Propulsion Systems for Monohull

The silence of an Oceanvolt electric propulsion is a skipper's dream. Whether quietly maneuvering through a harbor or motor-sailing on low-wind days to create your own apparent wind, our electric solutions will enhance and extend your sailing enjoyment.

Oceanvolt offers Hybrid or Electric systems as a power & propulsion option in partnership with many leading monohull boat builders - adding new partners continuously. We also offer repowering solutions for converting away from legacy diesel engines – removing the diesel engine, fuel tanks and exhaust system - cleaning up greasy, smelly engine compartments and freeing up both weight and space below deck.

Oceanvolt systems are scaled and configured to achieve maximum efficiency - taking into consideration boat length, beam and displacement as well as system weight and placement within the boat. Range, beyond battery capacity, is extended through hydro generation while sailing above 6kn. This can be complemented with either a portable AC generator or a DC generator (in larger boats or for long distance cruising).

All Oceanvolt systems are engineered to operate at 48 volts for passenger safety and ease of repair. Oceanvolt systems are extremely low maintenance and do not require winterizing (no annual engine maintenance/storage costs).

system & price examples

Owner testimonials.

Maxi Dolphin MD55

RM Yachts RM 1180

Sirius 40 DS

- THE PRINCESS PASSPORT

- Email Newsletter

- Yacht Walkthroughs

- Destinations

- Electronics

- Boating Safety

- Uncategorized

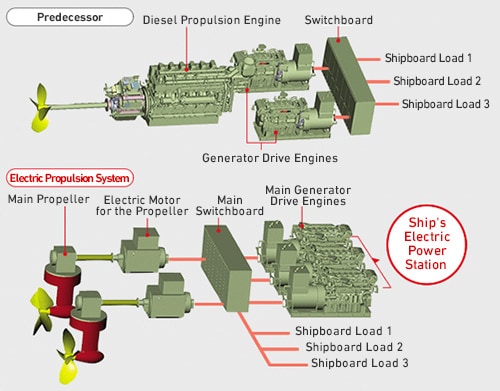

Diesel Electric Drive

- By Chuck Husick

- Updated: October 4, 2007

Siemens EcoProp

Your next yacht may be powered with a new, but at the same time old and extensively proven, power system-a diesel electric drive. First used in 1903 to propel the triple-screw Russian tanker Vandal on the Volga River and Caspian Sea, diesel electric propulsion is now used in the most modern cruise ships and in thousands of other commercial vessels. Although the idea of powering your yacht with the indirect, two-step diesel electric energy transfer system may appear to be unnecessarily complex, its many advantages can make it a compellingly attractive alternative to a conventional direct mechanical prop-shaft drive.

The benefits of diesel electric drive begin with the design freedom the system affords the yacht’s designer. The engine can be installed wherever appropriate to achieve optimum use of space for the accommodation. Noise and vibration are more easily suppressed than in a conventional direct engine-to-propeller drive. Turning the props with electric motors enhances slow-speed maneuverability by providing unrestricted minimum prop speeds with 100 percent torque available to provide immediate power response at all times. Prop synchronization is automatic and extremely precise. When under way all of the electrical power required by the vessel can be supplied from the diesel electric propulsion system, eliminating the need to run a genset. A diesel electric power system can drive multiple propellers from a single engine or use multiple engines to power one or more props. In a twin-engine/twin-prop system, one engine can power both props when operating within the speed limits imposed in many areas. Electrical power from the vessel’s genset can be used to propel the boat, providing a built-in backup-especially valuable for yachts with single-engine installations. Conversely, the propulsion system can serve as a backup for the yacht’s gensets.

The more than 100-year history of marine diesel electric systems began as a response to the impossibility of quickly reversing the direction of rotation of early direct-to-prop-shaft-coupled diesel engines. With a diesel-powered direct current (DC) generator and a DC motor connected to the prop shaft, the direction of prop rotation could be controlled by a switch. The 100 percent torque, zero-speed capability of the electric motor led to the overwhelming use of diesel electric power for railroad locomotives. Diesel electric drives found a natural application in submarines and many surface ships. Today’s cruise ships, where 70-80 percent of the total onboard power is required for the “hotel” side of the vessel, are diesel electric powered. The power demands can be enormous at times. A trivial example: 1,500,000 watts, equal to more than 1,400 hp, is needed to simultaneously power half of the 1,500-watt hair dryers on a 1,400-stateroom cruise ship.

While the equipment designed to serve the massive needs of cruise ships is unsuitable for any reasonable-sized yacht, numerous land-mobile applications including buses, very large trucks and the cranes used in container ports need power levels similar to those required by a yacht. These land-mobile applications require high overall efficiency, installation flexibility, virtually 100 percent torque at close to zero speed and must meet demanding reliability and durability standards. Fortunately, equipment designed and perfected for these uses is ideal for propelling many types of yachts.

From the helmsman’s standpoint the Siemens diesel electric propulsion system is totally transparent, functioning identically to a conventional power control system, with some welcome and useful advantages. In a twin-prop installation, two conventional-appearing single-lever electronic power controls send commands to the drive control system computer (DICO in Siemens’ terms). Digital messages from the DICO manage the diesel engine’s speed governor and control the current flow from the propulsion converters to the prop-drive motors. The power curve of the engine is programmed into the control computer and used to set engine rpm to the speed that provides the required power with optimum fuel efficiency. It is generally unnecessary for the helmsman to monitor engine rpm. Placing a prop control in neutral allows the prop to freewheel, with no risk of damaging the gearbox, a benefit when the vessel is propelled by the other prop. There are no restrictions on rapid movement of the control from ahead to astern. Moving both controls beyond a preselected prop shaft speed, usually about 400 rpm, will automatically and very precisely synchronize the propellers. In fact, the precision with which the system “knows” the relative rotational position of each prop shaft appears to be sufficient to allow future addition of a prop-phase relationship control. Vibration and noise can be minimized with careful control of the relative position of the blades on one prop with those on the other prop. This technique is common on many multiengine aircraft and is called prop phasing.

In a diesel electric system, the engine can be mounted virtually anywhere in the hull and in whatever orientation is required to achieve optimum use of space. With no need to provide a mechanical power-transfer connection to the hull, the engine mounts can be chosen for optimum vibration isolation. If desired, the engine can be totally enclosed in a sound shield, providing superior sound attenuation without the need to insulate an entire compartment. The incorporation of thrust bearings on the prop shafts ensures precise alignment with the “P” bracket and the prop-drive gearbox, reducing wear on the cutlass bearing and shaft noise. The small size of the prop-drive motor and gearbox also makes it possible to locate the props at the most advantageous position on the hull-a great advantage.

A typical Siemens single-engine twin-prop diesel electric propulsion system is comprised of a permanent magnet three-phase alternator powered by the diesel engine through a speed-increasing gearbox, two short-circuit-proof solid state power inverter modules, two 3-phase permanent magnet prop-drive motors, associated prop-drive gearboxes, a control computer and a conventional-appearing helm control station. System components are surprisingly compact and lightweight. The 145 kW (194 hp) alternator suitable to power a 48-foot trawler yacht is 10 inches square, 22 inches long and weighs 264 pounds. Each of the 114 hp drive motors is similar in size and weight. The 40 x 23 x 7 inch inverter modules are typically bulkhead mounted. The spiral bevel gearboxes used to connect the alternator to the driving engine and the drive motors to the propellers are 98 percent efficient and have a medium duty life expectancy of 25,000 hours. Gearbox power capacities range from 150 to 600 hp, meaning that they can be coupled to multiple alternators or motors to meet the power requirements of larger vessels. All of the system’s power-handling components, alternators, motors, gearboxes and power inverters are cooled with a circulating flow of water/glycol. The system is also continuously monitored, by using temperature sensors built into the alternators, motors, gearboxes and inverters.

Operating efficiency is an important part of the evaluation of any power delivery system. Although the alternators, inverters, motors and gearboxes used in the Siemens system operate efficiently, the total energy loss through the system will typically exceed the losses imposed by a conventional marine gear-coupled drive. However, the efficiency loss is to a large degree offset by the ability of the electronic control to precisely match the engine’s power curve to the vessel’s propellers. In a conventional direct mechanical prop-drive system, the fixed pitch propeller can be matched to the engine and the hull at only one point, maximum engine rpm. At all other engine speeds the engine turns faster than is necessary to produce the required power. The diesel electric drive matches the prop load to the engine, producing a result similar to that achieved with use of a controllable pitch prop. Using one large engine to power two propellers can provide an efficiency advantage compared with use of two engines providing the same total power. Depending on the positioning of the engine, power loss due to exhaust backpressure may be less than what can be achieved in a conventional installation. The option of drawing the vessel’s AC house power from the propulsion system when under way, eliminating the need to run the vessel’s genset, can improve fuel efficiency. Overall, the fuel economy of the diesel electric drive will be close to or as good as what can be achieved using a direct-drive system.

In many installations the cost of a single-engine twin-prop diesel electric power system will be no more than a conventional twin-engine direct-mechanical drive installation. Properly integrated into the design of the vessel, the diesel electric drive’s many attributes will likely make it the preferred propulsion system for a growing number of yachtsmen.

Contact: www.sea.siemens.com/marine/ .

- More Uncategorized

BoatUS Launches Online Advocacy Tool

Dock Danger

A Dream Fulfilled

3 America’s Cup Hashtags to Follow

For Sale: 2021 Hatteras Yachts GT59 Convertible

Price Reduction: 114-foot Hargrave “Brandi Wine”

10 Motoryachts Over 80 Feet For Sale Now

Top Five Common Marine Generator Issues

- Digital Edition

- Customer Service

- Privacy Policy

- Email Newsletters

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

- Subscribe Now

- Digital Editions

Volvo Penta D4 Hybrid first look: Is this the future of boat propulsion?

- Electric boats

- Top stories

Hugo Andreae gets an exclusive insight into Volvo Penta’s plans for a range of new diesel electric hybrid engines, starting with the Volvo Penta D4 Hybrid…

Volvo Penta has revealed a fascinating insight into its greener future with the launch of its first diesel electric hybrid leisure boat engine.

Although still a prototype, it is based on a standard 320hp D4 engine and DPI sterndrive with an electric motor/generator added to the driveline.

Speaking exclusively to MBY , sales project manager, Jonas Karnerfors, has confirmed that this will form the basis of a range of production Volvo Penta D4 and D6 hybrid engines.

To assess how well it works in the field, two of the prototype engines have been fitted to a 50ft aluminium fast cruiser.

Built by Marell Boats Sweden and operated by Hurtigruten Svalbard, a Norwegian-based adventure travel company, it will take visitors into the remote and environmentally sensitive waters of the Svalbard archipelago approximately halfway between Norway and the North Pole.

Recommended videos for you

Article continues below…

Electric boats: A-Z of the 37 best all-electric models

Candela c-pod drive system aims to scale up the electric boats revolution.

The sub-zero temperatures and long running hours (it is expected to clock up 1,000 hours this year) will provide a rigorous test of the engines’ reliability, while their ability to run almost silently in electric boat mode should minimise disruption to wildlife and improve the visitor experience.

Hybrid modes

Volvo is not yet ready to share full technical details of the new hybrid engine, such as the power rating of the electric motor or size of the lithium ion battery pack, but has confirmed to MBY that the parallel hybrid system will offer three different driving modes: electric, hybrid and power.

In electric mode, it will only be capable of speeds up to around 10 knots but should be able to cruise at 5-6 knots for up to five hours, giving a range of around 30nm on battery power alone.

In hybrid mode the system itself will select whether to use the electric motor, the diesel engine or both depending on a number of different factors such as speed and battery state. In power mode both the diesel engine and electric motor will run concurrently to boost acceleration and speed.

The electric motor adds less than 500mm to the length of a D4. The battery is mounted remotely.

In fact, the electric motor actually replaces the mechanical supercharger normally fitted to the D4 and D6 engines by providing a similar torque boost to bridge the throttle lag at low RPM before the turbochargers kick in.

In the case of the Hurtigruten boat, the two 320hp hybrid engines are expected to deliver a top speed of 32 knots and a constant cruising speed of 25 knots.

Although the electric motor will be fully integrated into the driveline, adding less than 500mm to the length of the engine, the battery itself can be fitted remotely to ease packaging constraints in the engine bay.

The Marell M15 is an ideal test bed for the new technology combining lots of high and low speed running in sub-zero conditions

This can either be charged in the marina to minimise fuel burn or while the diesel engine is running. In the latter case, the system’s control unit is programmed to take advantage of the unused potential between the power that it is currently being used to propel the boat and its actual peak efficiency to recharge the batteries as efficiently as possible.

Both the driving and charging modes can be selected manually by the operator or left in fully automatic mode for the engine management system to decide.

Crucially, Volvo is determined to offer the hybrid drivetrain as an off-the-shelf package that includes the battery and propulsion unit rather than letting boat manufacturers or customers choose their battery supplier.

It hasn’t yet committed to a launch date for the production units but did indicate to MBY that it was likely to be within the next five years.

One of the big determining factors will be the size, availability and price of the battery packs. At the moment this is by far the most expensive component of the hybrid package, more than tripling the cost of a conventional Volvo Penta D4 diesel engine.

The hope is that battery density and price will come down substantially in the next few years as the drive towards electric vehicles brings reduced production costs.

Pay as you go

In the meantime Volvo is experimenting with a new form of pay-by-the-hour billing that will see Hurtigruten’s owners charged according to kW hours of engine use rather than the much higher upfront capital expenditure of buying the engines outright.

Volvo says this is an experiment in what it calls “e-mobility as a service”, and is said to be attracting a lot of interest from commercial operators.

However, it’s harder to see how the numbers would add up for leisure boat owners, who typically only run their engines for around 50-60 hours a year.

The ability to cruise in silence for up to 5 hours at a time will be ideal for wildlife watching in Svalbard. Photo: Daniel John Benton

The pilot programme is being run in partnership with Marell Boats and the Hurtigruten Group, giving Volvo a vital insight into how the new engines will integrate into the boat manufacturing process as well as how they perform in a real world environment.

Volvo is confident that the hybrid engines’ longer footprint should fit into the majority of existing boats’ engine bays but finding a suitable space for the batteries that doesn’t upset the weight distribution may prove trickier on some craft.

Volvo Penta D4 Hybrid test results

Jonas is confident that by the end of the season, the Hurtigruten test will have provided all the information needed to finalise the technical specification of the production engines.

That will just leave the question of when to make them available to the wider public and at what price they will be offered.

Either way Volvo is adamant that it is committed to launching a full range of hybrid engine solutions, not just for the D4 and D6 engines but right across its marine portfolio, including its larger IPS offerings.

“Our aim is to be the world leader in sustainable power solutions,” Jonas explains. “To do this we want to partner with companies that have the vision and courage to join us.”

What we know so far about Enata’s designer foiling motor boat, Vatoz

Cormate chase 32 tour: fast, stylish and practical weekender, axopar 29 sea trial: sun top vs cross cabin – which is best, latest videos, sunseeker ocean 182 – see how this compact superyacht copes in a wet and windy sea trial, delphia 10 boat tour: great value family cruiser.

FULL-RANGE HYBRID SYSTEMS FOR YACHTS

Protect what you love

SUPPORTED BY ALESSIA ZECCHINI

World Record Freediver

THE FUTURE IS ELECTRIC

E-motion is the only supplier of standardized hybrid propulsion systems that fit into the existing engine room of all serial production yachts from 40-250 feet..

Innovation Award Winner

We are the proud winner of the nmma innovation awards designated by discover boating® miami international boat show®, nmma and bwi., come visit our booth.

and check out how you can electrify your vessel!

OCT 30-NOV 3

MARCH 20-23

Advantages of our hybrid propulsion for yachts.

Significant savings on fuel consumption

Drastically reduce main engine and variable speed generators running hours

Savings on scheduled maintenance

Our hybrid yacht propulsion system is maintenance free. Only the dedicated water cooling pumps require service

Higher resale value of your vessel

Improved Quality of Life on Board

Reduce environmental exhaust and water pollution

Drastically reduce your vessels yearly CO2 emissions

Mooring and swimming in a bay without any gas emissions and noise

Silent and zero-emission departure from mooring and cruise in medium-range

Cabins are noise-free in Zero-Emission or Diesel-Electric Mode navigation

Fishing and trolling in Zero-Emission Mode

HYBRID YACHTS POWERED BY E-MOTION

The e-motion hybrid propulsion systems for yachts are supported worldwide for sales and after-sales services by:.

EXPLORE OUR PRESS PAGE

Stay up to date on all the latest news and events in the rapidly evolving world of hybrid and full electric yacht propulsion. as seen in:, boat , international.

XQUISITE YACHTS - e-MOTION PARALLEL HYBRID- THE 60 SOLAR POWER

The e-Motion Parallel Hybrid - Full-Electric Navigation, Winner NMMA Award 2022

Parallel vs. Serial Hybrid for Yachts - What's the Difference?

e-Motion Hybrid Q&A

Wall Street - Interview Michele Maggi

HYBRID TYPES

The advantages, hybrid functionalities.

The world is going electric.

Interested in the electrification of your yacht download our brochure and get in touch today , “while there have been serial and parallel hybrid systems in boats for years, i have not seen any manufacturer implement a large system with such graceful integration and ease of use for the end-user.”, gary reich - judge of miami 2022 nmma awards.

- BOAT OF THE YEAR

- Newsletters

- Sailboat Reviews

- Boating Safety

- Sailing Totem

- Charter Resources

- Destinations

- Galley Recipes

- Living Aboard

- Sails and Rigging

- Maintenance

The Promises and Pitfalls of an All-Electric Yacht

- By Tim Murphy

- Updated: November 8, 2021

This past October, I saw one of the most interesting exhibits in more than 500 new cruising sailboats I’ve reviewed over two decades. It was the Arcona 435Z, built in Sweden and introduced by Graham Balch of Green Yachts in San Francisco. Balch describes his business as “a new brokerage dedicated to the electric revolution on the water,” and it was the “Z” in the boat’s name, which stands for “zero emissions,” that made this boat so interesting. This was the first electric propulsion system—not hybrid but all-electric —I’d ever seen on a cruising sailboat.

Electric propulsion isn’t new. Since 1879, electric motors have propelled boats; a fleet of some four-dozen electric launches transported visitors around the 1893 Colombian Exposition in Chicago. But cruising sailboats are not launches, and the open sea is not a protected canal. When we’re using cruising boats as they’re meant to be used, they seldom end their day plugged into a shore-power outlet. Cruising boats comprise many devices —stove, refrigerator, freezer, windlass, winches, autopilot, radar, lights—whose power typically comes from a tank of fossil fuel. And today’s cruising sailors are accustomed to using diesel auxiliary power to motor through lulls or punch into headwinds and seas.

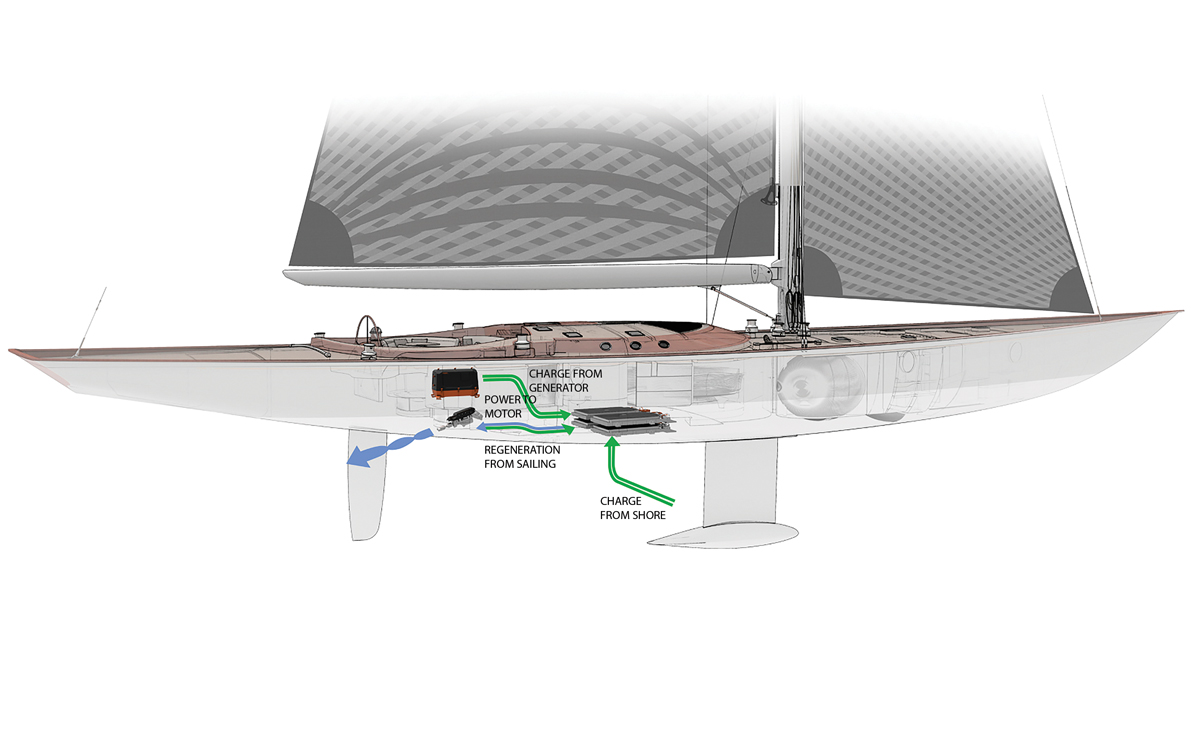

Starting about 15 years ago, we saw a wave of diesel-electric and hybrid propulsion systems on production and custom cruising boats ( see “Perpetuated Motion,” CW , March 2005 ). Both of those systems ultimately start with an onboard internal-combustion engine. A diesel-electric propulsion system relies on a running genset to directly power the electric motor that turns the propeller. A hybrid system relies on batteries to power the electric motor, plus an internal-combustion genset to recharge the batteries. One of the promises of a hybrid system is the ability to regenerate electrical power. Regeneration means using boatspeed under sail to turn the propeller, whose spinning shaft sends electrons from the electric motor back through an electronic controller to recharge the batteries. In such a system, the boat’s propeller is both an electrical load (when running under power) and a charging source (when sailing in regeneration mode).

The Arcona 435Z was different from both of these systems: It incorporates no onboard fossil-fuel engine at all. Instead, it has a bank of lithium batteries, several solar panels, and a proprietary propulsion leg that looks like a saildrive. “This boat,” Balch said, “has the very first production unit in the world of Oceanvolt’s newest electric propulsion system, called the ServoProp.”

For our sea trial, Balch was joined by Derek Rupe, CEO of Oceanvolt USA. “If you can sail the boat and you have some solar, you can go anywhere in the world, and you can make all your power underway while you go,” Rupe said. When we spoke in October 2020, he touted three high-profile sailors who were using the Oceanvolt electric propulsion system: Alex Thomson, for his Hugo Boss Open 60 Vendée Globe program; Jimmy Cornell, for his Elcano 500 expedition; and Riley Whitelum and Elayna Carausu, who had been teasing their new boat for months on their popular Sailing La Vagabonde YouTube channel.

The efficiency of Oceanvolt’s ServoProp and the regeneration from it is the promised game-changer in each of these boats. The ServoProp is a leg with a feathering propeller that can be set for optimal pitch in three modes: forward, reverse and regeneration.

“You don’t need fuel,” Rupe said. “You don’t need to dock; you can go anywhere you want to go and always have the power for living and propulsion.”

That’s the promise. But are there also pitfalls?

Innovation and Risk

Marine electric propulsion is an emerging technology. Compared with the mature and settled technology of diesel engines and lead-acid batteries, electric-propulsion systems—with their electronic controllers and lithium batteries—are in a stage of development best described as adolescent. Every sailor has his or her own tolerance for technical innovation. For the promise of fewer seconds per mile, grand-prix-racing sailors willingly trade a high risk of expensive damage to the sails, rig or the boat’s structure itself; cruising sailors, by contrast, tend to favor yearslong reliability in their equipment as they seek miles per day.

Folks who identify as early adopters take special joy in the first-wave discoveries of a new technology; if they’re clear-eyed about supporting an ongoing experiment, they see themselves as partners with the developers, accepting failures as opportunities for learning. Sailors motivated primarily by changing the trajectory of climate change might be especially willing to modify their behavior to limit their own output of greenhouse gases. Investing in any emerging technology asks you to start with a clear assessment of your own risk tolerance. We’ll return to this theme with one or two real-life examples.

The American Boat and Yacht Council, founded in 1954, sets recommended standards for systems installed on recreational boats. For decades, ABYC has published standards related to installations of diesel and gasoline engines, as well as electrical systems based around lead-acid batteries. By contrast, it was only three years ago that ABYC came out with its first electric-propulsion standard (revised July 2021). And only last year it published its first technical-information report on lithium batteries (a technical-information report is an early step toward a future standard). The takeaway is that if you need help servicing your diesel engine or electrical system built around lead-acid batteries, you can pull into any reasonable-size port and find competent technicians to help you. With electric propulsion and lithium batteries, that pool of skilled talent is significantly scarcer.

To say that a technology is mature simply means that we’ve learned to live with it, warts and all, but that it holds few remaining surprises. Certainly, diesel-propulsion and lead-acid-battery technologies each leave plenty of room for improvement. When a charge of fuel ignites in the combustion chamber of a diesel engine, some three-quarters of the energy is lost in heat and the mechanical inefficiencies of converting reciprocating motion to rotation. Lead-acid batteries become damaged if we routinely discharge more than half of their capacity. During charging, they’re slow to take the electrons we could deliver.

Lithium batteries are comparatively full of promise. Their power density is far greater than that of lead-acid batteries, meaning they’re much lighter for a given capacity. They’re capable of being deeply discharged, which means you can use far more of the bank’s capacity, not merely the first half. And they accept a charge much more quickly; compare that to several hours a day running an engine to keep the beers iced down.

But the pitfalls? Let’s start with ABYC TE-13, Lithium Ion Batteries. Some of its language is bracing. “Lithium ion batteries are unlike lead-acid batteries in two important respects,” the report says. “1) The electrolyte within most lithium ion batteries is flammable. 2) Under certain fault conditions, lithium ion batteries can enter a condition known as thermal runaway, which results in rapid internal heating. Once initiated, it is a self-perpetuating and exothermic reaction that can be difficult to halt.”

Thermal runaway? Difficult to halt? Self-perpetuating?

“Typically, the best approach is to remove heat as fast as possible, which is most effectively done by flooding the battery with water,” TE-13 continues, “although this may have serious consequences for the boat’s electrical systems, machinery, buoyancy, etc.”

If you were following the news in January 2013, you might remember the story of Japan Airlines Flight 008. Shortly after landing at Boston’s Logan Airport, a mechanic opened the aft electronic equipment bay of the Boeing 787-8 to find smoke and flames billowing from the auxiliary-power unit. The fire extinguisher he used didn’t put out the flames. Eventually Boston firefighters put out the fire with Halotron, but when removing the still-hissing batteries from the plane, one of the firefighters was burned through his professional protective gear.

Samsung Galaxy cellphones, MacBook Pro laptops, powered skateboards—in the past decade, these and other devices have been recalled after their lithium batteries burned up. In that period, several high-end custom boats were declared a total loss following failures from lithium batteries. In March 2021, a 78-foot Norwegian hybrid-powered tour boat, built in 2019 with a 790 kW capacity battery bank, experienced thermal runaway that kept firefighters on watch for several days after the crew safely abandoned the ship.

Yes, experts are learning a lot about how to mitigate the risks around lithium batteries. But we’re still on the learning curve.

ABYC’s TE-13 “System Design” section starts, “All lithium-ion battery systems should have a battery management system (BMS) installed to prevent damage to the battery and provide for battery shutoff if potentially dangerous conditions exist.” It defines a bank’s “safe operating envelope” according to such parameters as high- and low-voltage limits, charging and discharging temperature limits, and charging and discharging current limits.

Graham Balch takes these safety recommendations a step further: “To our knowledge, the BMS has to monitor at the cell level. With most batteries, the BMS monitors at the module level.” The difference? “Let’s say you have 24 cells inside the battery module, and three of them stop working. Well, the other 21 have to work harder to compensate for those three. And that’s where thermal events occur.”

Balch followed the story of the Norwegian tour boat this past spring. He believes that the battery installation in that case didn’t meet waterproofing standards: “The hypothesis is that due to water intrusion, there was reverse polarity in one or more of the cells, which is worse than cells simply not working. It means that they’re actively working against the other cells. But if the BMS is monitoring only at the module level, you wouldn’t know it.”

On the Green Yachts website, Graham lists five battery manufacturers whose BMS regimes monitor at the cell level. “If I were sailing on an electric boat, whether it be commercial or recreational, I would feel comfortable with having batteries from these five companies and no other,” he said.

The broader takeaway for today’s sailors is that lithium batteries bring their own sets of problems and solutions, which are different from those of conventional propulsion and power-supply technologies. A reasonably skilled sailor could be expected to change fuel filters or bleed a diesel engine if it shuts down in rough conditions. With lithium-ion batteries aboard, an operator needs to understand the causes and remedies of thermal runaway, and be ready to respond if the BMS shuts down the boat’s power.

Real-World Electric Cruising Boats

When we met Oceanvolt’s Derek Rupe a year ago, he and his wife had taken their all-electric boat to the Bahamas and back the previous season. Before that, he’d been installing electric-propulsion packages for six years on new Alerion 41s and other refit projects. “My real passion is on the technical side of things—installations, really getting that right. That’s half the picture. The technology is there, but it needs to be installed correctly.”

When talking to Rupe, I immediately encountered my first learning curve. I posed questions about the Oceanvolt system in amps and amp-hours; he responded in watts and kilowatt-hours. This was yet another example of the different mindset sailors of electric boats need to hold. Why? Because most cruising boats have just one or two electrical systems: DC and AC. The AC system might operate at 110 or 220 volts; the DC side might operate at 12 or 24 volts. On your own boat, that voltage is a given. From there we tend to think in terms of amps needed to power a load, and amp-hours of capacity in our battery banks. Going back to basics, the power formula tells us that power (watts) equals electrical potential (volts) times current (amps). If your boat’s electrical system is 12 volts and you know that your windlass is rated at 400 watts, it follows that the windlass is rated to draw 33 amps.

But an all-electric boat might comprise several systems at different voltages. A single battery bank might supply cabin lights at 12 volts DC; winches and windlasses at 24 volts DC; the propulsion motor at 48 volts DC; and an induction stove, microwave and television at 110 volts AC. A DC-to-DC power converter steps the voltage up or down, and an inverter changes DC to AC. Instead of translating through all those systems, the Oceanvolt monitor (and Derek Rupe) simply reports in watts coming in or going out of the bank.

“We keep all our thoughts in watts,” Rupe said. “Watts count in the AC induction. They count in the DC-to-DC converter. They count the solar in. They count the hydrogeneration in. And the power-management systems tracks it that way for shore-power in.

“On a boat like this, maybe I have 500 watts coming in the solar panels,” he continued. “So then I can think: ‘Well, my fridge is using 90 watts. My boat has an electric stove. When I cook a big meal, I can see that for every hour we cook, we lose about 10 to 12 minutes of our cruising range.’”

During his Bahamas cruising season, Rupe observed that on days that they were sailing, the combination of solar panels and hydroregeneration supplied all the power he and his wife needed. “When we weren’t sailing,” he said, “we found that we were losing 8 percent each day, in the difference from what the sun gave us to what we were using for the fridge, lights, charging our laptops, and all that stuff.”

Rupe’s solution? “Twice in Eleuthera and once outside Major’s, we went out and sailed laps for a couple of hours because the batteries were below 30 percent of capacity. It was good sailing, and the wind was coming over the shore, so we didn’t have any sea state. We did a couple of hot laps on nice beam reaches, and generated about 700 watts an hour.”

Of the three sailors Rupe touted in October 2020—Alex Thomson, Jimmy Cornell and the Sailing La Vagabonde couple—only Cornell can report back on his all-electric experiences with Oceanvolt. Alex Thomson ended his circumnavigation abruptly last November, just 20 days after the Vendée Globe start, when Hugo Boss collided with an object in the South Atlantic. And at press time in early fall 2021, Riley and Elayna had just recently announced the build of their new Rapido trimaran; keep an eye on their YouTube channel for more about their experiences with the Oceanvolt propulsion system.

As for Cornell—circumnavigator, World Cruising Routes author, creator of the transoceanic rally, and veteran of some 200,000 ocean miles—he suspended his planned Elcano 500 round-the-world expedition solely because of the Oceanvolt system in his new Outremer catamaran. His Aventura Zero Logs on the Cornell Sailing website, particularly the Electric Shock article posted on December 2, 2020, are essential reading for any sailor interested in sailing an electric boat. “Sailing around the world on an electric boat with zero emissions along the route of the first circumnavigation was such a tempting opportunity to do something meaningful and in tune with our concern for protecting the environment that my family agreed I should do it,” Cornell wrote. “What this passage has shown was that in spite of all our efforts to save energy, we were unable to regenerate sufficient electricity to cover consumption and top up the batteries.”

Cornell’s experience in that article is raw, and his tone in that moment bitterly disappointed. We recommend it as essential reading—not as a final rejection of the electric-boat concept or of Oceanvolt’s system, or even as an endorsement of Cornell’s own decision that the system didn’t work. I suspect that I may have arrived at the same conclusion. Yet given the same boat in the same conditions, one imagines that a new breed of sailor—a Graham Balch or a Derek Rupe—may have responded differently to the constraints imposed by an all-electric boat, as nearly every cruising sailor today habitually responds to the inconvenient constraints of diesel engines and lead-acid batteries.

“If you bring electric winches, electric heads and an induction stove, and then sail into a high-pressure system, you’ll set yourself up for failure,” Balch said. “You have to balance your power inputs and your power outputs.

“Sailing an electric boat is a return to the tradition of sailing that the crutch of a diesel engine has gotten us away from,” he added. “Magellan’s fleet got all the way around the world, and they didn’t have a diesel engine.”

Tim Murphy is a Cruising World editor-at-large and longtime Boat of the Year judge.

- More: Green Wakes , Hands-On Sailor , navigation , print nov 2021 , sailboat review , Sailboat Reviews

- More Sailboats

Sailboat Review: Italia Yachts 14.98

For Sale: 2000 Oyster 53

Lagoon 60 Prepares for World Premiere

Now For Sale: Leopard 45

Preparing to Head Out

Competitive Cruising: It’s a Rally, Not a Race

The Data Difference: Advances in Marine Weather Forecasting

- Digital Edition

- Customer Service

- Privacy Policy

- Email Newsletters

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

- Yachting World

- Digital Edition

How hybrid sailing yachts finally became a feasible option

- May 17, 2019

They’ve been a long time coming, but marine hybrid propulsion systems are finally a working reality, as Sam Fortescue reports

The Bootswerft Heinrich-built 13m Yamila uses an Oceanvolt electric motor rather than a diesel engine. Photo: Peter Minder

Every sailor is familiar with the wet cough of the diesel engine, and the acrid smell of its exhaust. For some it’s the sign that an adventure is starting, for others it is the reassurance that all is well on board the boat. The traditional engine is perhaps your boat’s most important safety feature, but its days may be numbered.

The electric sailing revolution is coming – and though adoption in the marine sector is proving much slower than in the automotive world ashore, progress is being made.

The market is still relatively small. Clear market leader Torqeedo had sales of €25m last year, most of which was in ferries and compact outboards. It also offers a range of saildrive and pod drive motors for yachts displacing from 2 to 50 tonnes, or roughly 20-60ft LOA.

But sailors have been slow on the uptake, and for one good reason: if you’re planning to cross an ocean or take on tough conditions offshore, you rely on your engine to help you outrun danger or motor through the doldrums – sometimes for days at a time.

Oceanvolt AXC series is a modular shaft drive system (10kW to 40kW) that will fit in place of a tradition diesel engine

Even with the current crop of advanced lithium-ion boat batteries , the range of an electric system is measured in tens of miles, not hundreds. So a 35ft monohull with 10kWh of lithium battery (four units weighing 96kg in total) would have a range of just 24 nautical miles at 3.8 knots, or less than 16 nautical miles at full throttle.

Taking into account the incredible wastage of combustion engines, which dissipate more energy as heat and noise than they provide in propulsion, diesel is still ten times more energy dense than batteries.

Full-carbon luxury daysailer Yamila uses an Oceanvolt SD8 8kW electric saildrive system. Photo: Tobias Stoerkle

“When you look at bluewater cruisers, of course you will have a diesel,” says Torqeedo’s founder and CEO, Dr Christoph Ballin. “And it’s right that not many coastal sailors opt for pure electric.”

But that doesn’t mean that electric has no interest for cruising sailors – far from it. The more common route for ‘normal’ sailors will be to combine diesel and electric in a hybrid sailing system.

Under this model, the engine is replaced by an electric motor, hooked up to a bank of lithium batteries. This can be charged via hydrogeneration – when the speed under sail turns the propeller and puts charge back into the batteries – and solar or wind. But when extended periods under power are required a standalone DC generator, which can be installed anywhere on board, supplies the electricity.

This is the set-up recommended by Finland’s Oceanvolt, which has focused on the cruising sailing market with a range of shaft and sail drive motors from 3.7kW to 15kW (roughly 10hp to 45hp in diesel engine terms).

“In the case of the round-the-world cruiser, we recommend a hybrid system with a backup genset to support continuous drive when/if needed,” says Oceanvolt CEO Markus Mustelin. “A regenerating prop, which spins while sailing and recharges the batteries (sacrificing 0.2-0.4 of a knot, depending on the boat and conditions) makes it possible to be almost independent of the genset and use it only for backup.”

Spirit Yachts starts construction on Spirit 111 – one of the largest single-masted wooden yachts ever

Ipswich-based modern classic builders Spirit Yachts has started construction on its largest project to date, a 34m sloop, Spirit 111.…

Electric propulsion experts Torqeedo wins top award for innovative electric drive

The electric propulsion pioneer Torqeedo won the largest marine equipment prize of the year today (15 November) – for the…

This system has the advantage that the generator is only needed on longer passages, so the boat still manoeuvres silently in and out of ports and anchorages.

And a well-designed, correctly sized generator is much more efficient at turning diesel into electricity than an engine not originally designed for the job. Some sailors opt for an in-line hybrid system, like those offered by Hybrid-Marine, which bolts onto the existing diesel.

These are easier to retrofit, with many of the same characteristics as the full hybrid system, but there’s the disadvantage of still having an engine boxed away somewhere near the middle of the boat.

Electro magnetism

Until now, most business has been done through retrofitting existing yachts. But an increasing number of yacht builders are looking to include electric propulsion as original equipment. The world’s third largest boatbuilder, Hanse Yachts , is perhaps the most advanced – offering its entry-level Hanse 315 with an electric rudder-drive option.

The system takes up less space than the standard diesel, is much quieter and vibration- and emissions-free. But Hanse admits take up has been disappointing.

The technology has found more interest among lake sailors. Innovative young German brand Bente has been fitting Torqeedo motors to its successful 24ft model, originally designed for Germany’s ‘Green Lakes’.

Closer to home, dinghy specialist RS Sailing has decided to fit a retractable electric drive to its new RS21 keelboat. Already christened the ‘invisible gennaker’, the system is based on Torqeedo’s Travel 1003 outboard motor.

Bigger race boats have also been attracted by the lure of low-weight propulsion. Just look at Malizia , an IMOCA 60 being prepared for the 2020 Vendée Globe with a lightweight Torqeedo system.

“Emissions-free round the world under race conditions, while simultaneously producing your own energy, is a thoroughly inspirational concept,” said Malizia skipper Boris Herrmann.

Electric has also been successful at the luxury end of the market, where lithium-ion batteries account for a smaller share of the boat’s overall cost. A 50ft Privilege 5 catamaran and a carbon fibre Gunboat 60 have both been retrofitted with Torqeedo kit, while Oceanvolt appears on a Swan 57 and an all-carbon Agile 42.

Overview of the Torqeedo Deep Blue propulsion system installed in the Gunboat Moonwave

The Gunboat Moonwave has two 25kW Deep Blue saildrives both capable of regenerating under sail. There is still a generator on board to extend battery range offshore, but “they no longer use the generator – it’s just for emergency,” says Torqeedo’s Ballin.

Spirit Yachts is also designing electric propulsion into its Spirit 111 flagship, due for launch this summer. With four big 40kW lithium batteries aboard and a 100kW motor, the yacht will be able to operate silently for hours, although it also has 100kW of diesel generator capacity.

“The real focus is not the propulsion,” explains Spirit director Nigel Stuart, “but that everything works in harmony, from galley equipment and hot water to heating, air conditioning, hydraulics etc.” The British yard is also building a 65-footer using Oceanvolt hybrid technology and a new 44-footer that is pure electric.

With racing on one hand and high-end cruisers on the other, there is something of a gap in the middle. By Torqeedo’s own admission, the cruising sailor hasn’t been a big focus of the electric revolution, but all that is about to change. “We started a bit late with sailing,” Ballin admits, “but in the next five to eight years it will be addressed big time.”

Fully integrated electric drive system will power the new 111ft Spirit Yachts flagship

What does that really mean? Well, in the first instance, it means system integration. If that doesn’t sound revolutionary, then imagine a set-up on board where solar panels, hydrogenerators, batteries, generators and motors all worked seamlessly together to keep the yacht supplied with ample power around the clock. “That’s what people are willing to pay for: plenty of energy with heating or air-con through the night,” says Ballin.

The future of hybrid sailing

In the near future, Torqeedo is planning a new range-extending DC generator specifically for hybrid sailing boats. Its existing unit is built by WhisperPower and provides 25kW, which is too much power for boats using the pod drive system.

The genset will be designed to operate at optimum revolutions, while clever DC to DC conversion decouples the battery voltage from the charging voltage, for much greater efficiency.

With boats, just as with cars, the breakthrough that will make all the difference is around battery capacity. Until range under electric power can match that of diesel, there will be many sceptics. And that isn’t likely to happen for a decade or more, according to Ballin.

“Theoretically, they’ve tested batteries in labs that are ten times more efficient than lithium,” he explains. “And if that comes through, then gasoline is done. But we are trying to combine long-term vision with short-term mindset.”

In the meantime, the prevalent technology is based on lithium-manganese-cobalt, and a process of steady development is making this 5-8% better each year. For example, BMW has just announced its next generation i3 battery, used by Torqeedo’s Deep Blue system, will be able to hold 40kWh of power – an increase of 33% for the same size, weight and nearly the same cost.

Torqeedo Cruise 2.0 FP Pod Drive is suitable for small yachts up to 4 tonnes – a folding prop can also be fitted

The other area of development is around the propeller. Most cruising systems use a folding or feathering prop designed for diesel engines. But Torqeedo’s own research shows that the consistently high torque of an electric motor is best utilised by props with variable pitch.

And yet it is Oceanvolt that has addressed this issue specifically for electric motors with its Servo Prop system, which it claims to be 30% more efficient ahead, 100% better astern and 300% more efficient in regeneration mode.

Oceanvolt says that this prop can pump around 500W into the batteries at just 5 knots – the average pace of a 30ft monohull. At 6 knots that rises to around 800W, and at a very manageable 7 knots for a larger ocean cruiser you get 1.2kW.

“A new technology can rarely compete in price with an established one in its initial growth phase,” says Mustelin. “However, we have passed this and today electric systems are offered at a quite competitive price. When you add to that the fact the electric system is almost service free, the total cost of ownership is turning in favour of electric.”

So, you may not hear them approach, but expect to see more and more electric-powered boats on the water as the revolution continues.

A question of torque

A key part of the viability of electric propulsion rests on the notion that a smaller motor can achieve the same work as a bigger diesel. There are two elements to this. First, a diesel engine is not an efficient converter of chemical energy into thrust, creating a lot of heat and noise in the process. Second, the torque characteristics of electric are much better than diesel.

Mustelin says that Oceanvolt’s 10kW motor “easily outperforms” a 30hp diesel. “Typically, maximum boat speed will be somewhat lower (0.5kt-1.0kt) than with a comparable diesel engine, but at the same time the boat will maintain the speed better in heavy seas and headwind due to higher torque. Manoeuvrability is much better in confined marina spaces.”

That’s because combustion engines only reach peak power (and maximum torque) over a small range of speeds. Torque is a measure of turning power – at the propeller in the case of a boat.

A diesel engine develops optimum torque between 1,800-2,000rpm, while electric motors deliver it from 0 to around 2,000rpm. This allows electric motors to use higher efficiency propellers that are slimmer and more steeply pitched.

Engine-driven: The ‘alternator on steroids’

It has taken years of development and over $10m of funding, but renowned boat systems expert Nigel Calder has helped design an alternator so powerful that it eliminates the need for a generator on board.

Mounted on the engine, on the second alternator position, the Integrel can produce five to ten times more power. Sitting behind the system is at least 10kWh of lead acid batteries (lithium is also an option), and Victron chargers and inverters.

“If you crank the engine it’ll charge the batteries; if you’re running with the engine in neutral, it’ll know it’s in standalone generator mode and switch to that algorithm,” explains Calder. “It will likely be cheaper than a generator installation, and eliminates the issue of the through-hulls, the cooling circuits, the long running hours, the maintenance.”

The system allows you to run all sorts of creature comforts on board that would normally require a generator: from hot water on-demand to coffee makers and freezers. “We honestly believe that this system is going to supplant generators on almost all boats that currently have, or would like to have, a generator,” adds Calder.

With the engine in gear and at low revs, tests show how the Integrel can produce some 2kW of power without increasing fuel consumption or reducing speed – simply utilising the engine’s wasted capacity. This means it will work with the yacht’s existing engine – no need to overspec – and it has already been successfully installed on a new Southerly 480, a Malo 46 and a similar-sized Hallberg-Rassy.

Case study: Dufour 382 Alcyone

Built by Dufour in 2016, Alcyone was immediately retrofitted professionally with Oceanvolt’s SD15 saildrive motor, supplied by a 14kWh lithium battery bank. Owners Michael Melling and Diana Kolpak also specced an 8kWh DC generator for range extension. The fit out cost €30,600 for the motor and battery system, plus an additional €13,744 for the generator, and installation costs were around €8,000.

They charter the boat out near Vancouver, for exploring Desolation Sound and the surrounding area where silent, clean propulsion is a selling point. “Nothing spoils the joy of sailing – or a secluded anchorage – more than the noise and smell of diesel engines,” they explained. “Installing an Oceanvolt system in our new boat has freed us from that. It’s the way of the future.”

Charter manager Merion Martin said the conversion has also been popular with charter customers, adding: “The main advantage of the system is that it consistently uses around 40% less fuel than a standard diesel engine over the course of a week’s charter. But understanding the power management system takes a bit of getting used to, and the many components involved in the system can make troubleshooting a challenge.”

If you enjoyed this….

Yachting World is the foremost international magazine for bluewater cruisers and offshore sailors. Every month we have practical features to help you plan and prepare to realise your sailing dreams. Build your knowledge month by month with a subscription delivered to your door – and at a discount to the cover price. S ee our latest offers now.

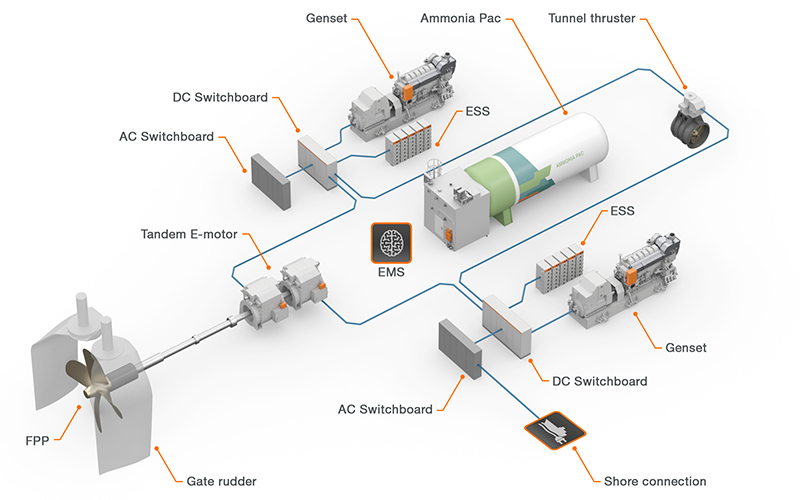

Diesel Electric Propulsion: Is This A Safer, More Efficient Solution For Your Vessel?

- June 18, 2017

- Quite Interesting

Although the idea of powering your vessel with the indirect, two-step diesel electric energy transfer system may appear to be unnecessarily complex, its many advantages can make it a compellingly attractive alternative to a conventional direct mechanical prop-shaft drive. When under way all of the electrical power required by the vessel can be supplied from the diesel electric propulsion system, eliminating the need to run a genset.

A diesel electric power system can drive multiple propellers from a single engine or use multiple engines to power one or more propeller. In a twin-engine/twin-prop system, one engine can power both props when operating within the speed limits imposed in many areas. Electrical power from the vessel’s genset can be used to propel the boat, providing a built-in backup-especially valuable for vessels with single-engine installations.

Conversely, the propulsion system can serve as a backup for the gensets. The use of electric propulsion in certain vessel types is well-known. In marine applications, nearly all the energy is produced by diesel engines. Using an electric propulsion system, where the energy transmission is electrical and the propulsion and thruster are variable speed electrically driven, fuel consumption can be reduced significantly for many vessel types with environmental benefits.

Diesel Electric Systems have been in use to propel vessels for more than 100 years. Branobel launched the first diesel-electric ship in 1903, and since that day, diesel electric propulsion systems have evolved and today they can be found in all boat sizes and applications. But how do you know when to utilize diesel electric technology for your vessel? The investment in Diesel Electric vessels have doubled in the past 4 years, while the construction of purely mechanically propelled vessels have slowed down. But what are the reasons for this growth? Some of the benefits of the Diesel Electric systems are:

Effective design: The ability to locate your generators in any part of the vessel independent of where the power will be used;

Smaller Engine Rooms: Possibility to replace a big slow speed engine with multiple smaller generators;

Reduced Noise and Vibration: No need for long drivelines;

Flexibility: Capability to share the power of one unit with multiple devices (main propeller, bow thrusters, hotel load, pumps, etc);

Redundancy: Generators can be reassigned to cover any machine downtime;

Efficiency: Depending on the application the system can provide better fuel efficiency (mainly if there are requirements for long periods of low speed/load)

Fuel consumption savings calculation: The optimum operation point of a diesel engine will typically be around a load of 85 percent of the Max continuous rating (MCR). Moreover, the efficiency level drops quickly as the load becomes lower than 50 percent of MCR. With the help of the electric system, the mechanical propulsion prime mover is replaced by diesel-electric prime movers that will automatically start and stop as load demand varies. In comparison to a conventional vessel with mechanical propulsion, this enhances the efficiency of the energy usage and reduces the fuel consumption by keeping the average loading of each running diesel engine close to its optimum load point.

However, in some vessel applications, the load variations can be large and rapid. It is impossible to make the generators switch on and off every five seconds as would be the case with DP vessels. By using super-capacitors to supply the load variations, and hence let the diesel engines provide the average load, the peak power of the power plant will be reduced, allowing the average loading of the engines to increase to a more optimal point with lower specific fuel oil consumption. The savings in fuel consumption will depend on many parameters such as actual variations in the load, the average load and the number of prime movers.

In many installations the cost of a single-engine twin-prop diesel electric power system will be no more than a conventional twin-engine direct-mechanical drive installation. Properly integrated into the design of the vessel, the diesel electric drive’s many attributes will likely make it the preferred propulsion system for vessel owners and operators now and in the future.

Related Posts

A compass is a device that indicates direction. It is one of the most important…

Ever wondered why the terms “Port” and “Starboard” are used to denote Left and Right…

Two types of propellers are commonly found in merchant vessels: Fixed Pitch Propeller (FPP) and…

- previous post: Controllable Pitch Propeller

- next post: Why Is It Called Port And Starboard?

The global authority in superyachting

- NEWSLETTERS

- Yachts Home

- The Superyacht Directory

- Yacht Reports

- Brokerage News

- The largest yachts in the world

- The Register

- Yacht Advice

- Yacht Design

- 12m to 24m yachts

- Monaco Yacht Show

- Builder Directory

- Designer Directory

- Interior Design Directory

- Naval Architect Directory

- Yachts for sale home

- Motor yachts

- Sailing yachts

- Explorer yachts

- Classic yachts

- Sale Broker Directory

- Charter Home

- Yachts for Charter

- Charter Destinations

- Charter Broker Directory

- Destinations Home

- Mediterranean

- South Pacific

- Rest of the World

- Boat Life Home

- Owners' Experiences

- Interiors Suppliers

- Owners' Club

- Captains' Club

- BOAT Showcase

- Boat Presents

- Events Home

- World Superyacht Awards

- Superyacht Design Festival

- Design and Innovation Awards

- Young Designer of the Year Award

- Artistry and Craft Awards

- Explorer Yachts Summit

- Ocean Talks

- The Ocean Awards

- BOAT Connect

- Between the bays

- Golf Invitational

- Boat Pro Home

- Superyacht Insight

- Global Order Book

- Premium Content

- Product Features

- Testimonials

- Pricing Plan

- Tenders & Equipment

How superyacht diesel electric power systems work

Diesel-electric power has powered ships and submarines for nearly a century. Today, it is the subject of more discussions between owners, captains, designers and builders as a cleaner, more efficient source of on-board power and propulsion. It has been hyped as a possible ‘greener’ way forward, but is it?

What it is and how it works

When Rudolph Diesel obtained the patent for his 1.58kW Rational Heat Engine with its 10ft diameter flywheel in 1892, he never could have predicted that what came to be called the diesel engine would be as popular as it is today. Nor could he have foreseen the many uses to which the engine has been put. He might, however, recognise the diesel-electric drive train.

Such a system, quite crude by today’s standards, was installed in 1903 in the Russian tanker Vandal , while Diesel was still alive. _The Vandal’s _diesel-electric drive was a far cry from today’s systems where the driving engine and its electric generator (often called by its abbreviation, genset) might be on one part of the vessel and the motor driving the propeller might be elsewhere, even outside the hull.

There are arguments both for and against diesel-electric drives. Proponents say that emissions are lower because only the power needed is used and fuel consumption is reduced, while those against suggest that the weight of a genset and driving motor increases the overall vessel weight, which requires more horsepower to drive the yacht. Additional electrical systems also add complexity, which can cause interference with other electrical systems.

From the naval architect’s standpoint, a diesel-electric system allows the drive engine to be moved away from the end of the propeller shaft. The diesel generator can also be located away from guests to reduce noise and vibration and placed in areas of the hull not normally used for engines or people.

For example, on a 40m yacht, the area under the cockpit may not have adequate headroom for crew cabins, but a pair of diesel generators might fit easily. On vessels over 150m, a gas turbine located in the stack where hot gases can be directed up and away from the deck may be used to generate power, moving power generation completely out of the hull.

A further advantage is that a yacht equipped with several generators can carefully optimise power levels between the house and drive loads. For example, when the yacht is under way, house loads tend to be lower than when the yacht is sitting in harbour with guests aboard. This enables the electronics system to adjust generator power levels between house and powering modes so that both are operating with minimum emissions and fuel consumption.

Under way, the electronic controls monitor propulsion performance as well as house loads and adjust the generators accordingly. This eliminates running high-horsepower main engines continually and still having to adjust generator loads. The end results are lower emissions and improved fuel performance. In addition, an electric propulsion motor can easily be controlled in terms of speed and be reversed without the need for a large gearbox or transmission.

The end result is lower emissions and better fuel performance. In addition, an electric propulsion motor can easily be controlled in terms of speed

An added benefit is the fact that the drive motor can be located outside the hull in a pod drive of the type that Siemens and Schottel have developed, or an azimuthing pod drive can also be used. Using pod drives allows seawater to cool the drive motors, reduces the size of the engine compartment and cuts down on vibration and noise inside the hull. By turning the actual drives, propeller thrust is directed where it can do most good, rather than being deflected off rudders. In addition, rudders and their complexity are eliminated, improving hull drag. In addition, because thrust lines are horizontal, propeller efficiency is considerably improved.

Gensets and batteries

The number of gensets required for a successful diesel-electric installation is critical. If, for example, three large generators are used, at least one will have to operate continuously unless the vessel is on shore power. In addition, one might be under repair. Considering that an 80m yacht might require 300kW when in port, and an additional 400kW when under way, it might seem sensible to have two 400kW generators. But at anchor at night, the generator loads might go down to 100kW, thus both generators would be oversized. In this case it might be more feasible to have a smaller genset of 100kW, two of 300kW, and one of 400kW or 500kW to enable loads to be matched to power consumption to minimise emissions and fuel costs.

For silent operation, say at night, the diesel-electric system could be combined with an energy-dense lithium-ion battery bank or two. In operation, the batteries could be used to drive the pod motors or to power the house lighting for totally silent, night-time operation. The battery banks would have to be quite large to store enough power – probably around 800 to 1,000 amp-hours at 600 volts for a 60m to 70m yacht – but with today’s lithium-ion batteries, such a system is not beyond the realm of possibility.

Diesel-electric and emissions regulations

For all its appeal, diesel-electric has a few disadvantages. To start with, instead of a mechanical engineer, an owner will require an electrical engineer.

As mentioned above, the increased weight of a diesel-electric system can be a drawback. With the new emissions controls that have just come into force in various parts of the world, each genset will require its own controls, should each set be in different parts of the yacht.

Throwing a wrench into the development of diesel-electric yachts are ECAs, or Emission Control Areas. These areas are intended to cut down on NOx (nitrogen oxides) and SOx (sulphur oxides). ECAs, which recently were put in place around the coasts of North America and affect every large vessel in those waters, will necessitate the use of Selective Catalytic Reduction (SCR) to reduce NOx and low-sulphur diesel fuel to reduce SOx. Generator manufacturer Northern Lights has just introduced what it calls its Diesel Exhaust Cleaning System (DECS). The system is based on DCL International’s Marine-X system, which removes particulates as they are emitted from the engine.

Throwing a wrench into the development of diesel-electric yachts are ECAs, or Emission Control Areas. These areas are intended to cut down on NOx (nitrogen oxides) and SOx (sulphur oxides)

In a non-Northern Lights installation, to reduce NOx, a diesel exhaust fluid (DEF) tank containing urea and an atomiser pipe would need to be located near the generators. The DEF is injected into the exhaust stream to react with NOx to create nitrogen and water. To simplify this installation, the entire generator compartment may have to be located in an easily accessible place where the DEF tanks and atomiser can be used on all the generators.

Because of SCR and its associated piping, engine rooms will grow larger, but by placing the drive motors on pods outside the hull, engine room size increases can be minimised. However, this will require widespread adoption of diesel-electric drives, instead of diesels with transmissions and shafts.

Alternative fuel systems

In order to reduce emissions, commercial ship owners are experimenting with using fuels that reduce costs and do not produce much in the way of emissions. Often, where commercial shipping leads, recreational vessels follow, thus a superyacht of the future might be powered by one of these fuels. However, terminals where ships using liquefied gas can refuel may be far and few between and until the infrastructure improves considerably yachts will not follow this trend.

A hydrogen-fuelled superyacht has been proposed. It is a 64m hydrogen diesel-electric yacht from Pharos Marine in Egypt. Given the explosive nature of hydrogen and the lack of refuelling facilities, though, this is more a marketing concept than a real project.

In the far longer term, nanotechnology could lead to major advances in solar and wind power generation. Combined with advances in electric motor and battery technology, nanotechnology could change the look and style of superyachts as we know them today.

More stories

Most popular, from our partners, sponsored listings.

- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Customer Service

- Free Newsletter

Hunter 35.5 Legend Used Boat Review

Pearson Rhodes 41/Rhodes Bounty II Used Sailboat Review

Hallberg-Rassy 42 Used Sailboat Review

How to Perform Your Own Pre-Buy Inspection

Thinking Through a Solar Power Installation

How Does the Gulf Stream Influence our Weather?

Can You Run a Marine Air-Conditioner on Battery Power?

Preparing Yourself for Solo Sailing

Practical Sailor Classic: The Load on Your Rode

Anchor Rodes for Smaller Sailboats

Ground Tackle Inspection Tips

Shoe Goo II Excels for Quick Sail Repairs

Diesel Performance Additives

What Oil Analysis Reveals About Your Engine

Painting a New Bootstripe Like a Pro

Penetrating Epoxy—Another Marketing Gimmick?

The Best Tools for Bottom Painting

The Hidden Maintenance Problems That Can Ruin Your Day: Part 1

Alcohol Stoves— Swan Song or Rebirth?

Living Aboard with an Alcohol Stove

Choosing the Right Fuel for Your Alcohol Stove

How to Select Crew for a Passage or Delivery

Preparing A Boat to Sail Solo

Re-sealing the Seams on Waterproof Fabrics

Waxing and Polishing Your Boat

Reducing Engine Room Noise

Tricks and Tips to Forming Do-it-yourself Rigging Terminals

Marine Toilet Maintenance Tips

Learning to Live with Plastic Boat Bits

- Systems & Propulsion

Electric and Hybrid Propulsion for Sailboats

Practical sailor looks at the players in the developing field of electric auxiliary engines.

How soon will electric auxiliary propulsion be available to everyman? That depends on whom you ask. Opinions differ widely not just on what type of drive system might surge to the forefront, but even on whether the concept itself is viable. While a handful of companies forge ahead, notably Glacier Bay and Electric Marine Propulsion on this side of the Atlantic, some expected participants are waiting on the sidelines.

Photos courtesy of Manufacturers

One of the big issues that divides promoters and detractors alike is whether the appropriate way to go in a sailboat is with a pure diesel-electric drive train, with a hybrid electric drive with a diesel generator as back-up, or as a pure electric drive with regeneration capability. We’ll take a look at these and other options later in this article. For now, the short answer is that no single approach suits every sailor all the time.

Simply put, in the diesel-electric system, the electric motor runs only when the diesel-driven generator is running. Such arrangements have long been employed in railway locomotives, submarines, and commercial vessels of many types. In the hybrid system, a large bank of batteries provides the energy for the electric motor and the diesel generator recharges the batteries. On the face of it, the hybrid system offers a certain degree of redundancy in that, assuming the batteries are kept well charged, the boat has a measure of emergency power should the generator fail at an inopportune moment. The hybrid also is capable of recharging its batteries when sailing: Driven by the turning propeller, the motor becomes a generator.

Each of these approaches has its strengths and weaknesses, and while we’ll leave it to their developers to work out the technical issues, we would like to urge anyone contemplating installing an electric drive, or purchasing a boat that has one, to first look very closely at how they expect to use the boat. There’s more entrained in the choice than in picking a flavor at Baskin-Robbins. More on this later.

Among the electric drives currently available in one form or another, or as components, the big variable is operating voltage. Motors are available that run on 24, 36, 48, 72, and 144 volts, and, in the case of Glacier Bay’s diesel-electric system with Ossa Powerlite technology, 240-volt DC. Each supplier will discourse at length on the merits of their voltage choice, but an inconvenient fact haunts the entire field: High-voltage DC is deadly, potentially more so in some circumstances than AC.

While neither form of high-voltage is “safe,” we have a lot more experience with AC aboard recreational vessels than with high-voltage DC. An extensive body of knowledge exists on which to base AC installations so as to make them safe as well as reliable. High-voltage DC is used in a variety of marine and non-marine commercial applications, but these installations are well protected from access by untrained operators.

What voltage constitutes high voltage? That, again, depends on whom you talk to. The American Boat & Yacht Council (ABYC), which sets voluntary standards for the marine industry, defines it as 50 volts and above. Prompted by rapid adoption of high-voltage services in small commercial craft and bigger yachts, though not specifically in propulsion systems, the ABYC is in the process of drawing up guidelines for voltages higher than the 48 volts covered by existing standards.

An absence of standards might not deter individuals from installing an electric drive, but it might impede widespread adoption of the technology. If a surveyor can’t state in an insurance survey that a boat is built according to ABYC standards, that could affect its insurability.

Jim Nolan, who manages the underwriting department for BoatUS, said the company has no clear cut guidance regarding insuring boats with electric propulsion. Each boat is dealt with on a case-by-case basis. A new boat with a factory-installed system would be a good deal easier to underwrite than a one-off or do-it-yourself project, especially in the absence of a standard practice. Lagoon Catamarans’ 72-volt-DC hybrid system, for instance, has qualified for the European standard (CE) certification on the strength of following industrial standards that apply to such applications as fork-lift trucks. Anyone contemplating an electric drive would be well advised to discuss it ahead of time with an insurer and even get a surveyor involved from the outset.

Because of the safety issues surrounding the voltages involved in electric propulsion, Fischer Panda has decided to limit its DC product line to boats weighing 10 tons or less. A company representative we spoke to said that while Fischer Panda currently sells DC generators up to 48 volts in the USA for marine use, it “won’t touch” high-voltage DC because it’s lethal.

A proposed collaboration with Catalina Yachts to fit a diesel-electric system in a Catalina-Morgan 440 never came to fruition due to budget constraints, according to Fischer Panda. But in Europe, Fischer Panda teamed up with Whisperprop to equip a Bavaria 49. (Beyond the fact that one of its boats was used, Bavaria Yachts was not involved in the project.) According to Fischer Panda, after evaluating the Bavaria project, the company decided that the diesel-electric AC system is a niche product that wouldn’t interest their prime market: original equipment builders.

“Although the AC system has some advantages in the improved response of the electric motors … and the quietness of the system, the desired fuel efficiency and weight savings were not evident,” Fischer Panda reported.

Fischer Panda considers the DC system to be more suitable for its North American customers. Although it’s limited in output due to its limited battery voltage of 48 volts, it is still able to power multihulls up to 10 tons.

Currently, much of the movement toward electric drives is taking place in the catamaran world. This makes sense when you consider that a single diesel generator can, in theory, provide all the boat’s electrical needs and also take the place of two diesel-propulsion engines. Taking the lead in the field, Lagoon Catamarans introduced in 2006 the Lagoon 420. Originally offered only as a hybrid, it now is also available in two diesel versions. Corsair Marine is building the Corsair 50 catamaran around the Glacier Bay diesel-electric drive, but the boat’s launch date—formerly set for this summer—has been postponed.

Dick Vermeulen, president of Maine Cat, tried the Glacier Bay system in a prototype power cat, but it failed to meet performance expectations, so production models will have conventional diesels. A number of other cat builders have announced hybrid or diesel-electric projects, but feedback on how they perform is scan’t.

So much for the mainstream—but backwater sailors will go their own way, as they always have. As more vendors and components enter the market, the options for do-it-yourselfers or custom-boat customers become broader and more attractive. However, before going ahead with an installation, make sure it’s appropriate to how you plan to use your boat, and even then be prepared to adapt the way you sail to take best advantage of the system’s characteristics. Here’s a rundown of the various types.

Electric Drive Only