Campy's "WICKED BEAT"

All days should be like today!

Friday, February 1, 2019

Building scamp, an 11 foot long, wood sailboat..

Keep us all up to date with picture's. Sounds like fun...

Post a Comment

- Create an Account

- Boat Plans & Kits ::

SCAMP Sailboat

Our own youthful dreams often featured small boats in starring roles. Aboard these simple, stalwart little vessels we'd venture across nebulous bodies of water in search of distant wild shorelines or uncharted islands. We'd land, hike into the interior, and make camp. But always our boats offered refuge from any threat, including summer storms, which we'd wait out beneath our boom tents. At night we'd read sea stories by oil lantern and sleep under a blanket of stars.

Curiously, never once did these visions include negative images of wrestling with a heavy mast and complex rigging, fussing with a smelly, recalcitrant outboard, or being held off shore by our boat's draft. And even when we pictured the afternoon breeze kicking up whitecaps, never once did the vision include a chilly capsize.

It was the dream of returning to those simple pleasures that inspired thoughts of S.C.A.M.P. (Small Craft Advisor Magazine Project). That and a persistent desire to go over "there" - that place we often see but are unable to reach. It seems to happen on every cruise. Never mind that we're usually sailing the smallest boat around for miles, we always come upon some ultra-shallow lagoon or serpentine tidal stream that disappears into the reeds, trees and rushes. To get in there - to really commune with nature - a boat needs to be light, shallow and easily propelled - and preferably flat-bottomed in case we decide to stay right though the ebb. —SCA

Features: Water Ballast Tank • Offset centerboard • Massive Flotation Stowage Cabin • "Veranda" Overhanging Cabintop • Kickup Rudder Flat Bottom and Skegs for Beaching • Voluminous Stowage Lockers 8' 3" Cockpit Sole Single Berth • Convert Cockpit Seats to Double Berth

Original Designer: John Welsford • Design Development: Kees Prins • Kit Adaptation: Turn Point Design

For more SCAMP discussion visit our Scamp Forum here. SCAMP's FaceBook page is here.

You can view the International SCAMP Registry to see where owners are located around the world.

A Boat Called SCAMP by Dick Herman

SCAMP Foils Kit

SCAMP Package: Every Article We've Published on SCAMP (issue #63 to #75)

SCAMP Mini Microcruiser Plans

SCAMP CNC Building Kit

SCAMP Class Sail (100 sq ft lugsail)

Official SCAMP Design Logo Burgee

Call Us: (253) 851-2126 Mon-Fri 9-5 Pacific Time

- 12′ Scamp

“I have to say it’s the biggest little boat I’ve ever sailed.”

– 48 north magazine.

The Scamp is a seaworthy 12′ sailboat that can handle a good dose of adventure.

Just under 12 feet in length, Scamp boasts an unusual combination of features that give her the unique ability to explore waters too shallow for a larger boat, while retaining most of the bigger boat’s comforts and capabilities. An offset centerboard opens up the cockpit and an 8′ 3″ sleeping area, and 172 pounds of water ballast provide exceptional stability. The cockpit is self-bailing, and a pair of grounding skegs on her flat bottom keep Scamp perfectly upright when landing on a beach or when the tide goes out.

Originally designed as a wood boat by John Welsford, Gig Harbor Boat Works worked closely with the designer and staff from Small Craft Advisor to create a fiberglass version. Scamp #1 hit the water for its first sea trial in July of 2013!

As a specialized boat, the Scamp has some different options than the rest of our boats. We have had quite a few questions about Scamp’s option list so I thought it best to go into more detail below about the various choices. Be sure to check out the “Scamp Options” tab below for photos and descriptions of all the available options.

I’d like to emphasize the fact that we build and sell all of our boats complete, ready to sail. Our “basic’” Scamp is sail ready with exactly the same top quality parts and materials as a “fancy” Scamp — you don’t have to add anything to go for a satisfactory sail. Our ‘Base’ boat’s level of completion is the same as specified in the Scamp plans or kit for DIY home builders. Options are exactly that… individual choices made by the owner to suit their cosmetic desires and refine performance.

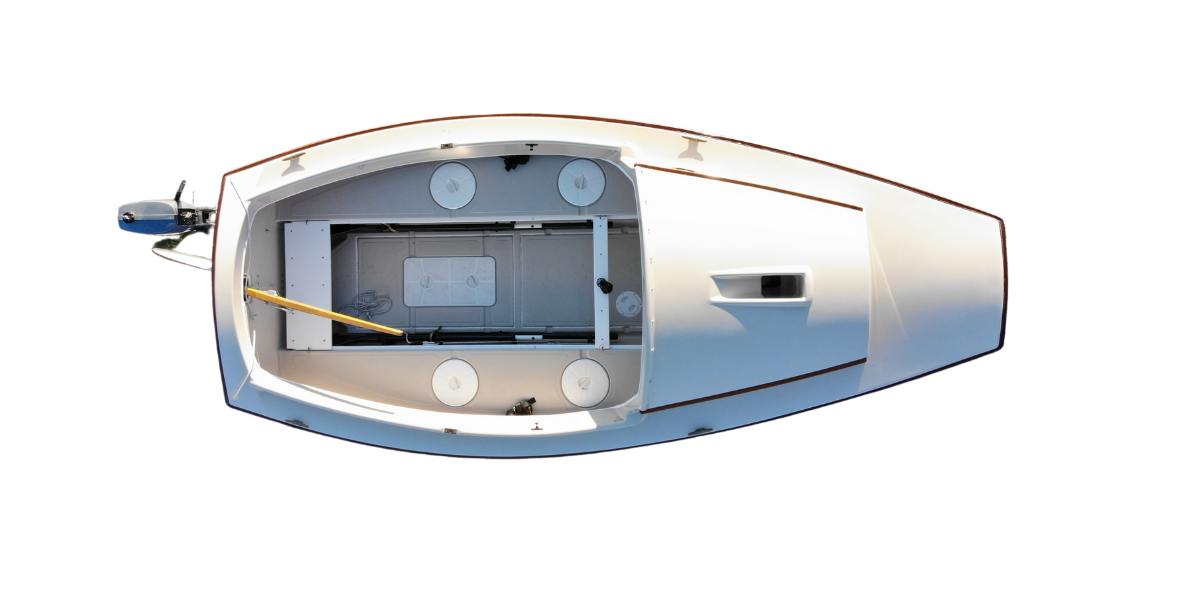

Fiberglass SCAMP Overhead View

Shown with optional floor storage hatch and optional wood trim. Motor not included.

12' Scamp Full Specifications

Scamp photo gallery (click to enlarge):, more about the scamp:.

- 48 North Review

- SCAMP Options (as of Jan 2016)

Gig Harbor Boat Works, known for their strong, esthetically pleasing rowing boats, has already shipped a number of the new SCAMPS all over the country and overseas. “The kit boat has a lot of intricate details that the home builder may not have the talent or tools to build,” says Dave Robertson, owner of GHB. “With the fiberglass version, they can enjoy using the boat right away.” The GHB boat is truly sail-away complete; from oars to sails.

There are many innovations designed into the SCAMP that make it truly a big little boat. One thing that usually takes up a lot of cockpit room of most small boats is the centerboard. The SCAMP’s centerboard, very heavy but swings up easily for trailer or grounding, is offset to starboard so that it doesn’t intrude into the cockpit. I’ll let you call Dave to explain the physics of the offset. Suffice it to say that we didn’t notice a difference on either tack. The result is it opens up the cockpit which feels more like that of a of a San Juan 24.

The boat was surprisingly quick and very stable. “This boat can’t be just 12’long,” I thought. I stood up and rocked it side to side with minimal affect. It felt like 20-footer. Sailing the SCAMP made me a believer that it actually would be a safe and enjoyable way to explore the San Juans, as well as just knocking around the bay for a fun day of sailing. The SCAMP had lots of surprises, all good. I have to say it’s the biggest little boat I’ve ever sailed.

See the price list for current pricing of Scamp options

Cosmetic options

Hull color change ( white hull exterior is standard).

This option allows you to customize the hull exterior to the color of your choice. For the best balance of pizzazz and reasonable maintenance, we recommend that color only be added to the top strake and the balance of the hull be left white. Why? A white underbody doesn’t show scratches like a dark color, it is easy to repair, and Scamp has high freeboard so a darker sheer strake lowers the apparent freeboard. If you add color to the top strake, we will extend the color across the top of the bow and leave the stern all white for best visual balance.

Deck and interior color change (Bisque Tan deck and interior are standard)

The Bisque color is neutral so goes with any accent color – it also doesn’t show scratches and is easy on the eyes. However, we can make the topsides any color you want; for more than a basic color change the price varies with color and pattern.

Bronze Deadlights (white nylon deadlights standard)

Mahogany gunwale trim (standard gunwale trim is tan vinyl).

This wood trim option also includes mahogany ‘eyebrows’ on the cabin sides. Other wood trim such as coaming or seat top overlay is available on a custom basis.

Custom Sail Color (standard is ‘Egyptian cotton)

Any color available, price varies with color and pattern.

Hull options

Stainless steel keel guards.

Over 90% of the boats we build are specified with stainless steel keel protection. Fiberglass is a wonderful boatbuilding material; easy to conform to compound shapes, hard smooth finish, eminently repairable; but it is NOT abrasion resistant. Pulling a boat onto a beach is asking for grief, especially if parts of the boat have a sharp edges forming high pressure areas…. like the keelsons on Scamp. Protecting the keelsons is a lot cheaper than fiberglass repair.

Floor storage hatch

There is a lot of usable, easily accessible space under the cockpit floor. This optional storage is a sealed chamber approximately 18″ wide x 30″ long with depth varying from about 8″ at the forward end to 4″ aft. The hatch accessing the storage is a rectangular Armstrong style with 14″ x 21″ opening. If you plan to add electric propulsion or accessories this is an ideal location for batteries!

Bilge pump, handheld manual style

Rain and spray is contained in the cockpit sump at the transom. This can be scooped or sponged out easily. However, if you somehow get water inside the seats or underfloor that is a relatively inaccessible area. Although chances of getting much water in this area are slim, it helps to have a portable handheld pump handy.

Outboard motor bracket

Removable outboard motor bracket

Bolts to outside of transom. Owners have noted that a permanent motor mount on Scamp is, well, ugly. So we researched a removable mount that has only a flat plate permanently bolted to the transom. The actual motor carrier clips onto the plate with a simple quick pin, no tools required to install or remove the bracket.

Bronze 5″ cleats

Bronze cleat

Stainless steel pop–up cleats

Pop-up cleat

Performance / operational options

Trailer, galvanized, custom designed for scamp.

Scamp is very difficult to fit correctly on a trailer; the twin keelsons, wide chines and flat bow just don’t work with any standard trailer. We designed a custom trailer specifically for this hull. It is 100% galvanized and has three aft rollers to accommodate self centering on the keelsons. Scamp has a tendency to skate sideways when loading, so we install carpeted side guides and a central crossmember roller to make loading simple. Forward is a carpeted transverse bunk to support the fairbody, and finally a special twin chock winch pedestal. Oh yeah, bearing buddies are standard too.

Swiveling mainsheet cleat with removable base

The mainsheet cleat is fastened to a transverse board between the seat tops. You can adjust the position of the board and cleat fore or aft the length of the cockpit or remove it entirely by pulling two stainless steel fastpins.

Jiffy reefing

Three Reef points in the sail are standard, but there are no reefing lines or cleats. If you want jiffy reefing we”ll set up two complete ready to use reefs.

Compass, bulkhead mounted Richie #RITV57.2

Oars, 9’4″ 2-piece fiberglass shaft with bronze oarlocks.

Scamp’s high freeboard and wide beam requires 9’+ oars which are impossible to stow in Scamps’ cockpit. We have engineered high quality, strong 2 piece 9’4″ spoon blade oars that disassemble and store concealed inside the cockpit coamings. Another practical storage area is on the vertical seat sides, clipped into modified fishing rod holders.

Cover for trailering/storage

Top Notch fabric, custom sewn for Scamp. Protects deck and cockpit during trailering and storage.

Bimini/Camping style cockpit cover

Fully enclosed bimini cockpit enclosure with zippered windows and side curtains. Sides zip off individually for fully-customized protection from the weather.

Scamp spar and sail bag

We are always looking for ways to simplify sailing, and one of the most vexing chores is the assembling the rig. Wouldn’t it be nice to be able to pull the completely assembled, ready to hoist sail and spars out of a bag? This special bag is 12′ long and has two long pockets; the lower pocket is for the two-section mast. The upper pocket has a full length zipper so you can store the sail lashed to the yard and boom with even the jiffy reefing in place. Just pull the mast with halyard attached from the bag and plop into the cabin-top ‘Scamp Ramp.’ Then fasten your halyard to the Yard and hoist the whole rigged sail out of the bag. All you have left to do is run the halyard and downhaul to their respective cleats, clip the mainsheet and lazy jacks to the boom and away you go. 10 minutes, done.

Stirrup reboarding system

Transom boarding ladder ….. still under development.

- 17′ Jersey Skiff

- 17′ Salish Voyager

- 16.5′ Melonseed

- 15′ Lobster Boat

- 14′ Whitehall

- 12′ Point Defiance

- 10′ Navigator

- 9.5′ Captain’s Gig

- 8′ Nisqually

- Available Now!

- New In Stock

SCAMP Rigging Tutorial

If you’re not familiar with balanced-lug rigging, here’s a great tutorial showing how to set up this simple and intuitive rig.

Imagining your ideal boat?

Take a turn through our online quote creator to see the possibilities. No haggling, no commitment.

Explore More Boats

Small Craft Advisor

Boat Designs: Evaluating SCAMP’S Big Sister

(this new welsford cruiser checks a lot of boxes…).

Over the past few days I’ve had email exchanges with John Welsford, New Zealand designer, regarding a brainstorm that’s been percolating in his clever, whimsical noggin: A bigger, more commodious takeoff on his wildly popular SCAMP design.

As most SCA readers know, the 11’ 11” SCAMP design was conceived 13 years ago when Josh Colvin, editor of this fine publication, asked Welsford to come up with a new kind of small cruising boat—one small enough to explore the most hard-to-penetrate backwaters, while being easy to rig, light enough to trailer with the smallest of tow vehicles, surprisingly great under sail, and comfy for overnight camp-cruising adventures. So, following some tweaks by designer and master boatbuilder Kees Prins, the resulting sailboat was dubbed SCAMP, for Small Craft Advisor Magazine Project.

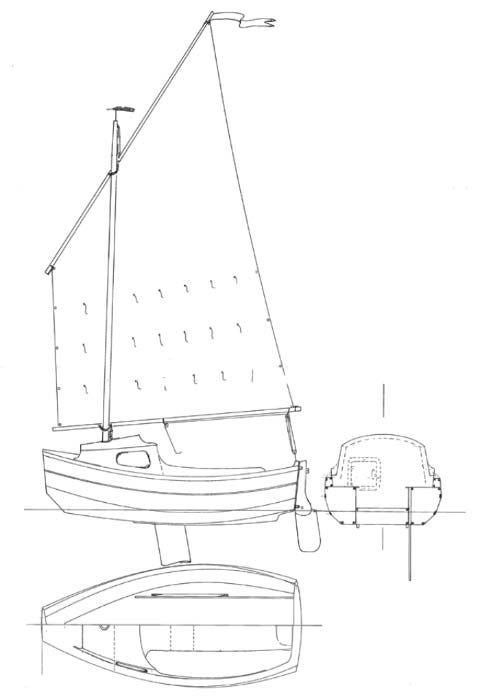

SCAMP DRAWING…

The rest is history: More building plans and kits for SCAMP have been sold over the years than any other small cruising boat we can think of. Besides the original wooden version, Gig Harbor Boat Works was licensed in 2013 to produce a fiberglass SCAMP, and the little giant killer—in wood and fiberglass—has since its debut been at the center of various small-boat rallies, workshops and sailing events.

While SCAMPs are still being built worldwide by enthusiasts, plan and kit sales have slowly been approaching what might be a kind of saturation point. It’s not that “everyone who wants a SCAMP has already built one,” but we get the feeling that it’s time for something new and different—like a SCAMP-inspired design that has the personality and quirky appeal of the original boat, but with more creature comforts (for an aging population of SCAMP lovers).

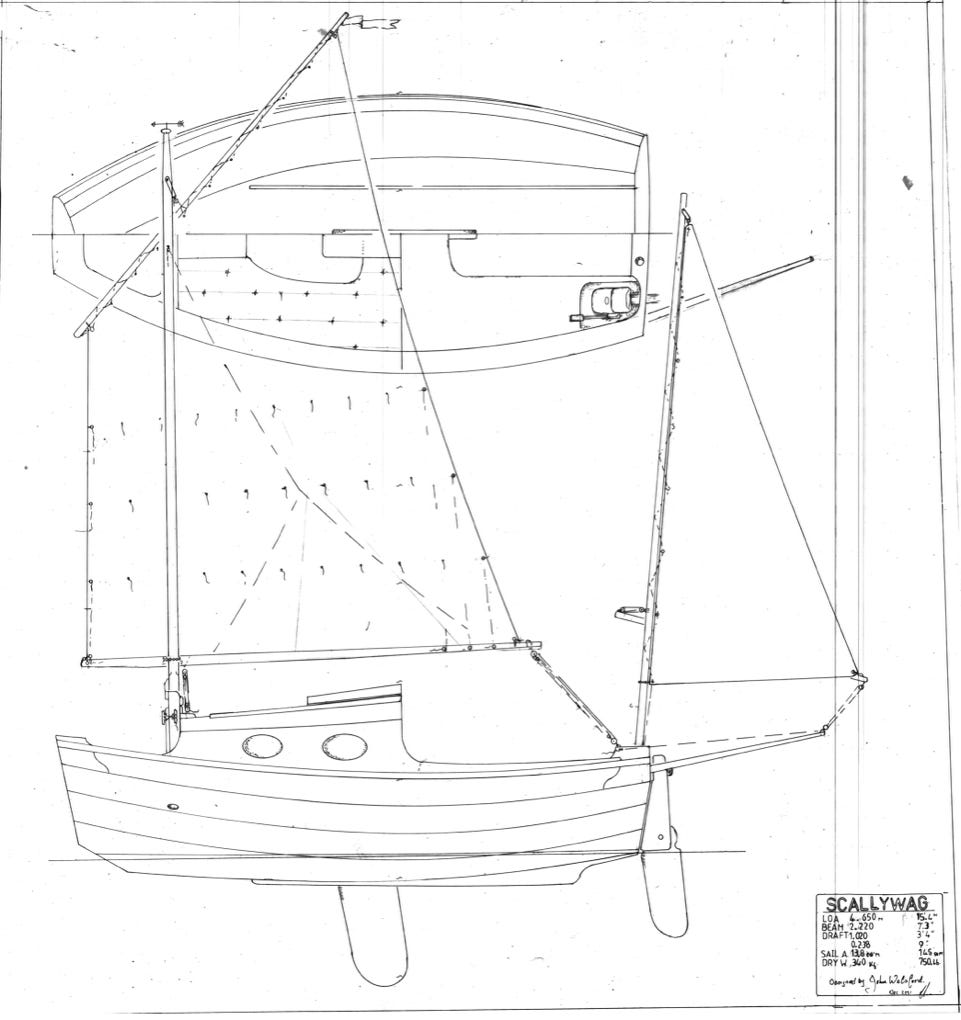

Meet SCALLYWAG, John Welsford’s big sister to SCAMP, a 15’ 4” x 7’ 3” wonder with a “real” cabin, tabernacle mast, mizzen sail, powerful main, water-ballast tanks, sitting headroom down below…and like SCAMP, faster than many onlookers might expect.

SCALLYWAG DRAWING…

This might turn out to be a timely, common-sense follow-up to the successful SCAMP design—so tempting that John Welsford is talking about building one for himself.

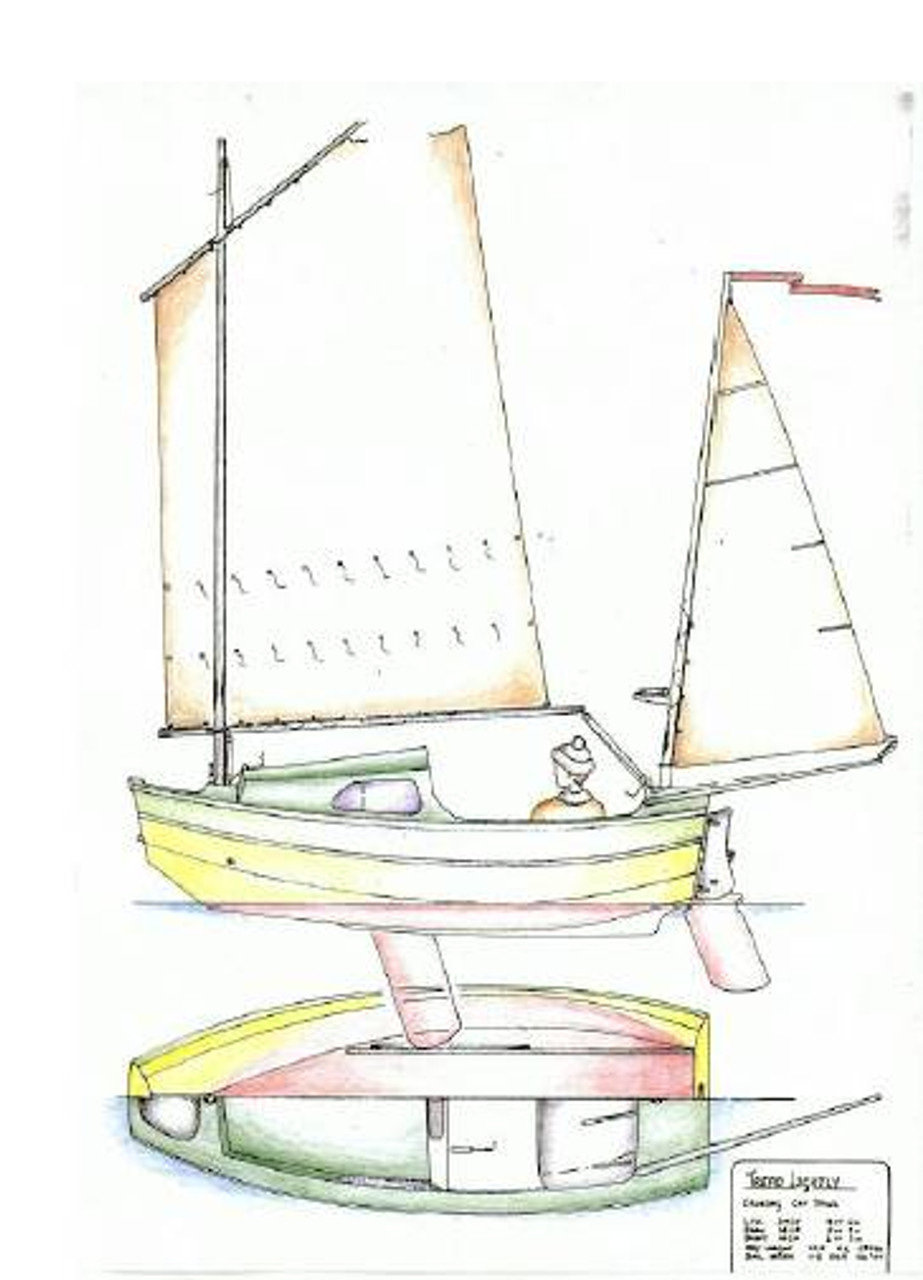

(As a footnote, we might add that in 2008, prior to the introduction of SCAMP in 2010, Welsford came up with another design that was similar to but somewhat larger than SCAMP—called TREAD LIGHTLY, which measured 13’ overall, with a beam of 5’ and addition of a mizzen. The series of similar hulls began with PEANUTS, an experimental build that never quite made the plans list. That design led to TENDER BEHIND, then SHERPA, then TREAD LIGHTLY, then SCAMP, then SCRAPS and now SCALLYWAG. Quite a series!)

TREAD LIGHTLY drawing…immediate predecessor to SCAMP)

Here is John Welsford’s description of the SCALLYWAG design:

“I’ve had a number of people tell me they love SCAMP, but they’d like a ‘real’ cabin—something that would provide shelter for a couple of friends to overnight out of the rain; somewhere with space enough for four to sit and chat over coffee or rum on a cold evening; somewhere with a bench for a cooker, a table to eat the food off of, and lockers for all the essentials…and room for the skipper and first mate to stretch out and sleep in comfort.

“SCALLYWAG is not so big as to make launching and retrieving a chore; her mainmast is in a tabernacle, which makes standing it up easy-peasy for clients who don’t like the idea of lifting a mast that size vertically into place. Her mizzen is light enough to not be a worry, too, in that respect.

“The rig is a powerful one, but easy to access for reefing, and she will heave to under mizzen with the main let free so she sits mostly head-to-wind, dry and restful if a gust has to be waited out.

“I’ve added a pair of big water tanks for ballast, so with that and her beamy shape she’ll be very stable. Her cockpit self-drains, the motor is inside the tall transom for easy access, and while there’s room in the cockpit for four, she’ll be easy to single-hand and relaxing to sail.

“While the relationship between SCALLYWAG and SCAMP is obvious, it’s not just the styling. The backroom calculations in hydrodynamics suggest she’ll handle well, and be faster than many expect. With high stability and the ability to sit upright when aground, she’ll be able to transition from hiding in the mud or sand up a creek somewhere, to making a longer coastal passage without any fuss.

“Construction is simply plywood over ply bulkheads, with stringers to line everything up, and with considerable buoyancy just in case. The plans will have scale drawings of all major components, and we anticipate soon having printable full-sized templates for frames and other key items.”

As for specifications, beyond the overall length of 15’ 4” and beam of 7’ 3,” SCALLYWAG will have board-up draft of 10,” a board-down draft of 3’ 4,” a total sail area of 143 s.f. and a fully-rigged dry weight of 750 lbs. (Incidentally, the beam-to-length ratios of SCAMP and SCALLYWAG are almost identical.)

John Welsford says that plans for SCALLYWAG will be available on December 1, but he can take orders in the meantime. Price will be $245 U.S. funds for emailed, printable PDFs, and the plans can be ordered via John’s website: jwboatdesigns.co.nz (Joel Bergen, well-known for the Welsford Navigator he built and sails in many Northwest small-boat events, will be developing a set of SCALLYWAG patterns in the not-distant future, according to Welsford. Editor’s note: We heard from Joel yesterday; he’s hoping to develop CAD-produced patterns “in a few weeks,” now that he’s received initial SCALLYWAG drawings. Stay tuned; we’ll provide updates on plans and patterns in this space.)

FIRST IMPRESSIONS OF THE SCALLYWAG DESIGN:

Eager to hear what SCAMP-savvy friends might have to say about the SCALLYWAG specs and just-released drawing, we sought initial reactions from…

JOSH COLVIN, editor of Small Craft Advisor , who commissioned the SCAMP design in 2010 and enjoys sailing SCAMP #1:

“There’s certainly no doubt who designed this one! It looks almost as much like Welsford’s PENGUIN as a SCAMP. SCALLYWAG’s length is a sweet spot in terms of accommodations potential. She’ll be rowed less than most SCAMPs, but I love the inboard motor well to keep her lines clean, and the engine right at hand. But her most exciting feature is the addition of the mizzen, which will improve seaworthiness and make managing the mainsail easier.

“Between LONG STEPS and SCALLYWAG, those looking for something like SCAMP, but larger, have great options. I’m excited to see the first boat built—she will be bigger than most expect, just looking at the drawing.” SIMEON BALDWIN, builder of an early SCAMP who has perhaps sailed more nautical miles with a SCAMP than anyone…and who has also served as a generous advisor to fellow SCAMP builders and is an expert on rigging and sailing the little 11’ 11” boats:

“I like what I see of this long-rumored design. Knowing John and his attention to ergonomics, I can anticipate it will work well. The tabernacled mast and addition of a mizzen are most appealing.

“From the drawing I think it may resemble LONG STEPS in terms of the recessed footwell. It also appears he is eschewing a by-design lazarette made popular by many SCAMP owners.

“The double water tanks are something to contemplate. I don’t envision SCALLYWAG as a purpose-built racer with crew, actively keeping high-side ballast on long tacks, like the SKATE 15 that Brandon Davis designed, which utilizes two tanks and a dump-valve system that may be more elaborate than a typical cruising sailor would want to live with. But John may be describing two water tanks that are filled and remain separate from one another.”

(Editor’s note: Welsford’s comment on tanks, “The ballast tanks are linked, and they’re not far enough off the centerline to work independently. There is one each side of the aft end of the centerboard case and they go out as far as the seat-front extensions.”)

“I’m looking forward to how all of this works out!”

BRANDON DAVIS, of Turn Point Design in Port Townsend, whose company cuts CNC kits for the SCAMP and a variety of other small boats. Brandon is also a skilled designer and small-boat sailor:

“I really like this boat, since it has just enough room to have a cabin but it’s still small enough to be trailered, beached and easily built in a garage. The enclosed cabin should encourage longer trips or taking a friend along.

“The longer waterline should increase average sailing speeds. My guess is that rowing speed will be lower than the SCAMP, as the rower will not be able to take advantage of the waterline length because of her weight.

“Will SCALLYWAG be offered as a kit? I could see it selling well as a kit and the market could be ripe. Many SCAMP builders might consider this as their next build.

“I look forward to seeing the first SCALLYWAGs on the water!”

KEES PRINS, designer and boatbuilder, who constructed the first SCAMP while serving as boatshop manager at the Northwest Maritime Center…and in the process suggested and implemented some changes that improved the design:

“I think SCALLYWAG will find a great following in the SCAMP world and beyond. Adding a cabin will greatly enlarge the ‘SCAMP Crowd.’ At that beam, and with twin ballast tanks, stability should be enormous for a boat this length. I would have liked to see a cross section through the cabin to know more about sitting comfort. (Four people hanging out inside seems a little optimistic, but two should be comfortable.)

“I’m curious about what the tabernacle for the unsupported mast will look like. A big sail area, together with a stiff hull will induce a significant load on the tabernacle. There seems to be a deep well for the mast base to swing through, judging by the drain hole.

“All in all, SCALLYWAG looks very promising.”

OSCAR LIND, a serious student of all various small-boat designs , and earlier builder of a SCAMP, who shares at least one thing in common with John Welsford—they’ve never met a pun they didn’t like:

“I might have to clear out the shop and make as much room as possible to build this boat (due to the 7’ 3” beam, especially). It’s so tempting and fills the bill for usability and function.

“It does need a Chinese lug rig, though. I expect quite a few SCALLYWAGS will ultimately be built.”

(Editor’s note: John Welsford comments, “I like the Chinese lugsail, but for a sail of this size on a boat that will be trailered, rigged and derigged for each outing and dry-stored, the extra complexity of the Junk sail slows the process. As well, the balanced lug is in my experience, a little quicker upwind—unless the junk rig has cambered-panel sails, and there are few sailmakers producing those, so I think in this case, simplicity and performance get the nod.”)

As for my personal view as a serial boatbuilder, restorer and sometimes buyer of project boats, I enjoyed owning a SCAMP several years ago. While I loved sailing the boat, I wished it was bigger and included a sleeping cabin. So, John’s new SCALLYWAG design checks many more boxes as an all-around keeper, and I prefer its overall hull, cabin and rig design, not to mention its potential as a serious cruising machine.

So, once again, here’s a chance for you, as a fellow boat nut, to offer your evaluation of SCAMP and her newly-hatched big sister, SCALLYWAG. (Also, please add other thoughts in the comments section below…) • SCA •

Ready for more?

Driftboat Wood Kit

Boatbuilders FORUM

Boat plans, patterns and supplies for the amateur boat builder.

Every year, thousands of amateurs much like yourself build their own boats the proven Glen-L way. Many builders save 50% or more over the price of a factory-built boat. It’s easier than you might think, and it can be a rewarding experience.

Industry experts

Established in 1953

300+ Models

International shipping

Plans & Patterns

All plans come with a 30-Day money back guarantee.

Providing boat Plans & memories Since 1953

For more than 60 years Glen-L has been the world’s premier supplier of boat plans and patterns designed for the amatuer builder. We make it even simpler by offering associated supplies and hardware kits for each design.

More Products

Boatbuilding hardware

Books, DVDs, & Audio

Tools & Raptor® Fastenings

Epoxy and Supplies

Featured designs.

View Plan Details

Cabin Skiff

This Fiberglass Camper Is Barely Longer Than A Smart Car, Yet You Can Still Sleep In It

- By Mercedes Streeter

- May 25, 2024

- 22 Comments

Summer has finally reached America, which means countless people are breaking their cabin fever by taking camping trips. The American way is to hitch up a massive trailer to a chunky truck and then hit the road, but it doesn’t have to be this way. One company in England felt you could go camping with something smaller, way smaller. Meet the Island Plastics Romini, a fiberglass camper standing just 9.8 feet long, or just 12 inches longer than a Smart Fortwo. Its body is even smaller, clocking in at just 7 feet, or smaller than a Smart. Yet, somehow, you can still sleep in this thing!

The Romini was never sold in America. As it is, it was barely even sold in the UK. Reportedly, fewer than 200 of these campers ever left the factory on the Isle of Wight. That makes a Romini rare anywhere in the world, but someone actually went through the work to find one and bring it into America.

If you buy this Romini, it’s unlikely you’ll ever see another ever again. Don’t think it’s just a rolling bed, either, because it has some real equipment inside.

The Romini was a product of Island Plastics Limited, a company that was based in Ryde on the Isle of Wight. Finding any history of this company is difficult, but corporate websites record its founding in 1959. While I couldn’t find who started the company or why, I can tell you that Island Plastics specialized in plastic products and largely built different vehicles out of glass-reinforced plastic. Some further searching revealed boats made by Island Plastics in the 1970s and 1980s.

The company also built land vehicles including emergency recovery trucks and an Austin-Healey frogeye Sprite replica called the “Megasprite.”

Island Plastics also got into the RV industry. One of the units produced by Island Plastics was the Romahome. According to the Roma Club , the Romahome was invented in the late 1970s by engineer Barry Stimpson. Tiny Kei trucks like the Honda Acty were finding their way over to the UK and Stimpson designed a little pod designed to fit on the back of one of these trucks. As the Honda Acty got a little bigger and faster, Stimpson upgraded his camper design to match. Island Plastics bought the design, improved it, and launched it in 1982 as the Romahome.

Later, Island Plastics realized that most Romahome owners never disconnected their campers from their Kei trucks. This gave the company the idea to just build permanent motorhomes with the Romahome name. The Romahome began an evolution that saw it move to a Citroën C15 base and eventually to vans.

Island Plastics would fall into Administration in 1998 and the company’s assets were listed for sale. That didn’t stop members of Island Plastics from relaunching the company in 2001 as Romahome Ltd., which continued building and evolving the Romahome.

The camper we’re talking about today came from that time in the 1980s that Island Plastics was open and still experimenting with RVs. While the Romahome converted Kei trucks into motorhomes, the Romini was a towable designed to be pulled by practically any car in existence at the time.

Production of the Romini began in 1985 and according to Island Plastics , the trailer was supposed to be the ultimate in tiny camping. The double-hulled fiberglass unit weighs just 826 pounds, which Island Plastics marketed as being able to be hauled by vehicles as small as the original Mini.

The low cost of ownership was another big selling point of the Romini. Island Plastics said that by having its tiny trailer, you would save money from the initial purchase price, save money on ferries, and have an easy time parking.

As I said before, this trailer has an interior just 7 feet long. Despite that, Island Plastics fit most of what you needed in there. A standard Romini came equipped with two full-size bunks, a sink, a stove, a dinette table, and storage solutions. If that wasn’t enough for you, there was a wide options list including a third bunk, an oven, a refrigerator, a chemical toilet, a heater, and a fire extinguisher. Island Plastics also optioned the trailer with an awning so you can chill outside of the trailer in shade.

The Romini was also fairly advanced. Island Plastics built the trailer on a galvanized chassis, and then encased the chassis within the fiberglass for further rust protection. A foam sandwich sat between the fiberglass hulls for insulation and dual-pane acrylics were used for windows. You got all of that, plus simulated teak trim and carpet in a capsule with six feet of headroom. You even had some cargo space, as the trailer weighed 1,433 pounds when loaded to the gills.

I haven’t been able to find the original price of the Romini, but for some reason, only around 200 of them were built between 1985 and 1990. Apparently, there was a longer version called the LS that had a bigger bed. Then, a company called Collier Designs bought the design in 1990, creating the Romini LXS. This one was a full two feet, six inches longer than the original, allowing the addition of a bathroom.

This 1985 Romini was imported into America 20 years ago by a collector of British cars. The trailer was then brought up to Oregon’s DMV code and then wasn’t used. When you pop open the door you’re brought back to 1985 since the trailer still has its original interior. While that’s cool, as is the fact that the bed sleeps a six-foot person, there are some quirks to be aware of. The first is that this trailer is a standard model, so you aren’t going to find any of the above-noted options.

The trailer being original means the stove is fueled by butane rather than the common propane that is used today. The Romini also has an electrical system but has UK connections. Thankfully, an adaptor for the trailer’s wiring harness allows the trailer to hitch up to an American car without an issue. What will be a slight issue is the trailer’s metric tongue. You’ll need to carry around the included metric ball because otherwise, you won’t be able to tow the trailer.

Other good news includes the fact that this trailer is light, but it has surge brakes. It also has a hand-operated parking brake so the trailer doesn’t roll when parked. The Romini rolls down the road on 12-inch wheels and a rubber torsion bar suspension.

If you’re interested, the seller has the trailer listed for $17,900 in Veneta, Oregon. That is a pretty penny for such a tiny camper, but its rarity and fun design might make the price worth it for someone.

The trailer looks great despite spending so much of its life sitting. Now, it’s ready to go camping after waiting for 20 years. You’ll want to replace those ancient tires and figure out an adapter for the electrical system, but this camper is ready to be the cutest thing in your campground. It’s just a foot longer than a Smart Fortwo and could be towed by that same Smart! How many other campers with stand-up room will you find like that?

(Images: Facebook Seller , unless otherwise noted.)

- What Is The Most Tedious Repair Job You’ve Ever Done?

- The Most Exciting Part Of The Monaco Grand Prix Might Be This Out-Of-Control Boat Hitting A Yacht On ‘Billionaire’s Row’

- A NASCAR Engineer Tells You Everything You Need To Know About Tire Temperature And Grip

- Autopian Readers, I Need Your Help Finding A Car Part To Put On My Necklace (And Also COTD)

- campers , camping , fiberglass camper , island plastics , romini , rvs , RVs for sale , travel trailers , Weird

Mercedes Streeter

Rubber torsion bars?

It makes for a very soft ride.

Very common for travel trailers, especially smaller ones. Could be original (but I’d be surprised the rubber lasted this long), or could be Dexter Torflex. It’s basically a solid square bar rotating within a hollow square bar, with rubber between for spring+dampener.

Yes, I know this has nothing to with campers, or real cars, but it is tiny and amazing;

https://www.youtube.com/watch?v=ck3Cycrmvcc&t=2s

It took eleven years and 5 million euros to build!

This site has opened my eyes to fiberglass campers. I saw a longer scamp the other week and just about died

Bigger on the inside? Is this the TARDIS of campers? Figures it’d be British!

I’m confused. If the body of this this thing is seven feet long, and it has a two-burner stone at the foot of the bed, and you lose a couple inches to double-wall construction, how do those beds accommodate a six-footer? Doesn’t seem to add up, does it? I do think it’s stand-uppable, because the profile is almost square.

Same, makes no sense.

I’m guessing they mean a single six-footer can sleep diagonally. Either that or tall folks can sleep as long as they do so in the fetal position.

I had an A-Liner Alite that I sold because I just wasn’t using it enough, but something like this would maybe be compelling enough to get me to try an RV again. Fortunately, it’s rare, out of production, and out of budget, so I don’t need to worry about dragging one home anytime soon

The question is would want to sleep in it? I would go Hulk Mode in that small of a space. Plus if someone is with you, you are constantly going outside to pass each other.

I think we need to discuss various definitions of “camper (trailer type)”. At the core of it might be “an enclosed space for sleeping in the outdoors that is towable by a vehicle”. This certainly meets that definition.

But there may or may not be additional qualifications, such as: Can you prepare food in it? Can you stand upright in it? Can you poop in it? Can you wash your body in it? etc.

I suppose every individual who wants a camping trailer gets to choose what is important to them, and how they prioritize it. For me, I’d rather trade out an indoor kitchen (cooking inside usually leaves lingering odors that I don’t appreciate in my sleeping space, and outdoor cooking is easier) and replace it with a wet bath. But everyone gets their own choices, and there’s probably a camper style for everyone.

you can poop in any vehicle

Heh. I wonder if an old friend who became an evangelist in the EU had one of these for his travels. He used to speak in metric tongues.

That’s a neat little trailer and adds to the Romahome lore. On the subject of dinky campers, I have seen photos of a Fiat 850 van from the 70s or early 80s that looked like a 3/4 sized VW Westfalia.

Love this! It’s like the uk equivalent of an og teardrop. I always loved the romahomes and before my wife and I had kids we talked about buying one to travel in while living in the uk

Is this an article or an argumentative essay to yourself why this should be your next purchase? ???? The use of a Smart as a metric is a dead giveaway this is heading for your fleet!

Only Mercedes is using Smart Car as a unit of measurement.

Yet another example of Americans being willing to use anything other than the metric system!

There are two kinds of countries, those who use the Metric system and those who landed a man on the moon. 🙂

We have to be such good engineers here because we have to deal with all types of units. I even have to occasionally deal with Imperial units!

Base units are fine. It’s when you get into derived units it starts getting really annoying. Or my least favorite unit, the ton. Long tons, short tons, metric tons, cooler tons, and boiler tons. Two are units of weight, one is a unit of mass, one is a measure of the rate of energy transfer over a unit of time, and the last one just sucks.

NASA used the metric system for that. Smart cars hadn’t been invented yet.

Recent Posts

How Driving ‘The Ugliest Car In The World’ Helped Me Discover The Masterpiece’s Real Flaws

Maybe don’t light a cigarette in a car carrying a propane tank, what are your automotive icks autopian asks.

BUY MORE SAVE MORE - Now Through Memorial Day! $15 off a $150 order / $40 off a $250 order / $100 off orders of $500+

- Plans & Kits

- Kits and Packages

- Qty in Cart

Scamp Foils Kit

SCAMP CNC PLYWOOD KIT

S.C.A.M.P. Plans Instant Download

Scamp Hardware

SCAMP Rigging Kits

Rudder Hardware for Scamp

S.C.A.M.P. Printed Plans

S.C.A.M.P. Sail

- Total: items /

- Add all to cart

Adding your products to cart

Welcome to eWillys.com, the best resource for Vintage Jeeps and Willys

email Need to contact me and don't have my email? Click on email button.

About eWillys

More information.

- Advanced Search: Try out the advanced search page

- About eWillys: More about the website

- About Finding Virginia: Information about my first Book

- David Eilers: Why do I suffer from Willys Sickness?

- Lost Biscuit: My 1949 CJ-3A Fiberglass Flattie • Biscuit's specs

- FAQs: Questions & Answers about eWillys

- Reader Feedback: A sampling of Virtual Hi-Fives from Readers

- Donation Information: Want to donate? Here's how ...

- Contact Me: Use this form to contact me or email me at d [at] ewillys.com

- 2013 Trips: FC-Roundup & Southwest , East Coast &Festivals

eBay Search

These quick searches can help you find things on eBay . People list in the wrong categories all the time, so don't be surprised to see brochures in the parts area for example.

- Vintage Jeeps: Find Jeeps for sale

- Jeeps Parts: Find parts for sale. There are thousands.

- Memorabilia: Search collectibles for brochures and more.

- Books: There are all kinds of books on eBay

- Models: Jeep puzzles and models on eBay

- Toys: Some toys are vintage and some are new.

- Clothing: Sometimes there are really unique items here.

Jeeps Showcase

The links to posts below show jeeps grouped by models, condition, and other ways. Some of these jeeps are for sale and others have been sold. If you are unsure whether a vehicle is still for sale or not, email me at d [at] ewillys.com for more info.

- Stock Jeeps:

- All Stock Jeeps

- DJ-3A & Surreys

- Willys Trucks

- Willys Wagons

- Forward Controls

- Nice Jeeps:

- All Nice Jeeps

- Other Models:

- Early Bantam/Ford/Willys

- Ford GPA / Seep

- CJ-2A Lefty

- FJ-Fleet Vans

- Mitey Mites

- VEEPs (VW Jeeps)

- Racing Jeeps

- Tender Trucks

- Austin Champ

Featured Articles

There are plenty of interesting, unusual, historic and surprising stories related to Jeeps and their owners. In addition, some of these features have nothing to do with jeeps. This link will display all featured stories starting from the latest.

- Museums with Jeeps

- Library Collections

- Vintage Images

- Past News Articles

- Drawings, Paintings, Statues

- Advertising & Brochures

- Magazine Articles

- Postcards with Jeeps

- Reader Builds

- Toys and Kids Stuff

- Craig's Weekly Pic

- Holiday Jeeps Stuff

- Artists/Drawings

- Dealership Information

- Life Magazine

- Toledo Public Library

- National Archives

- Mechanix Magazine

- Popular Mechancis

- Popular Science

- Canadian Archives

- Four Wheeler Magazine

- Denver Public Library

- Sam Thomas at Flatfender Willys:

- Ideas, tips and tricks

- Custom Sedan Jeeps

- Parmley Body

- DJ-3A Surrey

- Parkway Conversion

- Traveller Wagon

- SAS or LDRG Jeeps

- CJ-2A Truck

- Body Extenders

- Jeep Trains

- Tow Capable

- Hawaii Boat Bodies

- Painting Ideas

- Diamond Plating

- Builds and Ideas

- Nate's builds and ideas

- Jim's builds

- My build (lost biscuit)

- Chassis Electrical

- Suspension/Steering

- Modifications & Options

- Louvered Hoods

- Windshield Mods

- Unique California Mods

- Dually Tire Examples

- Service Mods

- Electric Jeeps

- Welders/Generators/Industry

- Package Delivery Van

- Roll Cage Examples

- Benders and Notchers

- Drive Train

- Transmissions

- Transfercases

- ATV, Warn, Saturn, and Borg Warner ODs

- Grover's Speed Calculator

- Early jeep/MB/GPW: G503.com

- Early jeep/MB/GPW: Steel Soldiers Forum

- Early jeep/MB/GPW: Antique Willys Assoc

- CJ-2A: CJ-2A Page Forum

- CJ-3A: CJ-3A Page Forum

- CJ-3B: CJ-3B Page Forum

- CJ-5 & 6: earlyCJ5 Forum

- M-38 & M-38A1: G503 - M38 forum

- M-38 & M-38A1: Willys Military Jeeps

- M-38 & M-38A1: Yahoo M Jeeps Group

- Jeepsters: Forum at Offroad.com

- Willys Trucks: Old Willys Forum

- Willys Trucks: Grovers Trucks

- Willys Wagons: Old Willys Forum

- Willys Wagons: Willys Country

- Forward Controls: The Forward Control Forum

- JeepTruck.com Forum: Jeep Trucks

- IFSJA Forum: Full Size Jeep Trucks

- Historic Jeep Materials: This Old Jeep

- General 4x4: Jeeps.net

- General 4x4: Willys Online

- General 4x4: JeepForum

- General 4x4: Pirate 4x4

- General 4x4: Offroad.com

Looking for parts and not sure where to go? There are a variety of large and small new and used parts sellers both online and offline.

- New Parts: Find New Parts

- Used & Salvage Parts: Find Used Parts

Buying Tips

Importantly, the allure of buying a project jeep can be romantic. The reality of restoring a jeep can be quite different, expensive and overwhelming without the right tools and resources. So, tread carefully when purchasing a "project". If you have any concerns about buying a vintage jeep, or run across a scam, feel free to contact me for help, comments or concerns .

- Options for Buying/Selling: Where to list/find Jeeps

- Buyer's Check List: Here's a simple checklist

Selling Tips

- List at eWillys: eMail [email protected] to list your jeep. No Cost.

- Scams: Learn more about Jeep related scams

- Photographs: View all , Camera Choice , Light Matters , Your Overall Pic , Image Backgrounds , Other Images , Editing Images , Sizing Images

Custom Wagon Build San Tan Valley, AZ $14,500

It’s not clear to me if the price includes the trailer or not.

https://www.facebook.com/marketplace/item/1087608242297952/

“1954 Willys Wagon – Custom Build Built by 4 Wheelers Supply in Phoenix with some later mods done by current owner.

✔️Crate GM Performance 350 385hp ($7400 current GM cost) less than 700 miles Holley Double Pumper, Ram Horns, Ron Davis Radiator, MSD ignition ✔️Th350 fresh rebuild, reverse manual valve body, all Hughes parts ✔️205 fresh rebuild ✔️Dana 44 with 4:88, chromoly axles, Detroit True Track ✔️Rear 9.5” 14 Bolt 33 spline, Detroit Locker 4:88 ✔️Deep PRP Suspension Seats ✔️Art Carr Shifter ✔️30 Gallon cell ✔️35” BFG Crawlers ✔️YJ Rubican Express 1.5” spring over ✔️Bilstein Shocks ✔️Warn Winch (new) ✔️Car trailer available separately ✔️Whole pallet of spare parts ✔️Steering Quickener with disconnect steering wheel ✔️Wipers, horn, turn signals, mirrors ✔️Custom Roof Rack

Car hauler available to make a package deal. San Tan Valley, AZ Location is approximate”

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Notify me of followup comments via e-mail

Subscribe without commenting E-Mail:

JEEPS BY MODEL

- Prototype Jeeps

- GPW (Ford MB)

- Hotchkiss M201

- The Lightweights

- CJ-2A (VECs)

- CJ-2L: Lengthened CJ-2As

- DJ-3A/Surrey/Gala

- DJ-5 & DJ-6

- FC150/FC170/M677

JEEPS BY TOPIC

- VEEP (VW Jeep)

- Mighty Mites

- International Related

- Mitsubishi Jeeps

- Italian Jeeps

- Nissan Jeeps

- CJ-2A Trucks

- Texas Hunting Jeeps

- Constabulary Jeeps

- Jeep Posses

- Circus Jeeps

- Coffee Jeeps

- Shore Patrol Jeeps

- Border Patrol Jeeps

- Sedan Jeeps

- Follow Me Jeeps

- Racing Related

- Fire/Police/Industry Vehicles

- Ice Cream Jeeps

- Jeep Mowers

- Tow-Capable Jeeps

- Odd Jeep Bodies

- Bill's Bantam Site

- Gavin's MA/GPA Site

- Bantam BRC 40

- Brian's Military Jeeps

- Bantam T3-C Trailers

- Andy's m201.COM

- 42 Ford GPW

- Jeep Fabrikken

WEB SITES Cont.

- 1943 GPW Build

- M Series Jeeps

- M38-M38A1_M606

- Rotabuggy (flying jeep)

- Farm Jeep (AgriJeeps)

- The CJ-2A Page

- The CJ-3A Page

- The CJ-3A Info Page

- The CJ-3B Page

- The Early CJ5 Site

- The FC Connection

- Willys Jeep Trucks

- Willys Country (Wagons)

- Old Willys Forum

- Willys Tech

- Hanson Mechanical

- Jeepster Registry & Info

- KaiserWillys History

- Visual Reference Site

- OffRoad Action Site

- This Old Jeep

- Bram Van Buuren Jeeps

- Paratrooper Vehicles

- Jeepster Club

- Hungarian Jeep Website

- Long Range Desert Group

- WWII Airborne MB

- 4x4 History from 1824

- Alex's Jp History Tahiti

- Jeep website in France

- Manuals at Archive.org

- Military Vehicle PS

- Wildenberg Parts

- Jeep Willys World

Copyright © 2008-2017 eWillys. All rights reserved.

Powered by Wordpress , theme based on the Simple Grid Theme .

Some of the Daimler Chrysler, Inc., trademarks including Jeep® .

- WordPress.org

- Documentation

- Support Forums

- My Boats & Boat Articles

- Boatbuilding Plans

- Scamp Sailboat

Steps in Building a SCAMP sailboat

Links to all my scamp building pages.

My SCAMP build, Making a Mast

Cutting lots of strips for mast staves..

I'm getting ready to cut the mast staves and at the same time I'll cut the support strips. Scamp seams are built using a combination of stitch and glue and strips of wood that give a point of attachment to the thin plywood. Not quite chine logs but a framework of strips that add rigidity and increased gluing surface.

It took a bit of time to clear the table saw, set up an out table, make sure the blade was perfectly square and set up the feather boards and stop blocks.

Because I'm cutting 2x4 lumber down to thinner strips some wood will certainly warp as I cut and there is a real danger of binding and kick back. The feather board and stop blocks make the process much safer. I also cut in 2 swipes, this helps release the tensions.

I spent a couple of hours of quality time with my table saw and ended up with a large pile of strips. I've rough cut only the thickness of the strips, the width I'll do later. The support strips which will be used to support various parts of the sailboat such as the seat, are 20mm plus a bit for shrinkage and planing, the mast staves are 17 mm plus some for cleaning up and I have some extra planks of various ends at about 15 mm that I can glue up if I need more strips.

I'm using 8 feet lumber select grade. There are lots of small solid knots. I'll have to remove any large knot and scarf pieces together for the mast, time consuming but it works well. That's what I did for my Skerry mast and it has been rock solid. I used old knotty pine shelving. It was a sort of patchwork mast.

NOTE IN HINDSIGHT: It took quite a lot of time to glue the pieces together and IF you consider time it would have been cheaper to buy better wood. I just did not have easy access to it. In terms of strength the seams are good so I don't think I've compromised strength.

This lumber is mostly spruce. I can see that there is the odd board of other wood thrown in.

I've cut lots of extra so I can pick the better pieces and use the rest in other projects. I always seem to need bits of wood.

I'll plane them after a day so that they will have had a chance to warp if they plan to.

Cutting the pieces for the mast.

After planing the long strips, I set up the table saw to cut the notches. I don't bother cutting the width of the board because when I cut the notch the width will automatically be right

Instead of using the fence I clamped a board. It is easier to feed and some of my boards have slight warps and this makes it easier to cut.

The blade is at 45 degrees. I've checked and measured the width.

I'm using 2x4 x 8 feet and the mast is to be 16 feet so I will have quite a number of smaller pieces that will need to be joined. I don't want to have to set up to cut really long strips, everything gets complicated and I have to feed to the outside because I don't have 32 + feet. That's why I have a garage door in the shop. It's winter and it's cold so I'm using a comfortable 8 feet.

I cut a couple of test pieces and assembled them. I'm finding that the plans's 30 mm long gives me a slightly too large diameter. I guess that there is a bit of extra for sanding and finishing.

I set this up to cut the scarf joints. I will need many joints to get the full length and to cut out the bigger knots or flaws. I did this for my Skerry mast and it has held up beautifully even though it was made of softer pine. My boards are spruce for the most part.

The blade is at a slight angle and the jig holds the piece to be cut between 3 guide boards. The little clamp holds it while I slide the whole thing through the blade. It fits on top of the table saw fence.

The blade is as hight as it will go and this gives me a 6 to 1 scarf, or a bit more. This is not ideal but I used an even smaller scarf on the Skerry and got away with it so I'm confident this will work. The joints end up looking like curved lines in the round mast and actually look like wood grain so it blends in well.

There are many ways to cut a scarf joint but this will be very easy, safe and fast.

The joints should be staggered so that they do not weaken an area. It looks better too. I'm not sure that a joint like this weakens the board because the filled epoxy glue is stronger than the wood and I will be coating the mast with epoxy as well. I don't think the mast is expected to bend very much

I did a quick check to make sure the pieces fit and they are nice and flat and well cut.

Joining some of she shorter pieces. Since the mast is to be about 16 feet and I'm using 8 feet lumber, there are at least 3pieces for each stave. I've cut out any of the larger knots and that means many more joints.

This allows me to use lesser quality wood at the expense of having to take much time building the mast. There are no handy lumber yards near here so it's not easy to go shopping for nice wood either.

Now that all the cutting out of bad knots is done the putting together will go quickly. For a while I had stuff everywhere and not a surface to work on. I've spent some time and cleared sawdust and extra wood away.

Once I have all the staves cut out and lined up so there is no join at the same level, I will plane them so that the mast tapers when it is put together.

Detail of one of the joints. I've checked the ones I've done so far and they are all sound. I'm sure the joints are more sturdy than the wood. I don't think this mast is intended to bend so having stiffer joints is not an issue.

8 pieces 17 plus feet long ready to be slightly tapered. I'll probably use the belt sander. There are too many small knots and joints to use the bench plane.

After measuring the staves and cutting them even, I realized that I had mis-measured. I will be about 10mm short. Dang and Poot!

I clamped the bundle together and using the belt sander thinned out the staves to create the taper on the mast. It worked very well.

Now I'm bracing myself, a nerve wracking marathon glue session to put it all together.

I plan to put 3 pieces of wood inside the mast at vulnerable spots, the base, the top and where the mast touches the top of the cabin.

The core was cut from a piece of a pallet. I had to experiment to figure out the size for the top of the mast but I got it.

I made a glue spreader from a plastic bottle. I used one when I made the Skerry mast and it works really well. By leaning it you can control how much glue is left and the sides keeps the glue from going to the sides of the wood.

I measured out several glasses of epoxy what I could mix quickly as required. In the end I under-estimated how much I would need and had to measure some more.

I like to use a gram scale to measure the epoxy. It's fast and more accurate than I can measure by making marks on containers. The pumps are not as accurate I think. At least not the ones I had. I don't think it really makes much of a difference. In this case I'm using MAS epoxy and the hardener and resin are almost the same weight so there is not a significant difference if it is measured 2:1 by weight. How do I know, I tried both ways.

I put plastic under the mast parts, got my gloves, epoxy, thickeners, drill with bit, clamps, plastic ties, paint brush, baggies, scissors, tongue depressors, put some wood on the fire, chose some music, and finally took a deep breath.

The first part is easy, coat the V and the inside face with epoxy so it does not suck up the glue and starve the joints. No problem if that starts to kick off.

The next 2 hours are fast paced and insanely stressful, at least for me. I mixed epoxy, thickened it with silica and wood flour, squeezed in the V, spread it as best I could, and repeated this until I had all 8 strips, all 16 feet of them, done. I would change my gloves regularly.

NOTE: In Hindsight I would have been better to forget about my little spreader and line up the 8 strips V side up, and paint on the thickened epoxy into the 8 together, maybe clamping them temporarily side by side. There would have been more squeeze out when I assembled them but it would have taken less time.

Even though I'm using slow hardener, and the shop is not warm, I only have about 45 minutes of open time. I was getting close to this and had not even put the mast together yet, let alone clamped it.

Sorry I have no photos, I was working too fast and everything was sticky.

Some pipe clamps and many zip ties secure the mast.

When I made the mast for the Skerry I had a lot of trouble getting everything together. This time I was wiser. I had put bar clamps with the end making a fence sticking up and stopping the staves from falling off the table so I did not have to worry about both ends at once. I took the photo after removing the clamps and taking the sticky gloves off the workbench.

When I made the spars I actually made a few semicircular stands that help position the staves. That worked well too. My Page on making the yard for the SCAMP

I went to the top of the mast, and forced the staves in position. I did not worry about anything except getting the very end lined up. This was quite easy to do. I slipped in the core which I had covered with thickened epoxy all ready to go. I then slipped on a round of cut off plastic pipe to roughly clamp the end and put a pipe clamp on. I then went down to about half way and manhandled the staves till they were in position, slipped on a clamp and went to the spot where I had marked the position for the core piece at roof level and put in the core and put a clamp. The end was pretty much in position so I put in the bottom core and put on another clamp. I used the drill with a driving bit to tighten the pipe clamps

Now my time is getting short, my epoxy is just starting to get thicker and it's harder to get it to squeeze out, YIKES. It took a lot more force than it would have 15 minutes earlier. I eventually got the mast clamped. I used pipe clamps and plastic ties. I had not expected to need a lot of pipe clamps so I had to tighten with the pipe clamp, put on a couple of plastic ties and remove the pipe clamp and go tighten further down. I had a couple of spots that did not want to squeeze in and I used a bar clamp to push in the resisting stave. Once pushed in I could add a plastic tie or 2 and move on. Once in position the staves did not come back out so the plastic ties were enough to hold the mast in postion. I had prepared plastic wrap but that was not enough force.

I spent some time going up and down the mast, tightening the clamps, adding plastic ties and removing some of the squeezed out glue.

By this time everything is gummy, the screwdriver and drill are covered with epoxy and some sawdust, I am covered with goo and I'm a basket case. There are used gloves everywhere and my glue mixing table is a mess. The good news is that the Scamp mast is together. It is also quite straight with no significant bend.

The Bird mouth method of mastmaking is very forgiving and for the most part a mast will be fairly straight unless it was clamped very crooked.

I spend the next while checking that the mast is straight and that there is no obvious problems. I checked the level of the supporting table and various bits I had set up to support the mast and wedged in anything not quite right. I had lots of little wedges from the joints I had cut so that worked out well. I put a log on the fire so that the shop would be warm to set the epoxy and went back to the house with my drill hoping to get some of the goop off. I used vinegar, not great but it got some of it.

The next morning I took off the clamps and snipped the plastic ties. The epoxy has set and there is no obvious flaw. It seems quite straight too.

Using my smoothing plane I have started rounding the mast. I plan to gradually work around the the mast rounding it. There are a few small gaps where the epoxy did not squeeze out. I'll drip some epoxy and hope it fills any gap. I don't think there are many though.

This is what the mast looks after my first pass. I'm not being particularly careful at this point since I'm still roughing off the extra corner.After going around the mast once my plane is already starting to feel dull. Silica thickener is rough on a plane edge. I sharpened it and am ready to get back to rounding the mast.

I've been rounding the mast gradually using my smoothing plane. The shop is warm, I have nice music on and I'm just gradually rounding the mast. I'm up to my ankles in shavings. I'll collect these, they are good to start the fire.

By the end of the afternoon I have a roundish mast. I'll need to sand some more but it's not bad. I had some tear-out in a couple of spots while I was planing so the sanding should take care of that.

I've checked the diameter of the scamp mast and it's about 2mm over. I'm hoping that will come off when I sand.

It's a bit heavier than I had hoped. I'm not finished shaping it so it will lose some weight, and I can handle it.

I spent most of the day sanding the mast and getting the flats out. It is now as round as I can get it. I need to finalize the size. The mast turned out about 3 mm too thick in most parts.

I checked the weight and I'm just short of 17 pounds.

Today I will finalize the size. I checked and rechecked the diameter and took my newly sharpened plane and took off a very thin shaving all around. After a couple of hours of careful planing and sanding I'm very close to exact size and that's good enough for me. The mast now weight just under 15 pounds. It will put on a bit of weight with epoxy and varnish but I don't think I'll be much over 15 pounds completed. Compare that to my carbon fibre mast which is just under 4 pounds for a 15 foot mast.

The top of the mast is tapered slightly less than the plans call for. My wood is not high quality and I'm not happy thinning it too much. It's only a couple of mm larger than the plan. There is a core for about 8 inches. I like the end to be full to support any screw or attachment that goes on the top.

I used the drill press to make a half inch hole in the top of the mast. It's useful to have a spot to quickly tie things to.

I used files and sandpaper to smooth the hole opening so that it will not damage lines tied to it.

After trimming the bottom of the mast I sanded everything with a fine paper, vacuumed it really well and wiped any dust off. I paid particular attention to a couple of spots that did not have enough epoxy between staves.

I made up a thickened epoxy and filled any gap and a couple of tear out spots. I then coated the mast with a coat of un-thickened epoxy. I plan to put 2 or 3 light coats of epoxy.

Fast forward a couple of weeks. I've been making the centreboard but I've almost run out of epoxy so I have to wait till tomorrow. Noah has promised delivery. I had put a couple layers of epoxy on the mast but it took some time to harden because of the cold. It's nice and set and is not clogging sandpaper anymore.

It's difficult to make sanding look interesting. We all agree that it's important but not much happens. Maybe I'll make little piles of sawdust and measure how high they become.

Anyway, I'm getting ready to add a final coat of epoxy on the mast. This will be the third. I had a couple of drips and various imperfections. I put on some music and sanded away while Edit Piaf sang to me. I'm not doing a perfect sand job. This will happen after the last of the epoxy has set. I'll put a coat on tomorrow and then get the scamp mast ready for varnish. I've been warming the last of the Mas epoxy because it was starting to crystallize. All epoxy will crystallize in cold weather, I've had the same problem with East System epoxy. After warming up the epoxy is fine.

I've put 3 coats of epoxy on the mast and let it sit for a couple of months. I'm now back at it sanding the epoxy in order to start varnishing. Because epoxy is sensitive to UV it must be protected.

I'll be using Epiphane varnish but with a small amount of stain added to help blend in the various colours of the many strips.

I've moved on to making the spars.

emails: Christine

This web site reflects my personal ideas and doesn't represent anyone else's point of view.

If you decide to build a boat be careful. These tools can be dangerous. If you don't know how to safely handle something find out. There are lots of forums out there.

to submit an obituary

To place an obituary, please include the information from the obituary checklist below in an email to [email protected] . There is no option to place them through our website. Feel free to contact our obituary desk at 651-228-5263 with any questions.

General Information:

- Your full name,

- Address (City, State, Zip Code),

- Phone number,

- And an alternate phone number (if any)

Obituary Specification:

- Name of Deceased,

- Obituary Text,

- A photo in a JPEG or PDF file is preferable, TIF and other files are accepted, we will contact you if there are any issues with the photo.

- Ad Run dates

- There is a discount for running more than one day, but this must be scheduled on the first run date to apply.

- If a photo is used, it must be used for both days for the discount to apply, contact us for more information.

Verification of Death:

In order to publish obituaries a name and phone number of funeral home/cremation society is required. We must contact the funeral home/cremation society handling the arrangements during their business hours to verify the death. If the body of the deceased has been donated to the University of Minnesota Anatomy Bequest Program, or a similar program, their phone number is required for verification.

Please allow enough time to contact them especially during their limited weekend hours.

A death certificate is also acceptable for this purpose but only one of these two options are necessary.

Guestbook and Outside Websites:

We are not allowed to reference other media sources with a guestbook or an obituary placed elsewhere when placing an obituary in print and online. We may place a website for a funeral home or a family email for contact instead; contact us with any questions regarding this matter.

Obituary Process:

Once your submission is completed, we will fax or email a proof for review prior to publication in the newspaper. This proof includes price and days the notice is scheduled to appear.

Please review the proof carefully. We must be notified of errors or changes before the notice appears in the Pioneer Press based on each day’s deadlines.

After publication, we will not be responsible for errors that may occur after final proofing.

All obituaries appear on TwinCities.com with a permanent online guestbook presence. If you wish to have the online presence removed, you can contact us to remove the guestbook online. Changes to an online obituary can be handled through the obituary desk. Call us with further questions.

Payment Procedure:

Pre-payment is required for all obituary notices prior to publication by the deadline specified below in our deadline schedule. Please call 651-228-5263 with your payment information after you have received the proof and approved its contents.

Credit Card: Payment accepted by phone only due to PCI (Payment Card Industry) regulations

EFT: Check by phone. Please provide your routing number and account number.

Cash: Accepted at our FRONT COUNTER Monday – Friday from 8:00AM – 3:30PM

- The minimum charge is $162 for the first 10 lines.

- Every line after the first 10 is $12.20.

- If the ad is under 10 lines it will be charged the minimum rate of $162.

- On a second run date, the lines are $8.20 per line, starting w/ the first line.

- For example: if first run date was 20 lines the cost would be $164.

- Each photo published is $125 per day.

- For example: 2 photos in the paper on 2 days would be 4 photo charges at $500.

Please follow deadline times to ensure your obituary is published on the day requested.

MEMORIAM (NON-OBITUARY) REQUEST

Unlike an obituary, Memoriam submissions are remembrances of a loved one who has passed. The rates for a memoriam differ from obituaries.

Please call or email us for more memoriam information

Please call 651-228-5280 for more information.

HOURS: Monday – Friday 8:00AM – 5:00PM (CLOSED WEEKENDS and HOLIDAYS)

Please submit your memoriam ad to [email protected] or call 651-228-5280.

Today's Paper

David JERUSALEM OBITUARY

Left on August 21, 2020 for an extended tour with his Higher Power. He had an RV from 2003-2007, and this latest venture doubtless appealed to his love of travel and adventure. David taught in the St. Paul Public Schools from 1976 to 2003; he was the creator of Hands On Work (HOW), a program that taught job skills, woodworking, canoe-building, etc. David was a marvelous teacher because he was dyslexic, and had instant sympathy and bonding for any youngster who struggled to learn. He worked for the Pullman schools as an educational assistant for students who had learning problems. He also was a disc jockey for the David Jerusalem Show on KRFP. If you were innocently walking downtown in Moscow, David probably stopped you and begged you to be on his program and talk about your life and living. He loved music and would invite anyone who sang, played an instrument, or owned a kazoo. David loved eating, walking, talking and listening. He loved dogs—Loki, Sunny, Benji and Katie. He loved travel, loved his boat, his RV, and lusted ceaselessly for a convertible. David was married to Jan in 1983, after an extended live in courtship (1976). Their son, Todd, daughter in law Charlie, the grandchildren Charlotte, Thomas and Millie, live in Oxford, England. David’s sister Cheryl lives in Coeur d’Alene, as does David’s mom, Billee. Nephews Tristan, Cullen and Owen complete the family. David leaves behind a host of KRFP listeners, many friends of Bill, and a 42 year medallion. Memorials are suggested to the Moscow Food Bank, KRFP, or the Latah Recovery Center. Arrangements were entrusted to Short’s Funeral Chapel, Moscow. www.shortsfuneralchapel.com

Honor with Flowers

In memory of David

Plant a Living Memorial

IMAGES

VIDEO

COMMENTS

Installing the bow eye. Making the portholes/deadlights. Oar Socket Placement. Making the SCAMP mast. Turning SCAMP over. Sanding, marking waterline and Painting outside of hull. Finishing shaping the Bottom. Making the centreboard. Centreboard pivot and details.

On these pages, I documented progress while building a SCAMP sailboat. My SCAMP sail# is 349, and she is called "ARGO". SCAMP is an acronym for Small Craft Advisor Magazine Project, and was conceived-of by the folks at that publication. It was designed by New Zealander John Welsford, and a photo of the finished boat along with a video of the ...

SCAMP features an offset centerboard, massive flotation from sealed seats and stowage cabin, a water ballast tank holding 173 pounds of water, an after cabin "veranda" that functions like a hard dodger, and a flat bottom and skegs for beaching. PLANS: Complete plans now available on 7 24 x 36" sheets. A complete "Building guide" with suggested ...

Decided to build a boat. How hard could it be? Let's find out! It's a SCAMP (designed by John Welsford). I've had my eyes on the design for a while, and ...

Steps in Building a SCAMP sailboat. Links to all my scamp building pages. SCAMP gets side planks. The Scamp has 3 sets of planks. Each is made from 6mm ply joined. The 2 bottom planks have bevels to accommodate the plank above it. Joining Planks. I used Dynamite Payson's method of joining the planks. He suggested butting the 2 sides, sanding to ...

Building SCAMP, an 11 foot long, wood sailboat. Ever since I was a kid, I've been amazed with boats, much in the way my grandson flips out over trains. Learned to sail in the early 70's, at Rhode Island's Camp Yawgoog. I've been a boat nut ever since. Now I'm a restless boat nut, having sold my last boat almost 4 years ago.

Building a Scamp Sailboat Building the Frame. While I have spent quite a lot of time making the mast, centreboard and rudder, and cutting out all the main parts of the boat, it does not look like much. This is about to change as I start to go 3-D. The SCAMP is built right side up at first, on a curved platform.

Some builders come as a pair or a team and this means they also benefit from boat building instruction. There is a $500 fee for an additional builder. Some participants wish to attend SCAMP Camp to learn and then build their own boat at a later date. The tuition for this type of builder is $2,100. There is a $900 Materials fee.

In 2015 I built a scamp sailboat from a kit. I took 3 years to build it, taking my time. I did this YouTube video to encourage people to finish their Boat an...

The SCAMP (acronym of Small Craft Advisor Magazine Project) is a wooden or fiberglass hulled Balanced Lug rigged sailing dinghy. The boat is 11 ft 11 in (3.63 m) long, and capable of accommodating four persons on a daysail or one to two for overnighting or extended cruising. Craig Wagner and Josh Colvin, editors of Small Craft Advisor Magazine ...

Spencer gives everyone a run down of the SCAMP him and his buddy, Walter built. 🥬Become a Paid Subscriber and Help Us Out:https://www.thelitzenbergers.com/h...

SCAMP ARGO's Birdsmouth Mast is made from Sitka Spruce. Construction photos below. The plans call for a hollow wooden mast made using "birdsmouth" joints. It makes for a strong, light, and quite pretty mast. The hollow design minimizes weight aloft and makes stepping the mast easier due to the overall lighter weight.

SCAMP Sailboat; SCAMP Sailboat. Our own youthful dreams often featured small boats in starring roles. Aboard these simple, stalwart little vessels we'd venture across nebulous bodies of water in search of distant wild shorelines or uncharted islands. ... SCAMP CNC Building Kit. $3200.00. SCAMP Class Sail (100 sq ft lugsail) $699.00. Official ...

The Scamp is a seaworthy 12′ sailboat that can handle a good dose of adventure. Just under 12 feet in length, Scamp boasts an unusual combination of features that give her the unique ability to explore waters too shallow for a larger boat, while retaining most of the bigger boat's comforts and capabilities. An offset centerboard opens up ...

The bevels are necessary because the hull planks intersect the transom at an angle, and the bottom is also angled. The transom will also get another reinforcement piece where the motor could attach. It's not easy to do this after the boat is built so I have to decide and add the backing before the seats get glued on.

The rest is history: More building plans and kits for SCAMP have been sold over the years than any other small cruising boat we can think of. Besides the original wooden version, Gig Harbor Boat Works was licensed in 2013 to produce a fiberglass SCAMP, and the little giant killer—in wood and fiberglass—has since its debut been at the center of various small-boat rallies, workshops and ...

Boat Plans, Patterns and Supplies For the Amateur Boat Builder! Every year, thousands of amateurs much like yourself build their own boats the proven Glen-L way. Many builders save 50% or more over the price of a factory-built boat. It's easier than you might think, and it can be a rewarding experience. ...

Boat Class Code DPN DPN1 DPN2 DPN3 DPN4. PRECALCULATED D-PN HANDICAPS CENTERBOARD CLASSES FJ (Int.) Centerboard FJ 97.90 100.90 99.30 98.20 (95.80) Flipper Centerboard FLIP (99.40) (99.50) Flipper (Canadian) Centerboard FLCA 97.00 (98.70) Flying Cloud Centerboard FLCL (133.00) [134.0] Flying Dutchman (Int.) Centerboard. FD.

This gave the company the idea to just build permanent motorhomes with the Romahome name. The Romahome began an evolution that saw it move to a Citroën C15 base and eventually to vans. ... The Most Exciting Part Of The Monaco Grand Prix Might Be This Out-Of-Control Boat Hitting A Yacht On 'Billionaire's Row' ... I saw a longer scamp the ...

Main-1002ft sail with 3 rows of reef points, bag, logo & ties included100 sq ft lugsail made exclusively by Neil Pryde Sails for SCAMP. This class sail is made from 5.5 oz. Challenge Sailcloth in either a classic cream color or Tanbark.

Glen-L Marine Designs, Moscow, Idaho. 6,889 likes · 5 talking about this · 7 were here. Glen-L has over 300 boat plans for boats you can build.

NEW YORK (AP) — Richard M. Sherman, one half of the prolific, award-winning pair of brothers who helped form millions of childhoods by penning the instantly memorable songs for "Mary Poppins," "The Jungle Book" and "Chitty Chitty Bang Bang" — as well as the most-played tune on Earth, "It's a Small World (After All)" — has died. He was 95.

More details on Shaping The SCAMP Sailboat Rudder. I found that shaping the rudder was intimidating and more complex than the centreboard. In this page I include more detail on the shaping. The main rudder-making page is here. The rudder blank before any markings. I had prepared a template of the cross section at the widest point.

NATO permits Ukraine to attack targets in Russia as a defensive measure. Learn more about the escalating conflict between Ukraine and Russia.

Shipbuilding is a developed industry in Russia. The main short-term plan of the industry is the Complex Program to Advance Production of the Shipbuilding Industry on the Market between 2008 and 2015, which was approved by the Russian Government in October 2006. It envisages the establishment of a scientific center at the Krylov Institute, two ...

"1954 Willys Wagon - Custom Build Built by 4 Wheelers Supply in Phoenix with some later mods done by current owner. ️Crate GM Performance 350 385hp ($7400 current GM cost) less than 700 miles Holley Double Pumper, Ram Horns, Ron Davis Radiator, MSD ignition ️Th350 fresh rebuild, reverse manual valve body, all Hughes parts

Steps in Building a SCAMP sailboat. Links to all my scamp building pages. My SCAMP build, Making a Mast Cutting lots of strips for mast staves. I'm getting ready to cut the mast staves and at the same time I'll cut the support strips. Scamp seams are built using a combination of stitch and glue and strips of wood that give a point of attachment ...

David JERUSALEM. Left on August 21, 2020 for an extended tour with his Higher Power. He had an RV from 2003-2007, and this latest venture doubtless appealed to his love of travel and adventure ...

He was 95. (Photo by Willy Sanjuan/Invision/AP) NEW YORK (AP) — Richard M. Sherman, one half of the prolific, award-winning pair of brothers who helped form millions of childhoods by penning the instantly memorable songs for "Mary Poppins," "The Jungle Book" and "Chitty Chitty Bang Bang" — as well as the most-played tune on Earth, "It's a ...