joined.

If you have purchased a joined kit many of the panels will already be joined up to the length that can be shipped in a container (12m).

Step 3 Joining the Panels

Set up the work space where the panels are to be joined.

The panels have a scarf join called a Z join that facilitate the join without needing tapes.

The joining can be done with a heated Z press that cures the epoxy join quickly. Alternatively they can be joined with clamping pressure.

If the panel are are being joined with the Z press you will need an elevated work bench the full length of the longest panels you are using. (image below).

If you are joining them with a clamping technique the space can be on the factory floor.

A nesting booklet is provided with the kit to show how the panels are joined (right)

Joining the panels with clamping pressure

Panels are being joined into a single long panel by painting the surfaces of the scarf join with epoxy screwing through plywood battens that have a release film applied to one side.

Joining the panels with the Z Press

Step 4 Stacking Joined Panels

Once the joins are cured the panels are stacked to one side until they are needed for the job. The inividual parts should not be cut free of the panels until they are required.

Bulkhead and floor panels will be needed before the hull sides and cabin top so they should be left to the front of the stack wherever possible.

Step 5. Separating the Parts

When assembly is ready to begin the individual parts are separated from the panels by cutting the joining tabs. It is likely you will be building onto moulded hull bottoms that have been built from strip planking or another method of building moulded components. The process for building moulded components is described in another article.

Step 6. ASSEMBLY

As the joined panels are assembled onto the job you will need to apply glass tapes to the joins as specified in your plans.

Panels can be surfaced and coated inside and out with high build while they are on the workshop floor to minimise fairing time once they are assembled to the boat. The paint on the panels shown here has been kept back from the edges to provide a good bond for the tapes.

Smaller items such as steps, seats and dagger cases are nested into the kit and for the more complex parts diagrams are provided to assist with the assembly process.

Step 7. Interior

Interior kits can be ordered with the primary kit, or they can be ordered later when final decisions have been made about the interior arrangement.

A compromise solution is to order the interior as a set of plain planels that can be cut to shape on site after finalising the layout.

Step 8 Fairing, Painting, Hardware Installation

8. The DuFLEX construction process goes a long way to minising the amount of fairing that has to be done, but inevitably any boat that has not come out of a female mould will require some level of fairing and surface preparation prior to painting.

The fillers and resin systems required for the fairing work are normally supplied as part of the kit.

Hardware installation is the same as for any other form of construction using high density core inserts or consolidated laminate in way of fittings.

Step 9. Sailing

Go Sailing. This Barefoot 40 Catamaran was built entirely with a Duflex kit in Foam/Glass and Epoxy resin systems from ATL Composites

DuFLEX Kits are manufactured and supplied world wide by ATL Composites

atlcomposites.com.au

And in Europe by VDL Composites

www.vonderlinden.de/her/28/vdL-Composites-GmbH

For more information on DuFLEX and associated Products

atlcomposites.com.au/category/27/DuFLEX

Join the Newsletter

- Scroll to top

How to Build a Catamaran Boat? (Step-by-Step Guide)

Building a catamaran boat from scratch is a rewarding and challenging endeavor.

It takes a combination of skill, dedication, and hard work to craft a seaworthy vessel.

In this step-by-step guide, you’ll learn how to design and size your catamaran, gather the necessary materials, cut and assemble the pieces, lay fiberglass and apply epoxy, make finishing touches, add hardware and paint, and rig the boat.

With the right tools, planning, and patience, you can make your dream of sailing in a catamaran a reality.

Table of Contents

Short Answer

Building a catamaran boat requires a lot of patience and skill.

The first step is to choose the right materials for the hull, such as fiberglass, wood or aluminum.

Then, you will need to build the frame of the boat, which includes the crossbeams and the main hull.

After that, you will need to install the decking, the rigging, and other components.

Finally, you will need to paint and varnish the boat, as well as install the outboard motor and other accessories.

Design & Size Considerations

When it comes to building a catamaran boat from scratch, the first step is to determine the design and size of the boat.

This should take into account the intended use of the boat, such as sailing, fishing, or leisurely cruising.

The size of the boat will depend on the number of passengers and the type of activities the boat will be used for.

For instance, a larger boat may be needed if passengers will be standing or participating in watersports.

The design of the boat is also important and should be chosen based on the intended use.

If you are looking to build a sailboat, you will need a design that is optimized for sailing.

On the other hand, if you are looking to build a fishing boat, you will need a design that is optimized for fishing.

There are a wide variety of boat designs available, so it is important to research and choose the one that best suits your needs.

In addition to the design and size, you will also need to consider the materials used for construction.

The most common materials for building a catamaran boat are wood, fiberglass, and epoxy.

Each material has its own advantages and disadvantages, so it is important to research them and determine which one is best for your project.

Finally, you will need to consider the cost of the project.

Building a catamaran boat from scratch can be a costly endeavor, so it is important to have a budget in mind before you begin.

The cost will depend on the type of materials used and the complexity of the design.

It is also important to factor in the cost of any tools that may be needed for the project.

By taking into account the design and size, materials, and cost of the project, you can be sure to build a catamaran boat that meets your needs and budget.

With the right amount of patience and attention to detail, you can build your own catamaran boat in no time.

Gathering Materials

Gathering the materials needed to build a catamaran boat from scratch can be a daunting task, but it is essential for creating a sturdy and safe vessel.

Before starting the building process, it is important to have an accurate and detailed plan for the boats design and size.

Once a plan is in place, it is time to begin sourcing the necessary materials.

The most common materials used to construct a catamaran boat are wood, fiberglass, and epoxy.

When choosing wood, it is best to select a species of timber that is strong and durable, such as mahogany, teak, or cedar.

Additionally, the wood should be clear and free of knots, splits, and other defects.

Fiberglass is a lightweight fabric that is resistant to water and provides additional strength to the boats hull.

Epoxy is a waterproof adhesive that is used to seal the boat and ensure that it is watertight.

It is important to ensure that the materials are of high quality, as this will help to ensure the boats longevity.

Additionally, it is important to purchase the necessary materials in the correct amount and size.

Too little or too much of a material can be a costly and time-consuming mistake.

Finally, it is important to keep any leftover materials for future repairs or modifications.

With the right materials gathered, the next step is to cut the wood and begin the assembly process.

Cutting & Assembly

Cutting and assembly are the most important steps when it comes to building a catamaran boat from scratch.

The first step is to decide the design and size of the boat.

This will determine the type of materials you need to gather and the amount of effort that needs to be put into the project.

After deciding on the design and size, you will need to cut the wood to fit the design.

This includes cutting the wood to the desired size, as well as cutting any additional pieces that may be needed to complete the design.

It is important to ensure that all the pieces fit together correctly and securely, as any mistakes could lead to a weak boat.

Once the wood has been cut, it is time to assemble the pieces together.

This involves attaching the pieces together with glue, screws, and nails, and ensuring that the pieces fit together securely.

It is important to be careful and patient when assembling the pieces, as any mistakes could result in a weak and unstable boat.

Once the frame is ready, it is time to lay the fiberglass, and apply the epoxy to seal the boat.

This is an important step, as it will make sure that the boat is waterproof and durable.

Finally, you can add the finishing touches, such as the hardware, paint, and rigging.

With the right amount of patience and attention to detail, you can have your own custom catamaran boat in no time.

Laying Fiberglass & Applying Epoxy

When laying the fiberglass and applying epoxy, it is important to take your time and be precise.

Fiberglass and epoxy are key components of a catamaran boat, as they provide the strength and waterproofing necessary to keep the boat afloat.

Start by laying the fiberglass over the frame of the boat.

Make sure to cut the fiberglass to size and overlap the edges for a strong seal.

Once the fiberglass is in place, mix the epoxy and begin to apply it.

It is important to apply the epoxy in a thin, even layer to ensure a proper seal.

Make sure to move the epoxy around to get it into all the nooks and crannies of the boat.

Allow the epoxy to cure and then you can begin to add the finishing touches.

Finishing Touches

Once the frame of the catamaran boat is built, it is time to add the finishing touches.

This includes adding the necessary hardware, painting, and rigging the boat.

Hardware: Before adding the hardware, it is important to ensure that the frame is stable and secure.

Add the appropriate hinges, screws, and nails to the frame.

Make sure that the screws and nails are the correct size and do not exceed the recommended load capacity of the frame.

Painting: Once the hardware is added, it is time to paint the boat.

Choose a paint that is suitable for the materials used in the construction.

Make sure that the paint is applied evenly and that the frame is completely dry before applying the next coat.

Rigging: The last step is to rig the boat.

This involves attaching the sails, running rigging, and standing rigging to the masts and booms.

Make sure that the rigging is properly tensioned and secured.

Once all of these steps are complete, your catamaran boat is ready to sail.

Hardware & Paint

The last step in building a catamaran boat is to add the hardware and paint.

This step is often the most rewarding, as it is the finishing touch.

Depending on the design of your boat, there are various types of hardware you may need.

Some of the most common items are cleats, winches, fasteners, and decking.

After selecting the required hardware, you will need to install them on the boat.

It is important to use the correct type of screws and bolts, and to secure them tightly.

Once the hardware is installed, it is time to apply the paint.

The type of paint and color you choose will depend on the design of your boat.

It is important to use a high-quality marine grade paint that is designed to handle the extreme environment of the ocean.

If you are up to the challenge, you can add some custom artwork or detail to your catamaran boat.

Adding the hardware and paint is the final step in building a catamaran boat.

With patience and attention to detail, you can create a beautiful and unique boat that will last for many years.

Be sure to take your time and enjoy the process of constructing your own boat.

Once you have finished the frame, fiberglass, and epoxy of your catamaran boat, you will need to move onto the rigging.

This is a crucial step in the construction process, as it will keep your boat safe and secure on the water.

When rigging a catamaran, there are a few key components that must be taken into account.

First, you will need to determine the type of rigging you will be using.

Typically, catamarans use a combination of standing and running rigging.

Standing rigging consists of cables and lines that stay in a fixed position to provide stability and strength to the boat, while running rigging consists of lines that are used to adjust the sail and mainsheet.

Additionally, you will need to choose the right type of rope and hardware for your rigging setup.

The rope should be strong and durable, and the hardware should be made of stainless steel and be corrosion-resistant.

Once you have chosen the type of rigging and hardware, you can start assembling the rigging lines.

This process involves carefully measuring and cutting the lines to the proper lengths, and then attaching them to the mast and boom.

Depending on the type of rigging setup, you may also need to attach the lines to the hulls and deck.

It is important to inspect the rigging lines and hardware regularly to ensure that everything is secure and in proper working order.

Rigging a catamaran boat can seem like a daunting task, but it is essential for the safety and comfort of your vessel.

With the right tools, materials, and attention to detail, you can successfully and safely rig your catamaran boat.

Final Thoughts

Building a catamaran boat is a rewarding experience that requires patience and attention to detail.

With the right plan, materials, and steps, you can build your own boat in no time.

Now that you know the basics of how to build a catamaran boat, why not grab your tools and get started on your very own project? With the right motivation and dedication, you can make your dream of owning a catamaran boat a reality.

James Frami

At the age of 15, he and four other friends from his neighborhood constructed their first boat. He has been sailing for almost 30 years and has a wealth of knowledge that he wants to share with others.

Recent Posts

When Was Banana Boat Song Released? (HISTORICAL INSIGHTS)

The "Banana Boat Song" was released in 1956 by Harry Belafonte. This calypso-style song, also known as "Day-O," became a huge hit and remains popular to this day for its catchy tune and upbeat...

How to Make Banana Boat Smoothie King? (DELICIOUS RECIPE REVEALED)

To make a Banana Boat Smoothie King smoothie at home, start by gathering the ingredients: a ripe banana, peanut butter, chocolate protein powder, almond milk, and ice. Blend the banana, a scoop of...

Log in or Sign up

You are using an out of date browser. It may not display this or other websites correctly. You should upgrade or use an alternative browser .

Open Source 13-15m Catamaran Plans

Discussion in ' Projects & Proposals ' started by archie1492 , Jan 3, 2018 .

archie1492 Junior Member

Dear all, I want to create a detailed building information model for a 13 - 15 meter catamaran that is capable of being CNC cut and assembled. I need some help finding plans I can use as a basis of design. Specifically, I need the hull profile information. Section cuts through the hull will give me the ideal contours for a boat of this size. Can someone help? After weeks of searching, I still cannot find these online. For now, this is merely an exercise in my 3d modeling capability. I'd like to share my drawing work with the forum if I can get some assistance to start off. There are future possibilities I am also considering. I'm an experienced Architect & construction designer with a strong background in computer aided design. Once I've modeled the boat in 3d, I would like to flatten the various parts and create plans for the individual boat parts to be CNC cut. I would like to build a small scale model first (1:2o or perhaps 1:10) with the ultimate goal of building the boat full scale.

TANSL Senior Member

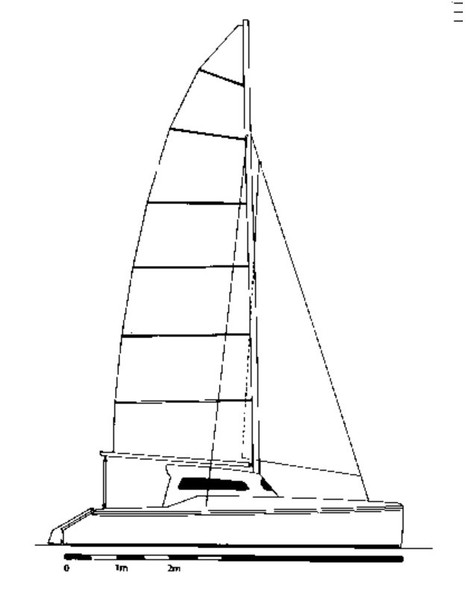

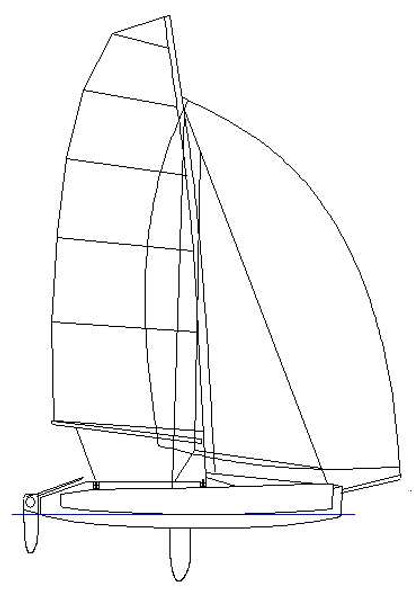

This is a very simple catamaran which, if you are interested, I can give you a lot of information. It is not a spectacular boat but it can help you in your first steps with boats. LOA = 16 m, Lbp = 14.6 m

Thanks I really appreciate it. The hull lines for the motor cat you've provided are not quite what i'm looking for. I'm specifically looking for the hull lines for a 14m catamaran sail boat. I guess there is some standard for these contours especially the area below the waterline. Check the attached document as well if anyone is interested in this.

Attached Files:

catdimension.pdf

I'm sorry, you never specified that it was a sailing catamaran. I thought that to carry out your purposes, " For now, this is merely an exercise in my 3d modeling capability ", any model was valid. Apparently, you have different purposes than, in addition to, to practice with 3D models. The better you clarify what you are really looking for, the better someone can help you.

Hi all, Here's an example of what kind of information I need to get started. Optimising Hull Lines for Performance https://www.graingerdesigns.net/the-lab/optimising-hull-lines-for-performance/ The boat shown here is a 8.5m cat sailboat. I'm looking for something a bit larger in the 14m range. Also, the images only show one of the hull profiles. I'd like profile lines for the entire boat. I will post some other images I've found online showing profile lines for smaller boats. I still cannot find any 14m hull lines. Can anyone help?

grainger_1488019480.jpg

Grainger_1488019410.jpg, grainger_1488019333.jpg, grainger_1488019265.jpg, grainger_1488019219.jpg.

Here are some other hull lines I've found online. Hope this is useful to anyone else looking for this information. Thanks!

Evergreen Lines small.jpg

Hull-lines.jpg, shark-20.jpg.

You could take any of those boats and scaleb the lines to get the desired length. Since it is only a 3D modeling exercise, you do not have to worry about anything else. You could even make a mix of 2 or 3 of those models to get the one you are looking for.

Thanks Tansl, I'd like to make the boat drawings accurate for the 14m size. Perhaps one day I will develop this into something worth building full scale. The more accurate I can draw the boat, the more I will learn about the boat design.

Maybe it does not look like it but I would like to help you. If you do not find what you want on the Internet I could draw a lines plan, strictly following your instructions, which would help you to make the 3D model. Or, if you find something similar on the internet I can adapt it to your needs and fill in the information that you indicate you need for your work. I insist that starting from the shapes of a 10 m boat you can get the shapes of a boat of 14 m, with total accuracy.

Dolfiman Senior Member

archie1492 said: ↑ I'd like to make the boat drawings accurate for the 14m size. Perhaps one day I will develop this into something worth building full scale. The more accurate I can draw the boat, the more I will learn about the boat design. Click to expand...

Cata 14m with Gene-Hull UE Catamaran 2.3_2018 01 15.ods

Gene-Hull Catamaran 2.3 User Guide_2018 01 16.pdf

Hull for cata 14m with Gene-Hull UE Catamaran 2.3_2018 01 16.pdf

Dolfiman, thanks so much! This is exactly what I was looking for. It's very interesting and probably a bit over my head at this point. I think this should work for modeling the basic hull shape. For the bridge deck and all of the stuff above the hull I can model this with a bit more creativity. Although, I'd like to learn more about understanding the center of gravity for the boat and the proper location of the mast. Are there any rules of thumb about this? Thanks again!

archie1492 said: ↑ I think this should work for modeling the basic hull shape. Click to expand...

Cata 14m V2 with Gene-Hull UE Catamaran 2.3_2018 01 15.ods

In complement to illustrate this first approach, my good friend Alain did some 3D views here attached of the hull V2 version with Multisurf (using fit for purpose ouput data in section 5. of the above file). To inspire you , some other examples of cata, more sport/day sailer oriented than the Saona 47 : - R/P 45 (Reichel-Pugh) : multihull http://reichel-pugh.com/tag/multihull/ - Dazcat 1295 : in this video, from 1:45 the launch, you can see the hulls from various angles https://www.youtube.com/watch?v=0BZF4Udda5E - SIG 45 (VPLP design) : from 1:20 you can see the winward hull fully lifted

dean 1962 New Member

archie1492 said: ↑ Dear all, I want to create a detailed building information model for a 13 - 15 meter catamaran that is capable of being CNC cut and assembled. I need some help finding plans I can use as a basis of design. Specifically, I need the hull profile information. Section cuts through the hull will give me the ideal contours for a boat of this size. Can someone help? After weeks of searching, I still cannot find these online. For now, this is merely an exercise in my 3d modeling capability. I'd like to share my drawing work with the forum if I can get some assistance to start off. There are future possibilities I am also considering. I'm an experienced Architect & construction designer with a strong background in computer aided design. Once I've modeled the boat in 3d, I would like to flatten the various parts and create plans for the individual boat parts to be CNC cut. I would like to build a small scale model first (1:2o or perhaps 1:10) with the ultimate goal of building the boat full scale. Click to expand...

- Advertisement:

Archie, I have been looking to do the same thing. Where are you at on the project? Very interested in hearing all about it. Thanks.

The Open Trawler Project!

- No, create an account now.

- Yes, my password is:

- Forgot your password?

- Outremer 45

- Outremer 4X

- Outremer 4.zero

- Outremer 52

- Outremer 55

- Outremer 51

- Outremer 5X

- All the Outremer Fleet

- Personalized support

- Blue Water Sailing Seminars

- Our concept

- The Outremer team

- Our commitments

- Construction principles

- Our catamaran services

- After-sales customer service & Quality control

- Offshore Connected Catamaran Maintenance

- Concierge Services

- Our owners’ stories

- FAQ – Outremer catamarans

- Brokerage: used catamarans for sale

- Privacy Policy

- Legal Notice

- Grand Large Yatching

Building expertise: our catamaran construction principles

At Outremer every specification has to be precise and consistent with what the naval architect has drawn. During catamaran construction, he or she works in close collaboration with the designers and engineers to reach a harmonious end result.

Safety, reliability, performance, comfort, and pleasure are the key words throughout the design of an Outremer blue water catamaran.

Peace of mind no matter the weather conditions.