Five of the Best Solar Powered Yachts of 2023

- Thursday 10 December, 2020

Silent Yachts founder Michael Köhler drew plenty of laughter across the industry back in 2005 when he announced he was moving away from diesel to build solar-powered luxury marine vessels. When his Köhler’s Solarwave 46 was launched five years later, though, those laughs turned to gasps.

Despite the limitations and expense surrounding the technology back then, he had achieved a stylish creation that had all of the mod cons and ran purely on the power of the sun. It should come as no shock then that Silent Yachts leads off our list of the top five solar-powered yachts on the market today.

Solar powered yachts are becoming increasingly popular in Australia, with more and more people looking for eco-friendly and sustainable ways to explore the country’s stunning coastline. These vessels harness the sun’s power to provide a clean and renewable energy source, reducing the need for fossil fuels and helping to protect the environment. With so many options on the market, it can be difficult to know which yacht is the best for you. To help you make an informed decision, here are five of the best solar powered yachts for sale in 2023.

Exploring solar-powered boats for sale

- Silent 80 Tri-Deck catamarans

- Silent Yachts Catamaran Silent 55

The solar-powered Catamaran Silent 55 combines eco-friendly propulsion with luxurious accommodations. It is a 55-foot ocean-going catamaran with four staterooms and restrooms that is solar-powered and self-sufficient. The only mechanical components that need maintenance are the generators; there are no engine noises or vibrations.

The most powerful E-Power+ propulsion option, which combines the largest battery bank with the strongest electric motors, is available on this fully equipped vessel. As a result, faster speeds can be maintained for much longer while optimising the amount of energy stored for backup and used when necessary. E-Power+ provides the best solar-powered yachting experience.

- Serenity Yachts Serenity 64

The Serenity Yachts range is focused on power and can run indefinitely on its array at a cruising speed of between four and six knots while it has top speeds of up to 16 knots. It has electric and hybrid motors that also power all of the amenities and the 64-foot vessel is available in several different layouts.

- Serenity Yachts Serenity 74

- Soel Senses 48

Updated February 2023

Latest Products

800W Peak 12V/24V 5 Blades Black Wind Turbine Power Generator With Charge Controller – 24V

800W Peak 6 Blades 12V/24V/48V Horizontal Wind Turbine Generator Residential Home Wind Power Generator – 48V

400W 12V/24V 5 Blades Lanterns Wind Turbine Generator Vertical Axis Windmill With Controller – 12V

Related blogs.

Harnessing the Breeze: Residential Wind Turbines and their Synergy with Solar Panels

Exploring EcoFlow’s Delta 2 Portable Power Station and 220W Bifacial Solar Panel

Unveiling the Elegance: House 5 on The Block 2023

Subscribe to energy matters' newsletter.

Stay up to date with the latest renewable energy news and special offers!

©2023 Energy Matters Marketplace

Site Map | Terms & Privacy | Refund Policy

Marketplace

- Retail Store

- Wholesale Store

- Learning Centre

- Monthly Specials

Information

- Free Solar Quotes

- Solar Calculator

- Recommended Products

About Energy Matters

- Why Energy Matters?

- Store Terms & Conditions

Silent Yachts

Creators of the world’s first series produced, solar-powered electric yachts.

Unlimited Range

Noiseless cruising, zero emission, minimal maintenance, pioneering solar powered yachting since 2009.

The Original Solar Yacht

As the original inventors of series produced solar-electric yachts, we pioneered this innovative approach. Our first model, the Silent 64, was launched to the market in 2016, several years before any other shipyard considered the possibility of going electric.

Leading Technology

Our founders began to research alternative energy sources to power yachts during the mid 1990s. Today, the technology of our in-house developed solar-electric drivetrain has been perfected and is multiple generations ahead in terms of reliability, performance and efficiency.

Historical Track-Record

In 2009, the Solarwave 46 was launched as our first prototype of a fully solar-electric, self-sufficient ocean-going catamaran. Since then, our electric yachts have cruised many 10.000s of nautical miles, performing flawlessly during a variety of weather conditions.

Enabling Self-Sufficiency

What differentiates a Silent is the unprecedented level of autonomy provided by our yachts. Being able to produce your own energy enables a fully self-sufficient lifestyle on board. Travel the oceans sustainably while making them your infinite playground.

The award-winning entry to solar-electric yachts.

Timeless design meets state-of-the-art technology.

120 Explorer

The boldest expression of solar powered yachting yet.

What Makes Us Unique

The tranquility on board of our yachts is unique. A lack of noise, fumes and vibrations create a deep connection with the sea. Luxury and sustainability finally merged into a holistic experience, working hand in hand with nature by minimizing the impact on the marine environment without compromising comfort.

For optimal performance and efficiency, our solar-electric drivetrain integrates seamlessly with all onboard systems. Compared to fossil fuelled powertrains of motoryachts, electric powertrains have very few moving parts, resulting in minimal maintenance, maximum reliability and significantly lower running costs.

The ability to recharge your own batteries with the sun marks a new era of freedom. Depending on cruising speeds and weather conditions, a Silent has virtually unlimited range, enabling you to live a fully self-sufficient lifestyle on board. Unbound by the limitations of fossil fuels, you are free to explore the horizons.

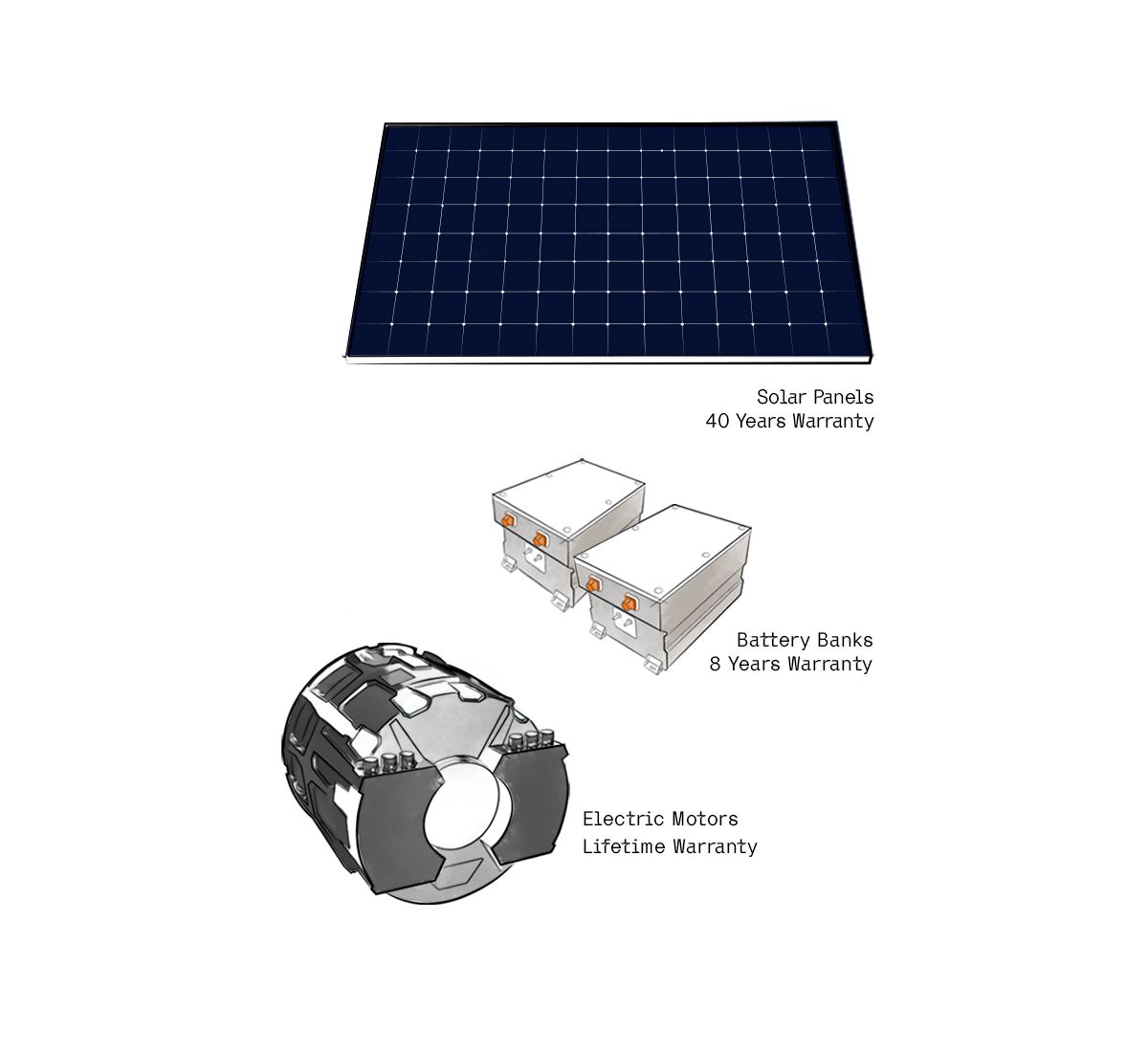

The technology powering our yachts today has been pioneered by our founders almost three decades ago. Continuous upgrading and steady optimization of the entire system are some of the key reasons our in-house developed solar-electric drivetrain offers a comprehensive portfolio of assurances and warranties.

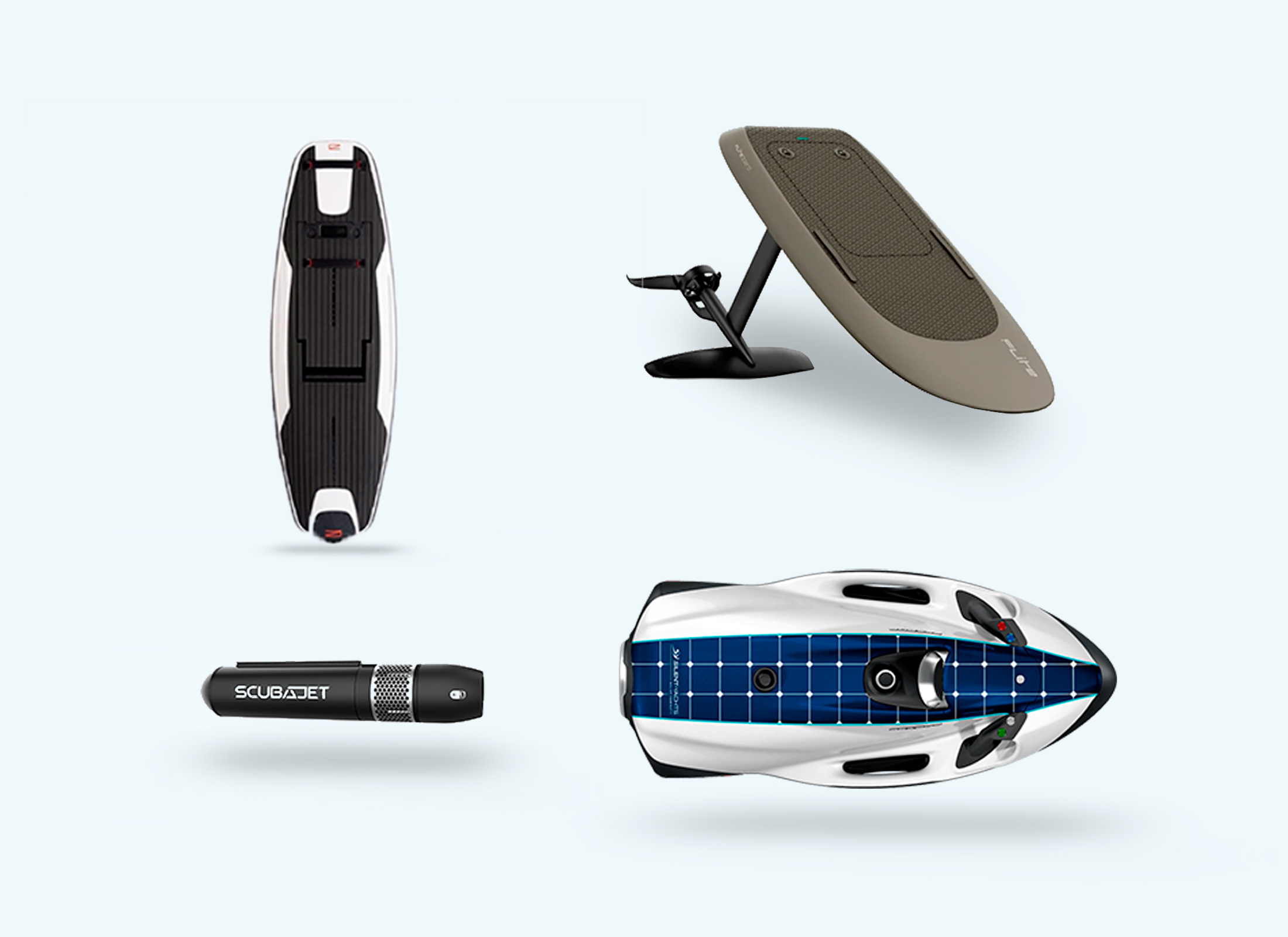

Powered by an advanced jet propulsion system, the fully electric Tender Series perfectly complements the experience on board of our catamarans. Following the same philosophy as our electric yachts, it was developed with a strong focus on being spacious, lightweight and efficient.

As a new breed of Silent, the Speed 28 combines futuristic design with blistering pace. Her high-performance drivetrain is supported by triple foils and embedded solar cells on the hardtop. Advanced hydrodynamics and latest AI management make for a stable ride which always remains comfortable.

Why Silent Yachts

A sensible approach to yachting which works in self-sufficient harmony with nature and creates a completely new experience on board.

New Silent Drivetrain

Tech shorts 2023

Electric power event on the water

Shipyard tour Italy by Michael & Heike

What is the range of a solar electric yacht?

Where are Silent yachts built?

“The Tesla of the seas! An amazing founding couple, a highly innovative product as well as a really cool story behind it. Furthermore, a lot of love and attention has been invested into every single detail – truly impressive!” Frank Thelen / TV Personality, Founder, Angel Investor & Disruption Expert

While the present has brought us the dawn of smart cars, I strongly believe the future will bring us solar powered smart boats – and I definitely want to be at the frontline of that journey. Michael Jost / Former Head of Group Strategy of Volkswagen Group

The idea of sailing while charging your own battery is super powerful to me – solar powered sailing is the perfect love story! Jochen Rudat / Former Tesla Central Europa Director, Advisory Board Silent Group

Elon Musk single handedly forced an entire industry to go electric, as a matter of fact if they don’t all go electric now they will soon die. I would like to see the same thing happening for boating. You are not just selling boats – you are the actual leading edge of a crucial and much overdue revolution to sustainable transport!” Klaus Obermeyer / Emmy Award Winner

I am completely excited about solar catamarans. I knew before they are great but now I truly believe this is the future. After so many boats I’ve seen in over 18 years with Boote Exclusiv, this yacht truly blew my mind. Such a silent and peaceful cruising experience – just the way it should be. Martin Hager / Editor in Chief for Boote Exclusiv - Yachts

Recommended water toys, accessories and products to enhance every Silent voyage:

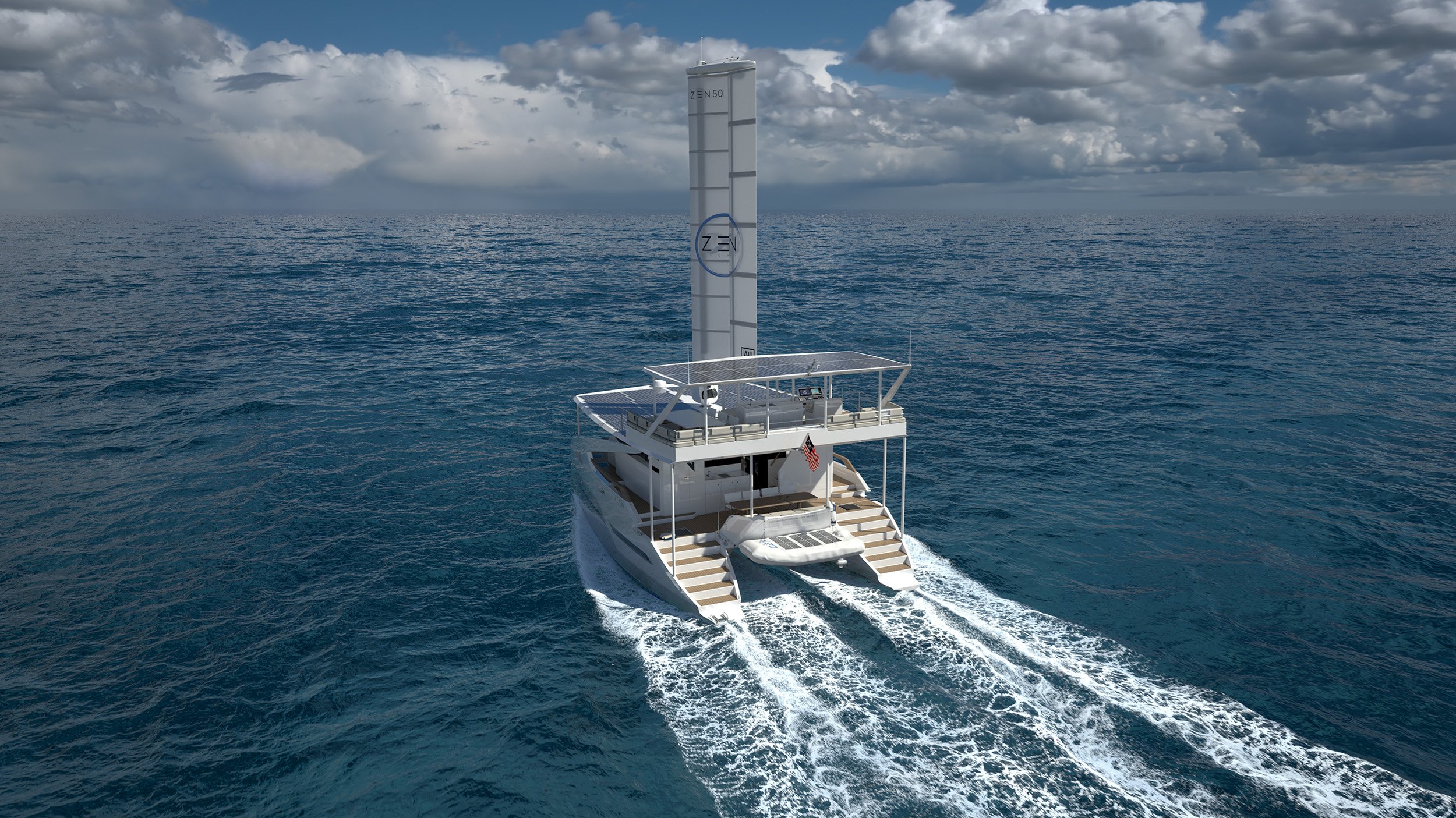

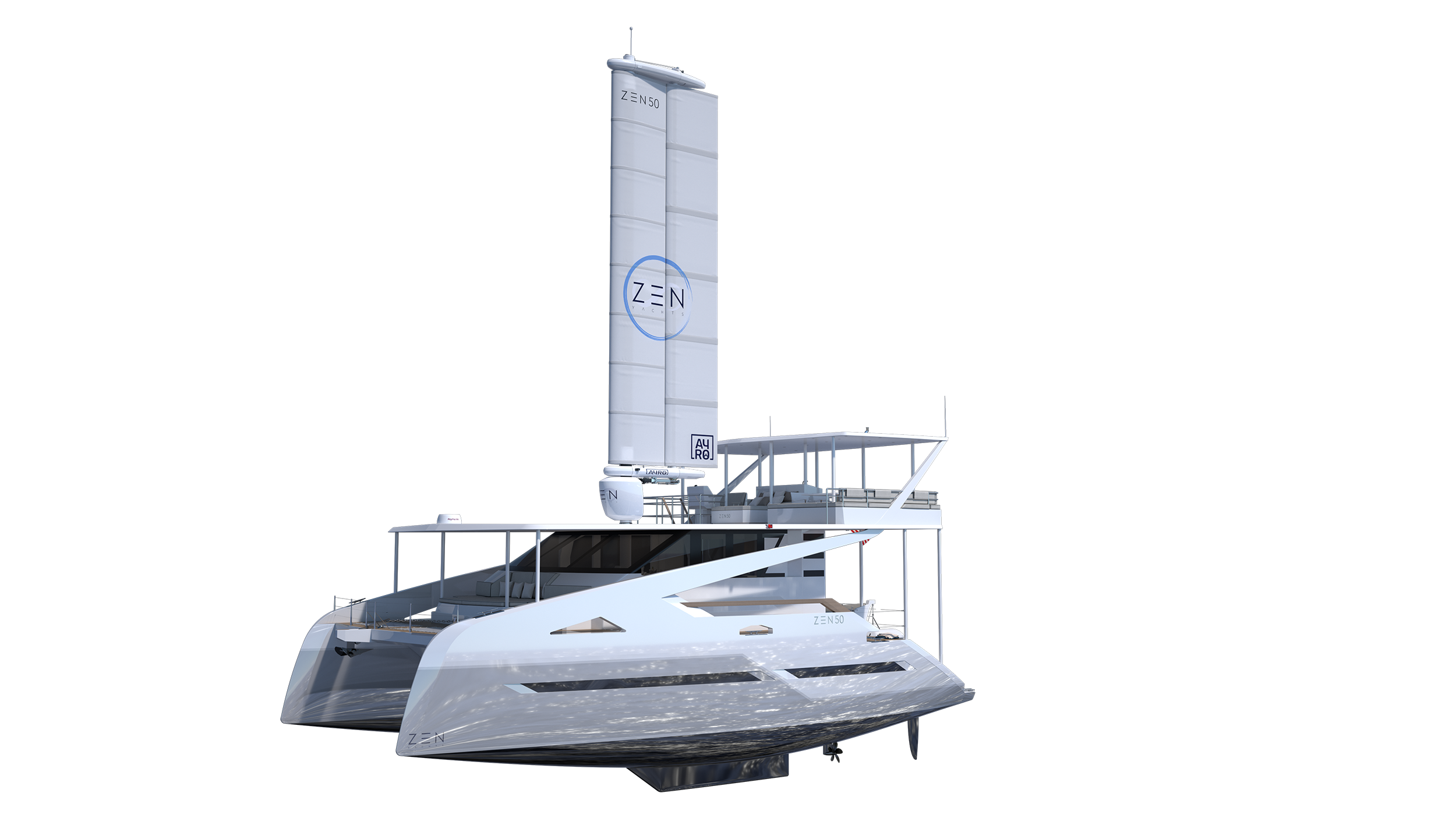

The ZEN50 is a game changer. World’s first series production catamaran equipped with a wingsail, it defines a new distinctive class of its own, where genuine zero-emission meets high comfort and performance, limitlessly.

Designed from scratch for ZEN Yachts by award-winning naval architect Julien Mélot , this full carbon catamaran is the ultimate essence of technology driven, high performance and luxurious, eco-friendly leisure yachting.

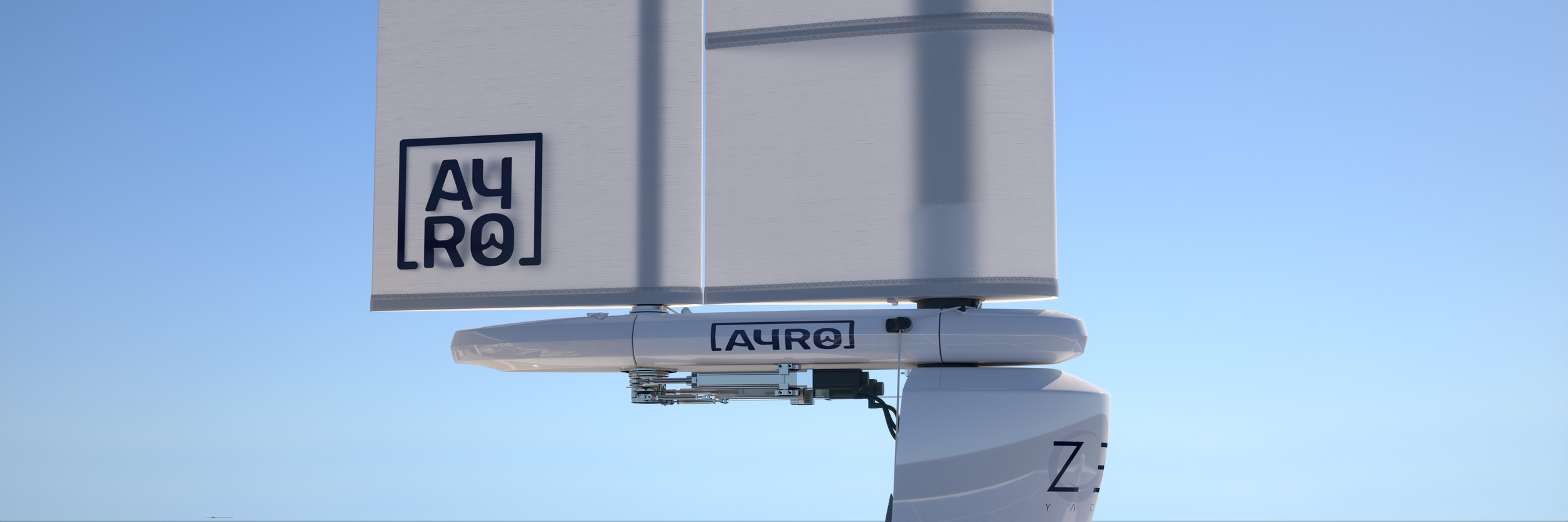

The blue water capable ZEN50 lightweight racing carbon hulls are combined with a huge solar roof for an unrivaled solar power vs. displacement ratio above 1:1 (18 kW / 17 tonnes), making this yacht completely energy self-sufficient. A revolutionary, fully automated, wingsail - by Ayro© - can be added as a range and speed extender. The yacht’s high capacity battery bank powers a powerful silent electric propulsion, allowing the ZEN50 to achieve 14 knots and maintain high continuous speeds in unrivaled safety and comfort, indefinitely…

The ZEN50 is offered with or without wingsail and comes in 3 main different versions: Racer, Cruiser and Explorer, each dedicated to a different usage and owner profile. We use these versions as a basis to define a final, bespoke specification for each of our valued clients and ZEN Community Members. Scroll down for more details, specifications and prices.

1st WINGSAIL series production yacht in the world!

The OceanWings32 - by Ayro© - was initially developed for Team Oracle, for the America’s Cup 2010 in Valencia. Over years, it has further been developed and automated by VPLP and was installed on Energy Observer in 2019. Two years of field feedback have allowed the Ayro team to fine tune the algorithm commanding the wingsail. The ZEN50 is the first series production leisure craft to be equipped with this fully automated wingsail. It is controlled at the touch of a finger on screens, is automatically adjusted and has several safety modes and features. The two parts of the wingsail can be hoisted and lowered independently and with the simple touch of a button. The wingsail OceanWings32 is the ideal complement for the solar roof for those wishing to cruise long distances off-shore with zero-emissions.

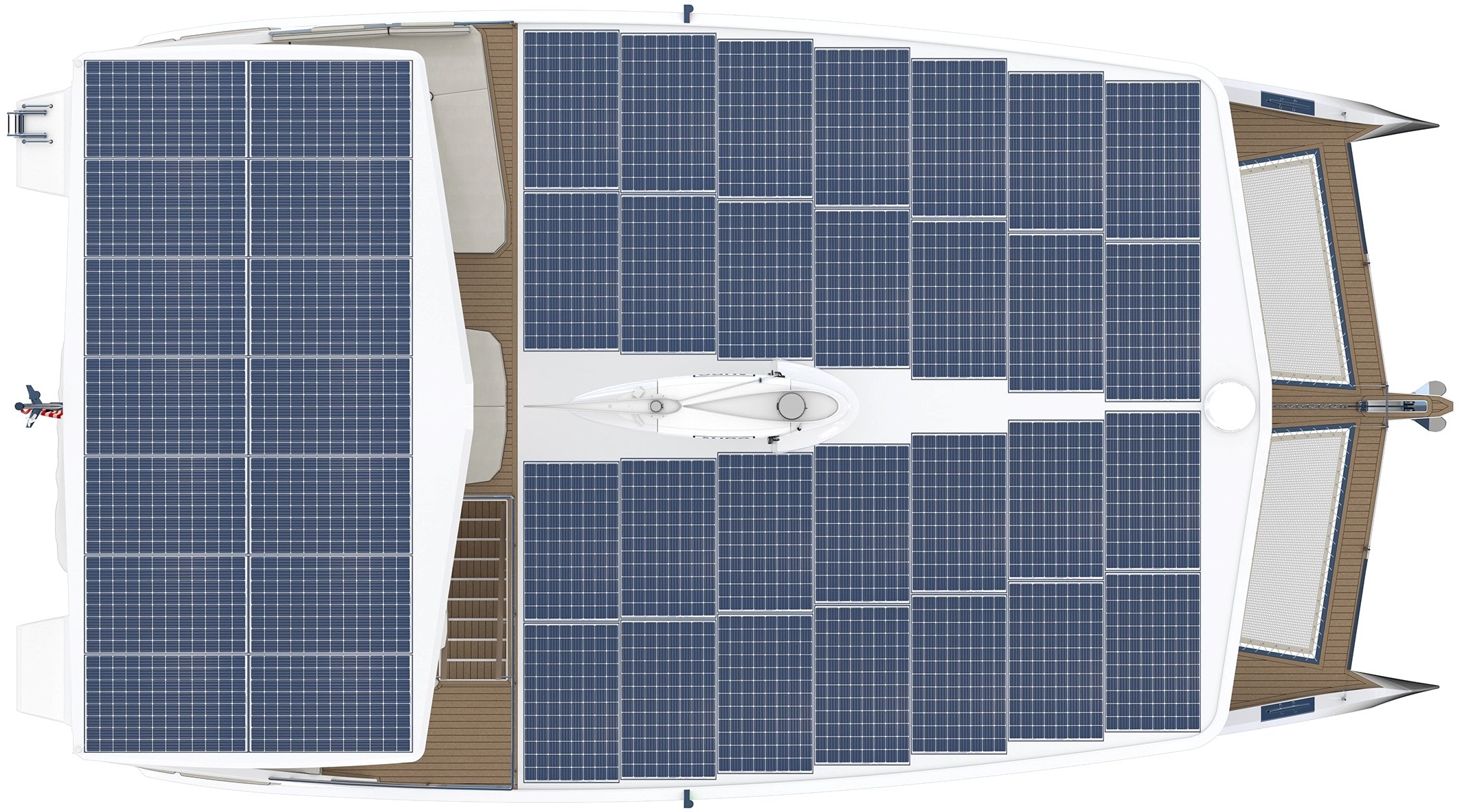

Greatest ratio SOLAR POWER / weight on the market

At 17 tonnes lightweight and 18,000 W of peak solar power, the ratio of the ZEN50 is at over 1 kW per displaced tonne of water or beyond 1:1 which is far beyond any other blue water CE Cat A yacht in this size range. Lots of solar power for little water to displace is the strong and healthy foundation the energy self-sufficient ZEN50 is built upon.

Performance CARBON sandwich hulls

The hulls of the ZEN50 have been designed from a blank screen for ultimate efficiency - understand minimum drag or minimal energy consumption for a range of speeds from 6 to 10 knots. Their shape is aggressive, sharp and slender. Their reverse bows cut through water like a sword cuts through butter and their curvature is reminiscent of graceful dolphin bodies. These hulls are undoubtedly of the performance type and are built with the best available composites: Carbon fibre and Corecell™. The combination of high strength, low weight and performance design allow the ZEN50 to reach speeds of up to 14 knots.

INFINITE range at high CONTINUOUS speeds

With maximized solar and wind power and minimized energy consumption… the ZEN50 can sail continuously at speeds varying between 6 and 10 knots. Thorough simulations in various sea states and weather system have consistently shown the ZEN50 will be able to achieve performance catamaran speeds continuously without using a genset. With the ZEN50, the world is your oyster and the wildest destinations are within your reach with this self-reliant vessel!

True ZERO-EMISSION operation

The first ZEN50 unit, whose construction started in March 2023, will not be equipped with a genset at all and will not have any fossil fuels onboard. The ZEN50 energy system with its very large capacity 160 kWh battery bank, has been designed to function for days in complete safety with minimal solar energy harvest and no wind. It is perfectly safe with no backup genset and operates 24/7 without any polluting emissions.

NO FUEL , no costs

Naturally, requiring no fuel to operate day in day out is great news for the environment, it is also fantastic news when sailing into remote areas where fuel bunkering might be near impossible or where the fuel quality might be an issue. Finally, it also makes a massive difference in this yacht’s costs of operation. Imagine the hundreds of liters of diesel saved over just a week, the obsolete engine maintenance schedules, the clogged filters and dirty tanks from another age… Welcome to a new burden-free, energy self-sufficient era, welcome to clean and graceful eco-yachting, welcome to ZEN Yachts.

Highest SAFETY & reliability

At ZEN Yachts, we have made some design choices to attain energy self-reliance with the ZEN50 that reduces the habitable volume in the hulls, similar to performance catamarans. Where we have not and will never compromise is on safety. Our main voltage system is 48V making it perfectly safe to work on. The level of redundancy of the batteries and solar panels is 10! The main electrical architecture is split in 2 so that should anything happen on 1 hull, the entire vessel can still operate normally. There are 2 independent helm stations and the ZEN50 is packed with special safety features, nonsubmersible compartments and we can even offer an in-depth practical course on safety equipment usage and management. Sailing with the ZEN50 is not only exhilarating and clean, it is ultra safe!

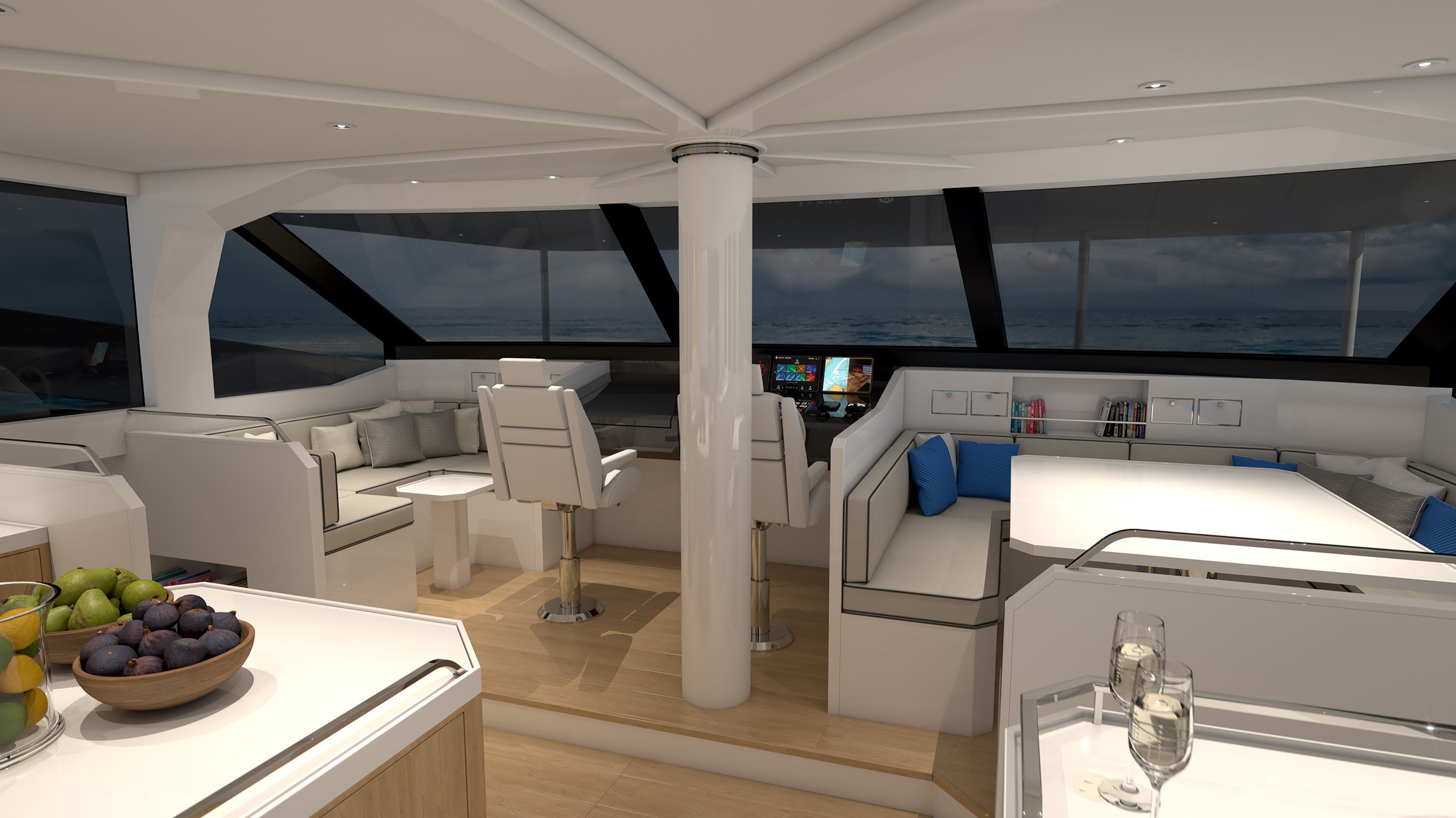

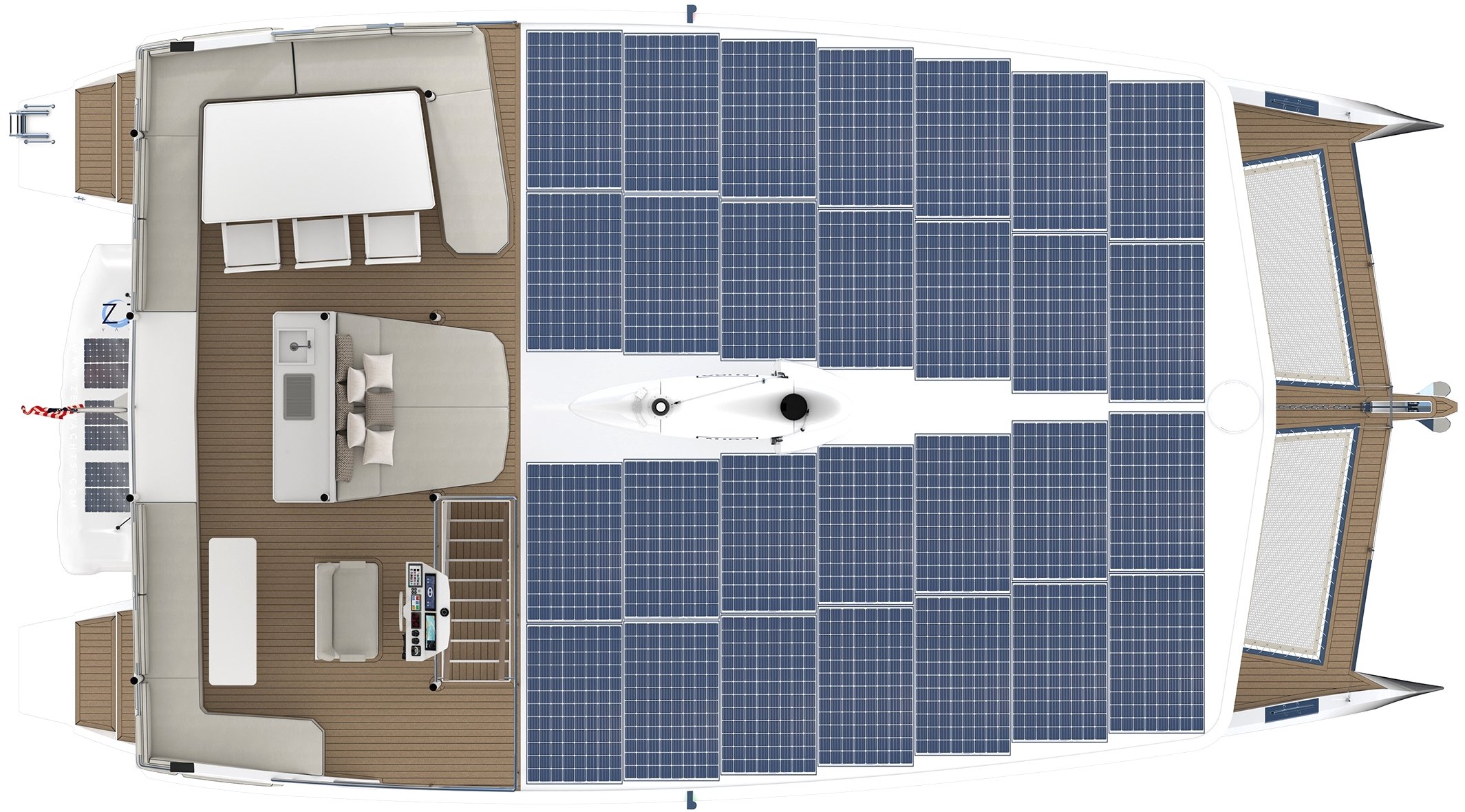

Unrivaled space & COMFORT

The ZEN50 offers the speeds of a performance catamaran, the comfort of a large motor yacht and the simplicity of an electric car. No less than 2 large day beds, 3 dining areas for over 10 people, 1 professional galley and 2 wet kitchens, 5 heads, up to 4 double ensuite cabins, 1 bunk double and 1 single together with both saloon and dining areas converting into extra sleeping areas, this is simply unrivaled on a 50 ft. catamaran. Add an electric tender, dive compressor, satellite internet, 2 helm stations (cockpit and flybridge), a solar roof that converts into a gigantic upper deck to enjoy the most epic sunrises and sunsets, welcome onboard the ZEN50!

SPECIFICATIONS

Main particulars.

• Length Over All: 15.7m

• Beam: 8.4m

• Depth Molded: 2.7m at midship

• Displacement (light) : 17 T

• Draft (design): 1.3m (4.3ft) incl. keel

• Passenger Capacity: 12

• Berths: 12 (4 x double + 2 x single + saloon)

• Building Material: Carbon Fiber - Corecell™ composite

• Certification: CE Cat A - Unrestricted with 12 persons

Note: Some of the above figures may vary between versions

PROPULSION & ENERGY

• Propulsion: 2 x 50 kW brushless DC motors

• Main Battery Pack Capacity: 160 kWh Lithium

• Solar Roof Peak Power: 18 kWp

• Wingsail: Oceanwings® OWS 3.2 by Ayro©

• Backup Battery Pack Capacity (Nav/Com/Wing): 5 kWh Lithium

• Main System Voltage: 48V - Low voltage for total human safety

• Accommodation Voltage: 110V or 220V

SPEED & RANGE

• Max. Speed on e-motor only: 10 kn

• Max. Speed on e-motor & Wingsail: 14 kn

• Cruising Speed for continuous operation - solar only: 4.5 - 5 kn

• Cruising Speed for continuous operation - solar and wing: 6 - 10 kn

• Cruising Speed day time: 8 - 10 kn

• Range Over 24 h: 180+ nm

Note: These values may vary between versions and sea / weather conditions

EQUIPMENT INCLUDED - RACER VERSION

• Integrated power management system

• Solar power & energy storage system

• Electric propulsion system

• By-wire steering system

• Helm stations at cockpit & flybridge

• Galley counters, storage, sink, oven, stove, fridge, freezer

• 4 en suite heads with enclosed shower, toilet, sink & faucet (in each head)

• All cabin furniture (as shown in layouts)

• Aft deck fixed dining table and aft sofa with collapsible back rest (as shown in layouts)

• Fore deck day bed and lateral seats (as shown in layouts)

• Outdoor marine cork decking / indoor saloon natural bamboo decking

• All cushions In/Outdoor upholstered with Sunbrella® fabric

• 6 deck hatches

• 2 x 500 liter (2 x 132 gal) fresh water tanks

• 2 x 100 liter approx. (2 x 26 gal) fresh water tanks + 1 fresh water pump

• 2 x 350+ liter approx. (2 x 92 gal) holding tanks

• Railings, cleats and fore deck trampolines

• Mooring equipment: 33 kg Rocna® stainless steel anchor + 50 m stainless steel chain 10 mm + 150 m nylon rope + e-windlass

• Regulatory navigation equipment including navigation lights & mast

• 2 x chart plotter 16”; 2 x VHF with DSC button

• Regulatory Life Saving Appliances

• Critical spare parts kit

Note: The above equipment is for the Racer version. Cruiser & Explorer versions carry additional equipment

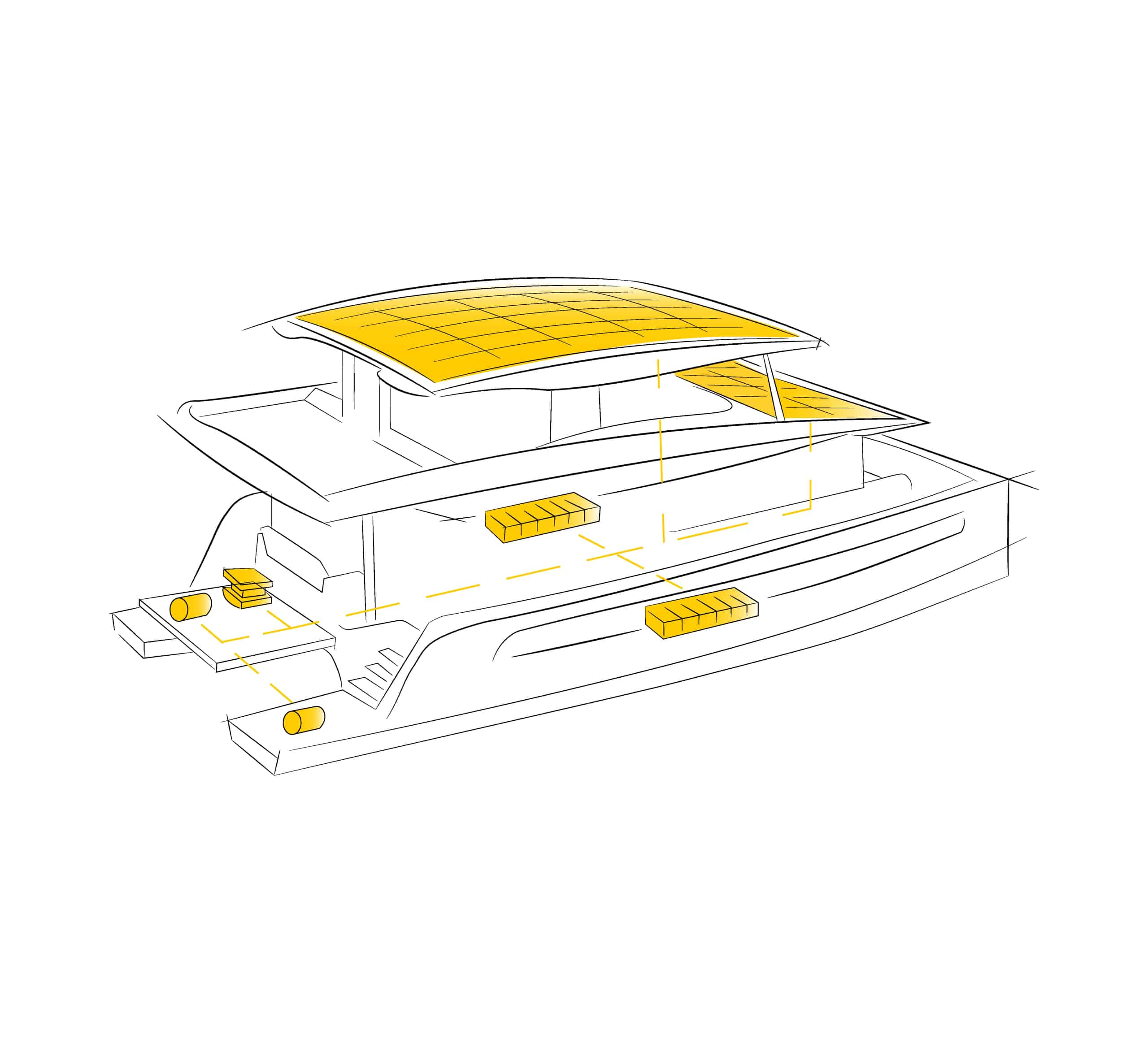

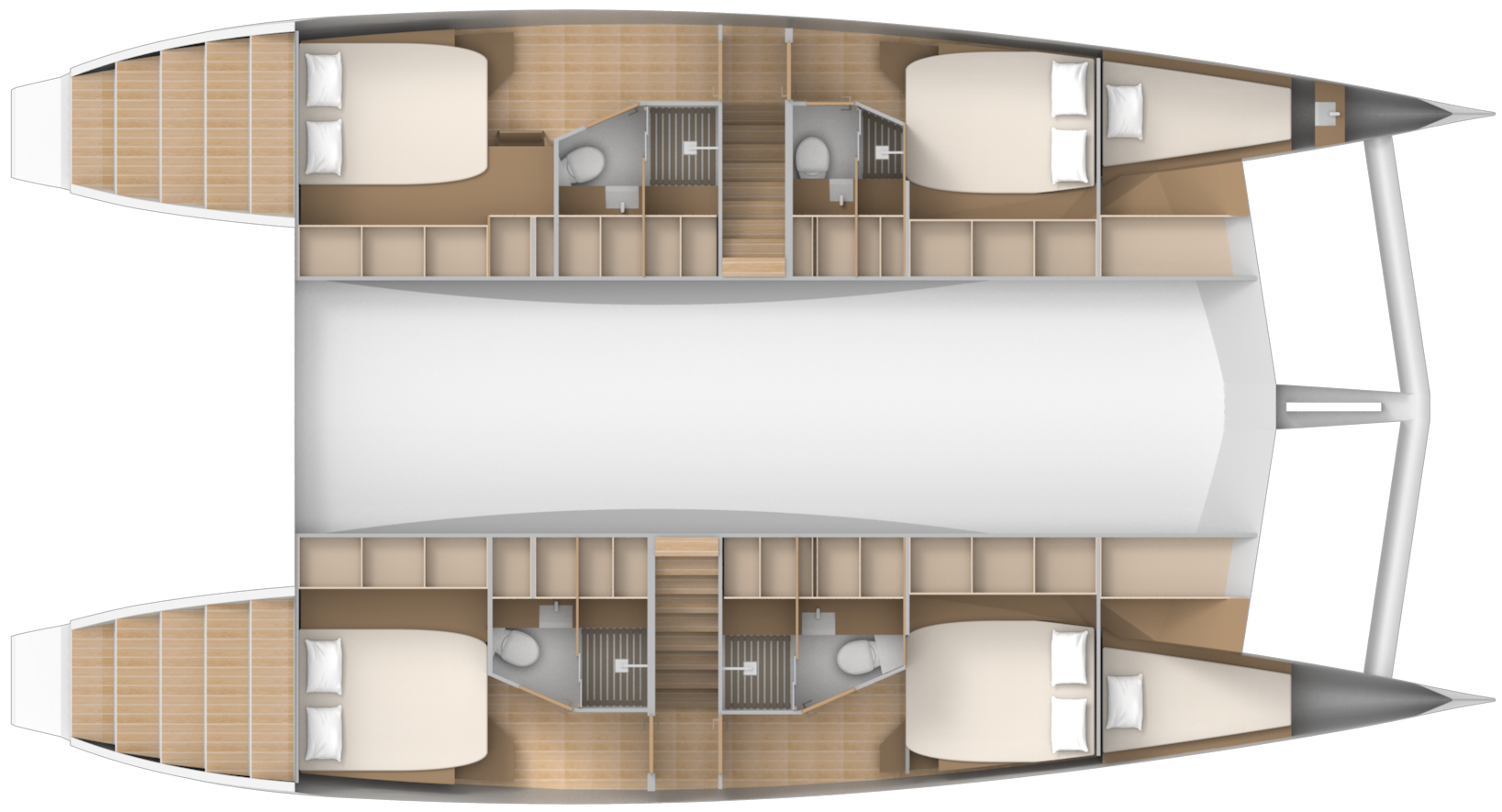

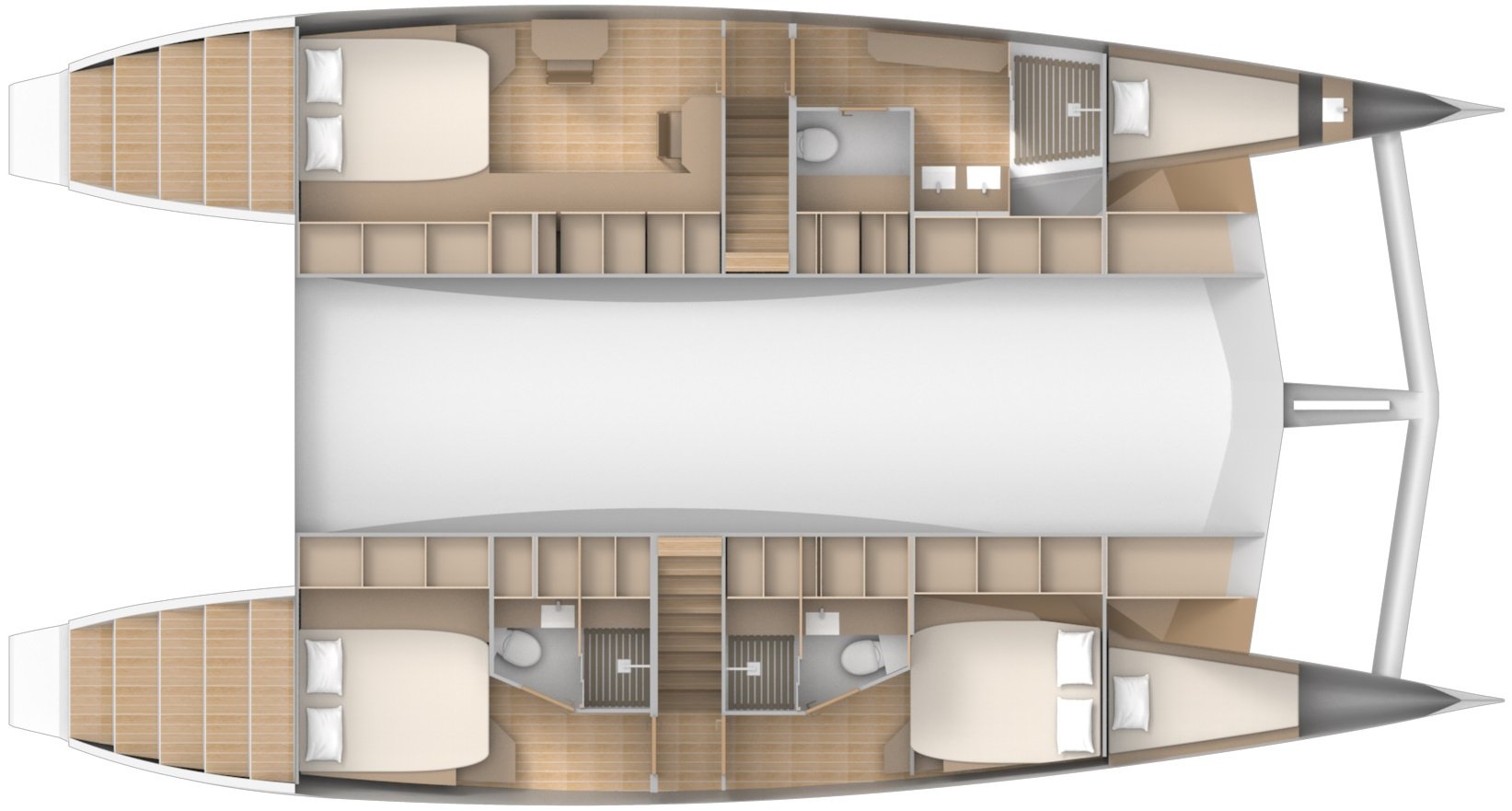

ZEN50 Solar Wingsail Electric Catamaran - Solar Roof Layout

ZEN50 Solar Wingsail Electric Catamaran - Flybridge Layout

ZEN50 Solar Wingsail Electric Catamaran - Main Deck Layout - Asymmetric D (subject to changes)

ZEN50 Solar Wingsail Electric Catamaran - Cabin Layout - Asymmetric D (subject to changes)

ZEN50 Solar Wingsail Electric Catamaran - Cabin Layout - Asymmetric E (subject to changes)

SOLAR & WINGSAIL

OCEAN RACER

Solar power & Wing, basic configuration, navigation, safety, fridge, etc.

EUR 2 150 000

WORLD CRUISER

Solar power & Wing, well equipped with A/C and water maker

EUR 2 400 000

ARCTIC EXPLORER

Solar power & Wing ultimate configuration with all available options

EUR 2 650 000

Solar power, basic configuration, navigation, safety, fridge, etc.

EUR 1 700 000

CONTINENTAL CRUISER

Solar power, well equipped configuration with A/C and water maker

EUR 1 900 000

TROPICAL EXPLORER

Solar power ultimate configuration with all available options

EUR 2 100 000

Ready to reserve your ZEN50?

Want more information .

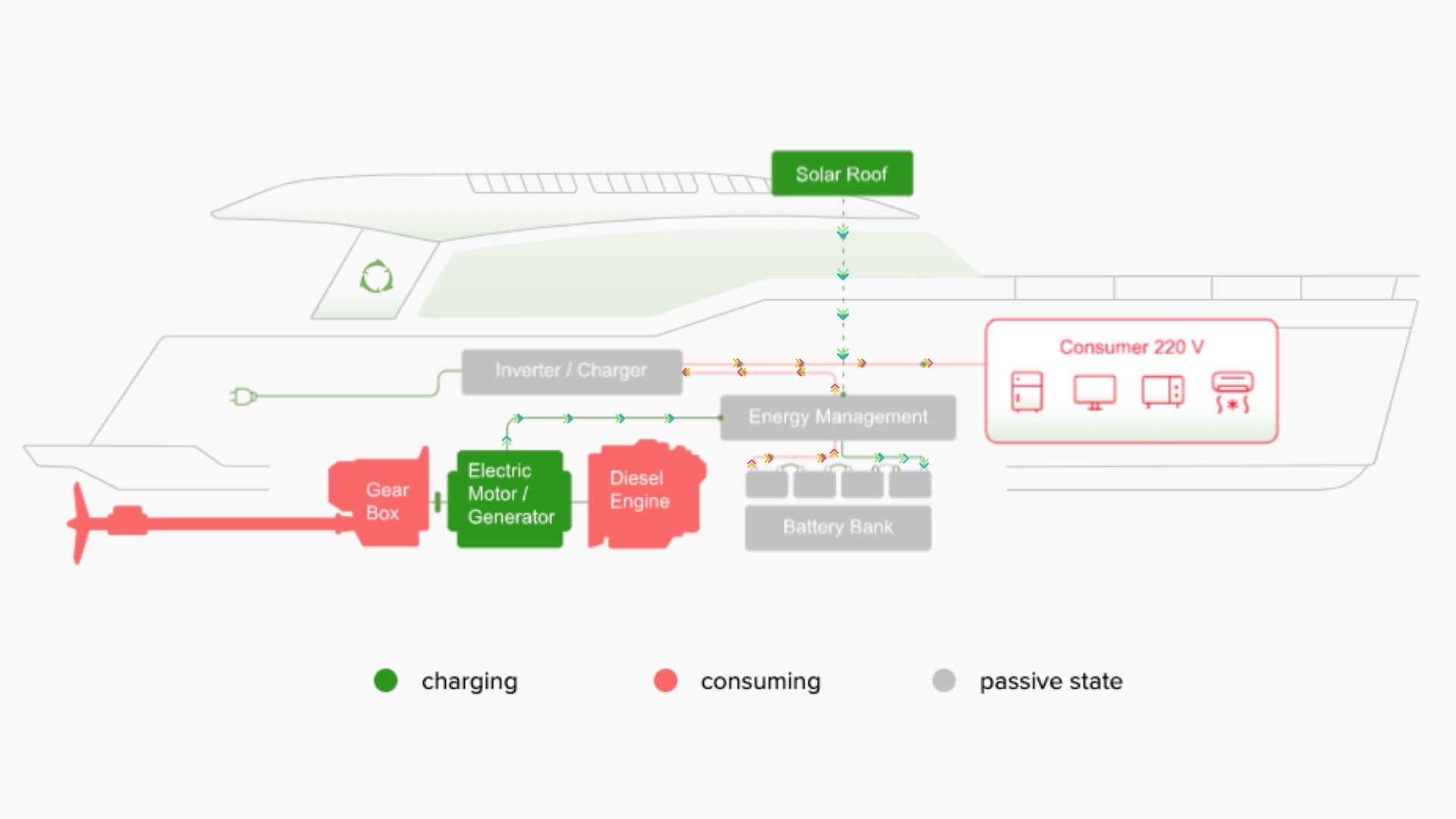

Responsible Boating with Maximum Comfort

The greenline concept is about innovation and environmental awareness, creating a motorboat for the future..

Greenline Yachts are created for boating enthusiasts that want to cruise in comfort and luxury, whilst minimising their impact on the environment. The sophisticated approach to design, coupled with the latest technologies has produced a range of liveaboard boats ranging in size from 10 metres to 21 metres in length.

All boats feature silent eco-performance of the hybrid drive engines, coupled with superior hull design resulting in an efficient boat that is a pleasure to drive. Onboard solar panels provide electric power reducing reliances on marina power or generators.

Each boats’ interior is full of natural light, with large windows offering great visibility and a feeling of connection to the natural environment. Well designed cabins offer flexibility in terms of layout and plenty of comfort to make living onboard a dream.

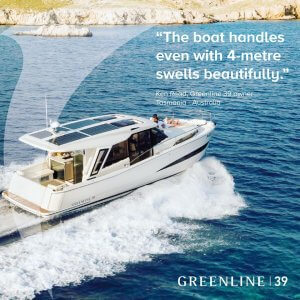

GREENLINE 39

Offers an unforgettable experience that is rarely found on small yachts due to its sophisticated design and technology.

GREENLINE 40

With comfort, convenience and safety that exceeds expectations, the 40 is ideal for social boat days or longer cruising with your family.

GREENLINE 45 COUPE

One-level-living meets sustainable boating with this solar-powered Greenline hybrid yacht.

GREENLINE 45 FLY

A new generation model that is a fast and more powerful hybrid yacht offering the perfect balance between comfort, space and cruising capability.

GREENLINE 48 COUPE

More power and more space in the new generation model. The sea class ‘big sister’ of the luxury hybrid eco yacht range from Greenline.

GREENLINE 48

The flagship of the Greenline range. Cruise in complete comfort while using up to four times less fossil fuels than a planing powerboat in similar conditions.

GREENLINE 58 FLY

With the 58 Fly, Greenline Yachts cements its position as the leading manufacturer of boats with alternative propulsion, as well as a new partnership with Marco Casali of Too Design and MICAD engineering.

GREENLINE 58 COUPE

With a solar power capacity of up to 7.04 kW, the Greenline 58 Coupe features 16 solar panels on its roof as part of its standard configuration. This substantial solar array provides continuous and nearly unlimited onboard power for all appliances, without the need for fossil fuels.

OCEANCLASS 68

A long-range go-anywhere yacht which sits at the top of her class in all aspects. Quality and convenience offers experienced boaters a satisfying boat for the onboard sailing lifestyle that is a true home away from home.

Let us know what you are interested in and a member of our expert team will contact you shortly.

EXCLUSIVE TO EYACHTS

Greenline yachts in australia.

Eyachts is the exclusive dealer of Greenline Yachts in Australia and New Zealand. Eyachts are proud to have been partnered with Greenline for over 10 years and witnessed the evolution of the brand, the technology and the design. Leading the world in eco-friendly boating, Greenline Yachts ethos fits the model Eyachts look for when choosing our product range. Importantly, superior design and engineering mean Greenline Yacht owners do not need to compromise on comfort or luxury.

ABOUT GREENLINE YACHTS

'We believe modern boaters are ready for the next step in the evolution of leisure boating and are becoming increasingly more aware that we are the only ones that can preserve the environment for our children and grandchildren to enjoy' - Vladamir Zinchenko - Owner & CEO

Greenline Yachts was established in 2008 and is principally about shaping the future of boat building in a responsible, environmentally way. Greenline Yachts offer electric and hybrid engines and are built using up to four times less fossil fuel than a planning powerboat in similar conditions. The clever battery system and standard solar power allow these boats to run with minimal environmental impact.

Greenline Yachts aims to deliver more comfort, greater ease of handling and more fun than any other boat in its class. The outstanding design adds a new dimension that allows you to savour the quietness of the water as you would on a sailing yacht without polluting your surroundings or the environment with exhaust, noise or wake.

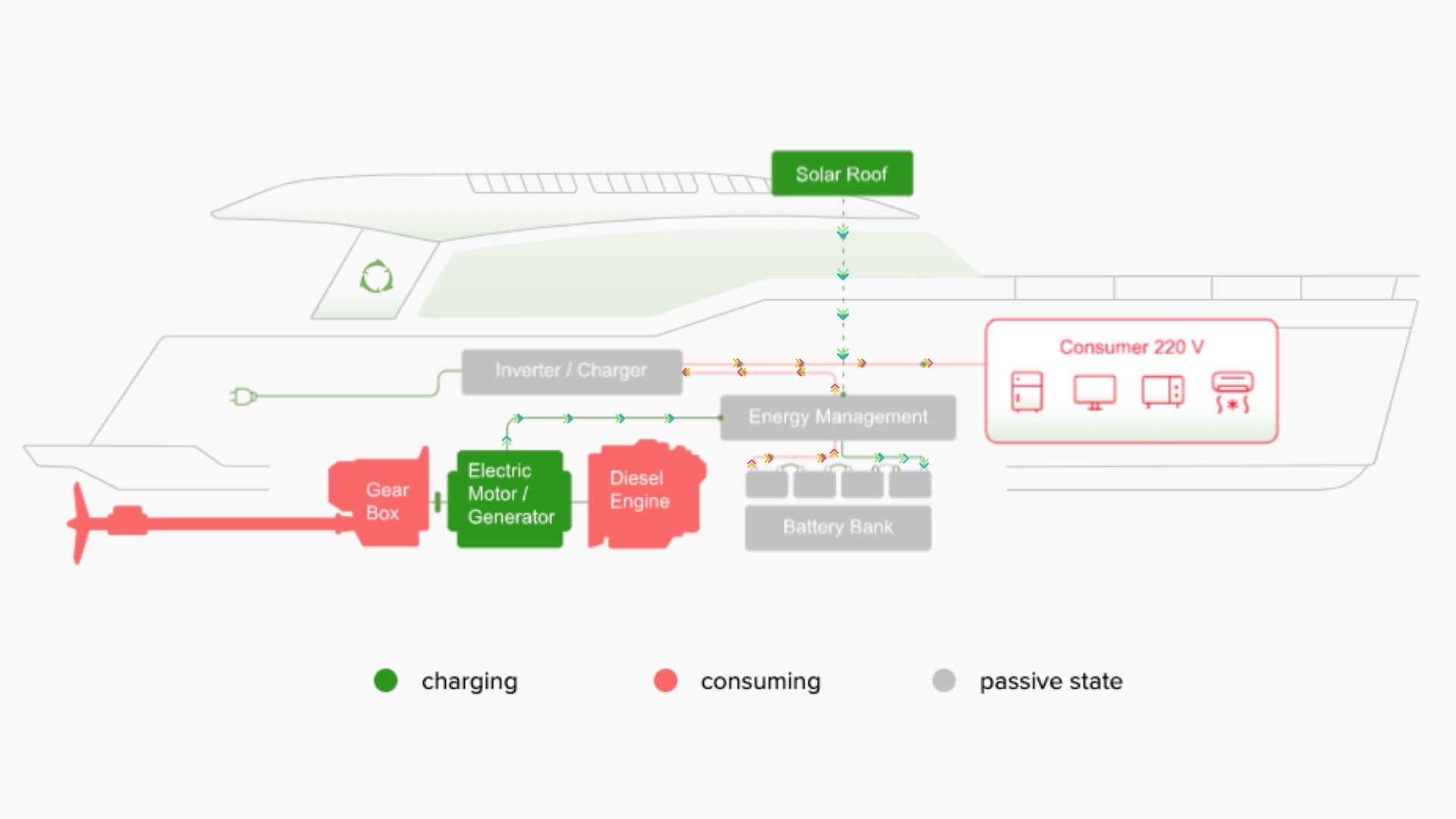

HYBRID SYSTEM

Greenline Yachts is the leading manufacturer of eco-friendly and sustainable yachts, with the only complete fleet offering hybrid propulsion. Since 2008 Greenline Yachts have been developing and investing in creating the best hybrid solution and have now launched their 6th generation of hybrid. Leveraging years of experience in hybrid drivetrains, the company has been able to refine their systems to optimize not only for propulsion but also for maximum efficiency and comfort while living on board.

SUPREME STANDARDS

All Greenline Yachts come standard with;

- Full Roof Solar Panels

- Battery Management System

- Lithium service batteries

- Minimum 5kW Inverter

- Full-size fridge & Freezer

- Bow Thruster

- Convection Oven

- Anchor Winch

EUROPEAN PICKUP

Pickup your Greenline Yacht in Europe, explore the Adriatic and then get it sent back to Australia.

For decades’ sailboat companies have been doing European pick-ups. Not only are many of the world’s best boats built in Europe but Europe is also home to some of the most picturesque waterways.

This opportunity is exclusive to Eyachts.

Ebrokerage Greenline 33 Review by Cres James

“Dianna and I wish to say a very big thank you for your generous gift. We will enjoy the Moët on board… I would also like to express my thanks for your assistance, advice and guidance during the purchase and insurance process as well as to all your staff. It was an absolute pleasure to conduct business with you and all at Eyachts (Ebrokerage).”

Greenline 33 to 39 Review

The 39 builds on the 33’s open, liveable, practical, modern attributes and adds more space, functionality and sea friendliness, it’s so much easier to use. Peter Hrones showed that he is a true Gentleman and his company, Eyachts, reflects this approach to business.”-Ian

Greenline 39 Review – Tasmania

Greenline 40 Testimonial by The Flemings

“The boat is perfect for extended cruising. With 6 solar panels built into the cabin roof, there is ample power always available through a 5kW inverter without the need of a generator. We have twin 150hp marine Diesel engines, plus the option of running on electric.”

Greenline 48 FLY Customer Review with Peter Osborn

“Transitioning from sail to motor – love the displacement hull that enables me to cruise 10knots if I want or crank up to 20 +. Huge range and least expensive which is important for a yachtie. Massive wide and deep sidewalks…”

Greenline 39 – Cheryl-Lynn and Greg Smith

Cheryl-Lynn and Greg have purchased the Greenline 39 after years of sailing. They plan to go on day trips on Lake Macquarie with the family, cruise down to Pittwater for the weekend and further explore the beautiful NSW coastline in the comfort and safety of their new Greenline.

Greenline owners – Jon & Anne Flemming

“The Greenline stood out from the crowd…We are absolutely thrilled with boat and our experience with Eyachts have been very good.”

Greenline 39 Review – John Bossi

“We love it! We have 3 children and lots of friends and family we like to entertain. The Greenline is a perfect fit for our lifestyle – it’s truly an entertainers’ boat.” John Bossi

Eyachts Team Review by John Bossi

Working with the team in Sydney was great… there were never problems, only solutions. I found that across the board with everyone I was in contact with at Eyachts. I’ve made a lot of purchases from dental equipment to motorcycles. I have never experienced a standard set so high across an organisation.

REVIEWS BY THE XPERTS

The 2023 greenline 58 fly: a stunning yacht redefining eco-friendly cruising, power boating – july 2023.

Discover the perfect blend of style, performance, and environmental consciousness with the Greenline 58 Fly, a luxurious and eco-friendly yacht that offers a breathtaking cruising experience without compromising on comfort and convenience.

GREENLINE 58 FLY HYBRID Yacht Tour

Nautistyles – september 2023.

From the Cannes Yachting Festival, the World Premiere of the 2023 GREENLINE 58 FLY HYBRID. Walkthrough and tour from NautiStyles.

Greenline 58 – Greenline’s New Cruiser

Yachting magazine – october 2021.

Greenline’s new eco-friendly cruiser – The Greenline 58 Fly is a 30-knot, three-stateroom yacht with efficiency in mind.

LATEST FROM THE BLOG

Discover the All-New Greenline 58

Rowan from Eyachts recently took the Greenline 58 for a sea trial in Cannes beautiful harbour, providing valuable insights into the key features of this impressive yacht.

Greenline Hybrid System

Greenline Yachts is the leading manufacturer of eco-friendly and sustainable yachts, with the only complete fleet offering hybrid propulsion. Since 2008 Greenline Yachts have been developing and investing in creating the best hybrid solution and have now launched their 6th generation of hybrid.

Greenline 45 Efficiency Review

Greenline Yachts are best known for their efficient hull designs. In this video, Joe tests the Greenline 45 at various speeds and details the fuel consumption.

ECO-FRIENDLY BOATING AT ITS FINEST

Limited offers, greenline 39.

You are using an outdated browser. Please upgrade your browser or activate Google Chrome Frame to improve your experience.

- Commercial & industrial PV

- Grids & integration

- Residential PV

- Utility scale PV

- Energy storage

- Balance of systems

- Modules & upstream manufacturing

- Press releases

- Sustainability

- Technology and R&D

- pv magazine UP initiative

- pv magazine Hydrogen Hub

- PV project exchange

- pv magazine Roundtables & Insights

- pv magazine Webinars

- Print archive

- pv magazine test

- pv magazine team

- Newsletter subscription

- Magazine subscription

- Community standards

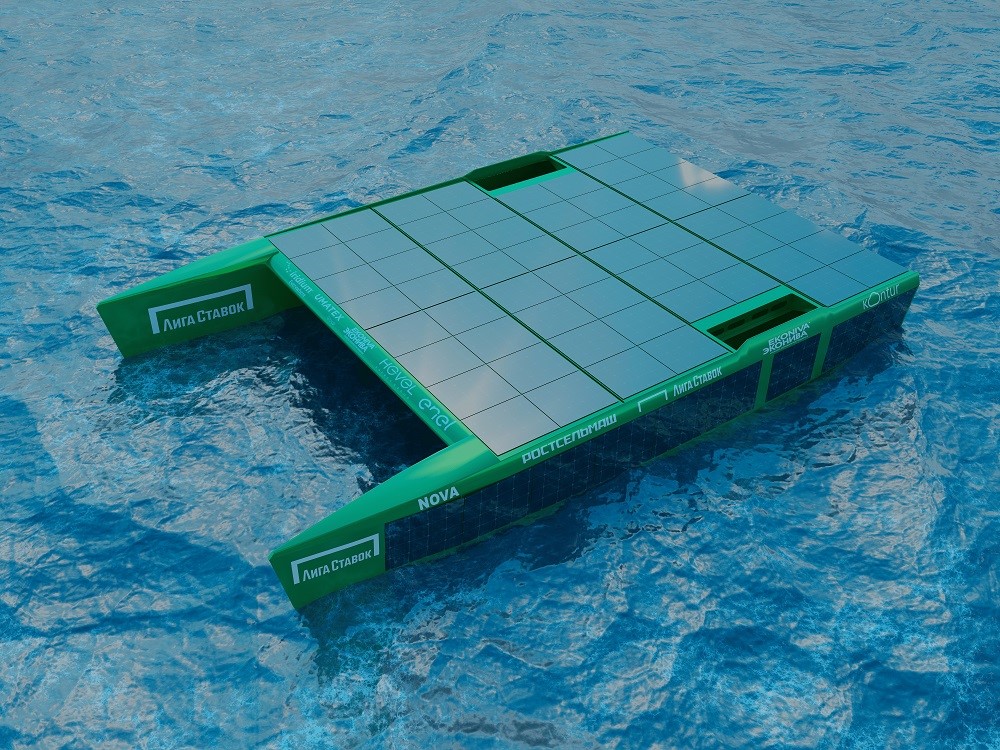

Solar catamaran 100% powered by heterojunction modules headed for Australia

The 100% solar-powered boat will be tested in a 9,000 nautical mile expedition from Chile to Australia that is set to start in December. The vessel is equipped with an 11 kW PV system built with heterojunction modules provided by Russian manufacturer Hevel Solar.

Hevel Solar

From pv magazine Global

A catamaran designed by English racer and engineer Phil Morrison and set to undertake a 100-day solo transatlantic trip from Chile to Australia will be exclusively powered by a PV power generator.

The boat will be helmed by Russian adventurer and survivalist Fedor Konyukhov in a first-ever solo transpacific 9,000 nautical mile expedition from Chile to Australia, which is set to start in December.

Called Nova, the vessel is 11m long, 7m wide and able to reach speeds of 5-7 knots. It is made of carbon-fibre composites and weighs only 2.2 tons. “The craft is designed to break down into two hulls and four deck sections, which together with ancillary equipment, launching and assembly, will fit into two 40ft containers,” Morrison said in a statement.

The boat is equipped with an 11 kW PV system built with flexible heterojunction solar panels developed by Russian module maker Hevel Solar . “T he cost of solar elements plus labor and without the storage system was RUB 1.1 million, which makes up to €12,000,” a spokesperson from the manufacturer told pv magazine .

The solar array will cover a surface of around 66 m2 on the vessel and the sides of the hull will also carry panels, providing an additional 12m2 per side. “Whilst these panels are not expected to be as efficient as the deck panels it is hoped they will gather valuable additional energy when the sun is low on the horizon and from light reflected off the water surface,” Hevel Solar explained.

The PV system will also ensure the supply of freshwater, as the boat is equipped with a desalination system powered by solar-generated electricity itself.

The catamaran is also equipped with an energy storage system designed by Enel X, a unit of Italian utility Enel . The system relies on 26 Li-Fe-phosphate batteries to ensure a stable power supply for the PV system, which could peak in excess of 5 kW in ideal conditions. “Sophisticated MPPT charge controllers capable of adjusting the current and voltage to maximise the charging potential will be allied with a complex monitoring system allowing the craft to optimise the power obtained,” Morrison stated.

Nova is claimed to be able to navigate with full autonomy in the ocean for up to six months.

The boat was also conceived with technologies provided by Mikhail Lifshitz, general designer at ROTEC JSC, which specialises in developing methods to power sea and river vessels using electricity-supplied engines, solar panels and the albedo effect.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com .

Emiliano Bellini

More articles from Emiliano Bellini

Batteries boom as investment in large-scale renewables slumps to a 5-year low

Containerised, retractable pv system for quick deployment, related content, elsewhere on pv magazine....

- Pingback: Australian research prompts rethink on silicon heterojunction cell production – News Feed

- Pingback: Australian research prompts rethink on silicon heterojunction cell production – pv magazine International – Business News Press

Leave a Reply Cancel reply

Please be mindful of our community standards .

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy .

By subscribing to our newsletter you’ll be eligible for a 10% discount on magazine subscriptions!

- Select Edition(s) * Hold Ctrl or Cmd to select multiple editions. Tap to select multiple editions. Australia (English, bi-weekly) Global (English, daily) Germany (German, daily) U.S. (English, daily) China (Chinese, weekly) India (English, daily) Latin America (Spanish, daily) Brazil (Portuguese, daily) Mexico (Spanish, daily) Spain (Spanish, daily) France (French, daily) Italy (Italian, daily)

- Read our Data Protection Policy .

Subscribe to our global magazine

Most popular

Keep up to date

pv magazine Australia offers bi-weekly updates of the latest photovoltaics news.

We also offer comprehensive global coverage of the most important solar markets worldwide. Select one or more editions for targeted, up to date information delivered straight to your inbox.

- solar electric yachts

- Soel Senses 62

- Soel Senses 82

- Soel Shuttle 14

- Custom model

SOEL YACHTS

Solar electric yachts.

With dedication and passion for high tech, sustainability and excellent design, Soel Yachts creates solar electric yachts that promise high efficiency, low emissions, outstanding comfort, low maintenance, and significantly reduced costs of ownership. We are driven by an unwavering commitment to accelerate the transition to sustainable and autonomous mobility on the water.

ENJOY THE RICHNESS OF THE SEA

Our solar electric catamarans combine all the elements for a luxurious and environmentally conscious aquatic lifestyle. With zero CO2 or noise emissions on board, you can reconnect with your senses and fully enjoy the journey.

electric models

The Soel Yachts portfolio offers solar electric catamarans for both private and commercial applications. With the vast experience gathered trough different projects worldwide and boats successfully performing on a daily basis for many years, we gladly can discuss individual requirements and find the ideal solution for your preferred electric yacht and destination

PIONEERS SINCE 2007

Bringing over 15 years of extensive expertise in electrifying solar electric yachts since 2007, we have been pioneers in the solar yachts industry. Our integral solar electric systems in-house have impressively powered more than 27 circumnavigations of the Earth across the world’s oceans, offering unmatched real-world testing and performance validation for an extraordinary and worry-free sailing experience.

LEARN MORE ABOUT US

INNOVATIVE TECHNOLOGY

At our core, we strive for the perfect balance between cutting-edge technology, purposeful design, and outstanding performance. Our innovative approach combines streamlined hull designs for electric propulsion, engineered in conjunction with our in-house systems, to ensure an exceptional range.

DISCOVER TECHNOLOGY

BOOK APPOINTMENT

It is undoubtedly the most effective approach to directly communicate your desires and preferences with one of our partners. They can provide you with a comprehensive presentation of the available options and take you on a virtual tour of your desired model. Our team eagerly awaits your message today to arrange your personalized appointment, which can be conveniently held either online or in person.

GET IN CONTACT

- [email protected]

- 08 9511 4911

Solar Explorer Yachts

Saggers Marine proudly represents Solar Explorer Yachts exclusively for Western Australia!

Solar Explorer Yachts was created as an offshoot of Herley Boats to focus its efforts on the future of electric boating.

The first model to be launched under this new brand will be the 5200, 15.85m (52-ft), displacement catamaran produced in infused composites. The hull mould is almost complete with the deck and cabin top moulds currently underway.

The Naval architecture was completed by Roger Hill, with the systems designed in-house by the Solar Explorer Yachts team. The propulsion system is still being kept under wraps but promises to be extremely user friendly, focused on solar capability, ease of maintenance and safety at sea. The layout has a full beam master, with each hull dedicated to guests. There is a large open plan living and dining area plus a galley on the main deck.

https://www.multihulls-world.com/news-catamaran-trimaran/solar-explorer-52-a-new-brand-in-the-electric-world

Join our unprecedented journey to modern water world

Solar Boats is an exclusive importer and distributor of innovative marine solutions including:

- Search Used Yachts For Sale

- Search Boats By Brand

- Search Boats By Type

- Search By Location

- Search By Price

- What's My Boat Worth?

- Search Boats Just Listed

- Small Yachts

- Custom Sport Fishing Boats

- Finance A Boat

- Amer Yachts

- Cabo Yachts

- French Yachts

- Gulfstream Yachts

- Hatteras Yachts

- Solaris Yachts

Sunpower Yachts

- Sunreef Yachts

- Vela Boatworks

- Virtus Yachts

- Why List With United?

- Why Own A Boat Or Yacht?

- Custom Website For Your Yacht

- United Sold Boats

- Buy A Yacht With Crypto

- Find a Yacht Broker Near Me

- Search For Broker By Name

- Meet The United Support Team

- Our History

- Fort Lauderdale Boat Show

- Stuart Boat Show

- Miami Boat Show

- Palm Beach Boat Show

- Other Boat Shows

- Yachting News

- Yacht Closing Services

- River Forest Yachting Centers

Search All Yachts

New Sunpower Yachts For Sale

Sunpower yachts are an australian shipyard at the forefront of solar-electric, sun-powered boating. through the development of new technology, embracing a commitment to clean, sustainable power, and minimizing the enviornmental impact of lithium ion batteries. sunpower yachts is going to transform traditional boating by creating endless opportunities for solar-electric propulsion systems and drive-chain solutions. sunpower yachts.

Sunpower VIP 44

Sunpower Charter 44

Sunpower Sports Sedan 44

Speak To A Sunpower Yachts Sales Professional

About the Sunpower Yachts Shipyard

Australian boat builders have been well known in the world for the highest quality boat and yacht building standards for decades with the latest in innovation and technology and visions of their products to date.

All building material and procedures are engineered to the highest level to make sure that every yacht is a proven work of art and will last for years after their manufacturer. technical components are supplied from trusted European brands with a worldwide service network.

Sunpower Yachts personally installs all of the components of the propulsion system and drive-chain as well as the energy production and storage systems. Our team will also be available for worldwide service and warranty if required by our clientele.

The important components such as batteries, propulsion, and powerful generators can be serviced remotely via the internet by the Sunpower Yachts team.

Facts About The Sunpower Solar-Electric Technology

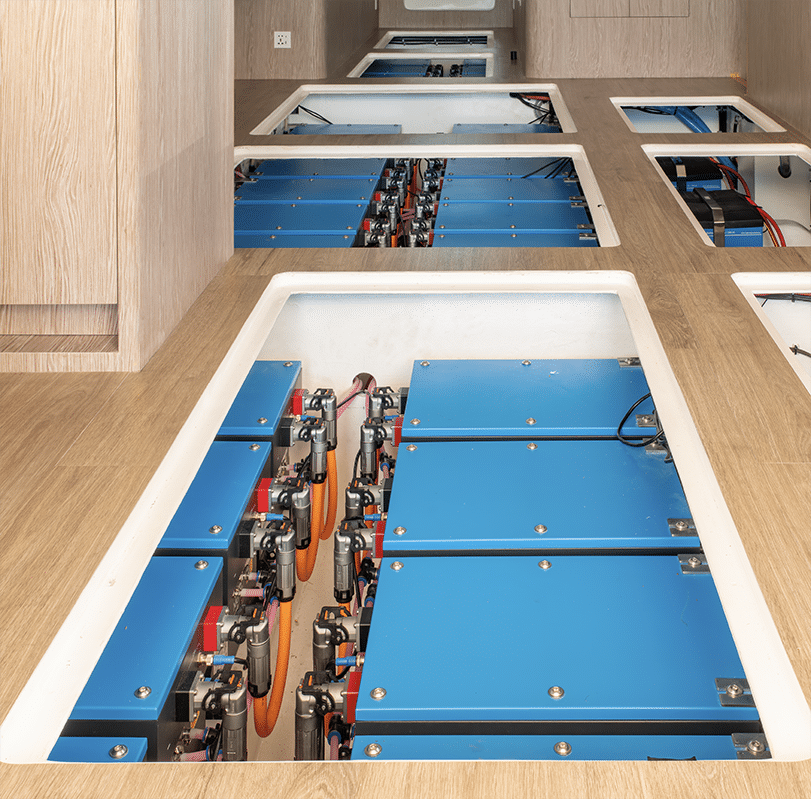

1. Solar Panels are integrated in the roof, so there is no wind-load on them. The batteries and electric-motors are inside the boat in a dry and safe place. All wiring is tin-covered and all plugs are specially designed for marine operation. All parts exposed to the marine environment are made of corrosion-resistant materials. All components are virtually free of maintenance. So the operating-costs are much lower than on a comparable conventionally powered catamaran.

2. Lithium-ion batteriesthat are light weightprovide sufficient energy for the propulsion system to run. There are many different types of lithium-ion batteries available for purchase. However, they vary in price dramatically if you are looking for quality. The brand we use is defiantly among the most expensive ones in the market. The reason we purchase this type of lithium-ion battery is the fact that they are best regarding packaging, liability, safety, performance, weight after sales service and life-span.

3. Engine rooms build up quite a lot of heat that e-motors do not so this can become a problem on large boats especially on hot days. Petrol engines projuce about seventy percent 70 % of the energy in form of heat. Electric-motors with an energy-efficiency of more than 90 % produce less than 10 %. Also, the gas burners stoves and ovens you may find in a yachts/boats produce a lot of heat into the interior of the yacht. As the inductioncooktops do not have an open flame, the inside of the yacht stays comfortably cool using no expensive dangerous or harmful gasses. Sunpower Yachts are equipped with a specially-designed ventilation system.

4. Comfort depends on the way you have to go about obtaining power. If electricity is always available with no impact to the planet, this goal should be first and foremost, Sunpower yachts have achieved this through design. Electricity is an always available gift from the sun injected into the solar panels. All kinds of electric appliances can be connected to the system setup. You do not need to use fuel generators to use all your onboard appliances, you can also use all lighting when needed without a worry. Watermakers are a real gift as now you do not even have to worry about water supply whilst on a large holiday or journey. Watermakers can produce up to 3.000L of drinking water per day giving you the comfort that you would not have previously had in the past. Sunpower yachts is to have comfort with zero emissions.

5. Engine maintenance and service in regards to electric motors do not need any service for up to 50 years. This will give you peace of mind knowing that you have reliable electric motors. If you have fuel engines the maintenance is continuous with oil and rusty water leaks from normal fuel engines. Electric motors we use have a 8 year warranty.

6. Sunpower yachts have custom made foam core e-glass that is 30 percent lighter than other yachts internal bulkheads and stringers yet is also stronger and engineered to the highest level. Yes, it is more expensive to make but our team focus on custom quality builds. The hulls are made by optimizing slower speeds unlike other yachts and boats which would use higher speeds this allows the slimline hull nose cone to cut through the water faster with less drag. SUNPOWER Yachts propulsion system works together in harmony.

History Of Sunpower Yachts

Grant Hudson has a history dating back to the 1970s in regards to electric propulsion systems that started with his electric remote-control speed boat and car at age 5.

At 7 years of age Grant could not understand why we were using fossil fuels when the first electric vehicles were in use as early as 1850s and the fact that his electric remote-control boat was faster than big boats on the water.

Grant first leant how to drive boats at age 5 taught by his father who navigated the best ocean fishing locations in Australia as a way to feed his family special seafood meals. Grant said his father always said we only need to catch what we needed allowing the ocean to regenerate. Grant currently has surpassed an estimate of ocean hours but the best was to describe his experience at sea is 45 years boating experience with a simple compass.

At age 21 Grant owned his first cabin cruiser a 24ft Haines Hunter that he lived on for over 2 years on the beautiful Gold Coast Australia. After this time, he bought and sold many boats that needed love and attention renovating the whole cruiser inside and out and then selling for a profit. He moved up to larger cruiser such as 35ft mustangs until one day he could not stand the backdraft of fossil fuels coming into the driver’s helm station. Thus, the journey began.

Grant started designing his vision what he believed to be the most popular and affordable size yacht the 44 and spent over 1-year R&D on the initial plans to make the yacht as perfect as possible in every way for the elderly retiring or retired sports sedan that has no flybridge to families to the next generation of youngsters entering the yachting world for the first time with a flybridge, even a charter version for small business or the larger family use that sleeps 7-9 patrons.

This yacht would have enough solar power on the top deck to power all onboard appliances, including the majors air-conditioning, watermakers, tv, stove, oven, fridge and lighting. Grant already had proof of many boats using the technology but wanted to integrate it one more stage by reducing the overall weight of a 2-3 story yacht to approx 11 tons which he achieved.

Sunpower Yachts has zero emissions, no fuel needed, no oil, no gas needed, no engine Service.

This yacht was designed for luxury and freedom of bills and location with a way and means to retire as the Sunpower 44 is all you need to unplug and live a luxury lifestyle off the grid as you explore the beautiful oceans around us.

Sunpower Yachts have now contracted the best superyacht building managers to offer the boat building industry who will take the vision and turn the designs of the Sunpower Yachts into reality.

For more information on Sunpower Yachts, please contact Wille McCormick at 561-301-8126 or at [email protected] .

Worldwide Yacht Sales

- Used Yachts For Sale California

- Used Boats For Sale in Corpus Christi

- Boats For Sale in Mexico

- Boat Trader New England

- Yacht Broker Near Me

- Price of Boats in Canada

- What Is The Best Sportfishing Yacht?

- Sailboat Brokerage Nc

- 1 Million Dollar Yacht

- Trawlers For Sale in Washington

- Nicest Yachts

- Yachts For Sale NYC

Luxury Boats & Yachts

- 60 Ft Yacht For Sale

- Prestige Yachts For Sale

- Trawler Boats For Sale

- Used Viking Boats For Sale

- Used Hinckley Boats For Sale

- Bertram Yachts

- Rybovich Boats

- Azimut For Sale

- Used Boats Near Me

- 40 Foot Boat

- Cabo Boats For Sale

Popular Builders & Models

- Pilothouse Trawler For Sale

- 50 Foot Viking Sport Fisherman

- Used Cabin Boats For Sale

- Catamaran Fishing Boats For Sale

- Tug Boats For Sale

- Sea Ray 400 Sundancer For Sale

- Catamaran Sailboat For Sale

- Bavaria Boats

- Albemarle Boats For Sale

- Small Sailboats For Sale

- Back Cove Yachts

Trending Brands & Types

- Used Grady White Boats For Sale

- Custom Boats For Sale

- Tiara Boats For Sale By Owner

- Ocean Reef Yachts For Sale

- Henriques Boats

- Magbay Yachts

- Legacy Boats

- Richie Howell

- Nordhavn Boats For Sale

Thank you for visiting nature.com. You are using a browser version with limited support for CSS. To obtain the best experience, we recommend you use a more up to date browser (or turn off compatibility mode in Internet Explorer). In the meantime, to ensure continued support, we are displaying the site without styles and JavaScript.

- View all journals

- My Account Login

- Explore content

- About the journal

- Publish with us

- Sign up for alerts

- Open access

- Published: 12 March 2024

The first demonstration of entirely roll-to-roll fabricated perovskite solar cell modules under ambient room conditions

- Hasitha C. Weerasinghe 1 na1 ,

- Nasiruddin Macadam 2 na1 ,

- Jueng-Eun Kim ORCID: orcid.org/0000-0002-3826-9537 1 , 3 na1 ,

- Luke J. Sutherland 1 , 3 ,

- Dechan Angmo 1 ,

- Leonard W. T. Ng 1 , 2 , 4 ,

- Andrew D. Scully ORCID: orcid.org/0000-0003-3116-3067 1 ,

- Fiona Glenn 1 ,

- Regine Chantler ORCID: orcid.org/0009-0000-7322-6121 1 ,

- Nathan L. Chang ORCID: orcid.org/0000-0003-2744-582X 5 ,

- Mohammad Dehghanimadvar ORCID: orcid.org/0000-0001-8160-5455 5 ,

- Lei Shi 5 , 6 ,

- Anita W. Y. Ho-Baillie ORCID: orcid.org/0000-0001-9849-4755 5 , 7 ,

- Renate Egan ORCID: orcid.org/0000-0002-8970-4703 5 ,

- Anthony S. R. Chesman ORCID: orcid.org/0000-0002-1807-4468 1 ,

- Mei Gao ORCID: orcid.org/0000-0002-0395-7006 1 ,

- Jacek J. Jasieniak ORCID: orcid.org/0000-0002-1608-6860 3 ,

- Tawfique Hasan ORCID: orcid.org/0000-0002-6250-7582 2 &

- Doojin Vak ORCID: orcid.org/0000-0001-7704-5563 1

Nature Communications volume 15 , Article number: 1656 ( 2024 ) Cite this article

9757 Accesses

170 Altmetric

Metrics details

- Chemical engineering

- Design, synthesis and processing

- Solar cells

The rapid development of organic-inorganic hybrid perovskite solar cells has resulted in laboratory-scale devices having power conversion efficiencies that are competitive with commercialised technologies. However, hybrid perovskite solar cells are yet to make an impact beyond the research community, with translation to large-area devices fabricated by industry-relevant manufacturing methods remaining a critical challenge. Here we report the first demonstration of hybrid perovskite solar cell modules, comprising serially-interconnected cells, produced entirely using industrial roll-to-roll printing tools under ambient room conditions. As part of this development, costly vacuum-deposited metal electrodes are replaced with printed carbon electrodes. A high-throughput experiment involving the analysis of batches of 1600 cells produced using 20 parameter combinations enabled rapid optimisation over a large parameter space. The optimised roll-to-roll fabricated hybrid perovskite solar cells show power conversion efficiencies of up to 15.5% for individual small-area cells and 11.0% for serially-interconnected cells in large-area modules. Based on the devices produced in this work, a cost of ~0.7 USD W −1 is predicted for a production rate of 1,000,000 m² per year in Australia, with potential for further significant cost reductions.

Similar content being viewed by others

Scalable fabrication and coating methods for perovskite solar cells and solar modules

Nam-Gyu Park & Kai Zhu

High-speed sequential deposition of photoactive layers for organic solar cell manufacturing

Rui Sun, Tao Wang, … Jie Min

Scalable two-terminal all-perovskite tandem solar modules with a 19.1% efficiency

Bahram Abdollahi Nejand, David B. Ritzer, … Ulrich W. Paetzold

Introduction

Organic-inorganic hybrid perovskite solar cells (PeSCs) are a promising next-generation photovoltaic (PV) technology that has a demonstrated power conversion efficiency (PCE) of 26.1% 1 . Despite the record efficiencies being competitive with the market incumbent technology, crystalline Si PV with 26.8% PCE 1 , numerous challenges must be addressed for PeSCs to be realised in real-world applications. Foremost is the need to translate small-area lab-scale cells, which are often fabricated using materials or methods that are not economically viable or scalable, to large-area devices produced by high-volume, low-cost manufacturing methods. As shown by other solar PV technologies with high PCEs, such as inorganic multi-junction or GaAs cells, a failure to lower production costs will prevent PeSCs from making an impact in the marketplace 2 , 3 .

A key difference between PeSCs and conventional inorganic PV technologies is the potential for low-cost and low-energy manufacturing using solution-based industrial processes, such as spray 4 , 5 , 6 , blade 7 , 8 , 9 and slot-die (SD) coating 10 , 11 , 12 , 13 , 14 , 15 . Recent advances in large-area glass-based PeSCs have resulted in promising efficiencies of up to 25.8% 16 , 17 , 18 , 19 . However, these devices have been produced using discrete sheet-to-sheet processing, utilise vacuum-based evaporation steps, and employ subtractive laser-patterning to achieve interconnections for large-area modules. These requirements will add challenges in lowering the cost of large-scale production. In contrast, flexible PeSCs enable high-volume and high-throughput manufacturing using continuous roll-to-roll (R2R) manufacturing techniques 20 , 21 , 22 . The lightweight and physical flexibility of flexible PeSCs also offer the prospect of solar PV panels having high specific power (power-to-weight ratio), which is highly desirable for emerging applications, including space 3 , vehicle-integrated PV, and building-integrated PV 2 , 23 . However, the process of manufacturing PeSCs on a continuously-moving flexible plastic substrate imposes several technical challenges, particularly time and temperature processing limitations 24 .

Beyond advancing the manufacturing process, replacing the high-cost components in the solar cell architecture with cheaper alternatives while retaining comparable performance remains a persistent challenge. The highest cost component is the vacuum-processed Au electrode, followed by commercially produced transparent conductive electrodes (TCEs). Vacuum deposition is costly, and the nature of the process is unsuitable for use with a conventional R2R manufacturing line. There have been several reports of solution-processed back electrodes in glass-based devices 25 , 26 , 27 , but their processing involved a prolonged high-temperature step that is neither compatible with flexible plastic substrates nor suitable for R2R-based upscaling due to time constraints in the continuous process. Due to these technical challenges, the first example of a small-area PeSC (0.09 cm 2 active area) having all layers deposited on a flexible plastic substrate using R2R processes was only very recently reported (in February 2023) 28 with individual cells displaying PCEs of up to 10.8%. While the first report marked a significant milestone in the field, the efficiency was still far from that of typical research cells and only small cells were demonstrated.

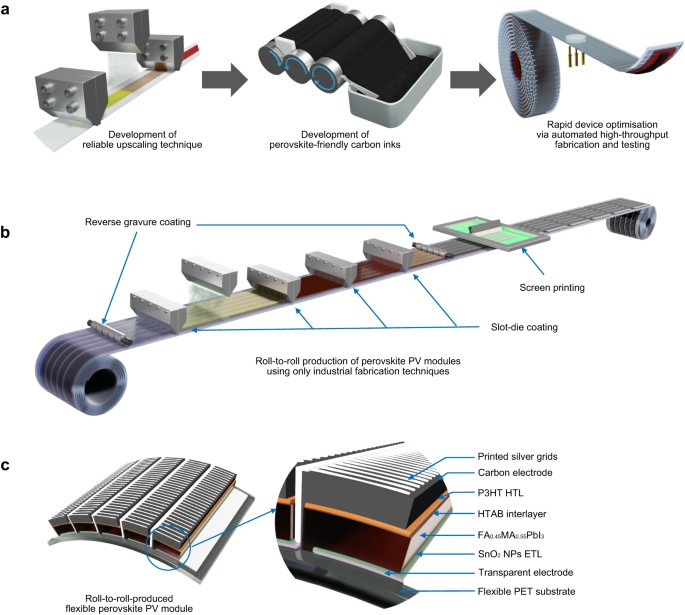

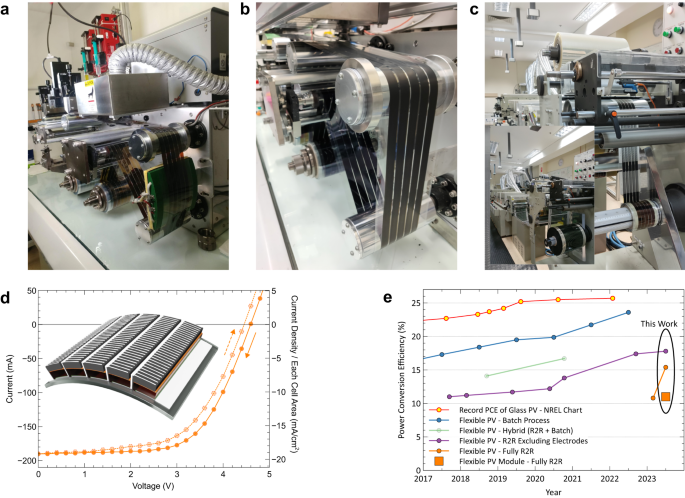

Here we report the fabrication of entirely R2R-printed individual PeSCs with a record-high 15.5% PCE. We also report the first demonstration of PeSC modules produced using only industry-relevant R2R fabrication techniques, and under ambient room conditions. This was achieved by developing: (i) a robust and scalable deposition technique, (ii) perovskite-friendly carbon inks to replace vacuum-based electrodes, and (iii) a R2R-based high-throughput experimental platform as illustrated in Fig. 1a . The latter mimics manufacturing processes to produce and test thousands of research cells a day. This allowed the seamless translation from the miniature factory to the full-scale R2R fabrication of PeSC modules (~50 cm² active area) exhibiting up to 11% PCE. The future prospects of the printed PeSCs are evaluated by considering manufacturing costs for various production scenarios calculated using cost models based on the production methods and materials used in the present work, together with the resulting device efficiencies.

a A reliable SD coating process and a perovskite-friendly carbon ink are developed to enable vacuum-free perovskite PV production. The carbon ink is upscaled using a three-roll mill and used to optimise device parameters by fabricating and testing numerous research cells using an automated roll-to-roll research platform. b Schematic illustration of roll-to-roll production of modules using SD coating, reverse gravure (RG) coating and screen printing. c The detailed structure of the series connected module, which is fully roll-to-roll fabricated on commercially available transparent electrodes.

Control of perovskite crystallisation for upscaling

Although spin coating has been widely adopted to produce efficient PeSCs, the deposition and drying parameters are significantly different in R2R production. As such, it is necessary to initially develop processing conditions using R2R or R2R-compatible methods. The introduction of the printing-friendly sequential deposition (PFSD) technique by select co-authors of this work in 2017 13 enabled the demonstration of the first PeSCs comprising R2R-deposited electron-transport layer (ETL), light-absorbing layer, and hole-transport layer (HTL), with up to 11% PCE achieved for a small-area device. Since then we also developed more facile single-step deposition techniques via the introduction of various additives such as polymers, ammonium salts, and 2D organic cations together with heating and nitrogen blowing 12 , 29 , 30 , 31 , 32 , 33 , and investigated R2R techniques reported by others 10 , 11 , 15 , 24 , 34 . Although it was possible to produce the perovskite layer in a single-step deposition, we found no approach that significantly outperforms PFSD for R2R-based upscaling.

The PFSD approach is described as ‘printing friendly’ due to its robustness and reliability under ambient conditions, and the absence of time-consuming processing steps. The key to PFSD is adding organic cations at a loading of less than 50 mol% of PbI 2 , far below the stoichiometric amount required to form perovskite crystals. This strategy retards crystallization and the precursor thin-film behaves like an amorphous material with much better film-forming properties than crystalline analogues. When additional organic cation is subsequently deposited, the reactive amorphous-phase film quickly converts to a perovskite without needing to remove the additive as it becomes a part of the perovskite. This allows the conversion to be completed on a time scale suitable for R2R processing.

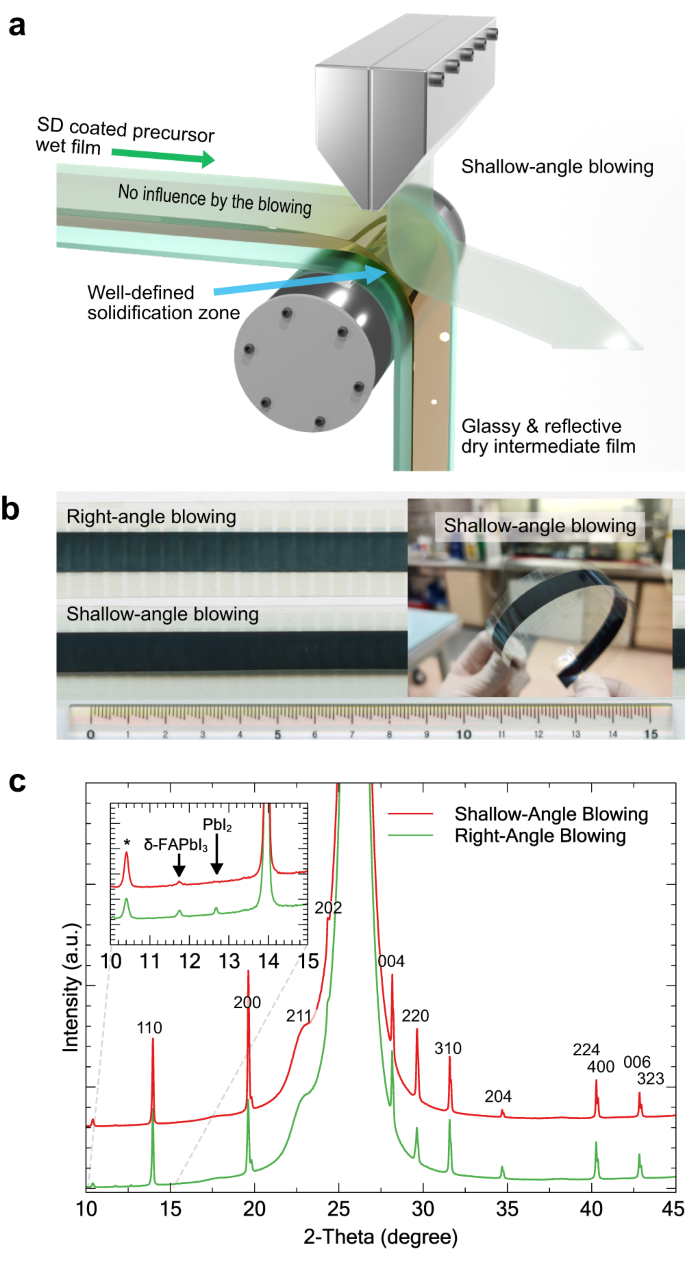

Our further development of the PFSD method resulted in up to 17.9% PCE from R2R-fabricated PeSCs with vacuum-deposited Au electrodes, as discussed in Supplementary Note 2 . One significant innovation in the PFSD technique is the introduction of a shallow-angle blowing technique, (Fig. 2a ) as opposed to the conventional blowing technique applied at a right angle, used to fabricate high-quality perovskite films involving blowing gas across the substrate 35 . While effective at a laboratory scale, creating a highly uniform gas flow over a large area is challenging. The shallow-angle blowing on the edge of a roller is a simple but effective way to upscale this process, and the angle of incidence can be easily adjusted to levels that can approach zero degrees by simply changing the blower-head position. Utilising this approach, the SD-coated wet films are not deformed by an aggressive air flow before entering the well-defined solidification zone. This significantly reduces the amount of crystalline defects, and amorphous glassy films can be fabricated that are then converted instantly to a perovskite when the methyl ammonium iodide (MAI) solution is deposited, as shown in Supplementary Fig. 1 .

a Schematic illustration of the edge-blowing technique in the roll-to-roll process. b An image (reflection mode) of perovskite films after MAI deposition. The upper sample shows a face-blowing sample with a hazy surface and the lower sample shows an edge-blowing sample with a darker and more uniform surface. Inset shows the mirror-like perovskite film fabricated with the shallow-angle blowing. c XRD data of the perovskite films produced using the two blowing methods. (The large peak at 27° is PET and the peak at 10.4° is hydrated perovskite of the air-exposed sample.) Source data are provided with this paper.

Figure 2b shows the improved quality of the perovskite film fabricated with the edge-blowing technique. The inset photograph shows the flawless mirror-like perovskite film continuously fabricated under ambient conditions (40–50% relative humidity). X-ray diffraction (XRD) analysis of the film does not indicate the presence of PbI 2 crystals, which would be evidence of ion migration followed by inhomogeneous local concentration in the solidification process. Shallow-angle blowing produced an intermediate layer that appeared to be amorphous or comprised of small enough grains that allowed for rapid and complete conversion to perovskite upon MAI deposition. Notably, this could not be examined directly as the reactive and unstable intermediate films continuously change upon exposure to air. Scanning electron microscope (SEM) images in Supplementary Fig. 2 show more homogenous films with compact grains of the shallow-angle-blown sample compared to the right-angle-blown sample. The introduction of the shallow-angle blowing not only improved the quality of the perovskite and the reliability of device performance, but also enhanced humidity tolerance (as discussed later), making the PFSD approach a suitable technique for low-cost manufacturing.

Automated, ambient, and vacuum-free device fabrication

The discovery of R2R-printable electrodes for PeSCs has long been a critical challenge in the realisation of fully R2R-fabricated vacuum-free cells. To date, most R2R-fabricated PeSCs in the literature incorporate vacuum or batch-processed back electrodes. The first fully R2R-fabricated PeSC was reported recently using a printed carbon electrode, achieving a PCE of 10.8% 28 . The efficiency was significantly lower than vacuum-based counterparts, suggesting performance degradation caused by the carbon ink. Therefore, we developed perovskite-friendly carbon inks and trialled them alongside commercially available carbon pastes, as discussed in Supplementary Note 3 .

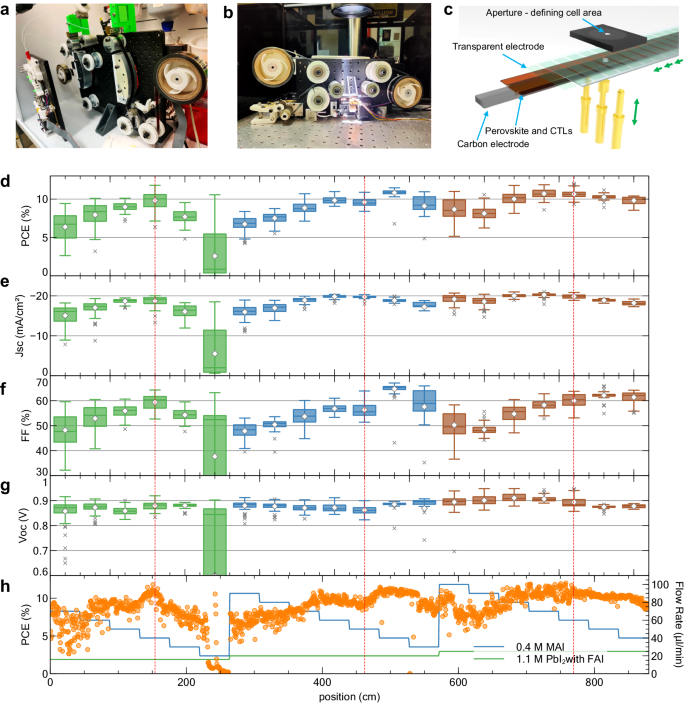

Replacing this vacuum process, which is not only costly but also time consuming, has the additional benefit of creating a new avenue for experimental optimisation. While such an approach improves throughput for conventional R2R systems with manual operation 36 , its full potential is realised with the development of a programmable R2R SD coater for unmanned operation, allowing for the fabrication of thousands of unique PeSCs daily. Manual characterisation of this many cells is not practical. We therefore developed an automated R2R tester to test over ten thousand solar cells a day. Device parameters were automatically calculated and saved online, permitting the analysis of thousands of solar cells in minutes, rather than hours or days. The custom-built R2R research tools are shown in Fig. 3a, b , and demonstrations of the system can be seen in the Supplementary Information . Figure 3c shows the device layout and testing setup for the high-throughput testing of R2R-fabricated solar cells.

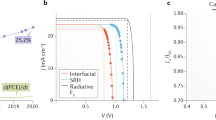

a The custom-built R2R SD coater used for the fabrication of thousands of unique solar cells in a day. b The custom-built automatic solar tester with a daily throughput of over 10,000 cells. c Schematic illustration of the automatic testing setup. d – h An example of a high-throughput R2R experiment to screen deposition parameters of the perovskite layer of PeSCs with a configuration: flexible TCE/SnO 2 /FA 0.45 MA 0.55 PbI 3 /PPDT2FBT/carbon electrode. Statistical ( d ) PCE, ( e ) J sc , ( f ) FF , and ( g ) open-circuit voltage ( V oc ) of 80 devices (along 44 cm substrate for each condition) for 20 different deposition parameter combinations of PbI 2 with 45 mol% FAI and MAI solutions. (centre line, median; diamond, mean; box limits, upper and lower quartiles; whiskers, 1.5× interquartile range; linecross, outliers) ( h ) PCE of 1600 consecutively fabricated PeSCs and deposition parameters along the position of the flexible film. Red dashed lines indicate the MAI amount that is nearest to the theoretical stoichiometric amount. The error bars in the box charts represent 1.5 times the interquartile range. Source data are provided with this paper.

This high-throughput experimental platform enabled us to explore the extensive fabrication parameters of vacuum-free PeSCs to rapidly identify the optimal conditions. Figure 3d–h show an example of the high-throughput R2R experiment, in this case being used to optimise deposition parameters for PbI 2 with 45 mol% formamidinium iodide (FA) and MAI solutions and to identify composition-dependant device parameters. Three PbI 2 conditions were selected to fabricate perovskite layers of about 600 nm to 1000 nm thickness. This range is somewhat thicker than typical vacuum-deposited electrode devices due to the absence of a mirror effect from the carbon-based back electrode. Also, a perfectly matched stoichiometry is not necessarily the best formulation in the FA 0.45 MA 0.55 PbI 3 system, as it can benefit from either a slight excess of lead 37 , 38 , 39 or a cation-excessive composition 40 . Therefore, the ability of SD coating to give quantitative control over the amount of material deposited allowed for the amount of MAI present in the perovskite layer to be varied from slightly cation deficient (lead-excessive composition) through to stoichiometric and slightly excessive compositions for each PbI 2 condition. The MAI-deposition flow rate was varied between 30 and 100 µL min −1 in 10 µL min −1 intervals. Figure 3h shows the deposition parameters together with the PCEs of 1600 consecutively fabricated PeSCs with 20 deposition parameters depending on the position along a 9 m-long substrate. The PeSCs were obtained in a roll form and the roll was transferred to the automatic R2R PV tester shown in Fig. 3b .

Figure 3d–h show statistical device parameters obtained from 80 cells for each condition. A thickness-tolerance hole transport material, poly[(2,5-bis(2-hexyldecyloxy)phenylene)-alt-(5,6-difluoro-4,7-di(thiophen-2-yl)benzo[c]-[1,2,5]thiadiazole)] (PPDT2FBT) 41 (further discussion on the material choice can be seen in Supplementary Note 3 ), which was used to screen carbon inks was used as an HTL in these devices. The devices with an MAI content close to the stoichiometric amount show better performance than others. The thinnest condition (16 µL min −1 ) shows the best performance at the stoichiometric amount and performance decreases rapidly with an excess of MAI or PbI 2 . Thicker films show more interesting behaviour; MAI-deficient films show better fill factor ( FF) with narrow performance variations, while films with excess MAI show higher short-circuit current ( J sc ). Most importantly, these results demonstrate the utility of the high-throughput experimental platform by identifying a composition-dependent performance trend in just one day.

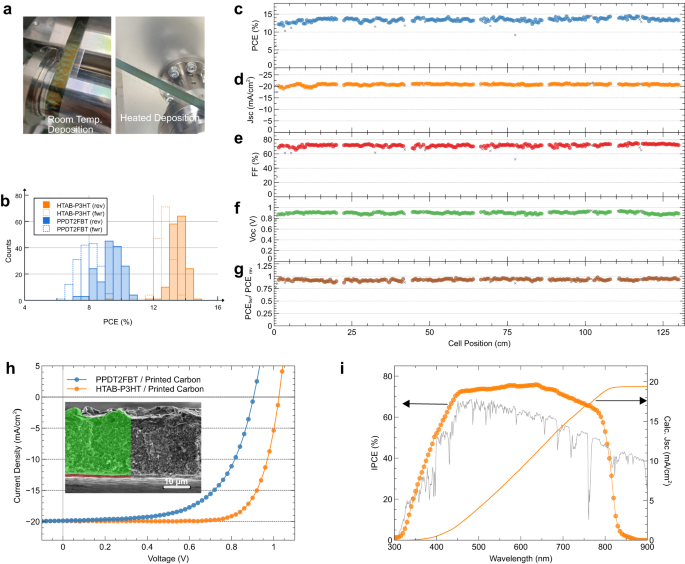

A significant improvement in fully R2R-fabricated cells was achieved by introducing a new hole-transport layer (HTL) system. Poly(3-hexylthiophene) (P3HT) is a simple, widely used conjugated polymer with good light-harvesting and charge-transporting properties 42 that lends itself to low-cost mass production. While the polymer alone shows relatively poor performance as an HTL, it shows promising performance when combined with n -hexyl trimethyl ammonium bromide (HTAB) 43 , which passivates the surface traps of the perovskite layer and also provides anchoring points for the hexyl side chain of P3HT to self-assemble in the preferred molecular orientation. Despite such advantages, this HTL system has never been used with R2R-fabricated PeSCs, likely due to the technical difficulty of forming an ultra-thin HTAB skin on perovskite layers utilising a scalable deposition technique. The fabrication of the HTAB skin is achieved through delicate control of surface reactivity by adjusting the ratio of relatively nonpolar and less reactive chlorobenzene to 2-propanol solvents. A uniform P3HT layer was achieved by heating the substrate to 45 °C, which lowers the surface tension of the polymer solution and promotes the self-assembly of P3HT on the HTAB surface. Without substrate heating, P3HT formed poor films on HTAB intermittently, as shown in Fig. 4a .

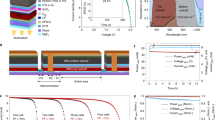

a R2R SD-coated P3HT films on perovskite films with and without gentle heating of the coating stage. b Histograms of fully R2R-fabricated PeSCs with a configuration of flexible TCE/SnO 2 /FAI 0.45 MA 0.55 PbI 3 /HTAB-P3HT or PPDT2FBT/carbon electrode. c PCE, ( d ) J sc , ( e ) FF , ( f ) V oc , and ( g ) hysteresis factor (forward-scan PCE divided by reverse-scan PCE) of the 240 consecutively fabricated HTAB-P3HT-based devices. The devices were fabricated in uncontrolled ambient conditions on a high-humidity (~60% RH) day. ( h ) Current density-voltage (J-V) curves of vacuum-free PeSCs comparing two HTLs. Inset shows an SEM cross-section image of the device with printed carbon (marked in green). i Incident-photon-to-current efficiency (IPCE) spectrum and calculated current density of the device with HTAB-P3HT HTL and printed carbon electrode. The AM 1.5 G spectrum used to calculate the current is shown in grey. Source data are provided with this paper.

The HTAB-P3HT HTL clearly outperformed PPDT2FBT, as shown in Fig. 4b . The devices not only showed higher performance but also improved reliability, indicated by the narrower distribution in the histogram. All device parameters, including the hysteresis factor of the HTAB-P3HT-based devices, can be seen in Fig. 4c–g . The figures show the parameters of the unfiltered 240 cells that were consecutively fabricated using the automated R2R SD coater. The substrate consists of blocks of 40 electrodes, separated by a 2 cm gap which can be seen in the data. The experiment was carried out under uncontrolled ambient conditions on a day with high relative humidity (~60% RH), demonstrating the robustness of the manufacturing process. In general, while the best devices were obtained on days with low humidity (30-40% RH), reliable production of PeSCs with an average PCE of ~13% was confirmed, regardless of the humidity in the lab. The J-V curve and IPCE spectrum of the best-performing device are shown in Fig. 4h, i , respectively, with 15.5% PCE, 19.9 mA cm −2 J sc , 76.1% FF and 1.02 V V oc . The IPCE spectrum shows good agreement with a calculated current density of 19.4 mA cm −2 .

Transitioning from cells to modules

The optimised device fabrication parameters were used to produce large-area modules. Since all processes were developed by scalable deposition methods, modules could be fabricated in the same way using larger SD heads, as shown in Fig. 5a , and a 10 cm wide substrate with a pre-patterned TCE. The SD heads have five channels (a detailed structure can be seen in Supplementary Fig. 3 ), and hence the optimised flow rate was simply multiplied by five to produce five-cell modules. Supplementary Fig. 4 shows images of high-quality perovskite stripes produced continuously using the R2R SD coating method. The HTAB and P3HT layers were also deposited at a flow rate five times higher than the optimised flow rate for single-stripe coating.

a Image showing the deposition of the perovskite layer using a 5-channel SD coater. The deposition of non-stoichiometric perovskite precursor solution, blow-drying, and the conversion to perovskite by SD coating the MAI solution were carried out in one coating run. b Image showing the RG-coated carbon film on the TCE/ETL/perovskite/HTL stack. c Image of the R2R-screen-printed perovskite PV modules. An industrial off-the-shelf screen printer was used for this production. Inset shows the capacity of the machine. The photo was taken when the printer was used to produce 30 cm × 500 m organic PV modules. d Current-voltage curves of a R2R produced module. Inset shows a schematic illustration of the module structure. e Record efficiencies of various perovskite solar cells. Details can be seen in Supplementary Table 1 . Source data are provided with this paper.

For the R2R-deposited electrode, the carbon ink was deposited using the reverse gravure (RG) technique 44 . The modules were completed by R2R screen printing a silver paste on the carbon film using an industrial R2R screen printer, shown in Fig. 5c and Supplementary Fig. 5 . The printed silver was used to form charge-collection grids and interconnect the 5 individual cells, as illustrated in the inset of Fig. 5d . It was crucial to incorporate additional conductive elements alongside the carbon layer, which had a sheet resistance of approximately 800Ω sq −1 . Supplementary Fig. 11 illustrates that cells without a grid design exhibited significantly poorer performance compared to those with grids. Nonetheless, excessively covering the screen-printed silver led to a decline in performance, most likely due to solvent damage to the underlying layers. Consequently, we designed the silver pattern to achieve minimal coverage while maintaining adequate conductivity, at least surpassing that of the front electrode, for efficient charge collection. We determined that a 0.2 mm line with a 180 mesh screen provided the finest pattern that we could consistently print onto the carbon surface, and this parameter was adopted for the module.

The interconnection of cells was formed through gaps between the stripe patterns at the same time as the grid. The active area is 49.5 cm 2 (1.1 cm × 9 cm × 5 cells) and the geometric fill factor (GFF), as defined as the cell area over total area (cell area + gap area) 45 of the modules, is 75%. The GFF is somewhat lower than that of laser scribed modules with a demonstrated GFF of up to 99% 46 due to the inherent limitation of the stripe-pattern approach. However, it’s worth noting that the laser scribing process may not be suitable for the high-throughput, cost-effective manufacturing of PeSCs. Therefore, our next challenge lies in developing modules with higher GFFs and larger areas while continuing to enhance cell efficiencies through scalable processes.

The entirely R2R-fabricated modules demonstrated up to 11.0% active-area-based PCE with 192 mA current output, 62.3% FF and 4.59 V V oc in a reverse scan and 9.96% PCE in a forward scan. This efficiency is lower than the small cells, likely due to the loss of FF caused by the high resistance of the TCE and partial solvent damage incurred during the screen-printing process. Nonetheless, this report marks a significant milestone in the development of fully R2R-fabricated PeSCs.

The efficiencies obtained in this work are compared with the previous records of various PeSCs, as summarised in Fig. 5e and detailed in Supplementary Table 1 . Flexible PeSCs have always shown inferior performance compared to their glass-based counterparts due to the intrinsic performance limitation of the flexible TCEs. Therefore, batch-processed flexible PeSCs are a more suitable benchmark for R2R PeSCs as they share the same intrinsic properties. While the performances of R2R devices still trail those of batch-processed analogues, this work demonstrates significant progress towards achieving high-efficiency flexible devices. Considering the low-cost nature and the scalability of the R2R-printed carbon electrode, achieving over 15% PCE represents a major milestone in the development of this technology. Through market surveys and considering advantages in the form factor, we established that R2R PeSCs could become competitive in the portable PV market at >10% PCE 47 . Therefore, the demonstration of an 11% R2R-fabricated module is a significant step forward in commercialising this technology. However, the printed silver used in this work may not be suitable for long-term operation for commercial applications due to the corrosion issue. The next challenge would be developing a perovskite-friendly conductive carbon ink that is at least as conductive as TCEs to produce efficient silver-free PeSC modules.

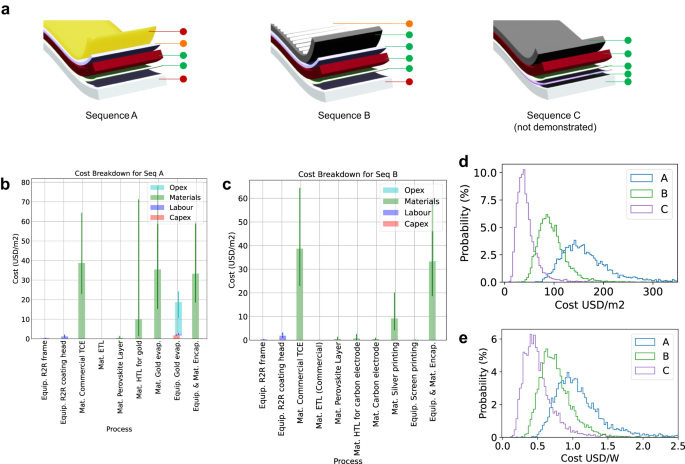

Towards ultra-low-cost manufacturing

This work aimed to develop low-cost manufacturing technologies for PeSCs. Therefore, we developed a cost model based on our previous work 47 which implemented the new materials, processes and device configurations used in this work, as shown in Fig. 6a . Further details of the cost model can be seen in Supplementary Note 4 . In addition to the demonstrated devices, a model device architecture (Sequence C) is also considered to predict the potential for further cost reduction by eliminating the remaining high-cost components, i.e., commercial TCEs and silver grids.

a Device configurations used for the analysis. Sequence (seq.) A: high-cost and high-performance option, seq. B: fully R2R-fabricated device, and seq. C: ultra-low-cost printing option to be pursued. Cost breakdown for ( b ) seq. A and ( c ) seq. B. Projected production costs of the modules ( d ) per module area and ( e ) per peak watt for all three sequences based on 17.9%, 15.5%, and 10% PCE, respectively.