- Paddle Board

What Is a Sailboat Rudder? An Overview of Its Function and Design

Sailboats have been used for thousands of years to traverse water. They have undergone many changes and improvements over the years, and one of the essential components of a sailboat is the rudder.

Quick Facts

| Topic | Description |

|---|---|

| Rudder | It is essential for steering and balancing the boat. |

| The main components are the stock, the blade, pintles, and gudgeons. | |

| Transom-mounted, skeg-mounted, keel-mounted, and spade rudders. | |

| Wood, aluminum alloy, stainless steel, and fiberglass-reinforced plastic. | |

| Influenced by the boat’s size, weight, speed, water and wind conditions, and the sailor’s skill level. | |

| Size, shape, placement, hydrodynamic, and aerodynamic factors. | |

| Involves regular inspection for signs of wear and tear, corrosion, loose components, and ensuring smooth operation. | |

| Corrosion, damage to the blade or stock, and loose components. | |

| Necessary when damage is extensive or to upgrade to a newer design for improved performance. |

Understanding the Sailboat Rudder

The rudder is a vital component of a sailboat that plays a crucial role in steering and maneuvering the vessel. The rudder works by changing the direction of the water flow around it, which moves the boat in the opposite direction. Without a rudder, it would be impossible to navigate a sailboat effectively, especially in different water and wind conditions.

Components of a Sailboat Rudder

A sailboat rudder comprises several components, each with a unique function that contributes to the rudder’s overall effectiveness. The stock is the main vertical shaft that connects the rudder blade to the boat’s helm. It is usually made of stainless steel or aluminum alloy and is designed to withstand the forces exerted on the rudder during navigation.

The blade is the flat portion of the rudder that faces the water current and directs the water flow in the opposite direction to steer the boat. The blade is typically made of fiberglass-reinforced plastic or aluminum alloy and is designed to be lightweight and durable. Pintles and gudgeons are the two connections between the rudder and stern that allow for easy installation and removal of the rudder. Pintles are the vertical metal pins that fit into the gudgeons, which are the horizontal metal brackets attached to the boat’s stern.

Different Types of Rudders

There are several types of rudders used in sailboats, each with its advantages and disadvantages. Transom-mounted rudders are the most common type of rudder, and they are mounted on the stern of the boat. Skeg-mounted rudders are attached to a fixed fin called a skeg, which provides additional stability to the rudder.

Keel-mounted rudders are attached to the boat’s keel, which is the central structural element that runs along the bottom of the hull. Spade rudders are free-standing rudders that are not attached to any part of the boat and are commonly used in racing sailboats. The type of rudder used depends on the boat’s size, design, and intended use.

Materials Used in Rudder Construction

Rudders can be made from various materials, each with its advantages and disadvantages. Wooden rudders are the traditional choice and are still used in some sailboats today. However, they are relatively heavy and require regular maintenance to prevent rot and decay.

Aluminum alloy rudders are lightweight and durable, making them an excellent choice for racing sailboats. Stainless steel rudders are also durable but are heavier than aluminum alloy rudders. Fiberglass-reinforced plastic rudders are the most common type of rudder used today, as they are lightweight, durable, and require minimal maintenance.

The sailboat rudder is an essential component that plays a crucial role in steering and maneuvering a sailboat. Understanding the different types of rudders, their components, and the materials used in their construction can help sailors choose the right rudder for their boat and navigate more effectively in different water and wind conditions.

The Function of a Sailboat Rudder

Steering and maneuvering.

The primary function of a sailboat rudder is to steer and maneuver the boat. The rudder’s blade directing the flow of water in a specific direction allows for the steering of the boat as the blade changes direction. Sailors can use the rudder to turn the boat in any direction they choose, allowing them to navigate through narrow channels or around obstacles in the water. It is essential to note that the rudder works in conjunction with the sails to control the boat’s direction and speed.

Balancing the Sailboat

The balance of the sailboat is critical to ensure safe maneuvering, and the rudder plays a crucial role in achieving this. A balanced rudder helps in keeping the boat steady, reducing drag, and preventing unwanted turning. Sailors can adjust the rudder’s angle to keep the boat balanced and on course, especially in rough water conditions. A well-balanced rudder also helps to reduce the risk of capsizing or losing control of the boat .

Rudder Effectiveness in Different Conditions

Rudder effectiveness varies depending on the boat’s size, weight, and water and wind conditions. A larger boat may require a bigger rudder for proper maneuvering, while a smaller boat can work with a smaller rudder. Sailors must also consider the water and wind conditions when choosing the right rudder for their boat. In calm waters, a smaller rudder may be sufficient, but in rough water, a larger rudder may be necessary to maintain control of the boat. Additionally, the rudder’s effectiveness can be affected by the boat’s speed, with higher speeds requiring more significant rudders to maintain control.

It is also important to note that the rudder’s effectiveness can be impacted by external factors such as weeds or debris in the water. These factors can reduce the rudder’s ability to steer the boat and require sailors to make adjustments to maintain control. Additionally, the rudder’s effectiveness can be impacted by the sailor’s skill level, with more experienced sailors able to make more precise adjustments to the rudder to control the boat’s direction and speed.

Design Considerations for Sailboat Rudders

Sailboat rudders are an essential component of a boat’s steering and maneuvering system. A well-designed rudder can make all the difference in a boat’s performance , especially in challenging weather conditions. In this article, we will explore some of the key design considerations for sailboat rudders.

Rudder Size and Shape

The size and shape of a rudder play a crucial role in determining its effectiveness in steering and maneuvering a boat. A larger rudder provides more leverage and maneuverability, allowing the boat to turn more sharply. However, a larger rudder may also produce more drag, which can slow down the boat’s speed.

The shape of the rudder is also important. A well-designed rudder should be streamlined to reduce drag and turbulence. The thickness of the rudder should be carefully considered to ensure that it is strong enough to withstand the forces exerted on it while remaining lightweight.

Rudder Placement and Configuration

The placement of the rudder on the boat can significantly affect its performance. A rudder that is too far forward can cause the boat to become unstable, while a rudder that is too far aft can make it difficult to steer. The location of the rudder must also take into account factors such as the propeller’s placement and the boat’s shape.

The configuration of the rudder can also determine its effectiveness and balance. A single rudder is the most common configuration, but some boats have twin rudders to provide more steering control. The angle of the rudder blade can also be adjusted to optimize its performance.

Hydrodynamic and Aerodynamic Factors

The design of a rudder must take into consideration the hydrodynamic and aerodynamic factors affecting the boat’s performance. Hydrodynamic factors include water flow, pressure, and turbulence, which can significantly affect the rudder’s performance. The shape and placement of the rudder must be carefully designed to minimize these effects.

Aerodynamic factors consider the wind and air resistance’s impact on the boat’s performance. The rudder’s size and shape must be designed to minimize the wind’s effect on the boat while providing sufficient steering control.

The design of a sailboat rudder is a complex process that requires careful consideration of many factors. The size and shape of the rudder, its placement on the boat, and its configuration must be optimized to provide effective steering and maneuverability. By taking into account the hydrodynamic and aerodynamic factors affecting the boat’s performance, a well-designed rudder can significantly improve a sailboat’s overall performance.

Rudder Maintenance and Repair

The rudder is a crucial component of any sailboat, providing steering and control. As such, it’s essential to keep it in good working order through regular maintenance and inspections.

Inspecting Your Rudder

Regular inspection of the rudder is essential to ensure its continued performance and longevity. A thorough inspection includes checking for cracks, wear and tear, and loose components such as hinges, pins, and screws. It’s also important to check the rudder’s alignment and ensure it moves smoothly and without any obstructions.

During your inspection, be sure to check for signs of corrosion, particularly on metal components. Corrosion can weaken the rudder and cause it to fail, so regular cleaning and maintenance are essential to prevent this.

If you notice any issues during your inspection, it’s important to address them promptly. Small cracks or damage can often be repaired, but if the damage is extensive, it may be necessary to replace the rudder entirely.

Common Rudder Issues and Solutions

One common issue with rudders is corrosion, particularly on metal components. Regular cleaning and maintenance help prevent corrosion and ensure the rudder’s longevity. If you do notice signs of corrosion, it’s important to address it promptly to prevent further damage.

Another common issue is damage to the blade or stock. This can be caused by impact with debris or other boats, or simply wear and tear over time. If the damage is minor, it may be possible to repair the rudder. However, if the damage is extensive or compromises the rudder’s structural integrity, it may be necessary to replace it entirely.

Loose components such as hinges, pins, and screws can also cause issues with the rudder. These should be checked regularly and tightened or replaced as needed.

When to Replace or Upgrade Your Rudder

Sailboat rudders can last for many years, but at some point, replacement or upgrade may be necessary. This includes upgrading to a newer design or larger rudder to improve the boat’s performance or replacing a damaged or worn-out rudder that is beyond repair.

If you’re considering upgrading your rudder, it’s important to consult with a professional to ensure that the new rudder is compatible with your boat and will provide the desired performance improvements.

Regular maintenance and inspections are essential to ensure the continued performance and longevity of your sailboat’s rudder. By staying on top of any issues and addressing them promptly, you can ensure that your rudder will continue to provide reliable steering and control for many years to come.

A sailboat’s rudder is a crucial component that helps steer and maneuver the boat safely. The size, shape, placement, and construction materials must all be taken into consideration when designing or replacing a rudder. Regular maintenance and inspection help ensure its continued performance and longevity.

Rudder FAQS

How does a sailboat rudder work.

A sailboat rudder works by changing the direction of the water flow past the boat’s hull, which in turn changes the direction of the boat. The rudder is attached to the stern of the boat and can be turned left or right. When the rudder is turned, it creates a force that pushes the stern in the opposite direction and turns the bow towards the direction the rudder is turned. This is how a rudder steers a boat.

What is a rudder and its purpose?

A rudder is a flat piece, usually made of metal or wood, attached to the stern of a vessel such as a boat or ship. The main purpose of the rudder is to control the direction of the vessel. It does this by deflecting water flow, creating a force that turns the vessel. Without a rudder, steering a vessel would be significantly more challenging.

Can you steer a sailboat without a rudder?

Steering a sailboat without a rudder is challenging but not impossible. Sailors can use the sails and the keel to influence the direction of the boat. By trimming the sails and shifting weight, it’s possible to cause the boat to turn. However, this is a difficult technique that requires a deep understanding of sailing dynamics and is usually considered a last resort if the rudder fails.

What controls the rudder on a sailboat?

The rudder on a sailboat is typically controlled by a steering mechanism, like a tiller or a wheel. The tiller is a lever that is directly connected to the top of the rudder post. Pushing the tiller to one side causes the rudder to turn to the opposite side. On larger boats, a wheel is often used. The wheel is connected to the rudder through a series of cables, pulleys, or hydraulic systems, which turn the rudder as the wheel is turned.

How do you steer a sailboat with a rudder?

To steer a sailboat with a rudder, you use the tiller or wheel. If your sailboat has a tiller, you’ll push it in the opposite direction of where you want to go – pushing the tiller to the right will turn the boat to the left and vice versa. If your sailboat has a wheel, it operates like a car steering wheel – turning it to the right steers the boat to the right and turning it to the left steers the boat to the left.

How do you steer a sailboat against the wind?

Steering a sailboat against the wind, also known as tacking, involves a maneuver where the bow of the boat is turned through the wind. Initially, the sails are let out, and then the boat is steered so that the wind comes from the opposite side. As the boat turns, the sails are rapidly pulled in and filled with wind from the new direction. This maneuver allows the boat to zigzag its way upwind, a technique known as “beating.” It requires skill and understanding of sailing dynamics to execute effectively.

John is an experienced journalist and veteran boater. He heads up the content team at BoatingBeast and aims to share his many years experience of the marine world with our readers.

What to Do If Your Boat Engine Won’t Start? Common Problems & How to Fix Them

How to launch a boat by yourself: complete beginner’s guide, how to surf: complete beginner’s guide to get you started.

Comments are closed.

Type above and press Enter to search. Press Esc to cancel.

Jordan Yacht Brokerage

We Never Underestimate Your Dreams

Sailboat rudder types – full, spade, skeg, outboard.

The four rudder types are: full, spade, skeg, and outboard. This article discusses the advantages and disadvantages of each.

Full The full or full keel rudder lies at the aft end of a full length keel. The keel-rudder streches along the entire length of the bottom of the hull. The full rudder is safe and nearly invulnerable to damage. The leading edge of the keel protects the rudder from flotsam. The full rudder is quintessential of offshore cruisers like Wetsails and Cabo Ricos. Even grounding may not cause damage. The boat will sit comfortable on its side until the tide returns and floats the boat back up.

Spade The spade rudder lies at the aft separate from the keel. A spade rudder is easy to turn because the water rushes both against its fore and aft edges – great for using a tiller. A spade rudder is also fast as the wet area less than a full keel. The boat racing along with less resistance. Spade and partial spades are becoming the most popular rudder type. The Hylas 70 has a partial spade rudder as well as early 54’s.

Skeg A skeg rudder is more modern in performance and safety. It is the most popular and common type of rudder on production boats these days. The rudder is fast and looks like a spade keel. Except, the skeg rudder has a fake keel which extends from the hulls aft and protects the fore edge. Most Hylas yachts have skeg rudders.

Outboard Outboard rudders are seen on smaller boats. They simply hang over the stern of the boat. For example, racing prams use outboard rudders. They are easy to fasion as emergency rudders. You can make one out of a handlerail and cabin door.

Conclusion A rudder is either full, spade, skeg, or outboard. Each type has its benefits. The most important part is make sure she is in good condition and have a spare.

4 Replies to “Sailboat Rudder Types – Full, Spade, Skeg, Outboard”

Ahoy Mateys, it’s Fox Axel the Pirate. I’ve got a swashbuckling yarn to tell ye. Me was drifting along way out at sea. Me had lost me steering while pillaging a friendly ship. The knaves canon knocked me rudder off. Me had nought to to turn to. The authorities would hang me, the villainous lot. But, me was getting desperate out of grub and rum, nothing to sage me drunken pirate ways. I had lost me last vestige of sanity.

Finally, me saw in the distance a giant whaler coming. The big ship sailed straight at me. “Ahoy mateys!” me spake. The freighter came near, too near. Shiver me timbers. The goulish crew must be drunk out of thee minds. Me could not steer away. She rammed straight slicing me ship in twain. Down to Davy Jones’ locker we went. Take care with ye rudders mateys – the Pirate of Monkey Isle.

Ok ye swabs ave a told me to finish me story. Ere dis da rest. As the freighter tore away leaving me to perish in the sea. I climbed on a board of driftwood from me sinkin’ ship. I passed out adrift, alone. When I came to, I found meself shipwrecked on a deserted island. I stumbled around and ran into, who of all? Big Red, me pirate enemy! Aye, I’m shipping as mate with his goulish fleet until I can betray and kill him. Aye, hope Big Red ain’t reading dis here blog. Black Fox the Pirate.

I am ye swab. I am too sharp for some ere fool like ye. I ain’t gots no book learning, but me hast carniving ways from many years below the mast. Iffen ye be trying to betray me, I am a gonna get ye.

Thank you for sharing this article.It’s quite easy to understand the difference.

Leave a Reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

INTRODUCTION TO SAILBOAT DESIGN: A TECHNICAL EXPLORATION

Sailboat design is a complex and fascinating field that blends engineering, hydrodynamics, and aesthetics to create vessels that harness the power of the wind for propulsion. In this highly technical article, we will delve into the key aspects of sailboat design, from methodology to evaluation.

1) Design Methodology

Designing a sailboat is a meticulous process that begins with defining the vessel’s purpose and performance goals. It involves understanding the intended use, whether it’s racing, cruising, or a combination of both. Sailboat designers must also consider regulatory requirements and safety standards.

Once the design objectives are established, naval architects employ various computational tools and simulations to create a preliminary design. These tools help in predicting the boat’s performance characteristics and optimizing its geometry.

Design methodology also encompasses market research to understand current trends and customer preferences. This information is critical for creating a sailboat that appeals to potential buyers.

2) Hull Design

The hull is the heart of any sailboat. Its shape determines how the boat interacts with the water. Hull design encompasses the choice of hull form, its dimensions, and the material used. The hull’s shape affects its hydrodynamic performance, stability, and overall handling.

For example, a narrow hull design with a deep V-shape is ideal for speed, while a wider, flatter hull provides stability for cruising. The choice of materials, such as fiberglass or aluminum, impacts the boat’s weight and durability.

The hull design is a balance between achieving efficient hydrodynamics and providing interior space for accommodations. As a designer, finding this equilibrium is a constant challenge.

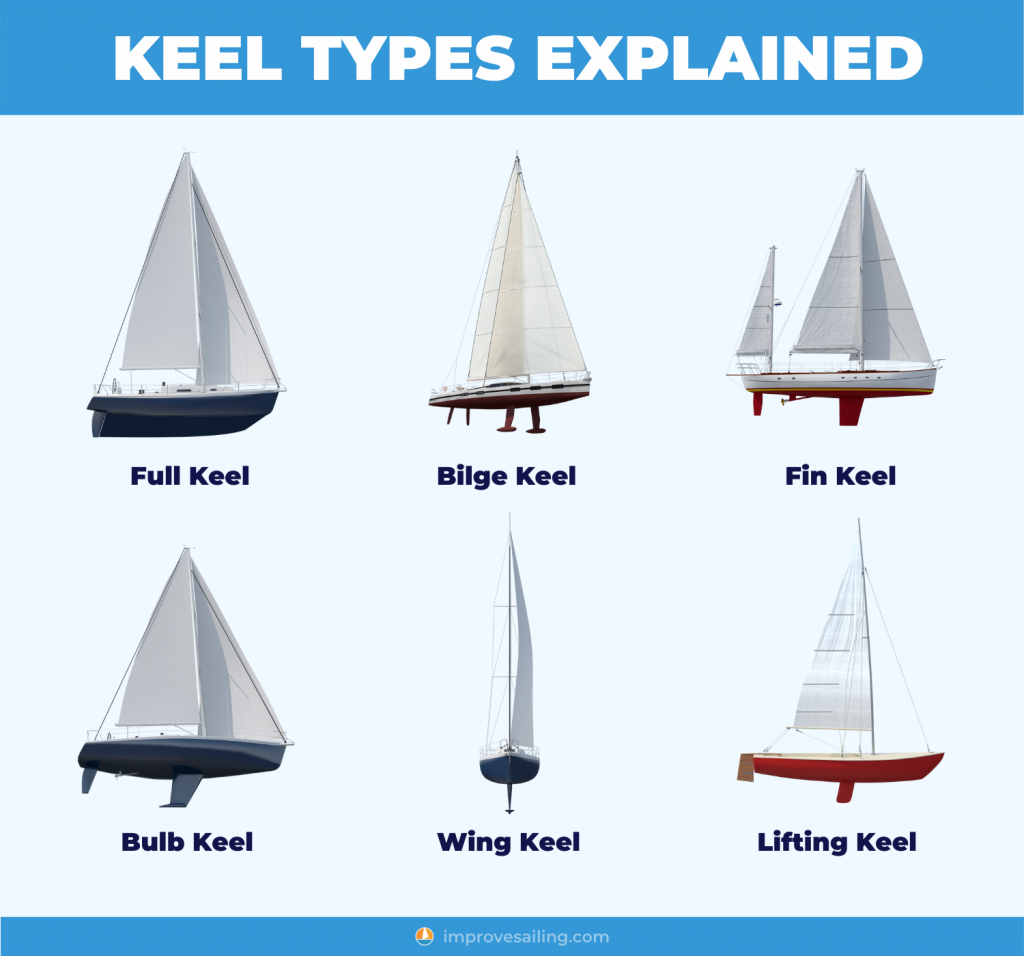

3) Keel & Rudder Design

The keel and rudder are critical components of a sailboat’s underwater structure. The keel provides stability by preventing the boat from tipping over, while the rudder controls its direction. Keel design involves selecting the keel type (fin, bulb, or wing) and optimizing its shape for maximum hydrodynamic efficiency.

Rudder’s design focuses on ensuring precise control and maneuverability. Both components must be carefully integrated into the hull’s design to maintain balance and performance.

Keel and rudder design can be particularly challenging because they influence the boat’s behavior in different ways. A well-designed keel adds stability but also increases draft, limiting where the boat can sail. Rudder design must account for both responsiveness and the risk of stalling at high speeds.

4) Sail & Rig Design

Sail and rig design play a pivotal role in harnessing wind power. Sail choice, size, and shape are tailored to the boat’s intended use and performance goals. Modern sail materials like carbon fiber offer lightweight and durable options.

The rig design involves selecting the type of mast (single or multiple), rigging configuration, and mast height. These choices influence the sailboat’s stability, maneuverability, and ability to handle varying wind conditions.

Balancing the sails and rig for optimal performance is a meticulous task. The sail plan should be designed to efficiently convert wind energy into forward motion while allowing for easy adjustments to adapt to changing conditions.

5) Balance

Balancing a sailboat is crucial for its performance and safety. Achieving the right balance involves a delicate interplay between the hull, keel, rudder, and sail plan. Proper balance ensures the boat remains stable and responds predictably to helm inputs, even in changing wind conditions.

Balance is not a static concept but something that evolves as the boat sails in different wind and sea conditions. Designers must anticipate how changes in load, wind angle, and sail trim will affect the boat’s balance.

Achieving balance is both an art and a science, and it often requires iterative adjustments during the design and testing phases to achieve optimal results.

6) Propulsion

While sailboats primarily rely on wind propulsion, auxiliary propulsion systems like engines are essential for maneuvering in harbors or during calm conditions. Integrating propulsion systems seamlessly into the boat’s design requires careful consideration of engine placement, fuel storage, and exhaust systems.

The choice of propulsion system, whether it’s a traditional diesel engine or a more eco-friendly electric motor, also impacts the boat’s weight distribution and overall performance.

7) Scantling

Scantling refers to the selection of structural components and their dimensions to ensure the boat’s strength and integrity. It involves determining the appropriate thickness of the hull, deck, and other structural elements to withstand the stresses encountered at sea.

Scantling is a critical aspect of sailboat design, as it directly relates to safety. A well-designed boat must be able to withstand the forces exerted on it by waves, wind, and other environmental factors.

8) Stability

Stability is a critical safety factor in sailboat design. Both upright hydrostatics and large-angle stability must be carefully assessed and optimized. This involves evaluating the boat’s center of gravity, ballast, and hull shape.

Achieving the right balance between initial stability, which provides comfort to passengers, and ultimate stability, which ensures safety in adverse conditions, is a delicate task. Designers often use stability curves and computer simulations to fine-tune these characteristics.

9) Layout

The layout of a sailboat’s interior and deck spaces is a blend of functionality and comfort. Designers must consider the ergonomics of living and working aboard the vessel, including cabin layout, galley design, and storage solutions. The deck layout influences crew movements and sail handling.

Layout design also extends to considerations like ventilation, lighting, and noise control. Sailboats are unique in that they must provide both comfortable living spaces and efficient workspaces for handling sails and navigation.

10) Design Evaluation

The final phase of sailboat design involves rigorous evaluation and testing. Computational fluid dynamics (CFD) simulations, tank testing, and real-world sea trials help validate the design’s performance predictions. Any necessary adjustments are made to fine-tune the vessel’s behavior on the water.

The evaluation phase is where the theoretical aspects of design meet the practical realities of the sea. It’s a crucial step in ensuring that the sailboat not only meets but exceeds its performance and safety expectations.

Conclusion:

In conclusion, sailboat design is a highly technical field that requires a deep understanding of hydrodynamics, engineering principles, and materials science. Naval architects and yacht designers meticulously navigate through the intricacies of hull design, keel and rudder configuration, sail and rig design, balance, propulsion, scantling, stability, layout, and design evaluation to create vessels that excel in both form and function. The harmonious integration of these elements results in sailboats that are not just seaworthy but also a joy to sail, and this process is a testament to the art and science of sailboat design.

Click here to read about “ HARNESSING THE POWER OF ARTIFICIAL INTELLIGENCE IN BOAT DESIGN “

Follow my Linkedin Newsletter here: “LinkedIn Newsletter”

0 comments Leave a reply

Save my name, email, and website in this browser for the next time I comment.

Recent Posts

- THE CHALLENGES Of SMALL CRAFT DESIGN COMPARED TO LARGER VESSELS

- UNDERSTANDING ROYALTY AGREEMENTS & DESIGN OWNERSHIP IN BOAT DESIGN

- FREQUENTLY ASKED QUESTIONS TO A BOAT DESIGNER: A COMPILATION

- ADVANTAGES OF HDPE COLLAR OVER REGULAR RIB

- HDPE’S EXCLUSIVE FEATURES DISTINCT FROM TRADITIONAL BOAT MATERIALS

Recent Comments

- Casey Lim on HDPE BOAT PLANS

- BRYN BONGBONG on HDPE BOAT PLANS

- Keith on HDPE BOAT PLANS

- Daniel Desauriers on WHY HDPE BOATS?

- November 2023

- October 2023

- February 2023

- January 2023

- September 2022

- January 2021

- ARTIFICIAL INTELLIGENCE

- boatbuilder

- BOAT CONSTRUCTION TECHNIQUES

- BOAT DESIGN COST

- boatdesign process

- CAREER PATHWAYS

- COMMERCIAL BOATS

- conventional boats

- custom boat

- DESIGN ADMINISTRATION

- DESIGN SPIRAL

- EXTREME CONDITIONS

- Freelance advantage

- freelance boat designer

- FRP Boat without Mold

- HDPE Collar

- INDIA'S MARITIME

- INVENTORY MANAGEMENT

- ISO STANDARDS

- Mass Production

- Monhull vs Catamaran

- Naval Architect

- Naval Architecture

- PLANING HULL

- Project Management

- Proven Hull

- PSYCHOLOGY OF BOAT DESIGN

- QUALITY CONTROL

- RECREATIONAL BOATS

- ROYALTY AGREEMENTS

- SANDWICH VS SINGLE SKIN

- SOLOPRENEUR

- YACHT DESIGN COURSE

What Is a Sailboat Keel and How Does it Work?

Keels are an essential part of any boat's design and determine handling properties, durability, and comfort. To understand why they matter, we must understand how they work first.

On this page:

The basics of sailboat keels explained, the importance of sailboat keels, keel design basics, what is a keel.

The keel is a structural member of a boat which runs length-wise across the hull from front to back. It is the lowest part of any hull and the backbone of a ship or boat. Sailboats use deep-running keel designs which extend out of the hull. They can be made from timber, metal, or fiberglass.

What does a keel look like?

Sailboat keels typically look like a long fin, or flat blade, at the bottom of the hull, which runs down for about 1.5 meters. While most modern sailboats use fin keels, the full keel is integrated into the hull, resulting in a more triangular shape that is shallow at the front and deeper at the back.

Since keel designs differ, the exact shape also differs. Here is a clear diagram showing the differences between different sailboat keel designs:

Where is the keel on a boat located?

The keel is located in the center of the bottom of the boat's hull, combining both hull sides. Sailboat keels extend out from the hull downwards. Depending on the exact keel design, the extended part can run from stem to stern, or just narrowly in the center of the boat's hull.

What does a keel do?

Keels help boats maintain course by countering the current and wind. They also stabilize boats by reducing roll and heel angle. Roll is the tendency of boats with round hulls to roll over. Heeling is the tendency of sailboats to heel due to the force of the wind on the sails.

How does a keel work?

Keels provide sideways resistance to reduce slippage. Sailboat keels usually carry iron or lead ballast in their tip to act as a counterweight to the wind's force on the sails, which reduces heeling. The keel's length acts as a lever, increasing the ballast's effectiveness and improving its stabilizing properties.

In other words, the deeper the keel runs and the heavier its ballast is, the more stable the boat will be.

Slippage simply means falling of course due to the current and wind.

The keel ballast lowers the center of gravity of the boat and counteracts the buoyancy of its displacement hull. As the boat tilts, the center of gravity and center of buoyancy move downwards, reducing the heel angle. This is called righting moment . More righting moment results in less heel angle.

Keels also increase the wetted surface of a boat. Wetted surface is simply the amount of surface underwater. The larger the wetted surface, the more resistance there is. Sailboats are among the boat designs with the largest relative wetted surface. A larger wetted surface increases sideways resistance which reduces slippage to leeward, helping to maintain course.

Do all sailboats need a keel?

All sailboats need a keel. Without it, a sailboat would very easily capsize due to a combination of hull design and wind force on the sails. Sailboats have displacement hulls, which tend to roll easily. Wind force is multiplied through the mast, which acts as a lever, and could capsize the boat if it didn't had a keel.

The displacement hull design is also used on canoes, and if you've ever tried to enter one a bit too quickly, you'll know how quickly they roll over.

However, there are sailboats that use a different hull design, which reduces the need for a keel or enables them to use alternative keel designs.

Do all sailboats have a keel?

Nearly all sailboats have some sort of keel. However, not all sailboats have a typical, deep-running fin keel, since not all need one, and in some cases, a shoal draft is desired.

For example, some sailboat designs use leeboards or removable keels, like daggerboards, which enable a boat to enter much more shallow waters.

What is a boat without a keel called?

Boats without a keel are called sailing dinghies. These small boats (under 20 feet) use a flat-bottomed hull design to stabilize instead of a keel. This makes them useful for entering shallow waters and beaching.

Examples of sailboats without a typical keel

- Barges , which use flat-bottomed hulls to reduce heel

- Sailing dinghies , which have a flat-bottomed hull and no keel

- Sunfish and lasers , which often use removable daggerboards

Two examples of sailboats with alternative keels are Dutch barges and Cornish Crabbers. Dutch barges use leeboards , while the Cornish Crabber uses a swing keel , which can be lifted or lowered according to water depth.

Sailing dinghies, sunfish, and lasers typically use no keel or come with daggerboards, which can be removed. They capsize easily and often, which is why you'll see so many toppled sailboats drifting across the lake at sailing camps.

Can you sail without a keel?

You can sail without a keel, however, you could easily capsize and would experience a lot of roll and heel. To prevent capsizing, you would need a different hull design. Historic sailboats without keels use flat-bottomed hulls to prevent excessive roll and capsizing.

The Dutch barge design actually uses a very flat bottom instead of a full round displacement hull, which makes it a bit faster, stiffer, and counters heel just by the hull design alone. But even these sailboats require some sort of stabilization, which is provided in this case by their leeboards.

Can a sailboat rest on its keel?

Most keel constructions can support the weight of the sailboat, but depending on the design, proper precautions need to be taken. Boats resting on a fin keel or full keel will require additional support. The bilge keel (or twin keel) is specifically designed to rest upright in tidal waters.

Fin keel sailboats can sag over their length over time. Other keel designs spread the weight over a larger surface, like the full keel.

The most common sailboat keel types

There are dozens of keel designs and variants out there. The most common ones are the full keel , fin keel , and centerboard . Each of these designs has different properties. Full keels handle better in rough conditions, while fin keels are easier to maneuver in and out of slips.

Discussing them all here would be beyond the scope of this article, but I've described the most common keel types and their properties in my illustrated guide. If you want to learn more about the different designs, I recommend you read that.

How deep is a keel?

On average, keels are between 1 and 2 meters deep , in order to get through the surface drift layer of the water. Some keel designs run less deep, like full keels, which require less depth due to increased weight and wetted surface, or alternative designs like leeboards, which only touch the water's surface.

The water's surface drift layer is the layer of water directly affected by the wind.

How heavy is a sailboat keel?

Most sailboats carry around 35-40% of their total weight in their keel. With an average cruising sailboat weighing 15.000 pounds, the average keel weighs between 5.000-6.000 pounds . However, the total required weight is not just determined by sailboat weight, but also by sail area and the length of the keel.

Deeper keels provide more leverage, reducing weight need. A larger sail area increases weight requirement.

What material are sailboat keels made of?

Sailboat keels are typically made of reinforced fiberglass layers, steel, or wood, depending on the hull material, boat model, and build year. Keel ballast in the tip is usually made of lead, iron, concrete, or even water.

How are keels attached to boats?

Some keels are integral to the hull's structure, like the full keel or modified full keel. Other keels are bolted onto the hull, like the fin keel, wing keel, or bulb keel. With this design, the top of the keel slides into a vertical keel box inside the hull and is bolted in place using keel bolts.

What is a skeg keel?

A skeg keel is a type of rudder design in which the rudder is integrated into the keel design, for example with full keels or modified full keels, therefore providing protection against damage from collisions and waste.

What is the chord of a keel?

A chord is a term used to describe the length of any edge on a keel, whether it's the leading edge, trailing edge, or top edge connecting to the hull. The top edge is referred to as the 'root end', while the length of this edge is called the 'root chord'.

- Source: David Vacant, published on repository TU Delft

The difference between the rudder and the keel

While the keel and rudder design can overlap, the rudder is generally the most aft part, while the keel sits in front of the rudder. The rudder is used to set a course, while the keel's function is to provide directional stability and prevent roll.

The difference between the keel and the hull

While in some keel designs the hull and keel are integrated, like, for example, full and modified full keels, with other designs, the keel is bolted onto the hull, like the case with fin keels. The hull is the bottom of the boat, while the keel is the fin below the bottom of the boat. The hull provides buoyancy, while the keel provides stability.

Keel replacement cost

Leave a comment, you may also like, sailboat keel types: illustrated guide (bilge, fin, full).

The keel type is one of the most important features of your boat. But the different designs can be confusing, so I've set out to create a very clear guide that will …

Yachting Monthly

- Digital edition

How keel type affects performance

- Chris Beeson

- December 2, 2016

James Jermain looks at the main keel types, their typical performance and the pros and cons of each

A fin keel and spade rudder configuration gives high pointing but can be sensitive on the helm Credit: Graham Snook/YM

James Jermain has tested hundreds of yachts in his 30 years as Yachting Monthly’s chief boat tester

The performance and handling of a yacht depends on many things, but perhaps the most important single feature is the shape of the hull and the profile of the keel. Over the years hulls have become shallower and keels narrower, but for many types of sailing this progression is not necessarily progress. Of the various shapes that have evolved, each has its own advantages in different circumstances. Here is a run-down of how they may fit your sort of sailing.

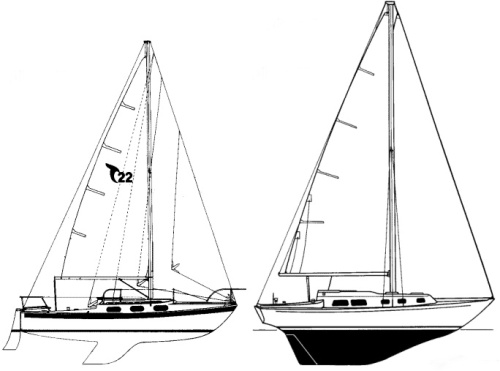

FIN KEEL WITH SPADE RUDDER

A low wetted surface area and aerofoil shape means speed and agility

The most common modern option, usually combined with light but beamy hulls with high freeboard.

GENERAL AND TO WINDWARD

- Low wetted surface and good aerofoil shape means good speed, high pointing and quick tacking

- Light steering

- Best designs can slice through heavy seas in reasonable comfort

- High volume, light-weight designs can be lively and tiring in heavy weather

- Flat sections can cause slamming

- Less steady on the helm, requiring more work and concentration

- Strong tendency to round-up when hard pressed

- Generally require earlier reefing

- Can be unstable when hove to

- Quick to surf and may even plane

- Can broach easily and suddenly

- Can be directionally unstable and hard to control in heavy conditions

UNDER POWER

- Handling is precise and turns tight and quick

- Some handle almost as well astern as ahead

- Limited lateral area so susceptible to beam winds at low speeds

- An unattended helm can slam over suddenly

FIN KEEL WITH SKEG RUDDER

The skeg running aft protects the rudder and improves tracking under sail and power

Similar to above but with some key differences.

- Skeg provides better support for the rudder

- Tracking under sail or power is improved

- There is less chance of damage

- More wetted surface so potentially slower

- Objects can get stuck between rudder and skeg

- Limited balancing can make helm heavier

The mass of a long keel is often more seakindly and will carry way well.

The traditional option, usually found on pre-1970s designs.

- Good tracking

- Slow, soft, comfortable motion

- Drive powerfully through short seas but can be wet

- Carry way through tacks

- Resist rounding-up

- Heave-to well

- High wetted surface area and a poor aerofoil shape, so speed reduced, tacking slow, leeway increased and pointing ability reduced

- Long ends can cause hobby-horsing

- An unbalanced hull or rig can cause heavy helm

- Track well and very resistant to broaching

- Very stable in heavy conditions

- Reluctant to surf (a mixed blessing)

- Carry way well

- Track straight

- Heavy construction can reduce vibration and noise

- Large turning circle ahead

- Unpredictable and hard to control astern

LIFTING OR SWING KEEL

A lifting keel enables beaching, but beware of stones jamming the plate

The ultimate shallow-draught option.

- A fully retracting keel offers shallowest draught

- A well-designed lifting keel can be very efficient and fast

- Grounding on anything other than soft mud or sand can damage an unprotected hull

- Stub keels offer better protection but are less efficient and prevent level drying out, except in soft mud

- Stones and dried mud can jam the lifting plate

- Internal keel boxes reduce accommodation space

- Directional stability is poor

- Early surfing and planing

- Control can easily be lost in strong winds

- Good performance and handling with keel down

- Directional control increasingly poor as the keel is raised

TWIN OR BILGE KEEL

A bilge-keeler will dry out upright on a flat bottom

A popular shoal-draught option in Britain, less so abroad.

- Shallower draught

- Dry out upright on a flat bottom

- Good protection when grounding

- Good designs are better to windward than long keels, almost as good as fins

- Pointing and speed to windward is reduced, considerably so in older designs

- When well heeled, waves can slap under the windward keel

- Can topple over if one keel finds a hole or soft ground

Modified water flow over the wing keel foot can give the motion of a longer, heavier boat

Once popular, now largely replaced with various types of bulb.

- Reduced draught

- Low CoG means good righting moment

- Modified water flow over keel foot means greater efficiency and gives the motion of a longer, heavier boat

- More likely to pick up lobster pots, etc

- Risky drying out

- Weed and barnacle growth under wings difficult to remove

Enjoyed reading this?

A subscription to Yachting Monthly magazine costs around 40% less than the cover price .

Print and digital editions are available through Magazines Direct – where you can also find the latest deals .

YM is packed with information to help you get the most from your time on the water.

- Take your seamanship to the next level with tips, advice and skills from our experts

- Impartial in-depth reviews of the latest yachts and equipment

- Cruising guides to help you reach those dream destinations

Follow us on Facebook , Twitter and Instagram.

All About the Sailboat Rudder

By Matt Claiborne

What Is a Boat Rudder?

The rudder is the underwater part of the boat that helps it turn and change direction. It’s mounted on the rear of the boat.

Rudder vs Keel

A rudder is there to steer direction and a keel provides stability and enable sailing windward.

How Does the Rudder Work?

Originally a steering oar and now a mounted panel, the rudder is an essential underwater control surface on boats that, by deflecting water flow, allows turning the bow by moving the stern.

Learn About Other Boat Parts

Do sailboats come with motors, prow of a boat.

New Rudders

Replacement Sailboat Rudders and Centerboards

Four Types of Rudders On Sailboats

The four rudder types are: full rudder, spade rudder, skeg rudder, and outboard rudder. We will discuss the advantages and disadvantages of each.

Full Rudder

The full or full keel rudder is at the aft end of a full length keel. The keel-rudder runs along the entire length of the bottom of the boat’s hull. This full length rudder is safe and more resistant to damage. The leading edge of the keel protects the rudder from debris. The full rudder is a trademark of offshore cruisers like Cabo Ricos and Wetsails. Damage may be avoided even when grounding. The boat will rest safely on its side until the tide returns and lifts the boat off the shoal.

Spade Rudder

The spade rudder rests below the transom separate from the keel. A spade rudder turns easily because the water rushes both against its fore and aft edges – good when using a tiller. There’s less wet area so the spade rudder is fast. The spade, along with partial spade rudders are becoming popular in many sailboat designs.

Skeg Rudder

Compared to other styles, the skeg rudder is modern in safety and performance and popular on current production boats. The skeg rudder is similar to a spade keel and is fast. The skeg rudder’s fore edge is protected by a “faux keel” that extends from aft of the hull. Hylas yachts are known for their skeg rudders.

Outboard Rudder

Outboard rudders are used on smaller boats. They are attached to the transom of the boat, hanging off the stern. Racing prams employ outboard rudders. They are also easy to jerry rig as emergency rudders. Any long piece of metal and flat piece of wood, as in a cabin door, can work.

Each type of rudder has its advantages and disadvantages. Most importantly, inspect your rudder regularly and carry a spare.

Foss Foam products can create a replacement rudder for your sailboat. Contact us for more information.

The Types of Sailboat Rudders

- Snowboarding

- Scuba Diving & Snorkeling

Full Keel Rudder

On a sailboat , as the rudder is moved to one side by means of the tiller or steering wheel, the force of the water striking one edge of the rudder turns the stern in the other direction to turn the boat. Different types of rudders have different advantages and disadvantages. The type of rudder is often related to the boat’s type of keel.

Rudder on Full-Keel Sailboat

As shown in this photo, the rudder of a full-keel boat is usually hinged to the aft edge of the keel, making a continuous surface. The engine’s propeller is usually positioned in an aperture between the keel and rudder.

Advantages of Full Keel Rudder

The primary benefit of this rudder configuration is the strength and protection provided to the rudder. It is hinged at top and bottom, well distributing the forces on the rudder. Rope (such as lobster pot warps) or debris in the water cannot snag on the rudder.

Disadvantage of Full Keel Rudder

Because the sideways force of the water on the rudder is entirely behind the rudder’s pivoting point at its leading edge, putting all the force on one side of the rudder, it takes more energy to move the rudder. This is one reason why larger boats seldom have tillers—because it can require much force to “push” the rudder out against the water streaming past the keel.

Spade Rudder

Most fin keel boats have a spade rudder, which extends straight down from the aft hull section. The rudder post comes down through the hull into the rudder itself, allowing the entire rudder to rotate to either side, pivoting around the post.

Advantages of Spade Rudder

The spade rudder is self-standing and does not require a full keel or skeg for its mounting. The rudder post inside the rudder can be moved aft from the leading edge (see next page on Balanced Rudder) so that the force of the water is not all on one side when the rudder is turned. This requires less energy to steer than with a keel- or skeg-mounted rudder.

Disadvantage of Spade Rudder

A spade rudder is more vulnerable to debris or objects in the water, which may strike the rudder and exert a force on the rudder post, the only structure supporting the whole rudder. Even the force of water when the boat “falls” off a wave can exert damaging stress on a spade rudder. If the rudder post is bent, the rudder may jam and become useless.

Balanced Spade Rudder

Note the clear air space at the top of the leading edge of this balanced spade rudder. The rudder post is several inches back from the front of the rudder. When the rudder is turned, the leading edge rotates to one side of the boat while the trailing edge rotates to the other side. While the turning action on the boat is the same, the forces on the helm are more nearly balanced, making it very easy to steer.

Skeg-Mounted Rudder

Some fin keel sailboats have a skeg-mounted rudder like the one shown. The skeg offers the same advantages as a keel mounted rudder: the rudder is protected from objects in the water and has more structural strength than a rudder mounted only on the rudder post.

It also has the same disadvantage: because it is not “balanced” as a spade rudder may be, with water forces distributed on both sides, it requires more force to turn the rudder.

Outboard Rudder

An outboard rudder is mounted outside the hull on the boat’s stern, such as shown in this photo, rather than below the hull using a rudder post or hinges to the keel or skeg. Most outboard rudders are turned with a tiller rather than a steering wheel since there is no rudder post to which to gear a wheel.

Advantages of Outboard Rudder

An outboard rudder does not require a hole through the hull for a rudder post and thus is less likely to cause trouble if damaged. The rudder can often be removed or serviced while the boat is still in the water. Hinges at the top and bottom of the rudder section may provide more strength than a single rudder post.

Disadvantages of Outboard Rudder

Like a spade rudder, an outboard rudder is vulnerable to being struck by or caught in objects or rope in the water. Unlike a spade rudder it cannot be balanced in the water flow, so the force of water is always on one side of the pivot point, requiring more energy for turning the rudder.

A rudder is often related to keel shape .

- Choosing a Centerboard or Fixed Keel Sailboat

- Learn How to Sail a Small Sailboat – 1. The Parts of the Boat

- Control Your Tiller Without a Tiller-Tamer

- 6 Types of Boat Engines

- Choosing an Inboard or Outboard Engine

- How to Tow a Dinghy Behind a Sailboat

- The Sunfish: A Perfect Lake or Urban Sailboat

- Do It Yourself Boat Trailer Tongue Extension

- How to Anchor a Sailboat

- Simple Reefing System for Sailors

- How Brake Calipers Work

- How to Rig a Preventer Line

- The What, Why, and How of Wheel Balancing

- RC Airplane Parts and Controls

- How to Keep an Installer from Damaging Your Wheels

- Interesting Facts About Navy Submarines

- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Customer Service

- Free Newsletter

Maine Cat 41 Used Boat Review

CS 30 Used Boat Review

Hinckley 49 Used Boat Review

Island Packet 31 Used Boat Review

Best Crimpers and Strippers for Fixing Marine Electrical Connectors

Thinking Through a Solar Power Installation

How Does the Gulf Stream Influence our Weather?

Can You Run a Marine Air-Conditioner on Battery Power?

Master the Sailing Basics: Never Stop Learning the Little Things

How to Mount Your Camera on Deck: Record Your Adventures with…

Un-Stepping the Mast for America’s Great Loop

Headsails and Spinnakers: How to Explain Their Functions to a Beginner

Sinking? Check Your Stuffing Box

The Rain Catcher’s Guide

How to Change Your Engine Mounts

Keeping Water Clean and Fresh

Vinyl Boat Lettering DIY Application and Repair

Those Extras you Don’t Need But Love to Have

Three-Model BBQ Test

Alcohol Stoves— Swan Song or Rebirth?

Womens Foul-Weather Gear

Preparing Yourself for Solo Sailing

How to Select Crew for a Passage or Delivery

Preparing A Boat to Sail Solo

Chafe Protection for Dock Lines

Waxing and Polishing Your Boat

Reducing Engine Room Noise

Tricks and Tips to Forming Do-it-yourself Rigging Terminals

Marine Toilet Maintenance Tips

- Sailboat Reviews

A Look at Sailboat Design: Fin Keels vs. Full Keels

Details like keel design count when considering cruising sailboats..

Photos by Ralph Naranjo

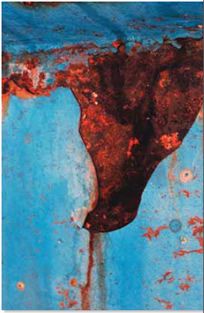

When a keel tears away from a sailboats hull, it makes the loss of a rig or rudder seem like a minor inconvenience. History shows that its an uncommon occurrence, but because we now annually hear of such incidents, weve decided to take a closer look at keels and see what keeps the ballast where it belongs.

The International Sailing Federation (ISAF) Offshore Special Regulations devotes pages to helping sailors prevent and respond to a crew overboard incident. There is nothing about how to handle the loss of a keel or ballast bulb. Some might say this is because such occurrences are so infrequent, while others note that, if youre still upright once the ballast breaks off theres not much you can do other than blow the sheets, douse the sails as quickly as possible and attempt to stop any leaks.

When solo sailor Mike Plants Open 60 Coyote lost her lead bulb in 1992, Mike was lost at sea. Other adventure-sailors have survived near instantaneous capsize precipitated by keel loss. In 2003, round-the-world racer Tim Kent and his crew capsized when Everest Horizontal lost its ballast on the way back from Bermuda. US Sailing Safety at Sea Committee Chairman Chuck Hawley was aboard the racing sloop Charlie, on the way back from Hawaii, when a loud groaning sound led to a deep heel as the lead peeled away from the keel bolts and ballast headed straight to the bottom. This encounter at least had a happy ending thanks to the crews quick actions to douse sail. Apparently the keel had been cast with too little antimony (an additive that causes lead to become a harder alloy). The point here is that keeping the keel attached is as important as keeping the crew safely on board. And for the offshore monohull sailor, preventing a keel loss, like preventing crew overboard, requires some informed forethought.

A ballast keel on a sailboat is a classic example of potential energy poised in a balancing act. The buoyancy of the hull itself offsets the effect of thousands of pounds of lead or iron. At rest, gravitys attraction for the dense material strains against the buoyancy of the hull, and the adjacent garboard region is continuously in tension. Few sailors spend much time contemplating how keel bolts corrode and what cycle-loading does to the resin matrix comprising the garboard region just above the ballast. What is apparent, is that the attachment material, whether it be wood, metal or fiber reinforced plastic (FRP), must be able to support a mass of metal weighing as much as a small truck-and do so day in and day out for decades.

Underway, every tack causes the rig and sailplan to try to lever this ballast package free from the hull. And when the helmsman starts daydreaming about lobster for dinner and wanders off course onto a granite ledge Down East, the keel designed to handle sailing loads takes it on the chin. Its easy to see why experienced designers and builders lose sleep over their decisions about keel shape, structure, and what kind of safety factor should be built into the structure.

Its surprising to discover that with better materials and computer-aided design, we still hear about incidents such as the Rambler capsize in the 2011 Fastnet Race (PS, May 2012). Just as significant is a spate of smaller race boat keel-ectomies that have caused ISAF to send out a cautionary note to sailors around the world, and introduce new structural standards for race boats. Keeping the ballast attached to the boat involves an awareness of a chain-like set of failure points. And one of the most difficult decisions each designer must make is how to marry foil efficiency with a structural safety margin that covers the boats intended usage and the unintended use of the keel as a depth sounding device.

For decades, engineers and naval architects have had to contend with some racing sailors Icarus-like quest-a trend that prioritizes shedding weight and making the keel foil a long, thin appendage with a high-aspect ratio. Though not quite a flight toward the sun with wings made of wax and feathers, some race-boat scan’tlings walk a fine line between lightweight and structural failure. The challenge lies in attaching a lead bulb on a high-tensile steel foil to a lightweight, high-modulus, FRP hull. Interconnecting the dense metallic ballast to the lower-density foam/fiberglass hull structure is a true engineering puzzle. Part of the challenge lies in the dissipation of point loads (confined to a relatively small area) and how to handle the resulting stress risers. A stress riser is the point at which theres an abrupt change in a materials flexibility, such as where a stiff, fin keel meets the more elastic hull bottom. In FRP composites like those found in a balsa-cored hull, stress risers are a likely place for delamination to occur. Over time, these can result in the failure of the FRP composite.

The see-saw effect of the keel counteracting a vessels righting moment is a mathematically predictable energy transfer. Even the effect of groundings such as those that turn hull speed into a dead stop can be quantified. But its the cumulative effect of fatigue (localized structural damage caused by cyclical loading) and corrosion that are harder to pin down.

The term allision refers to hitting a fixed object such as a granite ledge or coral reef. Naval architects analyze the energy transfer and evaluate the stress and strain characteristics that occur. The recognition that the keel-to-hull connection must endure even more punishment than is doled out in heavy-weather sailing episodes is at the heart of how structural specs are devised.

Designers also must consider the jack-hammer-like pounding of a keel on a reef in surf, and realize that there are limits to the abuse a keel and hull can endure. With this in mind, its reasonable to assume that sailboat keels should be built to handle sailing induced loads for decades. It is the extra safety factor built into the boat that defines what happens when the sandbar is a rock pile.

What is harder to anticipate are the unusual encounters that can inflict serious damage to the keel connection. Take, for example, what happens when a sailboats deep fin keel is wedged in a rocky cleft and a good Samaritan with a big powerboat attempts to pivot the sailboat using a line attached to the bow. The distance from the keels vertical centerline to the stem may be 20 feet or more, and with a couple of thousand pounds of bollard pull, the 20-foot lever arm creates a rotary force that can spike to 40,000 foot-pounds or more. This level of torque goes well beyond what most designers and builders model as sailing loads, and its likely to seriously damage the boat.

In plain low-tech talk, extreme fin keels provide a valuable performance edge, but they come with their own set of downsides that every owner needs to be aware of. In essence, the more radical the keel shape, the better the crew must navigate.

A couple of decades ago, PS Technical Editor Ralph Naranjo ran a boatyard and had a client who liked to cut the corners during Block Island Race Week. His first spinnaker reach into a granite boulder stopped the boat and shoved the companionway ladder upward six inches. This underscored how an allision that causes the keel to stop abruptly transfers a shock wave through the entire hull. The resulting compression cracked several transverse members in the New York 40 and damaged the core in the canoe body near the garboard.

The FRP repairs had to be tapered and all delamination problems resolved. The moderate-aspect-ratio lead fin keel absorbed a good deal of the blunt trauma. Judging from the cannonball-size dent on the leading edge of the lead keel, it was clear that the impact was significant. The dent offered grim proof of the advantage of having soft lead instead of steel as keel ballast. New floor frames were added, the broken transverse members were replaced, and the boat was off and sailing.

The next season, the boat had another Block Island encounter, and only because the Petersen-designed New York 40 was a pretty ruggedly built boat was a second repair even considered. This time, an equally violent keel-to-hull trauma came from an on-the-wind encounter with a different rock. The extent of the delamination was greater than it had been in the first go round, and more extensive core removal and repair was required. The keel was dropped in order to check the bolts and the garboard. With the bilge fully opened for the FRP repair work, the repair crew made a pattern of the canoe body dead rise and fore and aft contour. As the glass work was being completed, they fabricated a stainless-steel grid that would spread keel loads fore and aft as well as athwartship. The new grid reinforced the keel attachment and returned the sloop to the race course.

Afterward, Naranjo and the owner discussed the details of the repair, including the possibility of hidden, widespread damage from the two groundings. These included the dynamic loads imposed upon the chainplates and rigging, the likelihood of hidden resin-cracking, and potential for more delamination and core shear linked to the torque induced by the accident. In short, any serious allision causes overt and hard-to-detect damage far from the actual impact zone, and these can lead to more problems down the road. When buying a used boat, look for a good pedigree, but also look for signs of previous blunt-force trauma. A good surveyor will be skilled in such structural forensics, and he or she will do more than comment on the gelcoat shine.

In the early days of wooden ships and iron men, a lack of dense metal ballast put less point-loading in the garboard region of the hull. Bilges free of cargo were filled with rocks or tighter-fitting granite blocks cut for more compact stacking. The principal of ballasting a vessel was to lower her center of gravity (CG) and create both an increase in the righting arm and a greater righting moment to offset the heeling moment created by the rig and sail plan. The keel also helped lessen leeway and would evolve into an appendage that added lift.

Movable ballast had a few downsides, not the least of which was its propensity to move in the wrong direction at the very worst moment. Even small boat sailors have found out what can happen to unsecured pigs of lead ballast when the boat heels far enough over for gravity to overcome friction. Whether stones, lead, movable water ballast, or a can’ting keel are used to augment the boats righting moment, a sailor must anticipate the worst-case scenario. This is when the weight ends up on the leeward side of the boat and a bad situation can turn into a real catastrophe. Fixing or locking ballast in place, controlling the volume of water put in ballast tanks, and limiting the can’ting keels range are sensible compromises.

Internal ballast, the ballast inside a keel envelope thats contiguous with the hull, is still seen in many new boats. Island Packet is an example of a builder has stuck with this traditional approach of securing ballast without using keel bolts. Its a sensible design for shoal-draft cruisers, and the upsides are numerous. These high-volume, long-range cruisers arent encumbered by the demands prioritized by light displacement, performance-oriented sailors. Instead, Island Packets combine a rugged laminate and a long-footed, shallow-draft keel. This may not place the lead or iron ballast as deep as the tip of a fin keel, but it does keep the all-important CG low enough to deliver a powerful righting moment along with shoal draft.

In order to deliver the high angle of vanishing stability (AVS) also known as limit of positive stability (LPS), designer Bob Johnson puts what amounts to an internal bulb in the very lowest point in the boat. This long slug of iron or lead (depending on the model) is then covered by Portland cement, locking it in the Island Packets monocoque structure. The result is a contiguous FRP structure spreading keel loads efficiently over a considerable amount of hull skin. Keel bolts and the infamous garboard seam are completely eliminated. This approach to sailboat keel design dates back to the Rhodes Bounty II and other prototypes in the production world of sailboats. Now over 50 years old, many of these boats continue to have a tenacious grasp on the lead or iron that they hold.

Encapsulated iron ballast is much less desirable than encapsulated lead, and its sad to see builders skimp on this. Iron, or even worse steel, has been used in many Far Eastern encapsulated keels. It works as long as water and the resulting oxidation havent caused expansion and cracking of the seal. Lead is also denser than ferrous metal, and therefore, the same amount of ballast will have a smaller volume and create less drag.

Encapsulated ballast starts to be less appealing as keels become more fin-like and high-aspect ratio. The reason for this is that the geometry of the support changes, focusing more load on less area of the hull. As hull shapes evolved into canoe underbodies with hard turns in the bilge, and fin-like keels became thinner, deeper, and with shorter chord measurements (thickness), the concept of encapsulated keel became impractical. The Cal 40, Ericson 39, Pearson 365, and a long list of similar genre boats signified the end of an era when performance racer/cruisers would be built with encapsulated ballast.

External Ballast

Performance-oriented sailors and race-boat designers quickly latched on to hull shapes marked by deep-draft, foil-shaped, high-aspect ratio fin keels. From the late 60s to whats currently glowing on CAD screens in designer offices around the world, keels have grown deeper and shorter in chord length, and bulb or anvil-like tips have grown more and more common.

The design development was sound, lift was enhanced, and deeper-not longer-became the answer to getting to windward faster. The challenge was not only in designing an efficient shape, it lay in creating an attachment means that minimized foil flex and twist, retained the low drag coefficient, and still had the ability to withstand an occasional, albeit modest, grounding.

During this same period, marine surveyors and boatyard techs began to see moderate groundings result in major structural problems. The classic example was the allision that produced a moderate dent in the lead at the leading edge of the keel tip. In many cases, further inspection revealed cracks radiating outward from a knot meter or depth sounder mistakenly placed just ahead of the keel. An even closer look often revealed grid damage or a cracked bulkhead just aft of the last keel bolt. Like the New York 40 mentioned earlier, this was a result of a shock wave radiating through the hull structure. As we learned in Mrs. McCrearys science class, Bodies in motion tend to stay in motion, unless acted on by an equal and opposite force. Fin keel sailboats encountering abrupt energy transfers,tend to endure more damage than their long-keel counterparts.

A forensic look at the Achilles heel of external ballast highlights a few pitfalls. First the good news: Lead absorbs impact well, consuming much of the imparted energy through deformation. However, the translation of the remaining energy from the metal keel foil and keelbolts into an FRP hull is where we often find stress risers, and point loading linked to material and hull shape changes. The near right-angle interface between a modern sailboats canoe body and its deep fin keel is a classic load-path hotspot. In the old days, fiberglass techs spoke of oil-canning or the dimpling of a large section of the garboard as tacks were swapped.

Today Naval Architects use Finite Element Analysis (FEA) to better engineer hull structure. Colorized graphics pinpoint load concentration, glowing bright red in the region where the keel joins the hull, the epicenter of the oil-canning. A common solution to coping with this high-load focal point, is to eliminate core in the region and to gradually increase the unit schedule (layers of FRP), or to add an internal FRP grid. Maximum thickness of a keel stub is located where the keelbolts penetrate the stub. In this region, the solid glass thickness is often equal to the dimension of the keel bolt diameter or even greater.

Laminate thickness at the keel bolts is only part of the equation. Just as important is how the transition to the general hull laminate transpires. A bullet-proof keel stub that immediately transitions into a core hull comprising two units of laminate on each side of the panel creates whats equivalent to a tear-on-the-dotted-line weakness. Transitions that involve sharp angles and marked differences in panel strength require a well-reinforced taper that spreads loads gradually rather than abruptly.

Occasionally, we see massive metal frameworks used in the bilge as support for keel bolts; these structures need to be carefully engineered to not create the same hard spot fracture points. When carefully tapered in order to gradually introduce more flex, the problem is abated, as it was in the repair of the New York 40 mentioned earlier. The stainless-steel grid built to support the keel loads incorporated a gradual decrease in stiffness to the framework. The keel was carefully mated to the underside of this grid to ensure full contact (See Keel Bolt Repair Options, online). As a result, the crew relieved the hard spots at the end points and made the transition to the more flexible FRP hull less dramatic.

For cruisers, the take-away lesson is that extra reinforcement, a long garboard keel-to-hull interface, and internal transverse and longitudinal reinforcement really do pay off. Keep in mind that the extra weight this entails is all below the center of gravity and contributes to the secondary righting moment as well as keeping the water out.

This is a big departure from the way many modern production boats are built. They carry a skimpy ballast ratio of 30 percent or less, have less structure to support the keel and are not designed to handle unintended cruising consequences. There are exceptions, and its worth looking at the keel design and structure of the Navy 44 Mark II and the USCG Leadership 44 (see PS, August 2012). These boats utilize external ballast and are examples of rugged keel attachment. They have a relatively long keel-to-stub garboard junction, the laminate scan’tling meets American Bureau of Shipping recommendations, and both utilize an overabundance of 316 stainless-steel keel bolts and an FRP grid to keep the keel where it belongs.

There are many reasons why were seeing more keel problems today. On one hand, light, fast, race-boat design pushes the envelope, and thats probably OK. But when mainstream racer/cruisers start to suffer from lead loss, too much of one good thing (high-aspect ratio) and too little of another good thing (reinforcement) can begin creeping into design and construction.

RELATED ARTICLES MORE FROM AUTHOR

Leave a reply cancel reply.

Log in to leave a comment

Latest Videos

How To Test a Boat Engine

Hunter Legend 35.5 – Behind the Curtain

Whipping Line On Your Sailboat

Hallberg Rassy 42 – Behind the Curtain

- Privacy Policy

- Do Not Sell My Personal Information

- Online Account Activation

- Privacy Manager

Practical Boat Owner

- Digital edition

Keel types and how they affect performance

- Peter Poland

- June 19, 2023

Peter Poland looks at the history of keel design and how the different types affect performance

The Twister is a well-proven example of a generation of production yachts with ‘cutaway’ full keels and keel-hung rudders. Credit: Graham Snook/Yachting Monthly

Having been a boatbuilder for around 30 years until the very early ‘noughties’, I’ve already witnessed – and even taken part in – a lot of changes in the world of yacht design and building.

Yacht design originally evolved as traditional workboats developed into leisure craft.

In his History of Yachting , Douglas Phillips-Birt writes that the Dutch, who gave the name ‘yacht’ to the world, were probably the first to use commercial craft for pleasure in the 16th century.

They created the first yacht harbour in Amsterdam in the 17th century.

When the schooner America visited the UK in 1851 and raced around the Isle of Wight, this led to the America’s Cup and the resulting merry-go-round of race-yacht design that continues to this day.

The Jeanneau Sun Odyssey 35 offers three different fin keel configurations with different draughts plus a lifting keel version with a centreplate housed in a shallow winged keel stub. Credit: David Harding

The creation of what is now the Royal Yachting Association ( RYA ) in 1875 led to the introduction of handicap rules, establishing the sport in Britain.

These rating rules – and their numerous successors down the ages – have helped determine the evolution of yacht design and keel shapes.

Many early yachts were closely based on workboats, commercial cargo carriers or even privateers and naval vessels.

Initially, the ballast was carried in a long keel and the bilges .

New racing rules of the day taught designers to seek and tweak performance-enhancing features.

Maybe racing did not always improve the breed, but it certainly kept it moving ahead.

Artwork inspired by Ted Brewer’s illustration of keel types (excluding centreplate or lifting keels)

The late, great designer David Thomas believed that fishing boats, pilot cutters and oyster smacks had a large influence on the sport of sailing.

Each type of workboat was built to fulfil a specific purpose. And many had to be sailed short-handed while carrying heavy cargoes.

So they needed to combine form and function, sail well and be able to cope with heavy weather.

Proof of the versatility of working boat designs was provided by Peter Pye and his wife, Anne.

They bought a 30ft Polperro gaff-rigged fishing boat (built by Ferris of Looe in 1896) for £25 in the 1930s.

Having converted her to a sea-going cutter, and renamed her Moonraker of Fowey , they sailed the world for 20 years.

It proves how the simplest working boat design can cross oceans and fulfil dreams.

Racing influence on keel types and design

Most early yacht designs were schooners, but during the latter half of the 19th century the gaff cutter rig started to dominate the scene.

Many notable yachts were built at that time and the most important racing design was probably the yawl Jullanar (1875).

Designed and built by the agricultural engineer EH Bentall, she had, in his own words, “the longest waterline, the smallest frictional surface, and the shortest keel”.

She proved to be extremely fast and in her first season won every race she entered. Jullanar became the forerunner of such famous designs as GL Watson’s Thistle (1887), Britannia (1893), and Valkyrie II and Valkyrie III , both of which challenged for the America’s Cup during the 1890s.

Compare the She 36’s graceful overhangs with the vertical stems and sterns of most modern cruiser/racers

In the USA, Nat Herreshoff experimented with hull forms for racing yachts and produced the ground-breaking Gloriana in 1890.

She was a small boat for the times, with a waterline length of 46ft. Her hull form was very different to anything yet seen in the USA.

With long overhangs at bow and stern, her forefoot was so cut away that the entry at the bow produced a near-straight line from the stem to the keel.

It was a revolutionary design, and nothing at the time could touch her on the racecourse.

Many French models, such as this Beneteau, have opted for substantial pivoting keels. Credit: Peter Poland

Herreshoff wrote: “Above the waterline everything on Gloriana was pared down in size and weight… and every ounce of this saving in weight was put into the outside lead.”

Early English rating rules produced the ‘plank-on-edge’ yacht, where the beam became narrower and the draught got deeper.

New rating rules were then adopted to discourage this extreme type and eventually the Universal Rule was introduced in the USA and the International Rule – which produced the International Metre Classes – took over in Europe.

Yet again, racing rules proved to be a major influence on design development.

By the start of the 20th century the big, long-keeled racing yachts like the J Class attracted a lot of public attention, but after World War II everything changed. Yachts built to the Universal Rule fell from favour.

The age of the racing dinghy arrived and the ocean racer became the performance yacht of the future.

To new extremes

A 300-mile race from New York to Marblehead saw the start of offshore racing and the first Bermuda race was run in 1906.