UNDERSTANDING BOAT DESIGN PROCESS: CONCEPT TO CREATION

The boat design process is a multi-faceted and technical endeavor that encompasses several stages, each with its own set of challenges and considerations. The process requires a comprehensive understanding of naval architecture, structural engineering, and materials science. In this article, we will outline the four primary stages of the boat design process and the specific technical considerations involved in each stage.

Stage 1: Conceptual Design

The initial stage of the boat design process is conceptual design. This stage involves creating initial sketches and concepts that will ultimately be refined and developed into a final design. During this stage, the designer must take into account factors such as the intended use of the boat, the type of water it will operate in, and the number of passengers and crew it must accommodate. Additionally, the designer will consider the overall aesthetic of the boat, including its lines, shape, and style.

- Brainstorming: The designer will gather information and ideas about the project and begin sketching various concepts that could work.

- Research: It is important to research the intended use of the boat and the type of water it will operate in, as well as the number of passengers and crew it must accommodate.

- Evaluation: After creating several concepts, the designer will evaluate each one, taking into account factors such as feasibility, cost, and overall aesthetic.

- Concept Sketches: The designer will sketch out different concepts, keeping in mind the intended use, size, and overall aesthetic of the boat.

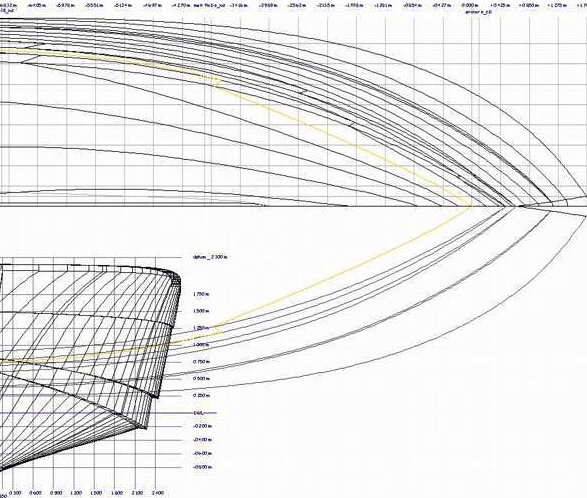

- Profile/top view 2D: The designer will create a 2D profile and top view of the boat, which will provide a detailed view of the overall shape and layout.

Stage 2: 3D Visualization & Renderings

Once the designer has settled on a final concept, the next step in the boat design is to create a 3D visualization of the boat. This stage involves creating a detailed, three-dimensional model of the boat that can be viewed from all angles. The model will include all of the major components of the boat, including the hull, deck, and superstructure.

- Complete 3D model: The designer will create a detailed 3D model of the boat’s exterior, including all of the major components such as the hull, deck, and superstructure.

- Photo-realistic renders: The designer will then create photo-realistic renders of the boat, using advanced texturing, lighting, and rendering techniques.

Stage 3: Detailed Design & Construction Drawings

Once the 3D model is complete, the final step in the boat design process is to create detailed construction plans. These plans will include all of the information necessary to build the boat, including detailed plans for the hull, deck, and superstructure, as well as specifications for materials and components.

- Final hull shape optimization: The designer will use the results of structural calculations to further optimize the shape of the hull for improved performance and stability.

- Weight Estimate: The designer will also estimate the weight of the boat, taking into account all of the materials and components that will be used in its construction.

- Structural Drawings: The designer will perform structural calculations to determine the strength and stability of the boat. These calculations will take into account factors such as the weight of the boat, the forces it will be subjected to, and the materials used in its construction.

- Stability: The designer will also perform stability calculations to ensure that the boat will remain upright and stable in various conditions. This will include determining the center of gravity and the metacentric height of the boat.

- Resistance and Powering Calculation: The designer will also perform resistance calculations to determine the amount of drag the boat will experience in the water. This will be used to optimize the boat’s hull shape and propulsion system.

- CNC Files: The designer will create CNC (computer numerical control) files, which will be used to control computer-controlled cutting machines during the construction process. These files will contain precise instructions for cutting and shaping the materials used in the construction of the boat.

- Manufacturing Drawings: The designer will create detailed manufacturing drawings for each component of the boat, including the hull, deck, and superstructure. These drawings will contain all of the necessary information for the construction and assembly of the boat, including dimensions, material specifications, and fastening locations.

- Bill of Materials: The designer will also create a bill of materials, which is a comprehensive list of all the materials and components that will be required to construct the boat. This list will include items such as the type and quantity of materials, as well as the suppliers and vendors who will be providing them.

Stage 4: Launch & sea trials

After the construction is completed, the boat is launched into the water. This can be done by either hauling it out of the dry dock or sliding it down a slipway into the water. Sea trials: Sea trials are conducted to test the boat’s performance and seaworthiness. This includes testing the boat’s speed, maneuverability, stability, and handling. The boat is also checked for any leaks or other issues that may have arisen during the construction process. Any necessary adjustments or repairs are made before the boat is delivered to the client.

In summary, the boat design process is a complex and technical endeavor that involves several stages. Each stage requires a thorough understanding of naval architecture, structural engineering, and materials science. By following these stages and paying attention to the specific technical considerations involved, a designer can create a safe, efficient, and aesthetically pleasing boat that will meet the requirements of the client.

To read about the “ QUESTIONS TO ASK A DESIGNER TO BUILD YOUR DREAM BOAT “, click here

0 comments Leave a reply

Save my name, email, and website in this browser for the next time I comment.

Recent Posts

- THE CHALLENGES Of SMALL CRAFT DESIGN COMPARED TO LARGER VESSELS

- UNDERSTANDING ROYALTY AGREEMENTS & DESIGN OWNERSHIP IN BOAT DESIGN

- FREQUENTLY ASKED QUESTIONS TO A BOAT DESIGNER: A COMPILATION

- ADVANTAGES OF HDPE COLLAR OVER REGULAR RIB

- HDPE’S EXCLUSIVE FEATURES DISTINCT FROM TRADITIONAL BOAT MATERIALS

Recent Comments

- Casey Lim on HDPE BOAT PLANS

- BRYN BONGBONG on HDPE BOAT PLANS

- Keith on HDPE BOAT PLANS

- Daniel Desauriers on WHY HDPE BOATS?

- November 2023

- October 2023

- February 2023

- January 2023

- September 2022

- January 2021

- ARTIFICIAL INTELLIGENCE

- boatbuilder

- BOAT CONSTRUCTION TECHNIQUES

- BOAT DESIGN COST

- boatdesign process

- CAREER PATHWAYS

- COMMERCIAL BOATS

- conventional boats

- custom boat

- DESIGN ADMINISTRATION

- DESIGN SPIRAL

- EXTREME CONDITIONS

- Freelance advantage

- freelance boat designer

- FRP Boat without Mold

- HDPE Collar

- INDIA'S MARITIME

- INVENTORY MANAGEMENT

- ISO STANDARDS

- Mass Production

- Monhull vs Catamaran

- Naval Architect

- Naval Architecture

- PLANING HULL

- Project Management

- Proven Hull

- PSYCHOLOGY OF BOAT DESIGN

- QUALITY CONTROL

- RECREATIONAL BOATS

- ROYALTY AGREEMENTS

- SANDWICH VS SINGLE SKIN

- SOLOPRENEUR

- YACHT DESIGN COURSE

Messing about in boats since 1975. Online Since 1997.

Home | Intro | Our Design Process | Stock Design Info | Motor Yacht Designs | Sailing Yacht Designs | Prototype Designs Plans List | Articles | Our CAD Design Stream | Maxsurf | News..! | SITE MAP..! | Site Search | Design Team | Contact Us Please see the AVAILABLE BOAT PLANS web page

Creating A New Yacht Design Copyright 2016 Michael Kasten Updated June 2016 The Yacht Design Process The following article is a summary of how a new custom yacht design is imagined, sketched and drawn. In addition to the following notes, our Introduction web page provides an outline of our general approach to yacht design. While seemingly complex, the design process is made up of a series of incremental steps, much like the building process itself. The goal of undertaking the design of any new yacht is to take a unique set of owner requirements and to turn them into the best possible solution to those requests. If the resulting design is to be what it should be, each of the steps outlined below must be addressed thoroughly. There is first the idea, and then the bringing forth of the idea into a functioning reality. In order to get the relevant information on the table, two primary ingredients are necessary: I. Owner's Specification: The first 'design task' is actually performed by the prospective boat owner. It is first to imagine the goal, and then to create an 'Owner's Specification' or 'mission statement' for the proposed vessel. With that information understood, we will provide a written Design Proposal to outline how we propose to meet the goals that have been set forth. Rather than being a detailed description of the result of the design process, the Owner's Specification is better if seen as a general guide to the intent of the design. Toward that end, ideally the owner's 'mission statement' will be kept fairly simple, since the details of the design will emerge as a result of the design process itself. The basic information needed is an outline of the intended vessel's size, layout, materials of construction, the intended use, range, speed, rig, and general aesthetic. The essential information should include the intended schedule for designing and building the yacht. II. Design Proposal: My first job is to understand the preliminary Owner's Specification, then to provide the prospective client with a detailed outline for creating the new design. This is in the form of our standard written 'Design Proposal' which includes the following: A written outline of the design process itself. A list of the deliverable drawings and documents. An estimate for the design work required in order to create the design and to detail the plans for the vessel as described. The following paragraphs describe our design process, and outline the deliverable drawings and documents. Stage I - The Preliminary Design Study After our ' Design Proposal ' has been reviewed, if the prospective boat owner approves of what we have proposed, then the actual design work can begin. A custom design starts with listening to the requirements of my clients. The objective is to create the best mutual design solution in terms of vessel type, layout, size and style. My goal is to propose an appropriate form and function to suit the vessel's intended purpose, and to follow that up with a thorough analysis of structure, stability and performance. There will first be a series of information exchanges, possibly including clippings of similar vessels or sketched layouts provided by the client. After the owner's requirements have been articulated I will usually begin by creating a preliminary 3D CAD model of the intended vessel, which is most often created by adapting one or more of our existing designs or prototype designs to its new purpose. The 3D model allows us to determine: The envelope available for the accommodations The overall size and hull form The preliminary internal structure (bulkheads and soles) The rig (if for a sailing vessel or motor sailor) The styling and features of the superstructure The preliminary hydrostatics With that, I will prepare a few CAD generated drawings in order to show the proposed layout in Plan and Profile views and a perspective view of the proposed Exterior Styling . Combined with a description of the proposed dimensions and other particulars of the vessel, this is the beginning of what I refer to as 'Stage I' or the preliminary ' Design Study .' Stage I is basically a process of ‘discovery’ wherein we mutually discover the best solution to your requests. In pursuit of that ‘discovery’ process we will review our proposed design solutions against the original specification -- or possibly the initial specification will be revised according to what we discover. This process is both flexible and adaptable. During Stage I we will strive to establish the accommodations, styling, size, dimensions, and the target displacement. Our goal here is to provide a "proof of concept" for the design so that further changes can be kept to a minimum. When the preliminary design has been approved by the owner, Stage II can begin. Stage II - The Estimating Plans The goal of Stage II is to create the first few sheets of the actual Building Plans, and to generate a number of essential documents that will be required by builders so that an accurate construction estimate can be provided. The first part of Stage II involves finalizing 'Stage I Study Drawings'. The preliminary Estimating Plans will therefore include: The proposed Sail Plan or Outboard Profile The proposed Interior Profile and Arrangement Plan Once those drawings have been approved, we can proceed knowing that further changes will be minimized. When completed, the Estimating Plans Package will include: Sail Plan / Outboard Profile Interior Profile and Arrangement Plan Structural Profile and Arrangement Plan Equipment List Vessel Specification Painting Specification Preliminary Weight Study Preliminary Power and Range Analysis Preliminary Hydrostatics Analysis List of Boat Builders Suited to the Project Designer's Cover Letter to Builders Sample Owner's 'Request for Quotes' Letter to Builders For smaller vessels there will be three drawing sheets at this point. For larger vessels there may be two or more sheets in each category. The goal of Stage II is that enough information be presented in the Estimating Plans Package that firm quotes can be obtained from prospective builders for construction of the vessel. If you would like to review an example of our design work up to this point, Estimating Plans are available for any of the designs listed on our Plans List page. Stage III - The Building Plans During ' Stage III ' the remaining design work is completed. With additional owner and builder feedback, further decisions can be made with regard to equipment and finish as needed. The drawings, Equipment List and Vessel Specification are refined and the remaining drawings are completed in order to create a final Building Plans package. These drawings and documents will finalize the interior and exterior details, the machinery arrangement, the deck plan, scantlings, construction sections, the boat's final dimensions and hull shape, and the as-designed displacement, range, performance, hydrostatics and stability. The Building Plan Drawings will include: Outboard Profile: Sail plan or other exterior details of the hull Deck Plan: Cabins, hatches, fittings, mooring and anchor gear Interior Profile and Arrangement: The vessel's accommodations Sectional Views: Structure and interior joinery sections Inboard Profile: Structure and primary equipment Various Structural Details as needed Mechanical / Machinery Details as needed Rudder Details Spar and Rigging Plan as needed Hull Fitting Details Hatch and Deck Fitting Details Companionway, Door and Portlight Details Interior Joinery Details Lofting Conventions Drawing Lines Drawing Several of the above drawing categories may include a number of individual sheets. Depending on vessel size and complexity, the Building Plans may include anywhere from 10 to 40 or more drawing sheets. During Stage III the Equipment List and Vessel Specification are finalized in order to accurately describe the intent, the layout, the scantlings, the construction, the systems and the outfit of the vessel. In addition to the above listed drawings, the following Documents will be included in the Building Plans set: Equipment List: The complete list of equipment items. Vessel Specification: Details of the intent, rationale and construction. Painting Specification Scantling List Welding Specification for metal structure Fastening Schedule for wooden structure Laminate Schedule for GRP structure Offsets Table (unless the vessel will be NC cut). Power and Range Analysis Report Weight Budget Summary Hydrostatics Report Stability Compliance Report Cover Letter to Builder Having finished Stage III, the Design Phase of the new yacht will be complete. Sufficient information will be contained in the drawings and documents to allow any professional or amateur builder to build the vessel as intended. Then the Construction Phase of the project may begin. Standards Used Design Goals : Throughout the design process we have the following goals: Suitability to the owner's requirements and to the intended service. An interior and on-deck layout per the owner's requirements. A pleasing aesthetic. A thorough specification to assure longevity and ease of maintenance. Sensibility of structure for the sake of ease of construction. A functional and accessible machinery and equipment layout. A distribution of weights to provide correct trim and adequate stability. Performance suited to the expectations of the vessel type. Structure per classification society scantling rules. Stability per international criteria. The general attributes of seaworthiness, seakindliness, strength and durability are considered to be requirements for each of our designs. It is interesting to note that for private yachts within the US, there are no requirements for stability or for structure. However if a US yacht is to be used commercially or Classed and built under survey, one or more of the following standards will apply. Whether or not a private yacht will be Classed, it is our position that all yachts be held to the following standards. STRUCTURE : When creating a new design, classification society rules are the best guide for the adequacy of structure. We will confirm compliance with one of the following rules as appropriate to the vessel type, size, materials or build venue (for more information, see our article on Designing to the ABS Rule ): ABS 2000 Motor Pleasure Yachts (applicable to motor yachts from 79' to 200' scantling length - all materials - now obsolete for yachts) ABS 1994 Offshore Racing Yachts (applicable to sailing yachts from 79' to 100' scantling length - all materials - now obsolete for yachts) ABS 2016 Steel Vessels (applicable to steel vessels up to 295' scantling length - obsolete for yachts, but still required by the CFR for commercial yachts carrying passengers) ABS 2016 Yacht Rule ( new rule applicable to all motor and sailing yachts in all materials up to 90 meters scantling length (295 feet) ISO-12215 for vessels subject to the EU-RCD standards (yachts up to 78' measurement length - all materials) Germanischer Lloyds (wooden yachts up to 78' scantling length - under revision as GL and DNV begin to merge their rules) Germanischer Lloyds (plank-on-frame commercial wooden vessels up to 115' scantling length - applicable to larger vessels on approval) British Lloyd's Register (plank-on-frame wooden yachts up to 98' scantling length - applicable to larger yachts on approval) STABILITY : To assess stability we use a variety of criteria depending on vessel size, use and location, as follows: For private yachts under 24 meters measurement length (78 feet) intended for registry in the EU, stability will be calculated according to the EU-RCD standards (ISO-12217). For private or commercial yachts above 24 meters measurement length, stability will be calculated according to IMO, MCA or other standards appropriate to the vessel type, size and use. For commercial charter yachts in the US, safety and stability will be calculated according to the US Code of Federal Regulations (CFR). For private or commercial yachts in the US, stability will be calculated according to the new ABS 2015 Rules for Building and Classing Yachts, which defer to the IMO or MCA standards depending on vessel type and size. For yachts in Canada, stability will be calculated according to criteria established by Transport Canada, which for the most part defer to to the IMO or MCA rules. For yachts in other locations, stability will be calculated according to locally applicable criteria - most often the IMO or MCA rules, depending on vessel type, service, and size. When a vessel is destined for construction and use within the European Union, we also prepare documentation regarding structure and stability in order to make obtaining a CE Mark a relatively easy process for the builder. Construction Support Services We ordinarily recommend that plans be submitted to a few selected yards for their construction estimates. We have worked with a variety of builders in a number of places worldwide. We will try to match a project with an appropriate builder, even if that may be outside the US. During the Construction Phase of the process, there may be various requests for additional services in support of construction. Although we don't get into project management per se, we remain available to act as the owner's representative during construction whenever we are asked to do so. In other words, although we do not get involved in managing personnel, scheduling or purchasing, we are pleased to remain involved in order to manage the flow of information and specifications for the builder. Additional Drawings, Documents, Schematics... Ordinarily, system schematics are developed in-house by the builder (e.g. plumbing, fuel system, etc.) or by system suppliers (e.g. electrical, hydraulic, air conditioning, etc.). On occasion the owner or builder may request that we provide basic schematics or additional drawings to illustrate specialized features or other details in support of construction in order to communicate specific owner requests to the builder. For passenger vessels or other commercial craft there may be the requirement to provide additional drawings and reports for documentation and compliance with the relevant standards. And when a vessel is destined for use within the European Union, we can prepare documentation that makes obtaining a CE Mark relatively easy for the builder. NC Cutting Files One of the most valuable Construction Support Services we provide for metal boats is to develop NC Cutting Files in order to automate a portion of the vessel's construction. What is NC...? It simply means Numerically Controlled... By this method a numerically driven plasma or water-jet cutter can be used to create frames and plates for a metal vessel. One can also use an NC driven router to cut mould frames for a wood or composite superstructure. It is even possible to carve an entire male plug or female mold out of foam for use in building a composite superstructure, directly from the computer generated surface model that was created during the design of the boat. This leverages the work that has already been done in order to create the design and can provide a significant labor savings to the yard. It also dramatically improves accuracy of construction. With NC cutting, the labor saved during fabrication of a metal hull will usually pay for the cost of developing the NC cutting files, plus some. In other words NC cutting is an opportunity to not only effect a true cost savings by shortening the overall build time, but to also improve the quality of the result. The Role of the Computer Designing the Boat : We use the Maxsurf family of software products, a series of programs for hull modeling, analysis, and construction. With Maxsurf, a preliminary hull model is quickly generated and an initial round of hydrostatics, stability, and performance calculations performed to see where the design can be improved. The computer generated model allows the design to be enhanced quickly at an early stage of design before it has become fixed, or even to be modified without too much fuss later in the process. In fact, without such an easily used computer modeling tool (as compared to manual drafting) those subtle refinements would rarely be undertaken even if given a substantial budget. Several other benefits are also evident. For example, via the computer generated model it is easy to assure that the surfaces are developable, so building a metal or plywood hull is made simpler. Testing the Design : With the computer generated model of the hull and superstructure having already been created, it is a simple matter to make a scaled down physical model for towing tank testing, or to verify the styling and features of the yacht in three dimensions. Building the Boat : A substantial benefit of having generated a model of the hull on the computer is that the vessel's structure can also be computer generated and actually pre-cut via computer guided laser or plasma cutting - or in the case of a GRP vessel, the mould created using a computer guided router. By this method, having detailed the hull plating and structure, the parts are nested onto available plate sizes. The completed plate nestings are then sent to the metal cutters - usually by email. This is extremely convenient since the cutter can receive the information immediately in order to start the work. When completed, the cutters have a "boat kit" that can be shipped wherever needed. The Savings : When building a metal boat in a production environment, assuming one-off construction, industry feedback is generally that NC cutting will save a professional builder some 35% or so of the hull fabrication labor. The percentage of fabrication labor saved by an amateur owner-builder is dramatically greater. For example, consider that lofting is eliminated, as are templating for frame and plate patterns. For an amateur builder, this also eliminates most of the "what to do and how to do it and why" kind of worries... Other Benefits: Via NC cutting an extremely accurate fit results. For a metal hull this means there will be far less distortion during the weld-up. For construction in other materials such as GRP, NC cutting nearly eliminates the labor required for lofting and for mold construction. An entire hull and superstructure mold can be carved by five axis NC router directly from the computer generated model, avoiding nearly all tooling labor. A builder can also pre-cut glass fiber or carbon fiber cloth, especially useful with 'pre-preg' cloth (cloth that is pre-impregnated with resin and post-cured by UV or by heat). Where the materials cost is high, the improved efficiency will quickly offset the cost of having developed the structure via computer modeling. Design-Stream Overview For more detail on our design and build strategy please see our CAD Design Stream article. The following flow-charts were created in order to show our design process - more or less taking the usual "design spiral" and stretching it out into a linear diagram. I have used two different ways to represent the work-flow. Software in Use - This is a simplified flow chart showing the software we use, and how a few basic software groups interrelate during the process of creating a new yacht design. Process & Deliverables - This is a workflow chart showing our Design Process arranged in terms of the "order of operations" that we follow in order to create each new yacht design. This process starts with our interaction with the client as described above, then moves into the stages of the design process wherein we produce the drawings and documents that we deliver to the client, the builder, and to the metal cutter. Cool 3D Models The following are two examples of how we make good use of a 3D CAD workflow in order to create a design and its structure, then to communicate the result using 3D PDF files for use by both client and builder. 3D Lines Drawing - This is a 3D perspective file showing the lines of one of our designs. As with all of our designs, it was created in Maxsurf , then imported to Microstation so that it could be "plotted" to a 3D PDF for customer review. Within the PDF, you can grab the 3D model, rotate it, zoom, pan, walk-through, and you can change the perspective. If you turn on the PDF menus, you can also manage the layers in the original CAD drawing, turning any of them on or off to simplify the view. This is an excellent tool for visualization of the spaces, and to see the vessel's shape from any angle. 3D Structure Drawing - This is a 3D perspective file showing the structure of a metal yacht design. Having been designed in Maxsurf , the vessel's structure was then created in Workshop ; after which the basic structure was brought into Microstation for editing and detailing, and then "plotted" to a 3D PDF for the builder to use as a guide during assembly. It is an excellent way to view the structure using simple, free Adobe Reader software. This enables the builder and his crew to see exactly how the structure interrelates. Why Develop A New Design...? As you may have surmised from the above, there is a fair bit of work involved in designing a boat well, even if it is a simple one! Given the number of designs that already exist it may seem a little bit wild to commission a new yacht design. On the other hand, it is an unquestionable delight to see one's ideas turned into one's own personal yacht. You will be surprised to discover that the cost to develop a new and unique yacht design is ordinarily less than a yacht broker's typical fee to purchase an existing yacht...! I'll repeat that in case you missed it... Even though there is quite a lot more work involved to create a boat design, the cost to create a new custom yacht design is ordinarily less than a yacht broker's fee for the simple act of signing the purchase papers...! As a percentage of the yacht's cost the amount expended on design is really not very much. If you also consider that a custom design will be tailored to your particular requirements rather than being an "off-the-shelf" solution, the difference in satisfaction will be well worth the effort expended. This is especially so if a custom designed yacht will better serve its intended purpose and will therefore be able to do so for a longer time, versus a vessel built to a stock design. In other words, by not having to replace the yacht quite so soon, the cost of custom design work will easily have paid for itself, in all likelihood many times over. Is It Proven? The question inevitably comes up: " Is it a proven design?" The answer is an unqualified " Yes !" The basic principles of boat design, while seemingly complex, are well established. If faithfully attended to, the success of a new vessel is assured, and the result will nearly always be an improvement on what has been done before on existing designs. Where unusual features or hull types are requested, it is prudent to involve tank testing, which can provide valuable insight as to vessel behavior; performance; stability; seakeeping; etc. What ultimately makes a boat a success is whether the vessel is safe, seaworthy, sea kindly, beautiful to behold, and above all, whether the vessel satisfies the originally stated wishes of the owner. Establishing a Design Philosophy... My aim is to engender superior aesthetics along with safe and comfortable boating. A distinguishing characteristic of our design work during the last few decades has been a focus on Nomadic Watercraft , in other words the design of truly pelagic blue water boats for family cruising and world voyaging. I strive for long term owner satisfaction with the resulting vessel, using the most up to date methods and design tools, including software optimized for hull modeling, stability and performance analyses. With this approach, I am able to leverage the work done to create the design into subsequent detailing of the vessel's structure in order to provide an NC cutting file package to automate parts of the vessel's construction, a process that is outlined in our CAD Design Stream article. My goal is to provide a complete "design service" from the point of imagining the vessel, to creating the ideal solution to those conjurings, in other words to take the concept all the way from 'napkin sketch' to building plans, and to then provide the various "construction support services" noted above. Where To Begin? The place to start the design process is to first create an Owner's Specification, or "mission statement." It need not be more than a few paragraphs that describe the proposed vessel, or possibly a simple list of desired features such as overall size, operational requirements, preferences with regard to rig, power, equipment, materials of construction, accommodations, budget, project timing, and so forth. The 'mission statement' need not be elaborate, since the vessel's particulars will be generated during the design process itself... however where specific requirements exist, they should be articulated. While sketches or design examples are not necessary, if preliminary sketches or design examples are available and relevant, they should be included. Once I've understood your requirements I will provide a written ' Design Proposal ' - usually by return email. Our Design Proposal is offered at no cost, and implies no obligation; it is just good information for your planning purposes... As for the inevitable questions regarding the cost of boat custom design, our Design Proposal will answer them definitively, however please also see our Articles On Costs involved with boat design and boat building. In order to pursue a design inquiry in greater detail, please feel free to contact me for more information or to request a Design Proposal . Creating a new yacht design is by far the most rewarding path to long term boat ownership, and the process itself can be quite a lot of fun...! What do our clients think...? Please review some of their Testimonials to find out... Member Royal Institution of Naval Architects Member Society of Naval Architects and Marine Engineers Member Society of Boat and Yacht Designers Member American Boat and Yacht Council Member Metal Boat Society

Please see the AVAILABLE BOAT PLANS web page. Home | Intro | Our Design Process | Stock Design Info | Motor Yacht Designs | Sailing Yacht Designs | Prototype Designs Plans List | Articles | Our CAD Design Stream | Maxsurf | News..! | SITE MAP..! | Site Search | Design Team | Contact Us

- All Web Site Graphics, Layout, and Written Content at this Domain Created by Michael Kasten.

- All Graphic and Written Materials at this Domain Copyright © 1989 - 2023 Michael Kasten.

- All Content Registered with US Library of Congress and US Copyright Office.

- Copyright Violations will be Prosecuted. All Rights Reserved.

- BOAT OF THE YEAR

- Newsletters

- Sailboat Reviews

- Boating Safety

- Sailing Totem

- Charter Resources

- Destinations

- Galley Recipes

- Living Aboard

- Sails and Rigging

- Maintenance

- Best Marine Electronics & Technology

Sailboat Design Evolution

- By Dan Spurr

- Updated: June 10, 2020

You know the old saying, “The more things change, the more they stay the same”? As a judge for the 2020 Boat of the Year (BOTY) competition at this past fall’s US Sailboat Show in Annapolis, Maryland, I helped inspect and test-sail 22 brand-new current-model sailboats. And I came away thinking, Man, these aren’t the boats I grew up on. In the case of new boats, the saying is wrong: “Nothing stays the same.”

OK, sure, today’s boats still have masts and sails, and the monohulls still have keels. But comparing the Hinckley Bermuda 40, considered by many to be one of the most beautiful and seaworthy boats of the 1960s, ’70s and even ’80s, with, say, the Beneteau First Yacht 53, which debuted at the show, is pretty much apples and oranges.

To get a better sense of what has happened to yacht design, boatbuilding and equipment over the past three, four or even six decades, let’s take a closer look.

Design Dilemmas

At the risk of oversimplification, since the fiberglass era began in the late 1940s and ’50s, the design of midsize and full-size yachts has transitioned from the Cruising Club of America rules, which favored all-around boats (racers had to have comfortable interiors) with moderate beam and long overhangs, to a succession of racing rules such as the IOR, IMS and IRC. All of them dictated proportions, and each required a measurer to determine its rating.

As frustration grew with each (no handicap rule is perfect), alternatives arose, such as the Performance Handicap Racing Fleet, which essentially based one’s handicap on past performance of the same boats in the same fleet. Also, one-design racing became more popular, which spread beyond identical small boats to full-size yachts, popularized in part by builders such as J/Boats and Carroll Marine. The ethos there was: Who cares about intricate rating rules? Let’s just go out and sail fast and have fun!

And that might best sum up the design briefs for the monohulls in this year’s BOTY competition: good all-around performance with comfortable, even luxurious accommodations. Gone are interiors that noted naval architect Robert Perry called “the boy’s cabin in the woods,” deeply influenced by stodgy British designers of the past century and their now-old-fashioned (though sea-friendly, one should note) concepts of a proper yacht, drawn and spec’d by the same guy who designed the hull, deck and rig. Today, dedicated European interior designers are specially commissioned to inject modernity, home fashion colors and textures, amenities, and more light—even dubiously large port lights in the topsides.

Overhangs, bow and stern, have virtually disappeared. Why? It seems largely a matter of style. Plus, the bonus of increased usable space below, not to mention a longer waterline length for a given length overall, which translates to more speed. Former naval architect for C&C Yachts and Hunter Marine, Rob Mazza, recalls that 19th-century pilot cutters and fishing schooners operating in offshore conditions generally had plumb bows, so in a sense, bow forms have come full circle.

Today’s boats are carrying their wide beam farther aft. Gone are the days of the cod’s head and mackerel tail. Wide, flat canoe bodies are decidedly fast off the wind, and might even surf, but they pay a comfort penalty upwind.

These boats have lighter displacement/length (D/L) ratios, which means flatter bottoms and less stowage and space for tanks. The Beneteau 53 has a D/L of 118, compared with the aforementioned Bermuda 40 of 373. Among entries in this year’s BOTY, the heaviest D/L belonged to the Elan Impression 45.1, with a D/L of 195. Recall that when Perry’s extremely popular Valiant 40 was introduced in 1975, the cruising establishment howled that its D/L of 267 was unsuitable for offshore sailing. My, how times have changed!

Perhaps more important, one must ask: “Have the requirements for a good, safe bluewater cruiser actually changed? Or are the majority of today’s production sailboats really best-suited for coastal cruising?”

The ramifications of lighter displacement don’t end there; designers must consider two types of stability: form and ultimate. As weight is taken out of the boat, beam is increased to improve form stability. And with tanks and machinery sometimes raised, ballast might have to be added and/or lowered to improve ultimate stability.

What else to do? Make the boat bigger all around, which also improves stability and stowage. Certainly the average cruising boat today is longer than those of the earlier decades, both wood and fiberglass. And the necessarily shallower bilges mean pumps must be in good shape and of adequate size. That’s not as immediate an issue with a deep or full keel boat with internal ballast and a deep sump; for instance, I couldn’t reach the bottom of the sump in our 1977 Pearson 365.

And how do these wide, shallow, lighter boats handle under sail? Like a witch when cracked off the wind. We saw this trend beginning with shorthanded offshore racers like those of the BOC Challenge round-the-world race in the early 1980s. As CW executive editor Herb McCormick, who has some experience in these boats, says, “They’ll knock your teeth out upwind.” But route planning allows designers to minimize time upwind, and cruisers can too…if you have enough room and distance in front of you. Coastal sailors, on the other hand, will inevitably find even moderate displacement boats more comfortable as they punch into head seas trying to make port.

A wide beam carried aft permits a number of useful advantages: the possibility of a dinghy garage under the cockpit on larger boats; easy access to a swim platform and a launched dinghy; and twin helms, which are almost a necessity for good sightlines port and starboard. Of course, two of anything always costs twice as much as one.

Some multihulls now have reverse bows. This retro styling now looks space-age. Very cool. But not everyone is sold on them. Canadian designer Laurie McGowan wrote in a Professional BoatBuilder opinion piece, “I saw through the fog of faddishness and realized that reverse bows are designed to fail—that is, to cause vessels to plunge when lift is required.” Mazza concurs: “Modern multihulls often have reverse stems with negative reserve buoyancy, and those are boats that really can’t afford to bury their bows.”

McGowan also cites another designer critiquing reverse bows for being noticeably wet and requiring alternative ground-tackle arrangements. The latter also is problematic on plumb bows, strongly suggesting a platform or sprit to keep the anchor away from the stem.

Rigging Redux

If there was a boat in Annapolis with double lower shrouds, single uppers, and spreaders perpendicular to the boat’s centerline, I must have missed it. I believe every boat we sailed had swept-back spreaders and single lowers. An early criticism of extreme swept-back spreaders, as seen on some B&R rigs installed on Hunter sailboats, was that they prevented fully winging out the mainsail. The counter argument was that so many average sailors never go dead downwind in any case, and broad reaching might get them to their destinations faster anyway—and with their lunch sandwiches still in their stomachs.

That issue aside, the current rigging configuration may allow for better mainsail shape. But as Mazza points out, it’s not necessarily simple: “By sweeping the spreaders, the ‘transverse’ rigging starts to add fore-and-aft support to the midsection of the mast as well, reducing the need for the forward lowers. However, spreader sweep really does complicate rig tuning, especially if you are using the fixed backstay to induce headstay tension. Swept spreaders do make it easier to sheet non-overlapping headsails, and do better support the top of the forestay on fractional rigs.”

Certainly, the days of 150 percent genoas are over, replaced by 100 percent jibs that fit perfectly in the foretriangle, often as a self-tacker.

Another notable piece of rigging the judges found common was some form of lazy jacks or mainsail containment, from traditional, multiple lines secured at the mast and boom; to the Dutchman system with monofilament run through cringles sewn into the sail like a window blind; to sailmaker solutions like the Doyle StackPak. This is good news for all sailors, especially those who sail shorthanded on larger boats.

Construction Codas

Improvements in tooling—that is, the making of molds—are easily evident in today’s boats, particularly with deck details, and in fairness. That’s because many of today’s tools are designed with computer software that is extraordinarily accurate, and that accuracy is transferred flawlessly to big five-axis routers that sculpt from giant blocks of foam the desired shape to within thousandths of an inch. Gone are the days of lofting lines on a plywood floor, taken from a table of offsets, and then building a male plug with wood planks and frames. I once owned a 1960s-era sailboat, built by a reputable company, where the centerline of the cockpit was 7 degrees off the centerline of the deck—and they were one piece!

Additive processes, such as 3D printing, are quickly complementing subtractive processes like the milling described above. Already, a company in California has made a multipart mold for a 34-foot sailboat. Advantages include less waste materials.

Job training also has had an impact on the quality of fiberglass boats. There are now numerous schools across the country offering basic-skills training in composites that include spraying molds with gelcoat, lamination, and an introduction to vacuum bagging and infusion.

The patent on SCRIMP—perhaps the first widely employed infusion process—has long ago expired, but many builders have adopted it or a similar process whereby layers of fiberglass are placed in the mold dry along with a network of tubes that will carry resin under vacuum pressure to each area of the hull. After careful placement, the entire mold is covered with a bag, a vacuum is drawn by a pump, and lines to the pot of resin are opened. If done correctly, the result is a more uniform fiberglass part with a more controlled glass-to-resin ratio than is achievable with hand lay-up. And as a huge bonus, there are no volatile organic compounds released into the workplace, and no need for expensive exhaust fans and ductwork. OSHA likes that, and so do the workers.

However, sloppy processes and glasswork can still be found on some new boats. Surveyor Jonathan Klopman—who is based in Marblehead, Massachusetts, but has inspected dozens, if not hundreds, of boats damaged by hurricanes in the Caribbean—tells me that he is appalled by some of the shoddy work he sees, such as balsa cores not vacuum-bagged to the fiberglass skins, resulting in delamination. But overall, I believe workmanship has improved, which is evident when you look behind backrests, inside lockers and into bilges, where the tidiness of glasswork (or lack thereof) is often exposed. Mechanical and electrical systems also have improved, in part due to the promulgation of standards by the American Boat & Yacht Council, and informal enforcement by insurance companies and surveyors.

We all know stainless steel isn’t entirely stainless, and that penetrations in the deck are potentially troublesome; allowing moisture to enter a core material, such as end-grain balsa, can have serious consequences. The core and fiberglass skins must be properly bonded and the kerfs not filled with resin. Beginning in the mid-1990s, some builders such as TPI, which built the early Lagoon cruising catamarans, began using structural adhesives, like Plexus, to bond the hull/deck joint rather than using dozens of metal fasteners. These methacrylate resins are now commonly used for this application and others. Klopman says it basically should be considered a permanent bond, that the two parts, in effect, become one. If you think a through-bolted hull/deck joint makes more sense because one could theoretically separate them for repairs, consider how likely that would ever be: not highly.

Fit-and-Finish

Wide transoms spawned an unexpected bonus; besides the possibility of a dinghy “garage” under the cockpit on larger boats, swim platforms are also possible. In more than one BOTY yacht, the aft end of the cockpit rotated down hydraulically to form the swim platform—pretty slick.

Teak decks are still around, despite their spurning for many years by owners who didn’t want the upkeep. In the 1960s and ’70s, they were considered a sign of a classy boat but fell from favor for a variety of reasons: maintenance, weight and threat of damaging the deck core (the bung sealant wears out and water travels down the fastener through the top fiberglass skin into the core). Specialty companies that supply builders, like Teakdecking Systems in Florida, use epoxy resin to bond their product to decks rather than metal fasteners. And the BOTY judges saw several synthetic faux-teak products that are difficult to distinguish from real teak—the Esthec installed on the Bavaria C50 being one example.

LPG tanks no longer have to be strapped to a stanchion or mounted in a deck box because decks now often incorporate molded lockers specifically designed for one or two tanks of a given size. To meet ABYC standards, they drain overboard. In tandem with these lockers, some boats also have placements or mounts for barbecues that are located out of the wind, obviating the common and exposed stern-rail mount.

Low-voltage LED lights are replacing incandescent bulbs in nearly all applications; improvements in technology have increased brightness (lumens), so some even meet requirements for the range of navigation lights. Advances in battery technology translate to longer life, and depending on type, faster charging. And networked digital switching systems for DC-power distribution also are becoming more common.

Last, I was surprised at how many expensive yachts exhibited at Annapolis had nearly the least-expensive toilets one can buy. Considering the grief caused by small joker valves and poorly sealed hand pumps, one would think builders might install systems that incorporate higher-quality parts or vacuum flushing, and eliminate the minimal hosing that famously permeate odors.

Dan Spurr is an author, editor and cruising sailor who has served on the staffs of Cruising World, Practical Sailor and Professional Boatbuilder. His many books include Heart of Glass , a history of fiberglass boatbuilding and boatbuilders .

Other Design Observations

Here are a few other (surprising) items gleaned from several days of walking the docks and sailing the latest models:

- Multihulls have gained acceptance, though many production models are aimed more at the charter trade than private ownership for solitary cruising. You’d have to have been into boats back in the ’60s and ’70s to remember how skeptical and alarmist the sailing establishment was of two- and three-hull boats: “They’ll capsize and then you’ll drown.” That myth has been roundly debunked. Back then, the only fiberglass-production multihulls were from Europe, many from Prout, which exported a few to the US. There are still plenty of European builders, particularly from France, but South Africa is now a major player in the catamaran market.

- The French builders now own the world market, which of course includes the US. Other than Catalina, few US builders are making a similar impact. In terms of volume, Groupe Beneteau is the largest builder in the world, and they’ve expanded way beyond sailboats into powerboats, runabouts and trawlers.

- Prices seem to have outpaced inflation, perhaps because, like with automobiles, where everyone wants air conditioning, electric windows and automatic transmissions, today’s boats incorporate as standard equipment items that used to be optional. Think hot- and cold-pressure water, pedestal-wheel steering, and full suites of sailing instruments and autopilots.

- More: design , print may 2020 , Sailboats

- More Sailboats

Sailboat Review: Tartan 455

Meet the Bali 5.8

Celebrating a Classic

New to the Fleet: Italia Yachts 12.98

Bitter End Expands Watersports Program

Miracle in a Bowl

Cole Brauer Completes the Global Solo Challenge

- Digital Edition

- Customer Service

- Privacy Policy

- Email Newsletters

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

March / April Issue No. 297 Preview Now

Yacht Design Terminology

By robin jettinghoff.

Our profile of yacht designer Paul Gartside in WB No. 230 included a number of design terms that space and style restrictions kept us from defining in the article. For those readers seeking a deeper understanding of the elements of design, here are the definitions of those terms—along with a few additional ones that were not listed in the article. — Robin Jettinghoff, Assistant Editor

Area of Wetted Surface: The hull’s surface below the waterline; what you cover with bottom paint. Besides determining the amount of bottom paint to buy, the area of wetted surface determines how much friction there is between the boat and the water. Minimize the wetted surface, and you maximize the speed. A boat flying on foil goes faster because it has none of its hull in the water; the only wetted surface is that of the foil.

Beam: The width of the hull measured perpendicular to the centerline of the hull. The beam is a significant factor in both carrying capacity and stability.

Maximum Beam (B or B MAX ): On a hull that flares toward the sheer, the maximum beam will be at the sheerline. On a hull with tumblehome , the maximum beam will be below the sheer. On a trimaran hull, the maximum beam of the main hull and the beam of the three hulls together are significantly different; the former gives a sense of the boat’s capacity, the latter, of its stability. The maximum beam is important when finding a slip in a marina, and is often a factor in racing rules.

Beam of Waterline (B WL ) : The maximum beam of the hull at the designed waterline. This is a factor in determining its displacement and prismatic coefficient .

Buttock Lines: In a set of lines plans, lines showing the underwater shape of the hull. In the profile view , they are seen as curved lines parallel to the centerline of the hull, spaced an even distance apart, showing how the shape of the hull changes moving outward from the centerline. In the plan view , which also shows the waterlines as curves, the buttock lines are at equal intervals and parallel to the longitudinal centerline of the hull. In the section view (seen from dead ahead or dead astern), they are vertical lines and parallel to the centerline of the hull.

Center of Buoyancy (CB): The center of volume of the underwater part of the hull, below the DWL. The water pushes on the hull with an upward force, centered on this point, keeping the hull afloat. As the hull moves through the water, the underwater shape changes and the CB moves, but it must stay in the same vertical line as the center of gravity or the hull will go out of trim. Designers need to know the longitudinal center of buoyancy (LCB) when the hull is at rest, so they can locate weights fore and aft of that point in such a way that keeps the hull in trim.

Center of Effort (CE): The geometric center of the sail area . A designer finds the CE of a sail by drawing a line from the midpoint of the luff of the sail to its clew. Then he draws a line from midpoint of the foot of the sail to the head of the sail. Where these lines cross is the center of effort of that sail.

To find the CE for the sail area of a main and jib, the designer computes the area and the location of the CE for the main and jib individually, then draws a line connecting their CEs. The CE of the two sails is on this line. Its location is in proportion to the areas of the two sails. For example, if the mainsail is 250 sq ft, and the jib is 100 sq ft, the jib is 100/250 or two-fifths of the area of the main. The CE would be two-fifths of the way along the line going from the main’s CE to the jib’s.

If the CE is too far aft of the CLR, the boat will have weather helm; if it is too far forward, it will have a lee helm.

Center of Gravity (CG): The weight of the vessel in the water creates a downward force that is concentrated at the center of gravity. The CG and center of buoyancy (CB) are opposing forces.

Center of Lateral Resistance (also called Center of Lateral Plane; CLR or CLP ): The geometric center of the profile of the underwater part of the hull. This is a center of balance. If you try to balance something on the tip of your finger, you move the object back and forth incrementally on your finger until it balances. Similarly, if an underwater force on the side of a hull is trying to push the hull at right angles to the force, and the force is the too far forward, the force will push the boat’s bow farther than it will the stern. If the force is too far aft, then the stern will be pushed farther than the bow. When the force is pushing on the balance point between these possibilities, the hull moves at right angles to the force. This point is the center of lateral resistance . The force of the wind is concentrated on the center of effort . Its location in relation to the CLR will determine if a boat has weather or lee helm.

A designer can find the CLR of a hull by tracing the underwater profile onto a piece of stiff paper. Then he cuts out this out and balances it on the edge of a ruler. Next he marks this line of balance, and rotates the hull profile, balances it again, and draws a second line showing where it balanced. The intersection point of these lines is the CLP.

Construction Method: The method of construction and materials used in building a boat. Both greatly affect the cost of a boat. One of the reasons fiberglass hulls became so popular was that they could be mass-produced more cheaply than wooden hulls. Boats have been built from wood, plywood, fiberglass, metal, combinations of composite materials, and concrete. Each has different properties in cost, ease of construction, strength, ease of repair, and accessibility of materials. The designer and owner together will discuss the pros and cons of the different methods to find the one that best fits the owner’s needs.

Deadrise Angle: The angle between the bottom of the hull and a horizontal plane drawn out from the hull’s centerline, looking at the hull sections. A steeper deadrise angle will mean the hull sharpens and narrows as it gets deeper, while a smaller angle means the hull bottom is flatter.

Displacement (Δ) : The underwater volume of a boat is equal to the volume of water it displaces. Underwater volume is expressed in cubic feet or meters; displacement is the weight of the water displaced, and is expressed in pounds, tons, or tonnes. A boat that has an underwater volume of 125 cubic feet displaces 125 cubic feet of water. This displaced water weighs 64 lbs per cu ft (in salt water, about 62.5 lbs/cu ft in fresh water); 125 x 64 = 8,000 lbs. Since the weight of that displaced water is equal to the weight of the entire boat, 8,000 lbs is the boat’s displacement .

A common demonstration of displacement can be done with a model boat, a bowl big enough to hold the boat, a shallow pan, a small scale, and enough water to fill the bowl. Put the bowl in the shallow pan, then fill the bowl with water up to the brim. Gently float the model in the water, and some of the water will overflow from the bowl into the pan. Weigh the water in the pan and weigh the model, and you will see they are same weight. The model weighs exactly the same as the water that it displaced.

Displacement/Length Ratio (Δ/L): The ratio between the LWL and the boat’s displacement. The formula is the displacement divided by 1/100th of the length of the LWL cubed, or Δ/.01LWL 3 , where the Δ is in tonnes (1 tonne = 2,240 lbs).

Draft: The maximum measurement from the designed waterline to the bottom of the hull. A boat with a centerboard will have two drafts. A sailing dinghy, such as Joel White’s Haven 12-1/2, will draw 18″ with the centerboard up, and 3′4″ with it down. Shallow-draft hulls, such as CARIB II (see WB No. 228), will often have centerboards so they can travel more easily in shallow water, such as that found in the Florida Keys and the Bahamas. Freeboard: The measurement from the designed waterline to the sheerline. This is most obviously demonstrated in a small dinghy with more than one adult aboard. As the weight inboard increases, the freeboard decreases. The freeboard is usually highest at the bow and lowest somewhere near amidships. The minimum freeboard is the number of most concern.

Interior Amenities: Cabin comforts and accommodations. To spend more than a few hours aboard a boat, people will need to consider their needs for food, water, rest, lighting, and elimination of wastes. Amenities aboard a boat might be as simple as a berth on the floor of the cockpit, a bucket, a candle lantern, and a portable stove. A weekender might have a small Coleman stove, a couple of battery-operated lamps, a V-berth, and Porta-Potti.

Offshore cruisers want the means for dealing with these fundamental human needs to be as convenient as they are at home. Lighting will need wiring and some source of power—perhaps a solar cell or generator. An efficient galley needs a sink, which requires a tank for fresh water, a hose from the tank to tap, and a drainpipe to deal with the wastewater. A galley stove needs some source of heat, requiring another tank and more hose. A head requires a sink with tank, hose, and drain, as well as a toilet with hoses for water in and water out, and a holding tank for the wastes. All of these systems add to the cost and complication of a design.

Length: The length of a hull as measured down its centerline. There are at least four descriptions of the length of a boat (see below); the length in question will depend upon what you are looking for. A marina manager wants to know the maximum length of the boat, so it can be seated in a slip. Racing rules are often concerned with the length of the load waterline. Designers working around these rules have led to some extreme hull forms in an effort to beat the rule constraints.

Length Overall ( LOA; sometimes Length of Hull ): The overall length of the hull. In a dinghy, this is relatively clear; with the boat out of the water, one can hold a tape measure down the centerline of the hull from the after side of the top of the transom to the forward edge of the stem. The measurement gets more complicated in a canoe with tumblehome stems, one whose stems curve inward as they rise from the waterline toward the top of the hull. For most motorboats and rowboats, the overall length is pretty evident. Rudders, anchor rollers, or other hull extensions are not included in this measurement.

Length on Deck (LOD): The length along the centerline of the deck, measured from its tip at the bow, the intersection of the deck line with the profile bow line, to the point where the deck meets the transom. This provides a better tool for estimating a boat’s carrying capacity than does overall length.

Load Waterline Length (LWL): The length of the hull measured at the waterline. When the designer draws the boat on the plans, he or she computes a plane on the hull where the boat will float in its expected operating condition. The actual waterline will vary from this in use. A fishing boat on its way out to the fishing grounds will float higher in the water than when it heads home fully loaded with fish. A cruising boat out for a weekend adventure will not have as much gear aboard as one fully loaded for an ocean passage. The designed waterline should lie between these two maximums.

The designed waterline (DWL) and load waterline (LWL) are usually in the same plane on the hull. The waterline length is the critical factor in determining the maximum speed of a displacement hull. Sailing boats with long overhangs at the bow and stern will increase their waterline length as they heel over while sailing; this increases their maximum speed potential.

A design will have several lines parallel to the LWL at set distances apart. These lines, also called waterlines , define the shape of the hull in plan view on the drawing board.

Sparred Length: The maximum reach from the tip of the bowsprit to the aftermost point of the boom. According the racing rules in place for the 1903 AMERICA’s Cup race, Nathanael Herreshoff’s RELIANCE was required to have a waterline length of no more than 90′. Herreshoff built her to be an extreme hull that still met the parameters required by the racing rules. Her measured waterline length was 90′, her hull length was 144′, and her sparred length was 201′.

Length-to-Beam Ratio (L/B): The ratio between the hull length and the maximum beam. This is a factor in the boat’s stability and speed. A sculling hull used by eight rowers has a length of about 50′ with a beam of about 2′, giving an L/B of 25. While a Cape Cod catboat might have a length of 22′, and a beam of 8′ giving an L/B of 2.75. As the L/B increases, the boat’s speed should also increase.

Offsets: A table of measurements taken vertically and horizontally that establish the shapes of the hull’s frames. The vertical measurements, or heights , are taken from a baseline established by the designer, either the DWL or a horizontal line parallel to the DWL below the boat’s profile as drawn on the plans. The heights are measured at equal intervals measured from the centerline of the hull. The lines joining the height measurements are called buttock lines . The horizontal measurements, or half-breadths , are taken from the boat’s longitudinal centerline. These are measured at equal intervals above and below the boat’s DWL. The lines joining the half-breadth measurements are called waterlines . The stations are measured at equal intervals from a forward perpendicular established by the designer.

Outside Ballast: Weight attached outside the main hull, as in a ballast keel, that lowers the CG and counterbalances the forces on the sails to keep the boat upright. A keel also provides lateral resistance to help prevent the sails from pushing the boat sideways in the water.

Prismatic Coefficient (C p ): The percentage of volume that a hull’s shape has when compared to a prism as long as the designed waterline, and the shape of the hull below the waterline at the largest hull section. For example, if the LWL was 25’, and the underwater cross-sectional area of the largest section was 12 sq ft, then the volume of that shape is 25 x 12 = 300 cu ft. But a boat does not have the same sectional shape all the way along its length; the actual volume of the hull is carved from this shape.

If you had a wood block in this shape, and carved the wood away until you only had the shape of the hull left, the volume of the material remaining is a percentage of the total volume of the block. This percentage is the prismatic coefficient . If you have 125 cu ft left, the boat has an underwater volume of 125 cubic feet; divide 125 into 300, and 125 is 42 percent of 300, so the Cp is .42. If you have 189 cu ft of underwater volume left, the Cp is 189 ÷ 300 = .63.

A lower C p means the boat’s volume is concentrated toward the middle of the boat. Hulls with a higher Cp move some of that volume toward the ends, increasing their speed and making them less inclined to pitch. If this coefficient is too high, wave drag increases, slowing the hull down. Most designers have a prismatic coefficient in mind for the hull they are designing.

Profile: The shape of the centerline of the hull as seen from the side. Most plans show the boat facing right so the profile is what you see from the right side. The profile is generally bounded on top by the sheerline, at the bow by the curve of the stem, underwater by the keel, and aft by the transom, with buttock lines showing the shape of the hull from the centerline outward.

Propulsion: The method by which a boat moves through the water. If a designer is designing a powerboat, he or she must know the weight of the boat to determine the correct engine horsepower and propeller to drive the boat most effectively. A designer also recognizes that engines are heavy and must be placed in a boat so they don’t upset the boat’s trim. Also the engine’s controls must be connected to some kind of helm station—providing the helmsman with a throttle, a gearshift, and a steering wheel, stick, or tiller. The designer of a sailboat must cope with another force acting upon the boat: wind. The designer must determine how much sail area is needed to move the boat through the water, the amount of ballast necessary to counteract the force on the sails, and the location of the sails and rig to keep the boat in balance.

Righting Moment: The restoring force by which a hull resists heeling, created by the ballast keel and the form stability of the hull.

Sail Area (SA): The surface area of sails needed to drive the boat. The designer draws each sail on the plans, then divides the sails into triangles. Then he applies the familiar formula for determining the area of a triangle (area = ½ base x height or ½ bh) and computes the area of each triangle in each sail, then adds them up to get the total sail area. Boats with multiple headsails—like staysails, genoas, or spinnakers—will have different sail areas depending on what sails are flying. A designer determines the total sail area needed to drive a boat by looking at comparable designs. The published sail area of a design is usually the sum of the mainsail area and the foretriangle area, which is the area bounded by the mast, headstay, and deck.

Sections: The hull’s shape on vertical planes cut perpendicular to the boat’s centerline. A designer shows three views of the hull on the drawing board: its profile , or appearance from the side; its plan view , or appearance from the top or bottom; and its sections , or appearance from the bow and stern. All the lines defining the hull appear in all three views; but in each view, two of the line types are straight lines at right angles to each other, and the third type is curved. The hull sections show how the curve of the hull changes as it moves fore and aft.

Sheer: The curve along the top edge of the hull’s side, as seen on the profile view. A sheerline often sweeps downward from the bow toward somewhere around amidships, then sweeps up again as it heads toward the transom. Some boats have reverse sheers where the highest point is not at the bow but closer to amidships.

Speed-to-Length Ratio (S/L): A dimensionless ratio that indicates a hull’s hydrodynamic limitations of speed. A boat creates a bow wave as it moves through the water. As the boat’s speed increases, the wave gets bigger and creates more resistance for the hull to move through. A planing hull , with a typical S/L of 2.5 or so, can get up on plane and move over this wave, minimizing the resistance and letting the boat go faster. A displacement hull is too heavy to get over this wave. For a displacement hull, its limit of speed, or hull speed, is a Speed-to-Length Ratio of 1.34. For a displacement hull, its maximum speed is limited by its length. The formula for the S/L is the boat’s maximum speed divided by the square root of its length. In numbers, this looks like V/√L. So a 36’ cruising sailboat with a S/L of 1.34 has a maximum speed of 1.34 = V/√36. The square root of 36 is 6, so this formula now reads 1.34 = V/6, or multiplying both sides by 6 gives 1.34 x 6 = V, and V = 8.04 knots.

Stem: The forward part of the profile of the hull. The stem timber forms the forwardmost part of the hull, reaching from below the waterline up to the sheerline, providing a place for the planks to land in the hull’s construction. The sharp bend in the stem, usually just at the waterline, is called the forefoot. The angle of the stem to the water, and the angle of the planks to the stem, is a factor in whether a hull cuts through waves or slaps the top of them.

Transom: The after part of the profile of the hull. The transom spans between the hull sides at the aft end of the hull. It may have a sharp rake as on a Friendship sloop, or be nearly vertical as on some runabouts. Double-enders have no transom at all. Some commuter boats of the last century, such as APHRODITE, have a curving reverse transom, where the line of the deck curves over gracefully into the hull.

Underwater Volume: The measurement of the amount of the hull under the water in cubic feet or meters. The underwater volume and the boat’s displacement are two measurements of the same thing. The volume is measured in cubic feet or cubic meters, and the displacement is measured in pounds, kilograms, tons, or tonnes. See Displacement also.

Waterline: The hull’s shape on horizontal planes cut perpendicular to the boat’s centerline. A boat lying in the water floats with some percentage of the hull above the water and the remainder of the hull below the water. The waterline established by the designer is the plane that divides these two parts of the hull and is called the designed waterline , or DWL . The amount of hull within the water is a factor in determining the boat’s displacement, prismatic coefficient, and stability. The waterline of a small boat will shift when the crew changes position aboard. The waterline plane of a sailing monohull changes its shape significantly as the hull heels. People will often apply bottom paint to the load waterline and add a thin stripe (called a boottop) of contrasting paint just above it. The area of the hull above the waterline is called the topsides .

Weight: The weight of a boat. As with length, weight can depend on the situation in which you weigh the hull. The hull weight is the weight of the hull itself with nothing in it. Dinghies and skiffs often have little gear in them other than a pair of oars, so the hull weight is an accurate measure of their weight. If you add a motor to a small boat, then it weighs more, with most of the weight now at the stern. If you add passengers, they should be placed to balance the boat’s trim, so she will move more easily through the water.

For bigger boats, the hull holds water and fuel tanks, a deck, spars and sails, and interior furniture such as berths and a galley. When designing a boat, the designer places these items so that the boat stays level—much as you balance the crew of a dinghy as you carry them from dock to mooring. The designer also factors the weight of the crew into the design. Indeed, sailors count on the weight and placement of the crew to counter the forces of the wind on the sails. The weight of a boat and its displacement are the same thing.

ACCESS TO EXPERIENCE

Subscribe today.

Publishing dynamic editorial content on boat design construction, and repair for more than 40 years.

1 YEAR SUBSCRIPTION (6 ISSUES)

Print $39.95, digital $28.00, print+digital $42.95, from online exclusives, extended content.

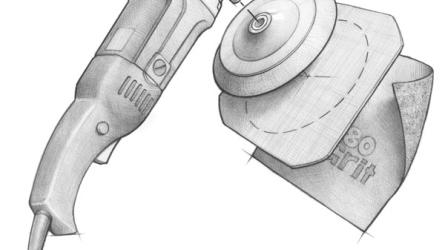

Fairing by Machine

Whiskey Plank

Visiting Bahamian Ruins By Boat—Part II

Tricks Of The Trade 01—Steam Boxes

From the community, boat launchings.

My first boat and first build

"If you want something nice, build it yourself." I've wanted a boat most of my life but was never

Restored Atkin Schooner GAFF RIGGED 1957 Billy's last Design

33′ Atkin fully restored 2012-2017 Schooner. Ready to cruise again to Maine.

Pre 1905 Warren Cole Adirondack Guideboat LOA 16′, 42″ beam

Restored in ME by Jonathan Minott (seen in WB "Launchings" July/Aug 2009).

Chesapeake Crab Skiff

Beautiful 15' Crab Skiff Sailboat. Built at the St. Augustine Lighthouse. $5,000.

Understanding the IOR Rating System & Formula

- August 25th, 2017

- Yachtmaster

Although the magazines and marinas are full of flat designed, chined and wide-sterned modern yachts made to perform and host large volumes, a great number of yachts nowadays have their origins in the Seventies and Eighties as we call them “Classic GRP Yachts”. As I was roaming the jetties of my home marina I came to rest in front of such a very, very nice and well kept yacht: A German made Hanseat in blue.

She bears the distinctive shape of a whole class of yachts which defined the Seventies yacht design: The IOR-yachts. IOR? Most of you may know this fictional conversation very well by their own neighbours in the berth: “Ah, this is a nice, classic boat indeed!”, “Yes, I like her. Her lines. She´s an IOR-yacht!”, “Yeah, for sure!”. IOR. We are all too familiar with the wide bulky hull shaped like a tea kettle. But what does IOR really mean? Here´s a short but hopefully clear explanation.

History of the IOR-Rating System

First of all, IOR, the “International Offshore Rule”, was a rating system introduced in the Sixties when for the first time in history regatta-rules and handicap ratings of Europe (namely of the Royal Ocean Racing Club of England, RORC) and America (to be precise of the CCA, the Cruising Club of America) sought to standardize their set of rules to ensure a worldwide rating system for sailing yacht races. The IOR has been kept in place up until the early Eighties when it was superseded by the more technical and scientific advanced IMS and IRC-rating, which are in place still today.

The set of rules changed massively during the years as their trustees tried to keep up with the pace of yacht designers and boat builders who sought to interpret the rules in such a way that thy would make the fastest boats possible within this set of rules. In such an environment, as we all know from other occasions, the mind of the people does incredible things and so the IOR set of rules sparked a whole generation of naval architects to create yachts and hull shapes within this set of rules – leading to this one, very iconic feature of IOR-yachts: The tea kettle shape of the hull. But what´s to it?

Design Features of Sailing Yachts under IOR-Rating

Well, in short, the IOR called for short waterline lengths. It favoured yachts with a short waterline and penalized longer boats. But as we all know: The longer the waterline length, the fast the boat sails. By the same time, naval architects and designers of the boats tried to keep the wetted surface of the yacht as small as possible, shortening the surface area of both hull, keel and rudder blades.

The yachts had been fitted with a sharp bow and the distinct “cruiser stern” which bears a large overhang. Now, let´s cast off and get the sails hoisted. What happens? First of all, when the IOR-shaped boat is now sailing, it will start to heel to leeward as expected. Due to the unique wide girth, the “tea kettle”-hull will now immerse into the water. As you may imagine by looking at such a tea kettle-shaped hull, due to the unique design features of the IOR-shaped hull, the length of the waterline increases greatly thus “imposing” a larger hull and increasing speed. That´s the theory.

Implications of IOR-designed Hulls

It really worked well for a number of yachts and IOR proved to be the offshore rule setting off a huge wave of new yachts to be built and new races to be raced. But the IOR-yachts had also some unwanted implications and sailing characteristics which are nowadays considered frowned upon the least if not to say dangerous.