~ Back to Rudder Hardware Main Page ~

BUY MORE SAVE MORE - Now Through Memorial Day! $15 off a $150 order / $40 off a $250 order / $100 off orders of $500+

- Sailboat Hardware

- Rudder & Tiller

- Qty in Cart

Weekender Vertical Gudgeon

Weekender Rudder Gudgeon

Canoe/Kayak Rudder Gudgeons

Racelite Light Duty Gudgeons

Racelite One Piece Gudgeons

Racelite Extra Heavy Duty Gudgeons

Ronstan Stainless Steel Gudgeons

Racelite 1/2" Heavy Duty Gudgeons

Kayak Rudder Mounting Gudgeons

Racelite Medium Duty Gudgeons

Viadana Transom Pintles and Rudder Gudgeons

Racelite Heavy Duty Gudgeons

- Total: items /

- Add all to cart

Adding your products to cart

- Paddle Board

What Is a Sailboat Rudder? An Overview of Its Function and Design

Sailboats have been used for thousands of years to traverse water. They have undergone many changes and improvements over the years, and one of the essential components of a sailboat is the rudder.

Quick Facts

Understanding the sailboat rudder.

The rudder is a vital component of a sailboat that plays a crucial role in steering and maneuvering the vessel. The rudder works by changing the direction of the water flow around it, which moves the boat in the opposite direction. Without a rudder, it would be impossible to navigate a sailboat effectively, especially in different water and wind conditions.

Components of a Sailboat Rudder

A sailboat rudder comprises several components, each with a unique function that contributes to the rudder’s overall effectiveness. The stock is the main vertical shaft that connects the rudder blade to the boat’s helm. It is usually made of stainless steel or aluminum alloy and is designed to withstand the forces exerted on the rudder during navigation.

The blade is the flat portion of the rudder that faces the water current and directs the water flow in the opposite direction to steer the boat. The blade is typically made of fiberglass-reinforced plastic or aluminum alloy and is designed to be lightweight and durable. Pintles and gudgeons are the two connections between the rudder and stern that allow for easy installation and removal of the rudder. Pintles are the vertical metal pins that fit into the gudgeons, which are the horizontal metal brackets attached to the boat’s stern.

Different Types of Rudders

There are several types of rudders used in sailboats, each with its advantages and disadvantages. Transom-mounted rudders are the most common type of rudder, and they are mounted on the stern of the boat. Skeg-mounted rudders are attached to a fixed fin called a skeg, which provides additional stability to the rudder.

Keel-mounted rudders are attached to the boat’s keel, which is the central structural element that runs along the bottom of the hull. Spade rudders are free-standing rudders that are not attached to any part of the boat and are commonly used in racing sailboats. The type of rudder used depends on the boat’s size, design, and intended use.

Materials Used in Rudder Construction

Rudders can be made from various materials, each with its advantages and disadvantages. Wooden rudders are the traditional choice and are still used in some sailboats today. However, they are relatively heavy and require regular maintenance to prevent rot and decay.

Aluminum alloy rudders are lightweight and durable, making them an excellent choice for racing sailboats. Stainless steel rudders are also durable but are heavier than aluminum alloy rudders. Fiberglass-reinforced plastic rudders are the most common type of rudder used today, as they are lightweight, durable, and require minimal maintenance.

The sailboat rudder is an essential component that plays a crucial role in steering and maneuvering a sailboat. Understanding the different types of rudders, their components, and the materials used in their construction can help sailors choose the right rudder for their boat and navigate more effectively in different water and wind conditions.

The Function of a Sailboat Rudder

Steering and maneuvering.

The primary function of a sailboat rudder is to steer and maneuver the boat. The rudder’s blade directing the flow of water in a specific direction allows for the steering of the boat as the blade changes direction. Sailors can use the rudder to turn the boat in any direction they choose, allowing them to navigate through narrow channels or around obstacles in the water. It is essential to note that the rudder works in conjunction with the sails to control the boat’s direction and speed.

Balancing the Sailboat

The balance of the sailboat is critical to ensure safe maneuvering, and the rudder plays a crucial role in achieving this. A balanced rudder helps in keeping the boat steady, reducing drag, and preventing unwanted turning. Sailors can adjust the rudder’s angle to keep the boat balanced and on course, especially in rough water conditions. A well-balanced rudder also helps to reduce the risk of capsizing or losing control of the boat .

Rudder Effectiveness in Different Conditions

Rudder effectiveness varies depending on the boat’s size, weight, and water and wind conditions. A larger boat may require a bigger rudder for proper maneuvering, while a smaller boat can work with a smaller rudder. Sailors must also consider the water and wind conditions when choosing the right rudder for their boat. In calm waters, a smaller rudder may be sufficient, but in rough water, a larger rudder may be necessary to maintain control of the boat. Additionally, the rudder’s effectiveness can be affected by the boat’s speed, with higher speeds requiring more significant rudders to maintain control.

It is also important to note that the rudder’s effectiveness can be impacted by external factors such as weeds or debris in the water. These factors can reduce the rudder’s ability to steer the boat and require sailors to make adjustments to maintain control. Additionally, the rudder’s effectiveness can be impacted by the sailor’s skill level, with more experienced sailors able to make more precise adjustments to the rudder to control the boat’s direction and speed.

Design Considerations for Sailboat Rudders

Sailboat rudders are an essential component of a boat’s steering and maneuvering system. A well-designed rudder can make all the difference in a boat’s performance , especially in challenging weather conditions. In this article, we will explore some of the key design considerations for sailboat rudders.

Rudder Size and Shape

The size and shape of a rudder play a crucial role in determining its effectiveness in steering and maneuvering a boat. A larger rudder provides more leverage and maneuverability, allowing the boat to turn more sharply. However, a larger rudder may also produce more drag, which can slow down the boat’s speed.

The shape of the rudder is also important. A well-designed rudder should be streamlined to reduce drag and turbulence. The thickness of the rudder should be carefully considered to ensure that it is strong enough to withstand the forces exerted on it while remaining lightweight.

Rudder Placement and Configuration

The placement of the rudder on the boat can significantly affect its performance. A rudder that is too far forward can cause the boat to become unstable, while a rudder that is too far aft can make it difficult to steer. The location of the rudder must also take into account factors such as the propeller’s placement and the boat’s shape.

The configuration of the rudder can also determine its effectiveness and balance. A single rudder is the most common configuration, but some boats have twin rudders to provide more steering control. The angle of the rudder blade can also be adjusted to optimize its performance.

Hydrodynamic and Aerodynamic Factors

The design of a rudder must take into consideration the hydrodynamic and aerodynamic factors affecting the boat’s performance. Hydrodynamic factors include water flow, pressure, and turbulence, which can significantly affect the rudder’s performance. The shape and placement of the rudder must be carefully designed to minimize these effects.

Aerodynamic factors consider the wind and air resistance’s impact on the boat’s performance. The rudder’s size and shape must be designed to minimize the wind’s effect on the boat while providing sufficient steering control.

The design of a sailboat rudder is a complex process that requires careful consideration of many factors. The size and shape of the rudder, its placement on the boat, and its configuration must be optimized to provide effective steering and maneuverability. By taking into account the hydrodynamic and aerodynamic factors affecting the boat’s performance, a well-designed rudder can significantly improve a sailboat’s overall performance.

Rudder Maintenance and Repair

The rudder is a crucial component of any sailboat, providing steering and control. As such, it’s essential to keep it in good working order through regular maintenance and inspections.

Inspecting Your Rudder

Regular inspection of the rudder is essential to ensure its continued performance and longevity. A thorough inspection includes checking for cracks, wear and tear, and loose components such as hinges, pins, and screws. It’s also important to check the rudder’s alignment and ensure it moves smoothly and without any obstructions.

During your inspection, be sure to check for signs of corrosion, particularly on metal components. Corrosion can weaken the rudder and cause it to fail, so regular cleaning and maintenance are essential to prevent this.

If you notice any issues during your inspection, it’s important to address them promptly. Small cracks or damage can often be repaired, but if the damage is extensive, it may be necessary to replace the rudder entirely.

Common Rudder Issues and Solutions

One common issue with rudders is corrosion, particularly on metal components. Regular cleaning and maintenance help prevent corrosion and ensure the rudder’s longevity. If you do notice signs of corrosion, it’s important to address it promptly to prevent further damage.

Another common issue is damage to the blade or stock. This can be caused by impact with debris or other boats, or simply wear and tear over time. If the damage is minor, it may be possible to repair the rudder. However, if the damage is extensive or compromises the rudder’s structural integrity, it may be necessary to replace it entirely.

Loose components such as hinges, pins, and screws can also cause issues with the rudder. These should be checked regularly and tightened or replaced as needed.

When to Replace or Upgrade Your Rudder

Sailboat rudders can last for many years, but at some point, replacement or upgrade may be necessary. This includes upgrading to a newer design or larger rudder to improve the boat’s performance or replacing a damaged or worn-out rudder that is beyond repair.

If you’re considering upgrading your rudder, it’s important to consult with a professional to ensure that the new rudder is compatible with your boat and will provide the desired performance improvements.

Regular maintenance and inspections are essential to ensure the continued performance and longevity of your sailboat’s rudder. By staying on top of any issues and addressing them promptly, you can ensure that your rudder will continue to provide reliable steering and control for many years to come.

A sailboat’s rudder is a crucial component that helps steer and maneuver the boat safely. The size, shape, placement, and construction materials must all be taken into consideration when designing or replacing a rudder. Regular maintenance and inspection help ensure its continued performance and longevity.

Rudder FAQS

How does a sailboat rudder work.

A sailboat rudder works by changing the direction of the water flow past the boat’s hull, which in turn changes the direction of the boat. The rudder is attached to the stern of the boat and can be turned left or right. When the rudder is turned, it creates a force that pushes the stern in the opposite direction and turns the bow towards the direction the rudder is turned. This is how a rudder steers a boat.

What is a rudder and its purpose?

A rudder is a flat piece, usually made of metal or wood, attached to the stern of a vessel such as a boat or ship. The main purpose of the rudder is to control the direction of the vessel. It does this by deflecting water flow, creating a force that turns the vessel. Without a rudder, steering a vessel would be significantly more challenging.

Can you steer a sailboat without a rudder?

Steering a sailboat without a rudder is challenging but not impossible. Sailors can use the sails and the keel to influence the direction of the boat. By trimming the sails and shifting weight, it’s possible to cause the boat to turn. However, this is a difficult technique that requires a deep understanding of sailing dynamics and is usually considered a last resort if the rudder fails.

What controls the rudder on a sailboat?

The rudder on a sailboat is typically controlled by a steering mechanism, like a tiller or a wheel. The tiller is a lever that is directly connected to the top of the rudder post. Pushing the tiller to one side causes the rudder to turn to the opposite side. On larger boats, a wheel is often used. The wheel is connected to the rudder through a series of cables, pulleys, or hydraulic systems, which turn the rudder as the wheel is turned.

How do you steer a sailboat with a rudder?

To steer a sailboat with a rudder, you use the tiller or wheel. If your sailboat has a tiller, you’ll push it in the opposite direction of where you want to go – pushing the tiller to the right will turn the boat to the left and vice versa. If your sailboat has a wheel, it operates like a car steering wheel – turning it to the right steers the boat to the right and turning it to the left steers the boat to the left.

How do you steer a sailboat against the wind?

Steering a sailboat against the wind, also known as tacking, involves a maneuver where the bow of the boat is turned through the wind. Initially, the sails are let out, and then the boat is steered so that the wind comes from the opposite side. As the boat turns, the sails are rapidly pulled in and filled with wind from the new direction. This maneuver allows the boat to zigzag its way upwind, a technique known as “beating.” It requires skill and understanding of sailing dynamics to execute effectively.

John is an experienced journalist and veteran boater. He heads up the content team at BoatingBeast and aims to share his many years experience of the marine world with our readers.

What to Do If Your Boat Engine Won’t Start? Common Problems & How to Fix Them

How to launch a boat by yourself: complete beginner’s guide, how to surf: complete beginner’s guide to get you started.

Comments are closed.

Type above and press Enter to search. Press Esc to cancel.

- Fair American

- Tools and Techniques

- Kit Database

- Bluenose Canadian Schooner

Pintles and Gudgeons

November 3, 2016

The most complex part of the rudder assembly is the hinges that allow the rudder to turn. These hinges are made from pintles and gudgeons . Both are basically metal ‘straps’ that wrap around the hull and rudder. The pintle has a pin that extends down from the bottom. The gudgeon has a tube that accepts the pin. When the pintle is inserted into the gudgeon, it can turn freely and forms the hinge.

On small scale static ship models, we can easily omit most of this detail. You probably won’t let people touch or play with the model, so it doesn’t matter if the rudder actually turns. When assembled and installed, these really just look like little straps stuck on the rudder and hull. In the words, we could just glue the rudder in place and fake it.

However, I’m trying to learn new stuff, and this seems like a fun detail to add.

The body of both pieces will be made from brass strip, cut to the right size. It will be a single piece that is bent in a few places so it can wrap around the rudder or hull.

The holes in the body are for the bolts that would have held these in place on the actual ship. My plan is to drill those holes before I bend the strips. Those holes will be tiny. After the pieces are installed, I’ll fill those holes in to simulate the heads of the bolts.

I’ve decided to use brass tubing on both the pintles and gudgeons. I think this will create a more uniform look, and will help line things up. The tube on the pintles will have a thin brass rod soldered in to form the pin.

I tried a few different ways of making the pieces out of brass strips. Getting the holes positioned correctly is difficult. To make things a little more complicated, the length of each piece is different depending on its location. To make things a lot more complicated, the thickness of the rudder and sternpost varies according to location.

The approach that worked the best for me was to cut a piece of wood to use as a building board. I marked this with 6 straight lines (1 for each of the 3 pintles, and 1 for each of the 3 gudgeons).

I used my dividers to measure the thickness at the three points on the rudder and on the sternpost, and transferred each of those to the board. This gave me markings indicating the back flat end of each piece. Next I measured and transferred the lengths of each piece from the plans, marking it for each side of each piece.

I cut brass strips that were longer than needed. I used the extra length to glue the pieces down on the board. I need these pieces to be very secure during the drilling process. Finally, I marked the positions of the holes I was going to drill.

Holes were drilled using a small Proxxon drill press and a compound X/Y table. The compound table lets me move the piece around in fine increments by turning some dials. This helps to get the position of each hole very precise. I drilled the holes with a #64 drill bit.

Brass strips were glued to a board to keep them steady during drilling.

Once all the holes were drilled, I had a nice set of strips. Using a #11 blade, I scored the strips to note the length and the places where they would be bent.

Drilled and marked brass strips, each a different size based on where it will go on the ship.

Next I removed the strips one at a time. Each piece was cut to the right length, then bent to form a ‘U’ shape. To keep my pieces straight, I modified my board by adding some thin wires that could hold the pieces while I worked on them.

One by one, pieces are removed from the board, cut to length, and bent to shape.

Each piece was tested on the ship to make sure it fits correctly. This is much easier to do now, before the other pieces are soldered on.

Now it is time to do some soldering.

I cut some short sections of brass rod and brass tubing. These were not provided in the kit, but I was able to find some at my local hobby shop. The brass rod I used was 0.032″ in diameter. The brass tubing was 1/16″ in diameter (outside). The rod slips perfectly into the tube. I cut these sections about an inch or so long. They will be trimmed later.

Each piece needs to be soldered to secure the rod to the brass strip. This is my first ‘real’ attempt at soldering. I did a bunch of reading, and it sounds like most people prefer ‘silver soldering’, but that is more involved than basic soldering. I’m going to keep it simple and just use a normal soldering iron, solder and flux.

I used two ‘helping hands’ (tweezers mounted to a heavy base) to hold the pieces in place. To help hold the brass tube in place, I placed it on a longer brass rod that we’ll pull out after soldering is complete.

Each piece will have brass tubing soldered on.

Soldering was pretty simple:

- Brush on a little flux on the top of the strip and the bottom of the tube.

- Position them so they touch, making sure they are aligned right.

- Cut two tiny pieces of solder, and set them on either side of the tube.

- Touch the soldering iron to the underside of the joint, heating the brass strip and melting the solder.

A completed simple solder.

This process was repeated for each piece. Care was taken to not mix up the parts, since each of these is for a specific spot on the ship.

The pieces go right back to their assigned spots on the board after soldering so they don’t get mixed up.

Once all 6 pieces had their tubes, I went through and cut the tubes down to size. I did this with some flush-cut metal sheers ( similar to these ). Using sheers to cut these distorts the hole in the tube, so I then used a simple reamer to open the hole back up and correct the shape. The cut was then filed smooth with a file, as were the solder joints.

That completes the gudgeons, but the pintles require another step to make the pins.

Each of the pintles got another pass with the soldering iron. I brushed a bit of flux inside the tube and on a small piece of brass rod. The rod was inserted through the tube, then solder was applied to fix the pin in the tube. This was messy, but it worked.

Brass rod is soldered into the tubes on the pintles.

The short end of the rod was then clipped off and filed smooth. The longer end was left long – it provides something to hold onto during painting. I’ll trim those to fit when I start the installation.

The finished set of pieces were kept organized on a small jig I made. Since these are sized to specific spots on the ship, I need to keep them in a known order.

Completed pintle and gudgeon pairs. They are shaped according to their specific spots on the ship.

The pieces then got a nice coat of flat black paint. Another option would have been to use a chemical blackening solution, but I didn’t have good results with that when I tried. Note that I only painted the outside of the pieces. Painting the inside would just reduce the effectiveness of any glue I use.

Once the pieces are all painted, we’re ready to start the installation.

The rudder, pintles and gudgeons ready for installation.

- Click to share on Twitter (Opens in new window)

- Click to share on Facebook (Opens in new window)

- Click to share on Reddit (Opens in new window)

- Click to share on Tumblr (Opens in new window)

- Click to share on Pinterest (Opens in new window)

- Phantom NY Pilot Boat

- Model Ship Kit Database

Copyright © 2018 SuburbanShipModeler.com The text, photos, and content are copyright of this site unless otherwise noted.

Photos were taken by the author unless otherwise noted. All brands and trademarks referenced are the property of their respective owners.

Discover more from The Suburban Ship Modeler

Subscribe now to keep reading and get access to the full archive.

Type your email…

Continue reading

× You are using an outdated browser. Please upgrade your browser to improve your experience.

We Ship Worldwide! | FREE SHIPPING! for US Continental orders over $99. Click for details.

Shopping Cart

Your cart is currently empty..

FREE SHIPPING! for US Continental orders over $99 click for details

Sailboat Pintles & Gudgeons

Pintles and Gudgeons are the components of the hinge mechanism on outboard mounted rudders. Pintles are made with a pin that fits into the holes of the gudgeons.

MAURIPRO Sailing, your direct access to Sailboat Pintles & Gudgeons and all your other sailing and boating needs.

Copyright © 2024 MAURIPRO Sailing LLC.

Sailing Errant

Life on gudgeon, a cherubini hunter 36.

Today I introduce Matthew Parsons, another inspirational sailor/livaboard who chronicles his adventure at Life on Gudgeon (blog URL is www.gudgeonblog.ca and he also posts pics on Instagram.com/ .) Unlike some of the snazzier, slicker sailing blogs, Parson doesn’t airbrush his experience. Reality unfiltered. It’s refreshingly honest and useful. Instructive.

In his own words:

I am a transplant from England… [residing] in Victoria [Canada]. The longer I stayed in Victoria, the more people I met who had made the jump to living on the water. This blog is about my attempts to join them.

I bought Gudgeon (then Wind Chime) in Dec 2013, moved on in June 2014, and have steadily been upgrading and improving her. My thoughts have started to turn to cruising around the world, but I have a lot of refitting and learning to do before then! ( Source: Life on Gudgeon )

Gudgeon, Parsons’ sailboat, is a 36 foot Hunter designed in 1980 by John Cherubini. She’s a solid vessel with clean lines, a reliable hull and rig, and a steady supply of projects. Parsons documents the ups and the downs, a healthy reminder that living aboard a sailboat isn’t all tie-dye sunsets and following winds.

Except when it is…

Share this:

- Click to share on Facebook (Opens in new window)

- Click to share on Twitter (Opens in new window)

- Click to share on Pinterest (Opens in new window)

- Click to share on Tumblr (Opens in new window)

- Click to share on Pocket (Opens in new window)

- Click to share on LinkedIn (Opens in new window)

- Click to share on Reddit (Opens in new window)

- Click to email a link to a friend (Opens in new window)

- Click to print (Opens in new window)

Windblown adventures aboard a Catalina 310

- Types of Sailboats

- Parts of a Sailboat

- Cruising Boats

- Small Sailboats

- Design Basics

- Sailboats under 30'

- Sailboats 30'-35

- Sailboats 35'-40'

- Sailboats 40'-45'

- Sailboats 45'-50'

- Sailboats 50'-55'

- Sailboats over 55'

- Masts & Spars

- Knots, Bends & Hitches

- The 12v Energy Equation

- Electronics & Instrumentation

- Build Your Own Boat

- Buying a Used Boat

- Choosing Accessories

- Living on a Boat

- Cruising Offshore

- Sailing in the Caribbean

- Anchoring Skills

- Sailing Authors & Their Writings

- Mary's Journal

- Nautical Terms

- Cruising Sailboats for Sale

- List your Boat for Sale Here!

- Used Sailing Equipment for Sale

- Sell Your Unwanted Gear

- Sailing eBooks: Download them here!

- Your Sailboats

- Your Sailing Stories

- Your Fishing Stories

- Advertising

- What's New?

- Chartering a Sailboat

- Sailboat Rudders

Sailboat Rudders

The primary purpose of sailboat rudders is of course to give the helmsman the ability to steer the boat, but a well-designed one will also provide hydrodynamic lift to windward, in the same manner as does the keel.

Placing sailboat rudders into distinct categories is fairly straight forward - they're either:

- Outboard or inboard rudders, which can be

- Unbalanced, balanced or semi-balanced, and be

- Keel-hung, skeg-hung, transom-hung or spade rudders.

Take a stroll around any fair-sized boatyard during the lay-up season and you'll see examples of most of them...

Inboard & Outboard Sailboat Rudders

If the rudderstock passes through the underside of a boat's hull, it's an inboard rudder. Conversely, if it doesn't, it's an outboard rudder.

Most outboard rudders are turned by a tiller as there's no rudderstock to which a wheel-steering quadrant can be mounted.

The two rudders shown below are quite different examples of outboard rudders.

Fig 1 shows an example of a keel-hung outboard rudder that is seldom seen on today's cruising boats.

Outboard rudders like the one in Fig 2 can be easily removed for service or repair with the vessel afloat. You might struggle with trying to do that with the 'barn door' of a rudder in Fig 1 though!

Examples of inboard rudders can be seen in Figs 3, 4, 5, 6, 7 & 9.

Unbalanced Rudders

This unbalanced rudder is supported by a full-length skeg.

It is unbalanced because the entirety of the rudder is aft of its axis, the axis being on the centreline of the rudderstock.

When turned, the full force of the water flowing past the skeg acts on one side of the rudder - a fact that will be very much apparent to the helmsman, particularly on a tiller-steered boat.

Recent Articles

Hallberg Rassy 42e for Sale

May 23, 24 03:01 AM

Westerly Oceanranger Specs & Data

May 20, 24 03:34 AM

Westerly Oceanranger 38 for sale

May 19, 24 04:09 AM

Here's where to:

- Find Used Sailboats for Sale...

- Find Used Sailing Gear for Sale...

- List your Sailboat for Sale...

- List your Used Sailing Gear...

Our eBooks...

A few of our Most Popular Pages...

Copyright © 2024 Dick McClary Sailboat-Cruising.com

Please verify you are a human

Access to this page has been denied because we believe you are using automation tools to browse the website.

This may happen as a result of the following:

- Javascript is disabled or blocked by an extension (ad blockers for example)

- Your browser does not support cookies

Please make sure that Javascript and cookies are enabled on your browser and that you are not blocking them from loading.

Reference ID: 896291ab-1a31-11ef-ab2f-b57e37bb4791

Powered by PerimeterX , Inc.

Free Shipping on Most Orders Over $200 - Restrictions Apply - Click for Details

- Auto Anchor

- Digital Antenna

- Digital Yacht

- MapMedia Charts

- Muir Windlasses

- New England Ropes

- Servo Cleats

- Shakespeare

- Simpson Lawrence

- Standard Horizon

- Batten Cars

- Deck Organizers

- Furling Systems

- Furling Accessories

- Genoa Leads

- Mast & Boom Hardware

- Pintles & Gudgeons

- Rope Clutches

- Tiller Heads

- Tiller Extensions

- Winch Handles

- Rigging Wire

- Rigging Terminals

- Chainplates

- Headstay Foils

- Hydraulic Backstay Adjusters

- Link Plates

- Turnbuckles

- Autopilot Tiller Arms

- Chartplotters

- Navigation Software

- NMEA Devices

- Plotter/Sounder Combos

- Sailing Instruments

- Transducers

- Weather Sensors

- VHF Antennas

- Anchor Rodes

- Anchor Rollers

- Anchor Snubbers

- Anchor Swivels

- Chain Stoppers

- Windlass Remotes

- Windlass Parts

- Lewmar Winch Parts

- Harken Winch Parts

- Harken Furler Parts

- Lewmar Windlass Parts

- Lofrans Windlass Parts

- Airmar Parts and Accessories

- Airmar Cables

- Lewmar Hatch Parts

- Lewmar Portlight Parts

- Cutlass Bearings

- Emergency Pumps

- Feathering Props

- Galley Pumps

- Hatches & Portlights

- Interior Lighting

- Radar Reflectors

- Shaft Seals

- Steering Pedestals

- Steering Wheels

- Wish List (0)

- Shopping Cart

- Schaefer Pintles & Gudgeons

- Schaefer Blocks

- Schaefer T Track & Sliders

- Schaefer Genoa Leads

- Schaefer Traveler Systems

- Schaefer Furlers

- Schaefer Deck Organizers

- Schaefer Rigging

- Schaefer Mast & Boom Hardware

- Schaefer Stanchions

- Schaefer Cam Cleats

- Schaefer Horn Cleats

- Schaefer Pad Eyes

- Schaefer Boom Vangs

- Schaefer Shackles

- Schaefer Lazy Jacks

- Schaefer Winch Handles

Schaefer Block Selection

Schaefer Genoa Lead Selection

Schaefer Traveler Selection

Schaefer Furling System Selection

Schaefer Snapfurl Selection

Schaefer welded Stainless Steel Dinghy and Small Keel Boat Pintles come in two lengths allowing for easier rudder installation. Made from type 304 Stainless Steel, built to handle the loads created by high performance boats.

Schaefer's Medium-Duty Pintles and Gudgeon components are most familiar as ”J/24 type” with separate pins and welded pintle straps contained between an upper and lower gudgeon strap. This high strength, easily removed design is excellent for trailerable boats.

P2 Marine 306 S Lake Dr Stevensville, MD 21666 USA

Toll Free: (800) 456-6740 Local: (443) 569-8529 Email: [email protected] Office Hours: M-F 8:30:-5:00 Eastern

Information

- Shipping Information

- Privacy Policy

- Terms & Conditions

Customer Service

- Order History

- Forums New posts Unanswered threads Register Top Posts Email

- What's new New posts New Posts (legacy) Latest activity New media

- Media New media New comments

- Boat Info Downloads Weekly Quiz Topic FAQ 10000boatnames.com

- Classifieds Sell Your Boat Used Gear for Sale

- Parts General Marine Parts Hunter Beneteau Catalina MacGregor Oday

- Help Terms of Use Monday Mail Subscribe Monday Mail Unsubscribe

Replacing the Gudgeons on a C-22

- Thread starter Aldo

- Start date Jan 27, 2005

- Catalina Owner Forums

- Smaller Boats

Let's chat about replacing the Gudgeons on a C-22. I know that I read an article, or a response, on this subject one time, but I couldn't find it in the Archives. I really like the gudgeons to fit the pintles so that the rudder doesn't clunk when the tiller is shifted from side to side. Over the years I have made several sets of replacement pintles for my C-22, and I always keep them well greased, but I really think that it is now time to replace the gudgeons. I like what Catalina Direct has done by making replacement gudgeons with nylon bushings in them. I had thought about doing that myself, but it certainly makes more sense just to buy theirs. (In the future, when the bushings wear out, I'll be able to just replace the bushings). The issue is, of course, replacing the upper gudgeon. (My C-22 is a 1980). I am not too excited about (hole)sawing the big hole that Catalina Direct recommends and putting the "Inspection Plate" over the drilled hole. I guess that the upper gudgeon is screwed on the same way that the lower one is, that is, I assume that it is backed with washers and nuts. If this is the case, would it be possible to grind a wrench thin, or make a thin wrench out of a piece of steel, and slide it up between the cockpit and the stern? This would be to keep the nuts from turning while the screws to the old gudgeon are being unscrewed. To screw on the new gudgeon, I was thinking about making a stainless steel plate with the 4 hole pattern drilled and tapped into it, and then pushing it up between the cockpit and stern, and then just screwing the screws into the plate. Does what I have proposed above make any sense to anyone who has already replaced the gudgeons on their C-22? I do have the skills and tooling to make the wrench and plate that I have proposed, and I would really like to keep my C-22 looking like it did when I bought it, and not drill big holes all over it. Thanks, Aldo

C22 Check the C22 site: http://www.catalina22.org/

upper gudgeon Aldo, This is not as hard as it seems, there are a few things one doesn't want to do though. trust me I did them all. First thing is you need two 1/4" all thread rods. Take out the outer two bolts and replace with the all thread then take out the inner bolts. Slide off the gudgeon caulk the new gudgeon and slide it on the all thread replace the inner bolts and remove the all thread replace the outer bolts, project over! If you want to read about my experience take a look at the fleet 52 website. Was it worth the change you bet changed the feel of the boat. http://www.highlandyachtclub.org/Fleet52/

Thanks Ken! Ken: Thanks for your reply, and thanks for writing the article on your fleet's webpage. So there is a plate backing the upper gudgeon but it isn't epoxied in. I feel a lot more comfortable now after reading your article. I have worked with mirrors on my boat too, and I agree that it is sure challenging. Thanks to you, I shouldn't have to do that again for this little project. How did it change the feel of the boat? Also, how are the Delrin bushings holding up? Do you keep your boat in the water, and do you keep the rudder up or down? Thanks again, Aldo

delrin Aldo, Your welcome, its been two years since I made the change, Changing to the new gudgeons was like adding power steering, I nor a few in the Fleet that haved helmed the boat could belive what a difference it made. I consider the gudgeons and making the heavy tiller straps two of the best changes I've made to the boat. So far I cannot tell there is any wear, I trailer the boat, and a mast up I made also uses the gudgeons. I was concerned at first but after two years and hundreds of miles on them they still look new.

Bayard Gross

replacing pintles and gudgeons Aldo: When I replaced my gudgeons and pintles, I also opted for the ½ inch upgrade from Catalina Direct. However, I discovered to my chagrin, that the four holes of the new ½ inch gudgeons from Catalina Direct did not match up with the four holes on the original 3/8 inch gudgeons. For the bottom gudgeon, that is not too serious an issue. However, for the top gudgeon that employs a brass bar to support the gudgeon, this becomes a considerable alteration. One cannot employ nuts there without cutting a hole in the cockpit lining, which I also decided to avoid. Further, the amount the holes are off center to the original precluded re-drilling and re-tapping the brass bar. Consequently, I had to bore out the holes in the gudgeons to almost ½ inch diameter to get them to fit onto the original holes. This is an agonizingly slow process that costs a mint in drill bits as the gudgeons are stainless. Also, as alignment is crucial, not changing the original holes on the boat is wise, therefore boring out the holes was the best action to take. As far as the discovery process about that brass bar, I too, like Ken went through a heavy learning curve. In my case, Catalina slapped the equivalent of the cable tube volcano over the brass bar. After unbolting the original upper gudgeon, I pounded off the “volcano” which brought down the brass bar imbedded within it. After removing the volcano off the brass bar, getting that bar back in is tricky, but I managed to do it myself. I slapped some sealant onto the side of the brass bar that lies against the transom. I somehow got its holes lined up with the transom holes using some 1/4 inch drill for temporary support. Then I temporarily secured the brass bar to the transom with bolts (no gudgeon) to let the sealant set up which will support the brass bar when one installs the gudgeons. Installing the new ½ inch pintles onto the rudder generated its own complications as the holes of the new pintles do not match the holes of the original 3/8 inch pintles. Again, as alignment is critical, great care is necessary when installing the pintles. This is not a simple drop in and bolt up application. Finally, when everything is all said and done, the derlin inserts have the nasty habit of jumping out of the gudgeons when I remove the rudder. This is not a crisis if you see it happen and can retrieve the insert. Yet more likely than not, you will not see it happen and it won’t be until the next time you go sailing that you will notice the missing insert. So, word to the wise, carry additional derlin inserts on board. Now Aldo, Ken has hull number 10475, which is at least a 1981 boat. I have hull number 9911, which is a 1981 boat and you have a 1980 boat. Being a betting man, I am willing to bet that your Catalina 22 has parts more similar to mine than those on Ken’s boat. What this means is that there is a distinct possibility that the Catalina Direct’s ½ inch upgrade gudgeons and pintles holes will not match up with the holes on your 1980 boat as they did not on mine. Therefore, you may also feel as I do, that you cannot use the Catalina Direct 3/8 inch replacements as those holes may not match as well. Nevertheless, I have found what I believe are the original pintles and gudgeons on early Catalina 22 boats. I removed the Catalina Direct ½ inch pintles and gudgeons and put these on, so I can attest to their almost exact replacement and very successful operation. Race Lite makes these pintles and gudgeons and they are available from Annapolis Performance Sailing. Heck, Annapolis Performance Sailing may be right up the street from were you live. The gudgeon is part number RL 490. The upper pintle is part number RL 490S (short pin) and the lower pintle is part number RL 490L (long pin). You can see these at the link below. Further, Annapolis Performance Sailing call these pintles and gudgeons Extra Heavy Duty, and I think they are. Aldo, as you use an auto pilot, you may find it best just to replace those parts that you already have as that auto pilot may not like the fancy pants half inch Catalina Direct upgrade. So I hope all this is helpful. Good Luck in your projects. Bayard Gross C-22 #9911 Baby Blue Greenwich, CT

Replaced the CD Gudgeons? Bayard: Thanks for the reply. It's great to hear from you again. And as always, thanks for all the details that you included in your reply. It's interesting to me that you also decided not to drill the hole in the cocpit when you replaced the gudgeons. Relative to elongating the holes on the CD gudgeons. I understand your coment about the hull number of my boat making it more like yours than Ken's . However, I could mill the holes to elongate them, rather than drilling them as you described. This would make that operation easier, and the gudgeons would still center themselves properly, and wouldn't have a tendency to be loose, up and down, or rotate. It looks like you needed to move the holes in yours by about 1/8 inch. Bayard, I don't understand your comments about the new pintles not matching the the holes of the original 3/8 piintles. Was the diameter of the new pintles bigger where they go through the rudder casting? Was the centerline different? Did you have to drill new holes in the direction of the front of the boat? I was surprised to read that the delrin bushings come out when the rudder is removed. The reason that I wanted to have bushings on my rudder, especially delrin ones, was so that I could replace them whenever they got a little loose. I have a little metal lathe, and make this kind of thing all the time. Delrin machines really easily. From what you explained, it sounds like a design change would be appropriate to the bushings either by adding an external clip, or possibly a stop screw to keep them from coming out. Out of curiosity, where did you get your extra inserts, from CD? Did they give you extra inserts, or did you have to purchase them? So, you actually removed your CD pintles and gudgeons and went back to the original design parts. You really must have been dissatisfied. Was it mostly due to the bushings jumping out, or were you concerned due to the holes being elongated? The autopilot doesn't mind the looseness of the pintles as much as I do when I'm on the tiller. The first 2 or 3 years that we had our boat we kept it at a marina right off the Chesapeake, and it rocked all the time. Now, we keep it up Middle River several miles, and it has an easy life. Even in thunderstorms, it just sits protected in it's slip. I also now keep it kicked-up so that there is no stress on it. I think that the gudgeons are still worn from the first few years of wear. I have made many sets of pintles, but I just thought that having Delrin bushings would be the answer. Writing this to you I just had a brainstorm. I could get the gudgeons from CD, and make new bushings to go with the existing pintles. Does this sound feasible to you? Thanks again, Aldo

Arrgh Aldo, you have a kick up rudder Arrgh Aldo, you have a kick up rudder Aldo, As you sail the waters of the great Chesapeake bay, I unfortunately assumed you have a standard rudder, as I do, instead of the kick up rudder as you do. This means comparing your pintles with my pintles is like comparing apples with oranges. Your pintles are pins inserted into the upper metal section of your kick up rudder while I have mine welded to straps that attach to the fiberglass rudder itself. Therefore, you just change pins to change your pintles while I must attach a new pintle with straps onto the rudder. Consequently, when I refer to holes not matching up on the pintles, I am referring to the holes in the straps that attach the pintle to the rudder, which, as noted, you do not experience. Nevertheless, I do not know whether your pins are ½ inch or 3/8 inch, as I think Catalina may have used half inch pintles on its kick up rudder while the standard rudder has (or had as I believe newer boats are ½ inch) 3/8 inch pintles. So, if your pins are 3/8 inch, and you want to upgrade to ½ inch, then you obviously need to make some changes to either the rudder head or the pins. For changing just the pins, it appears you would need only make pins that are ½ inch on the part that enters the gudgeons and then 3/8 inch on the part in the rudder head. This I think is a wise course than boring out the holes in the rudder head to accept ½ inch pins. For the gudgeons, I note an article by Dennis Slaton written in 1998 that can be read on the Catalina 22 Fleet 20 web site at the link below. Toward the bottom of this article he notes that the ½ inch upgrade gudgeon holes do not match the original 3/8 inch gudgeon holes. I think his experience is more likely to be with earlier C-22's, unlike Ken’s more recent C-22. While this does support my concern that the upgrade ½ gudgeons holes may not match your holes, you have a kick up rudder that may have ½ inch gudgeons originally and therefore may have a different hole pattern than the 3/8 inch gudgeon. Maybe if Ken Palmer is reading this, he can respond to say whether he has a kick-up or standard rudder and if it has ½ inch pintles originally or not. Further because you have a kick-up rudder and I do not, drawing any conclusions for yourself from my pintle and gudgeon experiences is inappropriate for you. For one thing, your rudder is heavier than mine, so that alone would make the Catalina Direct ½ inch upgrade gudgeons with the derlin inserts a worthy modification. As far as the derlin inserts popping out is concerned, that would only be a serious issue if one removes their rudder at the end of sailing, as I do. Keeping your rudder, standard or kick-up, on your transom at a mooring or slip, is bad practice, I think, as water may penetrate its core. Ship the rudder into the cabin. The inconvenience of installing it every time for a sail is minor compared to having it break while sailing. Catalina Direct readily supplies extra derlin inserts, so if you do get the upgrade from them, I would also order a couple of spare inserts simultaneously and keep them aboard. So Aldo, if you think everything I said in the earlier post is totally useless to you, you’re probably right. The real reason for my removing the Catalina Direct upgrade ½ inch pintles and gudgeons and replacing with 3/8 inch Race Lite pintles and gudgeons is that the ½ inch ones were “too tight”. By this I do not mean too tight for sailing or operating the rudder, as for that they were fine. By “too tight” I mean the rudder did not lift easily off the gudgeons. This was bothersome when I removed the rudder after sailing. Yet more important, this prevented the rudder from rising up and off the gudgeons when the rudder hits something when I am going along with my keel up. I once hit my own mushroom anchor at low tide when maneuvering about with my keel raised. At that time I had on my original 3/8 inch pintles and gudgeons. The rudder lifted up and out of the gudgeons as opposed to breaking something, such as the pins, the gudgeons, or even damaging the transom. Due to this experience, I concluded, after a season with the Catalina Direct upgrade, that whatever benefits I experienced with the upgrade, my need to have the rudder lift up easily superceded these benefits. Therefore, I opted for the 3/8 inch Race Lite pintles and gudgeons that I find let the rudder lift more easily than the Catalina Direct ½ inch pintles and gudgeons. This past spring when I put in my new Race Lite pintles and gudgeons, one year after I installed the Catalina Direct upgrade ½ inch pintles and gudgeons, a joke went around that I replaced my pintles and gudgeons annually wether I needed to or not. Well, Aldo, may fair winds and weather surround you.

pindles Yes I do have the kick up rudder, and it had 3/8" pindles. They are the pin type with a nut to secure them to the rudder. One then needs to chisle lock the nuts. I would advise using never seize on the pindles and lock tight on the retaining nuts. I have never had the delrin inserts to pop out, as I trailer the boat the rudder is removed often. (although I now think its a good idea to have extras)

More on Pintles and Gudgeons Ken and Bayard, We might as well keep discussing this. There hasn't been anything too exciting on this forum for a while. I guess everyone is working on non-boat winter projects. Anyhow Ken, are your new pintles 1/2 inch on the diameter that goes into the Delrin bushings? I use self-locking nuts on mine, the kind that have the little nylon inserts in them to keep them tight. They may even be double nutted, I haven't looked at my rudder for a while. But, I machined my pintles from rod stock, so the threads may be longer than the ones that you get from CD. Relative to using antiseize, that sounds like a good idea. There certainly is a galvanic corrosion thing going on between the stainless steel pintles and the cast aluminum of the rudder. What I do is wrap plastic shim material around the pintles, (it's around .005 inch thick), and this helps prevent the pintle and rudder from corroding together, and also takes up all the slack between the two. Bayard: Yes, my rudder is a kick-up rudder. To be honest with you, I can't remember when I saw a C-22 rudder that wasn't a kick-up rudder where we sail. I do keep mine kicked-up whenever we aren't sailing, like when the boat is in the slip, and often even when we are at anchor overnight. I use a 1 inch webbed strap to hold the rudder straight front to back, cleating the strap to the stern cleats. The rudder is out of the water and the tip is just near the water. I don't think that it is waterlogged, but it is heavy. I'll weigh it in the spring when I get a chance. I use a 1/8 inch diameter nylon shear pin to keep it in the down position. There is a little leaf spring near one of the pintles that keeps the upper aluminum part of the rudder from jumping off of the gudgeons when the rudder touches the bottom. We don't touch the bottom with the rudder too often, but we certainly have had it kick-up a few several times in the last 24 years. It sounds to me like you are using yours as sort of a kick-up rudder, since you changed to pintles that allow the rudder to come off of the gudgeons easier. Do you have the leaf spring near one of your pintles. If you don't, you might want to consider tying the rudder to the side of the traveler with a little line. You would hate to loose it if it popped off. After discussing this with you I think that I am still leaning toward changing the gudgeons to the ones with the delrin inserts. Not having the rudder clunk when the tiller is moved from side to side would be great. Plus, I think that the delrin bushings would be the wear item since they are made from the softer material, and I can easily buy or make plenty of them and replace them every year. The diameter of my current pintles where they go into the gudgeons is 3/8 on an inch. I don’t really have a problem with that, I’m sure that they are strong enough, but I guess that going to ½ inch would give more bearing surface on the delrin, and allow it to wear longer. Depending on what condition my current pintles are in, I might just make two new bushings for the CD gudgeons 3/8 inch I.D. Do you think my boat would go faster if I made them from Teflon instead of delrin? They both machine like butter. Thanks again for your replies, it’s great to have someone to discuss these little things with while it’s snowing outside. Aldo

Kick-up rudder with 1/2 inch gudgeon Aldo: I will address your last post essentially in the order of your questions. First, regarding your question to Ken Palmer, I will take the unauthorized liberty to answer for him as I think he may be using special ½ inch pins in his kick-up rudder that originally has 3/8 inch pins. I recently discovered that Catalina Direct provides special pins that are ½ inch for the part that enters the gudgeon but 3/8 inch for the part that goes onto the head of a kick up rudder. One sees this upper special pin at http://tinyurl.com/5wjn6 and the lower special lower pin at http://tinyurl.com/5726y These pins permit kick-up rudders with 3/8 inch pins to use the Catalina Direct ½ inch upgrade gudgeons with the delrin insert. One replaces the original 3/8 pins in the kick-up rudder with these special pins that are 3/8 inch for the rudder head and ½ inch for the gudgeon. After reading Ken’s comments, I really think he employed these pins himself, but for some reason he failed to mention this. Depending how adapt you are with your metal turning apparatus, you might make up these pins yourself. Nevertheless, I think their design will follow the Catalina Direct special pins. Second, my rudder floats. Keeping the rudder bone dry in the cabin when not in use does indeed create wonderful benefits. Nevertheless, I discovered that my rudder floats the hard way when I accidentally dropped it into about six feet of water. After panicking as the rudder dropped well below the surface, it pleasantly surprised me to watch it float up. So, I do not require any items to secure the rudder to my vessel. No life line, no leaf spring, both of which would be more of a hindrance when setting up and removing my rudder. Regarding the weight of rudders, you may want to read an article by Dennis Slaton, the skipper of Tar Baby. This is at http://tinyurl.com/4fke2 Third, in light of Ken Palmers very positive experiences with the Catalina Direct ½ inch gudgeon and pintle upgrade with a kick-up rudder like yours, I think you should go ahead with the upgrade. However, do so with the advisement of certain caveats. As you have an “early” boat, you will need to employ the four hole pattern gudgeon. The four hole pattern on the Catalina direct upgrade may have different hole centers than your current gudgeons. This, as noted earlier, was the case for me, and as I subsequently understand is apparently not a unique case. So, if you find the Catalina Direct ½ inch upgrade four hole pattern hole centers do not line up with yours, you will need to plan to rectify the situation. You can enlarge the holes on the upgrade gudgeons. However, as a process it is a poor course, although it should work well and is far simpler than alternatives. If you find that after removing the old gudgeon the tapped metal plate stays in place inside the transom, you may decide that dickering around with that metal plate would be such a hassle, that hole enlargement is the wisest course. You can fill the old holes and drill new holes into your transom. However, you will then need to remove the old strap for holding the screws on the upper gudgeon and make up a new tapped strap for holding the screws on or cut an inspection hole in the cockpit transom wall to reach nuts that hold the gudgeon screws. This is considerable more work than just enlarging the holes. Further, as the new holes must line up perfectly to afford smooth rudder operation, one must take great care in the drilling operation. After you put in the new gudgeons, you can make up whatever inserts you wish of whatever materiel you wish to your heart’s content. I think the metal hole in these new gudgeons is about 5/8 inch in diameter. The hole in the delrin insert is, of course, ½ inch. However, you could experiment with your own insert with a 3/8 inch hole. So I hop all this beneficial to Aldo. Good luck in your projects, and keep ‘em floating.

Link error in Bayard Gross post Of course, the edit function for replies seems to have vanished. Nevertheless, the post written just before this one contains an error in the third instance of "Link submitted by author" Below is the correct link for the Dennis and Pan Slaton Article about rudders.

Thanks guys for all the info on C22 I have been following your discussion closely & feel like I have just completed a diploma course in C22 rudder/gudgeon/pintle. I sail a 1980, hull #9102, swing keel, kick up rudder. My 3/8" pintles are the original. There is some wear but not excessive & works OK for me. One comment I will make. The pintle shank where it fits into the aluminum rudder head is 5/16" with NC thread. (not 3/8") Is the 1/2" upgrade also 5/16" on the shank? On mine, the top pintle is longer with the leaf spring keeper. Without thinking of the consequences, I always leave my rudder in the down position when parked. I have kept the finish paint coat in good shape & feel there is no water in the rudder. The alumnum head & rudder weighs 28 pounds. Does this weight sound correct? I made a 1/4" thick, soft rubber washer approx 6" in diameter to fit between the aluminum rudder head & the rudder to provide more friction. It never kicks up except when needed. I think a few months ago, I saw the C22 parts manual on-line but can't find it now. This illustrated manual showed every nut & bolt on the boat. Do you know where this is on-line or is this just wishful thinking? Thanks again for your contributions to this board. Bob B.

Will it Float??? Thanks again Bayard and Bob. Bob: I had the bolt that my rudder pivots on snap one time while I was motoring back to my slip several years ago. I didn't realize it at first, but the tiller felt really sloppy. I have plastic shims on each side of my rudder, between the fiberglass blade and the aluminum housing. I was never successful with using just the clamp to keep the rudder blade from rotating back when sailing. That's why I added the nylon shear pin. Even if the blade moves back an inch, it greatly multiplys the force on the tiller. I'm always amazed at how many C-22 sailors haven't figured this out yet. Anyhow, back to my story. When the rudder broke, the locking handle, of course, went into the water. I made a new handle from a piece of 3/4 inch hex stainless steel. I have used this handle ever since, and it is fine. I actually like it better than the original handle. I replaced the bolt with a high strength stainless bolt. So Bob, you might want to replace your bolt in the rudder too, since you are depending on your clamping force to keep the rudder from kicking up, and since you are probably putting plenty of force onto the bolt. As they ask on the David Letterman Show, "Will it Float", that is, will the blade of the rudder float if it comes out of the housing? I really don't know, but I would bet that it would sink. I glad you wrote with your solution to the kick-up issue. This is about the forth solution that I know of. The first is Catalina's with a detent pin. The second involves bungie cord pulling up on the rudder blade, in front of the pivot point. Using a shear pin is the third, and now your solution with a big rubber pad is the fourth. Aldo

For Bob B I will attempt to address your questions to the best of my knowledge. Please keep in mind, I do not have a kick-up rudder and I have no experience with it. I have a standard rudder, which at least for the pintles, is quite different from the pintles on a kick-up rudder. I do not know the diameter of the threaded part on the pintles for the kick-up rudder. However, I understand that Aldo has made his own replacement pintles, so he would be the definitive expert here. Nevertheless, based upon the pictures and information in the link in the previous post, I would think the Catalina Direct ½ inch upgrade would have 5/16 on the shank as these pintles are supposed to replace the 3/8 inch pintles that you currently have. Nonetheless, your question is a good one that perhaps Ken Palmer who did the Catalina Direct 1/2 inch upgrade with a kick-up rudder with 3/8 inch pintles originally may best answer. Regarding pintle length, for all boats, not just the Catalina 22, with a transom mount rudder, kick-up or standard, the shorter pintle almost universally always goes on top. The rational for this is that it should be easier to install and remove the rudder when the upper pintle is shorter than the lower pintle and therefore enters its gudgeon after the lower pintle starts to enter its gudgeon and helps to align the upper pintle into its gudgeon. Your pintles are backwards. However, I do not think this is necessarily bad, but as it does not follow convention, you may wish to switch your pintles around and see if installation and removal are easier. The metal head in the kick up rudder makes it heavier than the standard rudder. If you read the article by Dennis and Pam Slaton that I mentioned earlier with a link (and link correction), I think you will draw the same conclusion as I and decide that twenty-eight pounds sounds correct for your kick-up rudder. However, you need better expert advice on this than I can provide. If you want to know what happens to a rudder when it gets soaked and breaks, please see http://catalina22fleet20.home.comcast.net/news/rpts/200306/200306.htm#WhatsInsidetheRudder While this article refers to a standard rudder, the same should apply to the blade on a kick-up rudder. So after looking at this, you may decide it is not too much an inconvenience to ship your rudder into your cabin following sailing. Keep in mind, a new blade from Catalina Direct is more than $300 and has heavy shipping charges to boot. That’s USA dollars, Canadian would be higher, although the way things are going, maybe it will be cheaper in the future. Your solution to the kick-up rudder problems appears meritorious in its simplicity. There are many solutions to the friction problem, and if you like yours, then so be it. Again as stated earlier, I have no experience with these kick-up rudder issues. A C-22 parts manual? Thinking that I would know anything about that is wishful; however, maybe its back to the old search engine routine. Well, Bob, enough said at this time. Stay warm

Bad Link Bob Sorry for the incorrect link in the just prvious post. The lack of the edit function, that used to be here, drives me crazy. Nevertheless, the link you want is: http://tinyurl.com/4j2vl

How about, Will it break???, Aldo Aldo, floating may be only half the issue. As I provided in the just previous post, you too might want to see what happens when a C-22 rudder breaks, and then you too may decide that inconvenience of shipping into the cabin is less than more than three hundred dollars for a new blade. Not to mention a possibly ruined summer excursion. If the rudder blade floats, then maybe you could watch it float away when it breaks. If it sinks, then perhaps the heartbreak and wide-eyed wonder of watching it float away will be mitigated by its perpetual disposal into Davy Jones locker. On the other hand, this could give you a wonderful excuse to get a new standard rudder and be done with all those annoying slipping kick-up rudder problems forever.

- This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register. By continuing to use this site, you are consenting to our use of cookies. Accept Learn more…

Currency: GBP

- Worldwide Delivery

Mooring Warps and Mooring Lines

- LIROS 3 Strand Polyester Mooring Warps

- LIROS Green Wave 3 Strand Mooring Warps

- LIROS Braided Dockline Mooring Warps

- LIROS Handy Elastic Mooring Warps

- Marlow Blue Ocean Dockline

- LIROS Super Yacht Mooring Polyester Docklines

- 50 metre / 100 metre Rates - Mooring

Mooring Accessories

- Mooring Compensators

Mooring Strops and Bridles

- V shape Mooring Bridles

- Y shape Mooring Bridles

- Small Boat and RIB Mooring Strops

- Mooring Strops

- Mooring Strops with Chain Centre Section

Mooring Assistance

- Coastline Bow Thruster Accessories

- Max Power Bow Thrusters

- Bonomi Mooring Cleats

- Majoni Fenders

- Polyform Norway Fenders

- Ocean Inflatable Fenders

- Dock Fenders

- Fender Ropes and Accessories

Mooring Components

- Mooring Swivels

- Mooring Shackles

- Mooring Cleats and Fairleads

- Mooring Buoys

Mooring Information

- Mooring Warps Size Guide

- Mooring Lines - LIROS Recommended Diameters

- Mooring Rope Selection Guide

- Mooring Warp Length and Configuration Guide

- How to estimate the length of a single line Mooring Strop

- Mooring Ropes - Break Load Chart

- Mooring Compensator Advisory

- Rope Cockling Information

- Fender Size Guide

- Majoni Fender Guide

- Polyform Norway Fender Inflation Guide

Custom Build Instructions

- More Article and Guides >

Anchor Warps Spliced to Chain

- LIROS 3 Strand Nylon Spliced to Chain

- LIROS Anchorplait Nylon Spliced to Chain

Anchor Warps

- 50 / 100 metre Rates - Anchoring

- Drogue Warps and Bridles

- Leaded Anchor Warp

- LIROS 3 Strand Nylon Anchor Warps

- LIROS Anchorplait Nylon Anchor Warps

- Aluminium Anchors

- Galvanised Anchors

- Stainless Steel Anchors

Calibrated Anchor Chain

- Cromox G6 Stainless Steel Chain

- G4 Calibrated Stainless Steel Anchor Chain

- Lofrans Grade 40

- MF DAMS Grade 70

- MF Grade 40

- Titan Grade 43

- Lewmar Windlasses

- Lofrans Windlasses

- Maxwell Windlasses

- Quick Windlasses

- Windlass Accessories and Spares

Chain Snubbers

- Chain Hooks, Grabs and Grippers

- Chain Snubbing Bridles

- Chain Snubbing Strops

Anchoring Accessories

- Anchor Connectors

- Anchor Trip Hooks and Rings

- Anchoring Shackles

- Bow Rollers and Fittings

- Chain and Anchor Stoppers

- Chain Links and Markers

Anchoring Information

- How To Choose A Main Anchor

- Anchoring System Assessment

- Anchor Chain and Rope Size Guide

- The Jimmy Green Guide to the Best Anchor Ropes

- What Size Anchor Do I Need?

- Anchor Size Guides

- Anchor Rope Break Load and Chain Compatibility Chart

- How to Choose Your Anchor Chain

- How to Establish the Correct Anchor Chain Calibration?

- Calibrated Anchor Chain - General Information

- Calibrated Anchor Chain Quality Control

- Calibrated Chain - Break Load and Weight Guide

- Galvanising - Managing Performance and Endurance expectation

- Can Galvanised Steel be used with Stainless Steel?

- Windlass Selection Guide

- More Articles and Guides

Stainless Steel Wire Rigging and Wire Rope

- 1x19 Wire Rigging

- 50 / 100 metre Rates - Wire and Fibre

- 7x19 Flexible Wire Rigging

- Compacted Strand Wire Rigging

Dinghy Rigging

- Dinghy Rigging Fittings

- Fibre Dinghy Rigging

- Stainless Steel Dinghy Rigging

- Wind Indicators

Fibre Rigging

- DynIce Dux Fibre Rigging

- LIROS D-Pro Static Rigging

- LIROS D-Pro-XTR Fibre Rigging

- Marlow Excel D12 MAX 78 Rigging

- Marlow M-Rig Max Rigging

Wire Terminals

- Cones, Formers, Wedges, Ferrules, Rigging Spares

- Hi-Mod Swageless Terminals

- Sta-Lok Swageless Terminals

- Swage Terminals

- Headsail Reefing Furlers

- Plastimo Jib Reefing

- Selden Furlex Reefing Gear

Furling Systems

- Anti-torsion Stays

- Straight Luff Furlers

- Top Down Furlers

Guard Wires, Rails and Fittings

- Guard Rail Fittings

- Guard Rails in Fibre and Webbing

- Guard Wire Accessories

- Guard Wires

Wire Rigging Fittings

- Babystay and Backstay Adjustment

- Terminal Backing Plates and Coquilles

- Turnbuckles and Rigging Screws

Rigging Accessories

- Rigging Chafe Protection

Standing Rigging Assistance

- More Articles and Guides >

- Cruising Halyards

- Performance Halyards

- Dinghy Halyards

Rigging Shackles

- Captive and Key Pin Shackles

- hamma™ Snap Shackles

- Soft Shackles

- Standard Snap Shackles

- Wichard Snap Shackles

Classic Ropes

- Classic Control Lines

- Classic Halyards

- Classic Sheets

- Cruising Sheets

- Performance Sheets

- Dinghy Sheets

Sail Handling

- Boom Brakes and Preventers

- Lazy Jack Sail Handling

- Rodkickers, Boomstruts

- Sail Handling Accessories

50 / 100 metre Rates - Running Rigging

- 50 / 100 metres - Cruising Ropes

- 50 / 100 metres - Dinghy Ropes

- 50 / 100 metres - Performance Ropes

Control Lines

- Cruising Control Lines

- Performance Control Lines

- Dinghy Control Lines

- Continuous Control Lines

Running Rigging Accessories

- Anti-Chafe Rope Protection

- Lashing, Lacing and Lanyards

- Mast and Boom Fittings

- Rope Stowage

- Sail Ties and Sail Stowage

- Shock Cord and Fittings

- LIROS Ropes

- Marlow Ropes

Running Rigging Resources

- Running Rigging Rope Fibres and Construction Explained

- How to Select a Suitable Halyard Rope

- How to select Sheets and Guys

- Dyneema Rope - Cruising and Racing Comparison

- Dinghy Rope Selection Guide

- Rope Measurement Information

- Running Rigging - LIROS Recommended Line Diameters

- Running Rigging Break Load Comparison Chart

- Colour Coding for Running Rigging

- Selecting the right type of block, plain, roller or ball bearing

- Replacing your Furling Line

- Recycling Rope

- Running Rigging Glossary

Custom Build Instructions for Sheets, Halyards, Control Lines

Plain bearing blocks.

- Barton Blocks

- Harken Element Blocks

- Low Friction Rings

- Selden Yacht Blocks

- Wichard MXEvo Blocks

- Wooden Yacht Blocks

Control Systems

- Ratchet Blocks

- Stanchion Blocks and Fairleads

- Snatch Blocks

- Genoa Car Systems

- Traveller Systems

- Block and Tackle Purchase Systems

Ball Bearing Blocks

- Harken Ball Bearing Blocks

- Selden Ball Bearing Blocks

Roller Bearing Blocks

- Harken Black Magic Blocks

- Selden Roller Bearing Blocks

Deck Fittings

- Bungs and Hatches

- Bushes and Fairleads

- Deck Eyes, Straps and Hooks

- Pad Eyes, U Bolts and Eye Bolts

- Pintles and Gudgeons

- Tiller Extensions and Joints

- Harken Winches, Handles and Accessories

- Barton Winches, Snubbers and Winchers

- Lewmar Winches, Handles and Accessories

- Winch Servicing and Accessories

Clutches and Organisers

- Barton Clutches and Organisers

- Spinlock Clutches and Organisers

- Lewmar Clutches

- Harken Ball Bearing Cam Cleats

- Barton K Cam Cleats

Deck Hardware Support

- Blocks and Pulleys Selection Guide

- Barton High Load Eyes

- Dyneema Low Friction Rings Comparison

- Seldén Block Selection Guide

- Barton Track Selection Guide

- Barton Traveller Systems Selection Guide

- Harken Winch Selection Guide

- Karver Winch Comparison Chart

- Lewmar Winch Selection Guide - PDF

- Winch Servicing Guide

Sailing Flags

- Courtesy Flags

- Red Ensigns

- Blue Ensigns

- Signal Code Flags

- Flag Staffs and Sockets

- Flag Accessories

- Flag Making and Repair

- Webbing only

- Webbing Soft Shackles

- Webbing Restraint Straps

- Webbing Sail Ties

- Sail Sewing

- PROtect Tape

Fixings and Fastenings

- Screws, Bolts, Nuts and Washers

- Monel Rivets

Hatches and Portlights

- Lewmar Hatches

- Lewmar Portlights

- Fids and Tools

- Knives and Scissors

General Chandlery

- Carabiners and Hooks

- Antifouling

Chandlery Information

Flag articles.

- Flag Size Guide

- Bending and Hoisting Methods for Sailing Flags

- Courtesy Flags Identification, Labelling and Stowage

- Courtesy Flag Map

- Flag Etiquette and Information

- Glossary of Flag Terms and Parts of a Flag

- Making and Repairing Flags

- Signal Code Message Definitions

Other Chandlery Articles

- Anchorplait Splicing Instructions

- Antifoul Coverage Information

- Hawk Wind Indicator Selection Guide

- Petersen Stainless - Upset Forging Information

- Speedy Stitcher Sewing Instructions

- Thimble Dimensions and Compatible Shackles

Jackstays and Jacklines

- Webbing Jackstays

- Stainless Steel Wire Jackstay Lifelines

- Fibre Jackstay Lifelines

- Jackstay and Lifeline Accessories

Lifejackets

- Children's Life Jackets

- Crewsaver Lifejackets

- Seago Lifejackets

- Spinlock Lifejackets

Floating Rope

- LIROS Multifilament White Polypropylene

- LIROS Yellow Floating Safety Rope

Guard Wires, Guardrails and Guardrail Webbing

Lifejacket accessories.

- Lifejacket Lights

- Lifejacket Rearming Kits

- Lifejacket Spray Hoods

- Safety Lines

Seago Liferafts

- Grab Bag Contents

- Grab Bags and Polybottles

- Liferaft Accessories

- Danbuoy Accessories

- Jimmy Green Danbuoys

- Jonbuoy Danbuoys

- Seago Danbuoys

Overboard Recovery

- Lifebuoy Accessories

- Purchase Systems

- Slings and Throwlines

Safety Accessories

- Fire Safety

- Sea Anchors and Drogues

Safety Resources

- Guard Wires - Inspection and Replacement Guidance

- Guard Wire Stud Terminal Dimensions

- Webbing Jackstays Guidance

- Webbing Jackstays - Custom Build Instructions

- Danbuoy Selection Guide

- Danbuoy Instructions - 3 piece Telescopic - Offshore

- Liferaft Selection Guide

- Liferaft Servicing

- Man Overboard Equipment - World Sailing Compliance

- Marine Safety Information Links

- Safety Marine Equipment List for UK Pleasure Vessels

Sailing Clothing

- Sailing Jackets

- Sailing Trousers

- Thermal Layers

Leisure Wear

Accessories.

- Rain Jackets

- Sweatshirts

Sailing Footwear

- Dinghy Boots and Shoes

- Sailing Wellies

Leisure Footwear

- Walking Shoes

Sailing Accessories

- Sailing Bags and Holdalls

- Sailing Gloves

- Sailing Kneepads

Clothing Clearance

Clothing guide.

- What to wear Sailing

- Helly Hansen Mens Jacket and Pant Size Guide

- Helly Hansen Womens Sailing Jacket and Pant Size Guide

- Lazy Jacks Mens and Womens Size Charts

- Musto Men's and Women's Size Charts

- Old Guys Rule Size Guide

- Sailing Gloves Size Guides

- Weird Fish Clothing Size Charts

The Jimmy Green Clothing Store

Lower Fore St, Beer, East Devon, EX12 3EG

- Adria Bandiere

- Anchor Marine

- Anchor Right

- August Race

- Barton Marine

- Blue Performance

- Brierley Lifting

- Brook International

- Brookes & Adams

- Captain Currey

- Chaineries Limousines

- Coastline Technology

- Colligo Marine

- Cyclops Marine

- Douglas Marine

- Ecoworks Marine

- Exposure OLAS

- Fire Safety Stick

- Fortress Marine Anchors

- Hawk Marine Products

- Helly Hansen

- International

- Jimmy Green Marine

- Maillon Rapide

- Mantus Marine

- Marling Leek

- Meridian Zero

- MF Catenificio

- Ocean Fenders

- Ocean Safety

- Old Guys Rule

- Petersen Stainless

- Polyform Norway

- PSP Marine Tape

- Sidermarine

- Stewart Manufacturing Inc

- Team McLube

- Technical Marine Supplies

- Titan Marine (CMP)

- Ultramarine

- Waterline Design

- William Hackett

Clearance August Race Boat Cleaning Kit £26.00

Clearance LIROS Racer Dyneema £55.08

Clearance Folding Stock Anchor £123.25

Clearance LIROS Herkules £0.00

Clearance Barton Size 0 Ball Bearing Blocks - 5mm £10.13

Clearance Marlow Blue Ocean® Doublebraid £18.48

Mooring Clearance

Anchoring clearance, standing rigging clearance, running rigging clearance, deck hardware clearance, chandlery clearance, safety clearance.

Barton Rudder Gudgeons

Reference: BRS-BA42519

Marine grade stainless steel

Durable black nylon

Select by width = gap between straps

Drilled for 5mm fixings

9.5mm diameter pintles

- Rudder Gudgeon - 19mm

- Rudder Gudgeon - 22mm

- Rudder Gudgeon - 35mm

- Rudder Gudgeon - 50mm

PayPal Credit is a credit line for your PayPal account that acts like a credit card for online shopping. You can get approved for a limit, use it at stores that accept PayPal, and make repayments directly through your PayPal balance.

They offer 0% interest for 4 months on purchases of £99 and over and allow you to pay in instalments with businesses like Jimmy Green Marine.

Apply online if you're a UK resident over 18 with a good credit history.

More Information

Barton Rudder Pintles and Gudgeons are manufactured from tough, durable black nylon mouldings and marine grade stainless steel.

Available in 4 sizes to suit 19mm, 22mm, 35mm and 50mm thickness of rudder stock.

i.e. the sizing refers to the gap between the straps.

Diameter for all pintles = 9.5mm

All Pintles and Gudgeons have drilled holes for 5mm fixings.

There are 3 fastening points on the pintle and 2 on the gudgeon.

Sold separately

Holt Stainless Steel Nuts and Bolts

Holt stainless steel pozi head screws, seasure penny washers, holt stainless steel nut pre-pack, holt stainless steel washer pre-pack, you may also like, barton rudder pintles, seasure transom pintles, seasure transom gudgeons, barton transom gudgeon, barton transom pintle.

Product Reviews

Rudder Hardware

For an easily installed rudder

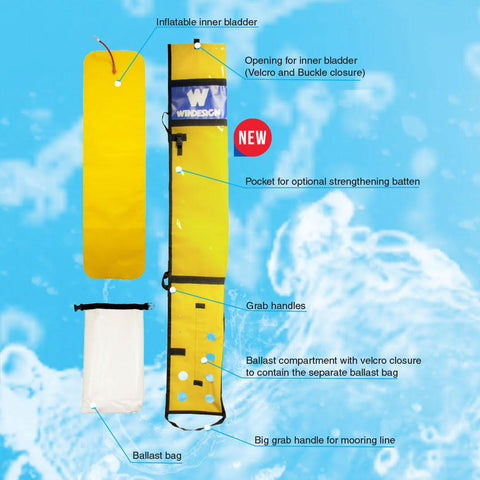

From Issue December 2022